When discussing materials and construction, a common term that refers to a long, sturdy piece of wood or metal is beam or bar, depending on the context. However, if you're specifically looking for a word that describes a long, sturdy piece of wood or metal used in structural or functional applications, joist or girder might be more precise for wood, while rod or rail could apply to metal. Understanding these terms is essential in fields like carpentry, engineering, and manufacturing, where clarity in material descriptions ensures proper usage and safety.

Explore related products

$9.99 $11.99

What You'll Learn

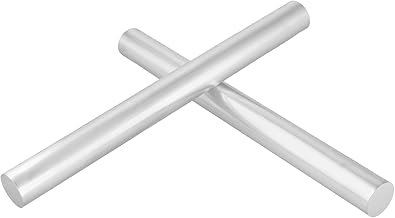

- Definition of Dowel: A cylindrical rod, often wooden, used to join or reinforce materials like metal

- Dowel Applications: Commonly used in furniture, cabinetry, and machinery for alignment and strength

- Material Variations: Dowels can be made from wood, metal, or plastic depending on the application

- Dowel Sizes: Available in various lengths and diameters to fit specific project needs

- Dowel Installation: Requires precise drilling and fitting to ensure stability and durability

Definition of Dowel: A cylindrical rod, often wooden, used to join or reinforce materials like metal

A dowel, typically a cylindrical rod made of wood, serves as a fundamental component in joining or reinforcing materials, particularly metal. Its design—simple yet effective—allows it to fit snugly into pre-drilled holes, creating a strong, stable connection between two or more pieces. This method is widely used in furniture making, cabinetry, and even automotive assembly, where precision and durability are critical. For instance, a wooden dowel can align and secure metal brackets in a shelving unit, ensuring the structure remains rigid under weight. The key to its effectiveness lies in its uniformity and the precision with which it is installed, making it an indispensable tool in both DIY projects and industrial applications.

When selecting a dowel for metal reinforcement, consider the material and diameter carefully. Wooden dowels are preferred for their natural strength and ease of customization, but they must be treated to resist moisture if used in humid environments. For heavier applications, hardwood dowels like oak or maple are ideal due to their density. Alternatively, metal dowels can be used for high-stress joints, though they require precise drilling to avoid misalignment. A practical tip: always pre-drill holes slightly smaller than the dowel’s diameter to ensure a tight fit, and use wood glue for added stability in wooden-to-metal connections.

The process of using a dowel to join wood and metal involves several steps. First, measure and mark the points where the dowel will be inserted, ensuring alignment between the materials. Next, drill holes in both the wood and metal, using a drill bit that matches the dowel’s diameter. If working with metal, a center punch can help guide the drill and prevent slipping. Insert the dowel into the holes, applying adhesive if necessary, and secure it firmly. For metal joints, consider using a thread-cutting tap to create a screw-like anchor for added strength. This method not only reinforces the connection but also distributes stress evenly, reducing the risk of breakage.

Comparing dowels to other joining methods, such as screws or bolts, highlights their unique advantages. Unlike screws, which can strip or loosen over time, dowels provide a permanent, invisible joint that maintains the aesthetic integrity of the piece. They are also less likely to corrode when used with metal, especially if treated with a protective coating. However, dowels lack the adjustability of bolts, making them less suitable for applications requiring frequent disassembly. For projects where appearance and longevity are priorities, dowels often outperform their alternatives, particularly in woodworking and light metal fabrication.

In practical applications, understanding the limitations of dowels is as important as recognizing their strengths. While they excel in static joints, they are not ideal for dynamic or load-bearing structures where movement is expected. For example, using a dowel to connect a wooden handle to a metal tool is effective, but employing it in a hinge mechanism would likely result in failure. Additionally, dowels should not be used in environments with extreme temperature fluctuations, as expansion and contraction can compromise the joint. By adhering to these guidelines, craftsmen and engineers can maximize the utility of dowels in their projects, ensuring both functionality and durability.

Perfectly Smoked Fingerling Potatoes: Timing Tips for Wood-Fired Flavor

You may want to see also

Explore related products

Dowel Applications: Commonly used in furniture, cabinetry, and machinery for alignment and strength

A dowel, typically a cylindrical rod made of wood, metal, or plastic, serves as a fundamental component in various industries, particularly in furniture, cabinetry, and machinery. Its primary function is to provide alignment and structural integrity, ensuring that assembled parts remain securely connected. In furniture making, for example, wooden dowels are often used to join two pieces of wood at right angles, creating a strong, invisible joint that enhances both durability and aesthetics. This method, known as dowel joinery, is favored for its simplicity and reliability, especially in mass-produced furniture where precision and efficiency are critical.

In cabinetry, dowels play a crucial role in reinforcing joints and ensuring that drawers, doors, and shelves remain aligned over time. For instance, a typical kitchen cabinet might use dowels to secure the sides, back, and bottom panels together. The process involves drilling precisely aligned holes in each piece and inserting the dowels with a small amount of wood glue. This technique not only strengthens the joint but also minimizes the need for visible hardware, maintaining a clean and professional appearance. Cabinetmakers often prefer hardwood dowels, such as maple or oak, for their strength and compatibility with wooden cabinetry.

