When the handrail isn’t long enough for a wooden staircase or walkway, it poses both safety and aesthetic concerns. A handrail that doesn’t span the full length of the stairs or ramp can leave users vulnerable to accidents, especially in high-traffic areas or where children or elderly individuals are present. Additionally, an incomplete handrail detracts from the overall appearance of the structure, disrupting its visual continuity. Addressing this issue often involves extending the existing rail using matching wood, ensuring proper measurements, and adhering to building codes for height and stability. Whether through custom carpentry or prefabricated extensions, resolving this problem is essential for both functionality and compliance with safety standards.

| Characteristics | Values |

|---|---|

| Issue | Handrail is shorter than required length |

| Material | Wood (various types: pine, oak, maple, etc.) |

| Common Causes | Incorrect measurement, pre-made rail too short, uneven wall/staircase |

| Safety Concerns | Increased risk of falls, non-compliance with building codes |

| Building Code Requirements (USA) | Minimum length: top of staircase to end of stairs/landing; continuous graspable surface |

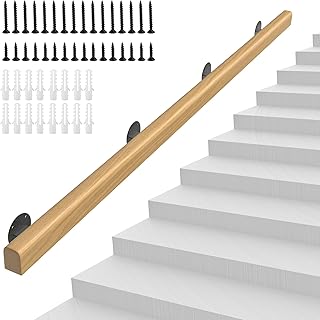

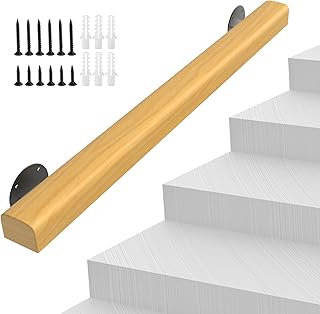

| Solutions | Extend rail with matching wood, add newel post extension, use wall-mounted brackets |

| Tools Needed | Saw, drill, screws, wood glue, measuring tape, sander |

| DIY Difficulty | Moderate (requires basic carpentry skills) |

| Cost | $50-$200 (depending on materials and tools) |

| Professional Help | Recommended for complex installations or code compliance |

| Prevention | Accurate measurements, consider pre-made kits with adjustable lengths |

Explore related products

What You'll Learn

Extending Handrails with Wood Planks

Wooden handrails that fall short of the required length pose both a safety hazard and an aesthetic challenge. Extending them with wood planks offers a cost-effective, customizable solution that blends seamlessly with existing structures. This approach not only ensures compliance with safety standards but also allows for creative design integration. By selecting planks that match the rail’s grain, color, and finish, the extension becomes nearly imperceptible, preserving the original aesthetic.

To execute this project, begin by measuring the gap between the existing rail and the desired endpoint, adding an extra inch for a secure joint. Choose a plank with similar dimensions to the rail, ensuring it’s straight-grained and free of knots for structural integrity. Cut the plank to length using a miter saw for precision, then sand the edges to prevent splinters. Attach the extension using galvanized screws or brackets, pre-drilling holes to avoid splitting the wood. For added stability, reinforce the joint with wood glue or metal plates.

While this method is straightforward, caution must be exercised to maintain safety. Ensure the extension aligns with local building codes, which often dictate minimum rail height (typically 34–38 inches) and strength requirements. Avoid overloading the joint by distributing weight evenly, and periodically inspect for signs of wear or loosening. For outdoor applications, treat the wood with a weather-resistant sealant to prevent rot and warping.

Comparatively, wood plank extensions outshine alternatives like metal or PVC in terms of versatility and warmth. Unlike rigid metal, wood can be shaped to fit curves or angles, while its natural texture complements traditional and rustic designs. PVC, though lightweight, lacks the durability and visual appeal of wood, often appearing out of place in high-end or historic settings. By prioritizing both function and form, extending handrails with wood planks emerges as a practical, enduring solution.

Freezing Wood to Kill Bugs: Optimal Time and Techniques Explained

You may want to see also

Explore related products

DIY Wood Handrail Lengthening Tips

A handrail that falls short can compromise safety and aesthetics, but extending it with wood offers a cost-effective, customizable solution. Before diving into DIY lengthening, assess the existing rail’s material, style, and structural integrity. Matching the wood type and finish ensures a seamless integration, while reinforcing joints guarantees stability. Measure the gap accurately, adding 1–2 inches for overlap to ensure a secure connection. This initial evaluation sets the stage for a functional and visually cohesive extension.

One effective method for lengthening a wood handrail is the splice joint technique. Cut a piece of matching wood to the required length, then create a 45-degree miter cut on both the new piece and the existing rail’s end. This creates a clean, angled joint that blends naturally. Secure the splice with wood glue and 1½-inch screws, then reinforce with a metal bracket hidden beneath the rail for added strength. Sand the joint lightly and apply a matching finish to disguise the seam. This approach is ideal for straight rails and requires intermediate woodworking skills.

