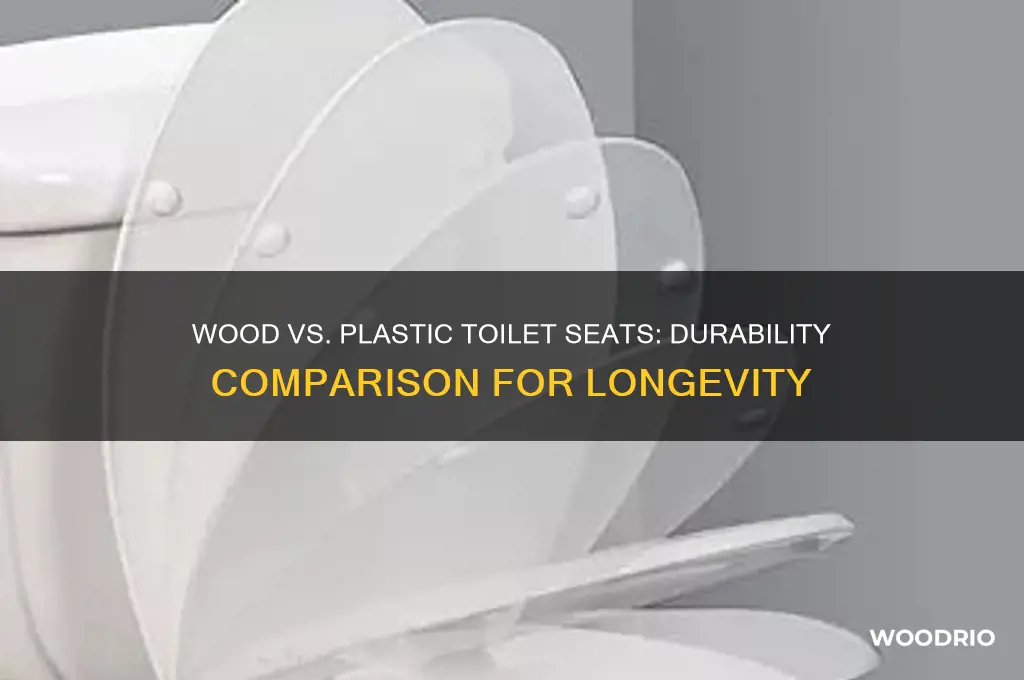

When considering the durability of toilet seats, the choice between wood and plastic is a common dilemma for homeowners. Wood toilet seats are often praised for their classic aesthetic and sturdy feel, but they can be more susceptible to moisture damage and warping over time, especially in humid environments. On the other hand, plastic toilet seats are lightweight, resistant to moisture, and generally more affordable, making them a popular choice for their longevity in various conditions. While both materials have their advantages, plastic toilet seats typically last longer due to their inherent resistance to water and ease of maintenance, whereas wood seats may require more care to extend their lifespan. Ultimately, the decision depends on personal preference, bathroom environment, and willingness to maintain the seat for optimal durability.

| Characteristics | Values |

|---|---|

| Durability | Wood: Generally lasts longer (10-15 years) with proper care. Plastic: Typically lasts 5-10 years, prone to cracking and discoloration. |

| Maintenance | Wood: Requires regular sealing and may warp if exposed to moisture. Plastic: Low maintenance, easy to clean, but can scratch easily. |

| Comfort | Wood: Warmer and more comfortable, especially in colder climates. Plastic: Can feel colder and harder, but some models have padded options. |

| Aesthetics | Wood: Offers a classic, elegant look with various finishes. Plastic: Available in multiple colors but may appear less luxurious. |

| Cost | Wood: Usually more expensive upfront. Plastic: Generally more affordable and cost-effective. |

| Hygiene | Wood: Can harbor bacteria if not sealed properly. Plastic: Non-porous, easier to sanitize, and resistant to bacteria growth. |

| Environmental Impact | Wood: Biodegradable and renewable if sourced sustainably. Plastic: Often made from non-renewable resources and may not be recyclable. |

| Weight | Wood: Heavier, which can make installation more challenging. Plastic: Lighter and easier to handle. |

| Noise | Wood: Quieter when closing due to its weight and density. Plastic: Can be noisier, especially if not properly fitted. |

| Customization | Wood: Can be custom-made or refinished to match decor. Plastic: Limited customization options, but available in various standard designs. |