Machinery applications introduce metal dowels, which are prized for their rigidity and resistance to wear. In industrial settings, dowels are used to align components in machinery, ensuring smooth operation and reducing the risk of misalignment-induced failures. For example, in CNC machines, metal dowels are employed to secure workpieces or tooling in place, providing the precision required for accurate cutting and shaping. Here, the choice of material is critical: stainless steel dowels are often selected for their corrosion resistance, while hardened steel dowels are used in high-stress applications where durability is paramount.

One practical tip for using dowels effectively is to ensure proper sizing and fit. A dowel should fit snugly into its hole, with a tolerance of approximately 0.001 to 0.003 inches for wooden dowels and even tighter tolerances for metal applications. Using a doweling jig can help achieve consistent hole alignment, particularly in woodworking. Additionally, when gluing dowels, apply adhesive sparingly to avoid excess seepage, which can weaken the joint or require tedious cleanup. For metal dowels, consider using thread-locking compounds or press-fit techniques to ensure a secure hold without the need for adhesives.

In conclusion, dowels are indispensable in applications requiring alignment and strength, from the delicate craftsmanship of cabinetry to the rugged demands of industrial machinery. Their versatility across materials and industries underscores their importance as a simple yet effective engineering solution. Whether you're a furniture maker, cabinet builder, or machinist, understanding the proper selection and installation of dowels can significantly enhance the quality and longevity of your work. By mastering these techniques, professionals and hobbyists alike can achieve robust, precise, and aesthetically pleasing results.

Jesus' Time in the Wilderness: Unraveling the Mystery of His Retreat

You may want to see also

Explore related products

Material Variations: Dowels can be made from wood, metal, or plastic depending on the application

Dowels, those unassuming cylindrical rods, are the unsung heroes of construction, crafting, and manufacturing. While the term often conjures images of wooden rods, the reality is far more diverse. Material choice—wood, metal, or plastic—dictates a dowel’s strength, durability, and suitability for specific tasks. Understanding these variations is key to selecting the right tool for the job.

Wooden dowels, the traditional choice, offer a balance of strength and workability. Commonly crafted from hardwoods like oak, maple, or birch, they excel in furniture making, cabinetry, and DIY projects. Their natural grain provides a secure grip for glue joints, making them ideal for joining wooden pieces. However, wood is susceptible to moisture and temperature changes, limiting its use in outdoor or high-humidity environments. For indoor applications, a ¼-inch diameter hardwood dowel is a versatile option, strong enough for structural support yet easy to cut and sand.

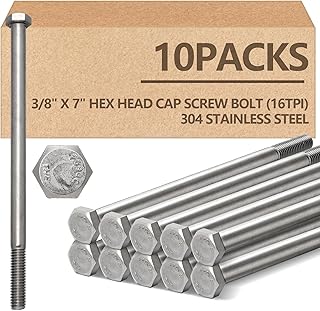

Metal dowels, typically made from steel or aluminum, bring industrial-grade strength to the table. Stainless steel dowels, resistant to corrosion, are perfect for outdoor structures or machinery exposed to harsh conditions. Aluminum, lighter and more malleable, is often used in aerospace or automotive applications where weight reduction is critical. A ⅜-inch stainless steel dowel, for instance, can withstand heavy loads without bending, making it a go-to for load-bearing assemblies. However, metal dowels require precise drilling and may not be suitable for projects where flexibility or insulation is needed.

Plastic dowels, often overlooked, offer unique advantages in specific scenarios. Made from materials like nylon, PVC, or acrylic, they are lightweight, corrosion-resistant, and electrically insulating. These properties make them ideal for electronics, marine applications, or environments where metal or wood would degrade. A ½-inch PVC dowel, for example, can be used to create waterproof joints in outdoor furniture or as a non-conductive spacer in electrical enclosures. While plastic lacks the sheer strength of metal, its versatility and affordability make it a practical choice for low-stress applications.

Choosing the right material depends on the demands of the project. For structural integrity, metal reigns supreme. For aesthetic appeal and ease of use, wood is hard to beat. And for specialized needs like insulation or corrosion resistance, plastic steps in as a reliable alternative. By matching the material to the application, you ensure not only functionality but also longevity and safety. Whether you’re building a bookshelf or assembling a machine, the right dowel material transforms a simple rod into a cornerstone of your project.

Boiling Wooden Spoons: Optimal Time for Safe and Clean Utensils

You may want to see also

Explore related products

Dowel Sizes: Available in various lengths and diameters to fit specific project needs

A dowel, often defined as a long, sturdy piece of wood or metal, is a versatile component in various projects, from furniture making to construction. When selecting a dowel, understanding the available sizes is crucial to ensure a perfect fit and structural integrity. Dowel sizes vary widely in both length and diameter, catering to specific project requirements. For instance, a 1/4-inch diameter dowel might be ideal for lightweight crafts, while a 1-inch diameter dowel could be necessary for heavy-duty applications like shelving or cabinetry.

