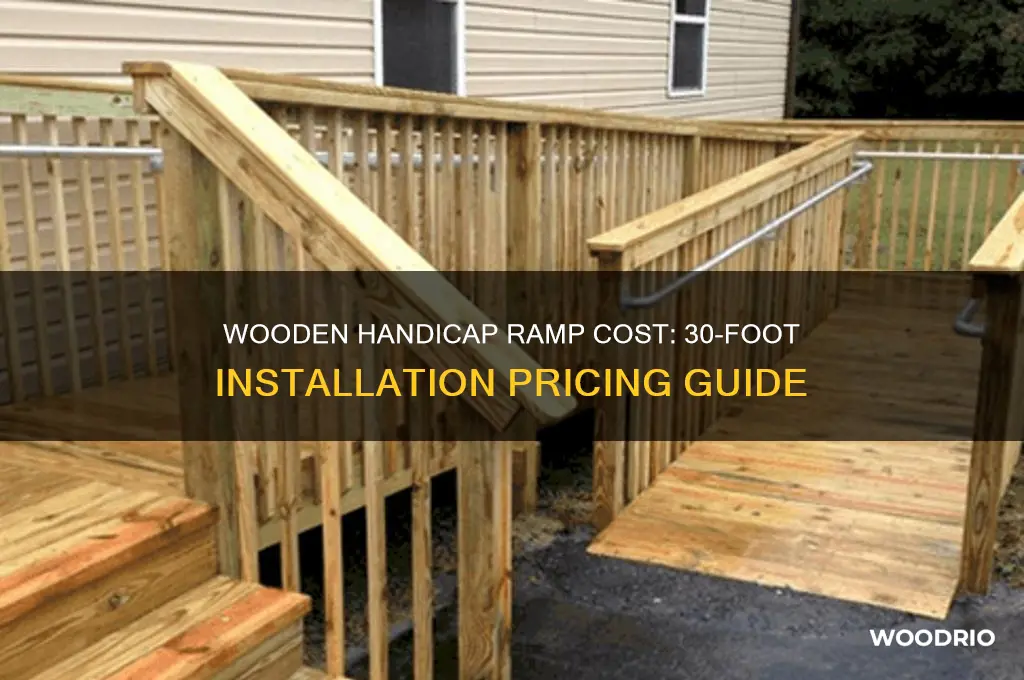

When considering the cost of a 30-foot wooden handicap ramp, several factors come into play, including materials, labor, design complexity, and local building codes. On average, a wooden ramp of this length can range from $1,500 to $4,000, depending on whether it’s a DIY project or professionally installed. High-quality pressure-treated lumber is commonly used for durability, while additional features like handrails, non-slip surfaces, or custom designs can increase the price. Labor costs, if hiring a contractor, typically account for a significant portion of the expense. It’s essential to obtain multiple quotes and ensure compliance with ADA guidelines for safety and accessibility.

| Characteristics | Values |

|---|---|

| Material | Wood (typically pressure-treated lumber) |

| Length | 30 feet (total length, may include landings and turns) |

| Width | 36–48 inches (ADA recommends minimum 36 inches for wheelchairs) |

| Slope Ratio | 1:12 (1 inch of rise per 12 inches of run, ADA standard) |

| Landings | Required at top and bottom, 5 feet minimum by 5 feet (ADA standard) |

| Handrails | Required on both sides, 34–38 inches high (ADA standard) |

| Cost Range | $1,500–$4,500 (DIY materials) or $3,000–$7,500 (professional install) |

| Factors Affecting Cost | Material quality, labor, complexity (turns, landings), local permits |

| Maintenance | Regular staining/sealing, inspection for rot or damage |

| Lifespan | 10–20 years (with proper maintenance) |

| Permits Required | Varies by local building codes, typically required for permanent ramps |

| DIY vs. Professional | DIY saves labor costs but requires carpentry skills; pros ensure compliance and safety |

Explore related products

What You'll Learn

- Material Costs: Lumber, hardware, and finishes impact the overall price of the ramp

- Labor Expenses: Professional installation vs. DIY construction affects the total cost