Explore related products

$36.99 $43.99

$18.94 $29.84

$23.49 $26.99

$33.49

What You'll Learn

- Durability comparison: wood vs. plastic under daily use conditions

- Impact of moisture on material longevity in bathroom environments

- Resistance to cracks, chips, and warping over time

- Maintenance requirements for extending toilet seat lifespan

- Cost-effectiveness: initial investment vs. long-term replacement needs

Durability comparison: wood vs. plastic under daily use conditions

Wood and plastic toilet seats endure daily use differently, with material properties dictating their longevity. Wood, a natural insulator, resists temperature fluctuations better than plastic, making it more comfortable in colder climates. However, it’s prone to warping or cracking if exposed to moisture over time, especially in humid environments. Plastic, while lightweight and resistant to moisture, can become brittle under prolonged exposure to cleaning chemicals or UV light, leading to cracks or discoloration. For households with high usage, plastic may show wear sooner due to its lower tensile strength compared to hardwood variants.

To maximize durability, consider the maintenance each material demands. Wooden seats require periodic sealing with waterproof finishes to prevent moisture absorption, ideally every 6–12 months depending on humidity levels. Plastic seats, though low-maintenance, benefit from avoiding abrasive cleaners like bleach or ammonia, which degrade their surface. A gentle cleanser and soft cloth suffice for daily upkeep. For both materials, tightening hinges annually prevents wobbling, a common issue that accelerates wear.

In comparative testing, hardwood seats like oak or mahogany outlast plastic by 2–3 years under average household use, provided they’re properly maintained. Plastic seats, while initially cheaper, often need replacement sooner due to aesthetic degradation (e.g., fading, scratching). For families with children or frequent guests, plastic’s ease of cleaning may offset its shorter lifespan, whereas wood’s sturdiness appeals to those prioritizing long-term value.

Practical tip: If opting for wood, choose a model with a multi-coat varnish finish for added moisture resistance. For plastic, select a thicker, molded design over thin, injection-molded variants, as these better withstand pressure and impact. Regardless of material, avoid standing or placing heavy objects on the seat, as this accelerates structural failure in both wood and plastic.

Ultimately, the choice hinges on balancing maintenance commitment with usage patterns. Wood demands care but rewards with longevity, while plastic offers convenience at the cost of a shorter lifespan. Assess your household’s needs—frequency of use, humidity levels, and cleaning habits—to determine which material aligns best with your durability expectations.

Wood Water Absorption: Understanding How Long It Takes for a Block to Soak Up Moisture

You may want to see also

Explore related products

$32.99 $38.99

$16.82 $22.92

Impact of moisture on material longevity in bathroom environments

Moisture is the silent adversary of materials in bathroom environments, accelerating degradation through mechanisms like warping, cracking, and mold growth. Wood, a hygroscopic material, absorbs moisture readily, causing it to swell and shrink over time. This cyclical stress weakens the structural integrity of wooden toilet seats, leading to eventual failure. Plastic, while non-hygroscopic, is not immune to moisture’s effects. Prolonged exposure to damp conditions can cause plastic to become brittle, particularly in low-quality variants, due to the leaching of plasticizers. Understanding these material-specific vulnerabilities is crucial for predicting longevity in high-moisture settings.

To mitigate moisture’s impact, consider the bathroom’s humidity levels and ventilation. Bathrooms with poor ventilation or frequent hot showers maintain relative humidity levels often exceeding 70%, ideal for material degradation. Installing a dehumidifier or exhaust fan can reduce humidity to safer levels (40–50%), significantly extending the lifespan of both wood and plastic toilet seats. For wooden seats, periodic sealing with a waterproof finish (e.g., polyurethane) every 6–12 months creates a barrier against moisture absorption. Plastic seats, though inherently water-resistant, benefit from regular cleaning with mild detergents to prevent surface degradation from soap scum and mineral deposits.

A comparative analysis reveals that while plastic toilet seats generally outlast wood in moisture-rich environments, the quality of the plastic plays a decisive role. High-density polyethylene (HDPE) or urea-formaldehyde plastic seats resist brittleness and warping better than cheaper polypropylene variants. Wooden seats, particularly those made from teak or cedar, offer natural resistance to moisture and decay but require meticulous maintenance. For instance, a well-maintained teak seat can last 10–15 years, compared to 5–7 years for untreated pine. Plastic seats, even premium ones, rarely exceed 8–10 years due to UV exposure from bathroom lighting and chemical wear from cleaning agents.