Analyzing the relationship between dowel size and project functionality reveals that precision is key. In woodworking, a dowel that is too thin may compromise strength, while one that is too thick can create unnecessary bulk. For example, in joinery, a 3/8-inch diameter dowel is commonly used for aligning and reinforcing wooden pieces, offering a balance between stability and subtlety. Similarly, in metalworking, a 1/2-inch diameter steel dowel might be chosen for its durability in load-bearing structures. Understanding these nuances ensures that the dowel not only fits but also enhances the project’s overall performance.

When embarking on a project, it’s instructive to measure twice and select once. Start by assessing the load requirements and aesthetic needs of your project. For furniture, consider the weight the piece will bear and the visibility of the dowel. A 5/16-inch diameter dowel, for instance, is often used in chair construction for its strength and minimal visual impact. For hidden applications, such as drawer alignment, a smaller diameter like 1/8 inch may suffice. Always account for the material of the dowel—wood for warmth and flexibility, metal for rigidity and longevity.

Comparatively, dowel sizes in metal applications often differ from those in wood due to the material’s inherent strength. A metal dowel with a 3/4-inch diameter can support significantly more weight than a wooden dowel of the same size, making it ideal for industrial or outdoor projects. However, metal dowels may require additional finishing to prevent corrosion, whereas wooden dowels are more forgiving in humid environments. This highlights the importance of matching dowel size and material to the project’s specific demands.

Finally, a descriptive approach to dowel selection emphasizes the tactile and visual aspects. Imagine a handcrafted wooden table where a 1/2-inch diameter hardwood dowel seamlessly connects the legs to the tabletop, adding both strength and a rustic charm. In contrast, a sleek metal cabinet might feature a 1/4-inch stainless steel dowel for a modern, minimalist look. The right dowel size not only serves a functional purpose but also contributes to the project’s aesthetic appeal. By carefully considering length, diameter, and material, you can ensure that the dowel becomes an integral, almost invisible, part of your creation.

Understanding Wood Glue Setting Time: A Quick Guide for DIY Enthusiasts

You may want to see also

Explore related products

Dowel Installation: Requires precise drilling and fitting to ensure stability and durability

A dowel, often defined as a long, sturdy piece of wood or metal, serves as a critical component in various construction and woodworking projects. When it comes to dowel installation, precision is paramount. The process demands meticulous drilling and fitting to ensure the final structure is both stable and durable. Even a minor misalignment can compromise the integrity of the joint, leading to wobbling, weakening, or eventual failure. This is why understanding the nuances of dowel installation is essential for anyone working with materials that require strong, lasting connections.

Steps for Precise Dowel Installation

Begin by selecting the appropriate dowel size and material for your project. For wooden joints, hardwood dowels are preferred for their strength, while metal dowels are ideal for applications requiring higher tensile strength. Measure and mark the drilling points with absolute accuracy, using a ruler or caliper to ensure consistency. Drill pilot holes slightly smaller than the dowel diameter to create a snug fit. Apply a thin layer of wood glue or epoxy to the dowel and insert it firmly into the hole, using a mallet if necessary. Wipe away excess adhesive immediately to prevent residue from affecting the joint’s appearance or strength.

Cautions to Avoid Common Pitfalls

One of the most common mistakes in dowel installation is drilling holes that are too large or misaligned. This can result in a loose fit, reducing the joint’s load-bearing capacity. Always use a drill press or a guide sleeve to maintain straight, perpendicular holes. Avoid over-tightening or forcing the dowel into place, as this can split the surrounding material. Additionally, ensure the dowel is fully seated by checking for flush alignment with the surface. If working with metal, consider using thread-locking compounds to prevent loosening over time due to vibration or stress.

Analyzing the Role of Precision in Durability

The stability of a dowel joint relies heavily on the precision of its installation. A well-fitted dowel distributes stress evenly across the joint, minimizing the risk of cracking or separation. For example, in furniture making, a precisely installed dowel can extend the lifespan of a piece by decades, even under heavy use. Conversely, a poorly fitted dowel can lead to structural failure within months. This underscores the importance of taking the time to measure twice and drill once, a principle that holds true across all scales of construction.

Practical Tips for Optimal Results

To enhance the durability of dowel joints, consider pre-drilling holes in both pieces of material to ensure they align perfectly. For added strength, use multiple dowels spaced evenly apart, especially in larger or load-bearing applications. When working with wood, allow ample time for the adhesive to cure before applying stress to the joint. For metal-to-wood connections, use dowels with threaded ends and secure them with nuts for a more robust hold. Finally, always test the joint under simulated stress conditions before finalizing the installation to ensure it meets the required standards.

By prioritizing precision in dowel installation, craftsmen and builders can create structures that not only withstand the test of time but also maintain their aesthetic appeal. Whether constructing furniture, cabinetry, or industrial frameworks, the meticulous approach to drilling and fitting dowels is a cornerstone of quality craftsmanship.

Wood Duck Egg Hatching Timeline: Incubation Period Explained

You may want to see also

Frequently asked questions

The word is beam.

The term is joist.

The name is strut.

The word is keel.