- Design Complexity: Straight ramps are cheaper; custom curves or turns increase costs

- Safety Features: Handrails, non-slip surfaces, and lighting add to the budget

- Permits & Codes: Local regulations and inspections may require additional fees

Material Costs: Lumber, hardware, and finishes impact the overall price of the ramp

The cost of building a 30-foot wooden handicap ramp hinges significantly on material choices. Lumber, the backbone of the structure, varies widely in price depending on type and grade. Pressure-treated pine, a common choice for outdoor projects, typically costs $2 to $5 per board foot, while cedar, known for its durability and resistance to rot, can range from $6 to $10 per board foot. Exotic hardwoods, though less common for ramps due to cost and maintenance, can skyrocket prices to $15 or more per board foot. For a 30-foot ramp, the sheer volume of lumber required—often several hundred board feet—means these per-unit costs add up quickly.

Hardware, though a smaller portion of the budget, is equally critical. Galvanized or stainless steel fasteners are essential to prevent rust and ensure longevity in outdoor conditions. A single box of 3-inch deck screws can cost $15 to $20, and multiple boxes will be needed for a ramp of this size. Handrails, often required by code, add another layer of expense. Pre-fabricated aluminum handrails can cost $20 to $40 per linear foot, while custom wooden handrails may require additional lumber and labor. Joist hangers, brackets, and other structural hardware further contribute to the total, with costs ranging from $50 to $150 depending on the complexity of the design.

Finishes play a dual role: enhancing appearance and protecting the wood from weather damage. A gallon of exterior stain or sealant typically costs $30 to $60, and a 30-foot ramp may require 2 to 3 gallons for adequate coverage. Opting for a higher-quality, UV-resistant finish can add $10 to $20 per gallon but may extend the ramp’s lifespan, reducing long-term maintenance costs. Paint, while less common for ramps due to slip risks, can cost $25 to $50 per gallon if chosen for aesthetic reasons. Labor for application, whether DIY or professional, should also be factored in, as improper finishing can void warranties or lead to premature deterioration.

Balancing these material costs requires careful planning. For budget-conscious projects, pressure-treated pine paired with mid-range hardware and a single coat of sealant can keep expenses under $1,000 for materials alone. For premium builds, cedar or composite lumber, high-end fasteners, and multiple layers of finish can push costs to $3,000 or more. Always account for local building codes, which may dictate specific materials or features, and consider the ramp’s intended lifespan—investing in durable materials upfront can save money on repairs and replacements down the line.

Perfect Wood Pellet Grill Chicken Breast: Timing and Tips for Juicy Results

You may want to see also

Explore related products

$150

Labor Expenses: Professional installation vs. DIY construction affects the total cost

The decision to hire professionals or embark on a DIY project for installing a 30-foot wooden handicap ramp significantly impacts the overall cost. Labor expenses can account for a substantial portion of the total budget, often ranging from 40% to 60% of the project cost. Professional installation ensures compliance with safety standards and building codes, which is critical for accessibility structures. However, this convenience comes at a premium, with hourly rates for skilled laborers typically ranging from $40 to $70, depending on location and expertise. For a 30-foot ramp, professional labor alone could add $1,200 to $3,000 to the total cost.

Opting for DIY construction can drastically reduce labor expenses, but it requires careful planning and execution. Building a ramp involves precise measurements, structural integrity, and adherence to ADA guidelines, such as a 1:12 slope ratio. Beginners should allocate extra time for learning and troubleshooting, as mistakes can lead to costly material waste. Essential tools like a circular saw, drill, and level may need to be purchased or rented, adding $100 to $300 to the project. While DIY saves on labor, it demands physical ability, time, and confidence in carpentry skills.

A comparative analysis reveals that professional installation is ideal for those prioritizing time efficiency, safety, and minimal hassle. DIY, on the other hand, suits individuals with carpentry experience and a willingness to invest sweat equity. For instance, a homeowner with intermediate DIY skills might complete the project in 20 to 30 hours, saving $1,200 to $2,100 in labor costs. However, errors in construction could negate these savings, emphasizing the need for thorough preparation and possibly consulting online tutorials or blueprints.