Practical tips for maximizing longevity include avoiding harsh cleaners containing bleach or ammonia, which degrade both wood finishes and plastic surfaces. Instead, opt for vinegar-based solutions or specialized bathroom cleaners. For wooden seats, inspect the hinges regularly, as metal components are prone to rust in damp environments; replacing them with stainless steel hinges can add years to the seat’s life. Plastic seats should be checked for hairline cracks, especially around the hinges, as these are precursors to breakage. Finally, in bathrooms with extreme moisture conditions, consider investing in composite materials like resin-bonded wood or reinforced plastic, which combine the aesthetic appeal of wood with the durability of plastic.

Perfect Wood-Fired Turkey: Optimal Cooking Time & Tips for Juicy Results

You may want to see also

Explore related products

Resistance to cracks, chips, and warping over time

Wooden toilet seats, while aesthetically pleasing, are inherently more susceptible to cracks and warping due to their organic nature. Wood expands and contracts with changes in humidity, leading to stress points that can cause splits over time. Plastic seats, on the other hand, are engineered to resist such environmental fluctuations. For instance, high-density polyethylene (HDPE) and urea-formaldehyde (UF) plastics maintain their structural integrity even in damp bathroom conditions. If you live in a humid climate, opting for a plastic seat can prevent the annual frustration of discovering hairline cracks in a wooden one.

Consider the impact of daily wear and tear. Plastic toilet seats are less prone to chipping compared to their wooden counterparts. A dropped brush or a heavy fall can leave a wooden seat with unsightly chips, whereas plastic’s uniform composition absorbs impact more effectively. Manufacturers often reinforce plastic seats with additives like fiberglass or molded cores, further enhancing their durability. For households with children or high traffic, this resistance to chipping is a practical advantage that extends the seat’s lifespan.

Warping is a silent enemy that creeps up on wooden toilet seats, often unnoticed until the seat no longer fits the bowl properly. This occurs when moisture penetrates the wood, causing it to distort. Plastic seats, however, are impervious to moisture absorption, ensuring they retain their shape indefinitely. To mitigate warping in wooden seats, regular sealing with a waterproof finish is necessary—a maintenance step plastic seats eliminate entirely. This makes plastic the low-maintenance choice for those seeking longevity without extra effort.

While wooden seats can be repaired with wood filler or sanding, these fixes are temporary and often detract from their appearance. Plastic seats, once damaged, are typically replaced rather than repaired, but their initial resistance to cracks, chips, and warping means such instances are rare. For long-term reliability, plastic’s consistent performance outshines wood’s charm, especially in environments where durability trumps aesthetics. Choose plastic if you prioritize function; opt for wood if you’re prepared to trade longevity for style.

Optimal Wood Therapy Duration: Mastering At-Home Sessions for Best Results

You may want to see also

Explore related products

Maintenance requirements for extending toilet seat lifespan

Toilet seats, whether wood or plastic, degrade over time due to moisture, cleaning chemicals, and mechanical stress. Extending their lifespan hinges on proactive maintenance that addresses these factors. For wooden seats, regular sealing with a waterproof varnish every 6–12 months is essential to prevent warping and cracking. Use a marine-grade sealant for maximum durability, applying a thin, even coat with a foam brush, allowing 24 hours for drying between coats. Plastic seats, while more resistant to moisture, require careful cleaning to avoid surface degradation. Avoid abrasive cleaners like bleach or scouring pads, which can scratch the surface, trapping dirt and bacteria. Instead, use a mild detergent mixed with warm water and a soft cloth for weekly cleaning.

The hinges are a critical but often overlooked component in toilet seat maintenance. Both wood and plastic seats rely on metal hinges, which corrode over time due to exposure to moisture and cleaning agents. Lubricate hinges every 3–4 months with a silicone-based lubricant to reduce friction and prevent rust. If corrosion is visible, replace the hinges immediately to avoid structural failure. For plastic seats, inspect the hinge screws monthly for tightness, as loose screws can cause wobbling and uneven wear. Wooden seats, being heavier, exert more stress on hinges, so consider upgrading to stainless steel hinges for added longevity.