For curved or complex handrails, consider a transitional piece instead of a direct extension. Craft a custom wooden segment with a gradual curve or decorative element to bridge the gap. Use a jigsaw to shape the piece, ensuring it aligns smoothly with the existing rail. Attach it with dowels and epoxy for a strong, invisible connection. While more time-consuming, this method preserves the rail’s original design and adds a unique aesthetic touch. It’s best suited for those with advanced woodworking experience.

Regardless of the method chosen, safety must remain paramount. Ensure the extended rail meets local building codes, typically requiring a height of 34–38 inches from the stair nosing. Test the rail’s stability by applying firm pressure before regular use. Avoid overloading the extension with excessive weight or decorative elements that could compromise its integrity. Regularly inspect the joint for signs of wear, tightening screws or reapplying glue as needed. A well-executed DIY extension not only solves a practical problem but also enhances the overall craftsmanship of your space.

Wood Hardener Drying Time: Factors Affecting Cure and Application Tips

You may want to see also

Explore related products

Matching Wood Grain for Seamless Extensions

Wood grain patterns are nature's fingerprints, each unique and irreplaceable. When extending a handrail, matching these patterns becomes an art form, demanding precision and patience. The challenge lies in finding a donor piece with a grain direction and texture that aligns seamlessly with the existing rail. This isn't merely about aesthetics; a mismatched grain can create visual disruption, undermining the elegance of the entire structure. To begin, examine the existing rail under natural light, noting the direction, tightness, and color variation of the grain. This initial analysis will guide your search for a compatible wood piece, ensuring the extension blends rather than clashes.

Selecting the right wood species is only the first step; the real challenge is aligning the grain. For a truly seamless extension, consider using a wood splice joint, where the new piece is carefully cut and fitted to interlock with the existing rail. This method requires meticulous planning: measure the length needed, then mark the donor wood to match the grain angle and pattern. Use a sharp chisel and a fine-toothed saw to create a clean, precise joint. Sanding both surfaces before joining them will ensure a smooth transition, but avoid over-sanding, as it can alter the grain’s natural texture. Clamping the pieces together while the adhesive dries is crucial for a secure bond.

While matching grain is essential, color consistency is equally critical. Over time, wood exposed to light and air develops a patina that new wood lacks. To bridge this gap, apply a wood conditioner to the new piece before staining or finishing. This evens out absorption rates, ensuring the color matches the aged rail. For best results, test the finish on a scrap piece of the same wood species to fine-tune the shade. If the existing rail has a clear coat, lightly sand it to create a uniform surface before applying a fresh coat to both the original and extended sections. This step not only unifies the appearance but also protects the wood from wear and tear.

A common mistake in handrail extensions is neglecting the tactile experience. Even if the grain and color match perfectly, a noticeable ridge or dip where the pieces meet can detract from the overall feel. To avoid this, use a wood filler that closely matches the rail’s color and texture to fill any gaps after joining. Once dry, sand the area with progressively finer grits (starting at 120 and ending at 220) to create a smooth, continuous surface. Finally, apply a topcoat to blend the repair into the surrounding wood. This attention to detail ensures the extension is not just visually seamless but also feels like an integral part of the original structure.

Teak Oil Drying Time: How Long Does It Take on Wood?

You may want to see also

Explore related products

Safety Standards for Extended Handrails

Extended handrails in wooden structures often fall short of safety standards, particularly in staircases and ramps where continuity is critical. The International Building Code (IBC) mandates that handrails extend beyond the top and bottom stairs by at least 12 inches horizontally, ensuring users have a stable grip during transitions. For ramps, the extension must continue the full length of the slope, without interruption. Failure to meet these requirements increases the risk of falls, especially for children, elderly individuals, and those with mobility challenges. Wood, while aesthetically pleasing, requires precise craftsmanship to achieve these extensions without compromising structural integrity or visual appeal.

When extending handrails, material selection and joinery techniques are paramount. Solid hardwoods like oak or maple are ideal for their strength and durability, but softer woods can be reinforced with metal brackets or splices. Avoid weak joints by using through-tenons or dowel joints, ensuring the extension is as sturdy as the original rail. Sanding and finishing must match the existing wood to maintain uniformity. For DIY projects, pre-drilling holes and using waterproof adhesives can prevent splitting. Always test the rail’s stability by applying pressure at the extended end before finalizing installation.

Compliance with safety standards isn’t just about avoiding legal penalties—it’s about preventing accidents. The Americans with Disabilities Act (ADA) specifies handrail diameters between 1.25 and 2 inches for ergonomic grip, a detail often overlooked in extensions. Additionally, the clearance between the wall and handrail must be at least 1.5 inches to accommodate fingers. In public spaces, regular inspections are crucial to identify wear or loosening, particularly in high-traffic areas. Homeowners should prioritize these standards even in private settings, as they significantly reduce liability and enhance user safety.