Ultimately, the choice between professional installation and DIY hinges on budget, skill level, and project timeline. For those unsure of their abilities, a hybrid approach—such as hiring a professional for the foundation and completing the decking independently—can balance cost and expertise. Regardless of the method, prioritizing safety and compliance ensures the ramp serves its intended purpose effectively.

Exploring the Traditional Long Flat-Bottomed Wooden Sled: History & Uses

You may want to see also

Explore related products

Design Complexity: Straight ramps are cheaper; custom curves or turns increase costs

The design of a wooden handicap ramp significantly impacts its cost, with straight ramps being the most budget-friendly option. A 30-foot straight ramp typically follows a simple, linear structure, minimizing material waste and labor hours. For instance, a basic straight ramp might require only standard 2x6 or 2x8 lumber for the frame and decking, with straightforward handrail installation. This simplicity translates to lower costs, often ranging from $1,500 to $3,000, depending on local labor rates and material prices. In contrast, introducing curves or turns complicates the design, requiring custom measurements, additional support structures, and more intricate carpentry work.

Custom curves or turns in a 30-foot ramp are not just aesthetically pleasing but often necessary for navigating tight spaces or blending with existing architecture. However, this customization comes at a price. For example, a curved ramp might need laminated wood beams to achieve smooth bends, specialized brackets for handrails, and precise angle cuts for each step or platform. These elements can increase material costs by 20-40% and labor costs by 30-50%, pushing the total price to $4,000 or more. Additionally, the complexity of the design may require a skilled carpenter, further elevating expenses.

When planning a ramp with curves or turns, consider the trade-off between functionality and budget. For instance, a 90-degree turn halfway through a 30-foot ramp might add $1,000-$1,500 to the project due to the need for a landing platform and additional framing. To mitigate costs, opt for modular designs that allow for pre-fabricated components, reducing on-site labor. Alternatively, consult with a designer to explore cost-effective ways to incorporate curves, such as using wider turns with gentler angles, which require fewer materials and less precision.

A practical tip for balancing design complexity and cost is to prioritize accessibility standards over decorative elements. For example, ADA guidelines recommend a 1:12 slope ratio, which can influence the length and layout of your ramp. If a straight ramp exceeds available space, consider a switchback design with intermediate landings instead of a curved approach. This not only adheres to safety regulations but also reduces the need for custom carpentry, keeping costs closer to the $2,500-$3,500 range. Always obtain multiple quotes from contractors to ensure competitive pricing for your specific design needs.

In conclusion, while straight ramps offer a cost-effective solution for a 30-foot wooden handicap ramp, custom curves or turns can significantly increase expenses due to material and labor demands. By understanding the factors driving these costs and exploring alternatives, homeowners can achieve a balance between functionality, aesthetics, and budget. Whether opting for simplicity or customization, careful planning and consultation with professionals are key to a successful and affordable ramp project.

Boiling Palo Azul Wood Chips: Optimal Time for Best Results

You may want to see also

Explore related products

Safety Features: Handrails, non-slip surfaces, and lighting add to the budget

A 30-foot wooden handicap ramp is a significant investment, and safety features are not optional—they’re essential. Handrails, non-slip surfaces, and lighting are critical components that ensure usability and compliance with accessibility standards, but they also add to the overall cost. Understanding these features and their impact on your budget is key to making informed decisions.

Handrails: A Non-Negotiable Safety Measure

Handrails are required by the Americans with Disabilities Act (ADA) for ramps longer than 6 feet, and a 30-foot ramp falls well within this mandate. The cost of handrails varies based on material and design. Wooden handrails, matching the ramp, typically range from $15 to $30 per linear foot installed. For added durability, consider aluminum or vinyl-coated options, which can cost $20 to $40 per linear foot but offer longer lifespans and lower maintenance. Ensure handrails are installed on both sides, at a height of 34 to 38 inches, to accommodate users of all ages and abilities.