Temperature and humidity control play a significant role in toilet seat maintenance, particularly for wooden seats. Bathrooms with high humidity levels accelerate wood degradation, leading to swelling, mold, or mildew. Install a dehumidifier or ensure proper ventilation by running the exhaust fan during and after showers. For plastic seats, extreme temperatures can cause brittleness or warping. Avoid placing heaters or hairdryers near the toilet, and in colder climates, insulate the bathroom to maintain a consistent temperature. Both materials benefit from minimizing direct water exposure, so encourage household members to lower the seat after use to reduce splashing.

Finally, user habits can significantly impact toilet seat lifespan. Educate household members to avoid standing or applying excessive pressure on the seat, as this can cause cracks in wood or stress fractures in plastic. For households with children, consider installing a child seat or teaching proper usage to prevent accidental damage. Replace the seat immediately if cracks or deep scratches appear, as these compromise hygiene and structural integrity. By combining material-specific care, environmental control, and mindful usage, you can maximize the lifespan of both wood and plastic toilet seats, delaying the need for replacement.

Wood Decomposition Timeline: Factors Affecting Decay and Breakdown Process

You may want to see also

Explore related products

$22.99 $29.84

Cost-effectiveness: initial investment vs. long-term replacement needs

The initial cost of a toilet seat is often the most immediate concern for buyers, but it’s a mistake to view this as the sole financial consideration. Plastic toilet seats typically range from $10 to $30, making them an attractive option for budget-conscious consumers. Wooden seats, on the other hand, can cost anywhere from $30 to $100, depending on the type of wood and finish. While the higher upfront cost of wood might deter some, it’s essential to factor in the longevity and durability of the material. A wooden seat, when properly maintained, can outlast several plastic seats, potentially reducing the frequency of replacements and associated costs over time.

Consider the replacement cycle as a key metric in assessing cost-effectiveness. Plastic toilet seats, despite their low initial price, often degrade faster due to exposure to moisture, cleaning chemicals, and daily wear. Cracks, discoloration, and warping are common issues that necessitate replacement within 3–5 years. Wooden seats, while more susceptible to water damage if not sealed properly, can last 10–15 years or more with regular care. This extended lifespan means fewer purchases and installations, translating to savings in both money and effort. For households or commercial settings with multiple bathrooms, the cumulative cost difference can be significant.

Maintenance plays a critical role in determining the long-term cost-effectiveness of either material. Plastic seats require minimal upkeep—wiping with mild cleaners is usually sufficient. Wooden seats, however, demand more attention. They must be sealed periodically to prevent moisture absorption, and harsh chemicals should be avoided to preserve the finish. While this adds a layer of responsibility, the investment in maintenance can pay off by extending the seat’s life. For instance, applying a waterproof sealant every 6–12 months can add years to a wooden seat’s usability, making the higher initial cost more justifiable.

A practical approach to deciding between wood and plastic involves calculating the total cost of ownership (TCO). For plastic, multiply the initial cost by the number of replacements expected over a decade (likely 2–3 times). For wood, factor in the initial cost plus maintenance expenses (sealants, occasional refinishing). In many cases, the TCO for a wooden seat remains competitive or even lower than that of plastic, especially in high-use environments. This analysis underscores the importance of looking beyond the price tag to evaluate long-term financial implications.

Finally, consider the environmental and aesthetic value as indirect cost factors. Wooden seats, often made from sustainable materials, align with eco-friendly preferences and can enhance the bathroom’s appearance, potentially increasing property value. Plastic seats, while cheaper, contribute to waste when frequently replaced. For those prioritizing sustainability or design, the higher cost of wood may be offset by these intangible benefits. Ultimately, the decision should balance initial investment, replacement frequency, maintenance requirements, and personal priorities to determine the most cost-effective choice.

Wood Therapy Session Duration: What to Expect During Treatment

You may want to see also

Frequently asked questions

Generally, wood toilet seats last longer than plastic ones due to their durability and resistance to wear and tear, provided they are well-maintained and not exposed to excessive moisture.

Yes, plastic toilet seats are more prone to cracking over time, especially under heavy use or when exposed to temperature fluctuations, whereas wood seats are less likely to crack but can warp if not cared for properly.

Wood toilet seats require slightly more maintenance, such as regular cleaning and occasional refinishing, to prevent moisture damage and maintain their appearance, while plastic seats are low-maintenance and easy to clean.

Wood toilet seats are often more cost-effective in the long run due to their longevity, despite a higher upfront cost, whereas plastic seats are cheaper initially but may need to be replaced more frequently.