Comparing traditional wood extensions to modern alternatives highlights the importance of innovation. Metal or composite extensions offer greater flexibility in meeting safety standards, often with pre-fabricated components that simplify installation. However, they may clash with wooden interiors, making them less desirable for certain designs. Hybrid solutions, such as wooden rails with metal cores, combine aesthetics with strength but require professional installation. Ultimately, the choice depends on the specific needs of the space, balancing safety, durability, and visual harmony.

Instructing homeowners and contractors on proper handrail extension techniques can save lives. Start by measuring the required extension length, accounting for horizontal projections and slope angles. Use a template to mark cut lines, ensuring precision. For ramps, consider the landing area, where the handrail should remain graspable without sharp turns. Always secure extensions with lag bolts rather than nails to withstand lateral forces. Finally, apply a non-slip finish, especially in outdoor settings, to counteract moisture-related hazards. By adhering to these steps, even novice installers can achieve compliance with safety standards.

Drying Pressure Treated Wood: Optimal Time for Safe, Durable Projects

You may want to see also

Explore related products

$79.99 $89.99

Cost-Effective Wood Handrail Solutions

A common challenge in home improvement is dealing with handrails that fall short of the required length. Whether due to miscalculations, structural changes, or budget constraints, the gap between the existing rail and the desired endpoint can pose both functional and aesthetic issues. Fortunately, wood offers versatile, cost-effective solutions that blend practicality with creativity. By leveraging simple techniques and readily available materials, homeowners can extend handrails without compromising safety or style.

Analytical Approach: Assessing the Gap

Before diving into solutions, measure the shortfall accurately. A gap of 6 to 12 inches often requires a straightforward extension, while larger discrepancies may demand more innovative approaches. Consider the handrail’s purpose—is it for stairs, a balcony, or a hallway? Load-bearing requirements and local building codes dictate the structural integrity needed. For instance, a stair handrail must withstand 200 pounds of force per linear foot, according to the International Residential Code (IRC). Understanding these factors ensures the solution is both safe and compliant.

Instructive Steps: Extending with Wood Splices

One cost-effective method is splicing additional wood onto the existing rail. Start by cutting a piece of wood to match the rail’s profile and length needed. Use a miter saw to create clean, angled cuts for seamless integration. Secure the splice with 3-inch wood screws or galvanized bolts, ensuring they’re countersunk for a flush finish. Reinforce the joint with wood glue for added stability. For a polished look, sand the splice and apply a matching stain or paint. This method is ideal for gaps under 18 inches and costs approximately $20–$50 in materials, depending on wood type.

Comparative Analysis: DIY vs. Pre-Fabricated Extensions

While splicing is budget-friendly, pre-fabricated wood extensions offer convenience for those less inclined to DIY. These extensions, available at hardware stores, range from $40 to $100 and come in standard lengths of 24 to 48 inches. However, they may not match the existing rail’s style or finish, requiring additional customization. DIY solutions, though time-consuming, provide greater flexibility and cost savings. For example, repurposing leftover lumber from previous projects can reduce expenses to near-zero, making it the more economical choice for frugal homeowners.

Descriptive Solution: Decorative Fillers for Small Gaps

For minor shortfalls, decorative wood fillers can bridge the gap while adding visual appeal. A turned wood baluster or a carved wooden accent piece, secured between the rail’s end and the wall, serves both functional and aesthetic purposes. These elements, often found at craft stores or online for $15–$30, require minimal installation—simply drill pilot holes and attach with screws. This approach is particularly effective for interior handrails where artistic flair is appreciated. Ensure the filler doesn’t obstruct grip or violate code requirements, typically maintaining a 1.5-inch diameter for graspability.

Persuasive Takeaway: Sustainability and Longevity

Opting for wood handrail solutions not only saves money but also aligns with sustainable practices. Reclaimed or locally sourced wood reduces environmental impact, while proper maintenance ensures longevity. Applying a weather-resistant sealant every 2–3 years protects outdoor rails from rot and warping. By choosing cost-effective wood solutions, homeowners address immediate needs while investing in durable, eco-friendly fixes. Whether through splicing, fillers, or pre-fabricated extensions, wood remains a versatile, affordable material for resolving handrail shortfalls.

Trex vs. Wood: Which Material Offers Superior Longevity for Decks?

You may want to see also

Frequently asked questions

If the handrail isn’t long enough, you can extend it by adding a matching wood piece, using a splice joint, or installing a decorative connector to ensure continuity and safety.

Yes, you can use a different type of wood, but ensure it matches in color, grain, and finish for a cohesive look. Alternatively, stain or paint both pieces to blend them together.

Secure the extension using strong wood glue, screws, or brackets. Ensure it’s firmly attached to the wall or balusters and complies with local building codes for height, strength, and spacing.