Non-Slip Surfaces: Preventing Falls Before They Happen

A non-slip surface is crucial for outdoor ramps exposed to weather conditions. Options include textured wood treatments, grip tape, or rubberized coatings. Textured wood treatments, such as roughed-up surfaces or grooved boards, add minimal cost but require regular maintenance. Grip tape, priced at $1 to $3 per linear foot, is affordable but may wear out quickly. Rubberized coatings, costing $5 to $10 per linear foot, provide superior traction and durability, making them a worthwhile investment for long-term safety.

Lighting: Illuminating the Path to Safety

Proper lighting is often overlooked but essential for evening or low-light use. Solar-powered LED lights are a cost-effective and eco-friendly option, ranging from $10 to $30 per fixture. Hardwired lighting systems, while more expensive at $50 to $100 per fixture plus installation costs, offer consistent illumination and are ideal for high-traffic areas. Place lights along the handrails or edges of the ramp, ensuring even coverage without creating glare.

Balancing Cost and Safety: Practical Tips

While safety features increase the budget, they are non-negotiable for a functional and compliant ramp. Prioritize handrails and non-slip surfaces as foundational elements, then allocate funds for lighting based on usage needs. For cost savings, consider DIY installation for simpler features like grip tape or solar lights, but always hire professionals for structural components like handrails to ensure compliance and safety. Remember, investing in safety now prevents costly accidents and repairs later.

Seasoning Wood: Optimal Time for Perfectly Dried Firewood Logs

You may want to see also

Explore related products

Permits & Codes: Local regulations and inspections may require additional fees

Before you start building a 30-foot wooden handicap ramp, understand that local permits and codes can significantly impact your total cost. These regulations are not just bureaucratic hurdles; they ensure safety, accessibility, and compliance with the Americans with Disabilities Act (ADA). For instance, a ramp of this length likely requires intermediate landings every 30 feet of run, handrails at specific heights, and a minimum width of 36 inches. Ignoring these details can lead to costly rework or fines.

To navigate this process, start by contacting your local building department. Most municipalities charge permit fees based on project scope, ranging from $50 to $500 for residential ramps. However, the real cost lies in potential inspections. A failed inspection due to non-compliance can halt construction, requiring corrections and additional fees. For example, in California, a re-inspection fee can be $150 or more, while in Texas, it might be a flat $100. Factor these possibilities into your budget to avoid surprises.

Beyond fees, local codes may dictate materials and construction methods, influencing your material costs. Some areas require pressure-treated wood for durability, while others mandate non-slip surfaces. For a 30-foot ramp, this could add $200 to $500 to your material budget. Additionally, if your project requires professional engineering plans—often necessary for longer ramps—expect to pay $300 to $1,000 for these services. These specifics vary widely, so research your local requirements early.

A practical tip: hire a contractor familiar with local regulations. While DIY can save labor costs, a professional can ensure compliance, potentially saving you from costly mistakes. For example, a contractor might suggest a modular ramp system that meets code, which could cost $1,500 to $3,000 more upfront but avoids inspection failures. Conversely, if you opt for DIY, allocate a contingency fund of 10-20% of your total budget for unforeseen compliance issues.

In conclusion, permits and codes are not optional expenses but essential investments in safety and legality. By understanding these requirements upfront, you can budget accurately and avoid delays. Treat these fees as part of the total project cost, not an afterthought, to ensure your 30-foot wooden handicap ramp is both functional and compliant.

Drying Green Wood: Essential Tips for Optimal Time and Techniques

You may want to see also

Frequently asked questions

The average cost of a 30-foot wooden handicap ramp ranges from $1,500 to $4,000, depending on materials, design, and installation complexity.

It depends on the provider. Some quotes include installation, while others only cover materials. Always confirm if installation is included in the price.

Factors like custom design, additional features (e.g., handrails, landings), local building codes, and labor costs can increase the overall price.

Yes, additional costs may include permits, site preparation, staining or sealing the wood, and ongoing maintenance to ensure durability and safety.

DIY can save on labor costs, but it requires carpentry skills, adherence to ADA guidelines, and proper tools. Mistakes can lead to higher costs in the long run.