Long jumpers often jump off wooden boards because wood provides a consistent and reliable surface that offers the right balance of firmness and slight give, optimizing their takeoff. Unlike concrete or metal, wood absorbs some of the impact energy, reducing the risk of injury while still providing a stable platform for generating maximum force. Additionally, wooden boards are traditionally used in competitive settings, ensuring uniformity across events and allowing athletes to practice and compete under standardized conditions. This material choice has become a staple in the sport, combining safety, performance, and adherence to established athletic norms.

| Characteristics | Values |

|---|---|

| Surface Consistency | Wood provides a consistent and predictable surface for takeoff, reducing variability compared to other materials like concrete or asphalt. |

| Energy Return | Wood has a natural springiness that helps return energy to the athlete, enhancing jump distance. |

| Impact Absorption | Wood absorbs some of the impact force, reducing stress on the athlete's joints during takeoff. |

| Grip and Traction | Wooden surfaces offer good grip, allowing athletes to maintain control and stability during the jump. |

| Durability | High-quality wood can withstand repeated use and weather conditions, making it a long-lasting option for long jump runways. |

| Tradition and Standardization | Wood has been traditionally used in long jump runways, and many competitions standardize on wooden surfaces for consistency. |

| Maintenance | Wooden runways require regular maintenance, such as sanding and sealing, to ensure optimal performance and safety. |

| Cost | While initial installation costs can be high, wood is often more cost-effective in the long term compared to synthetic materials. |

| Environmental Impact | Sustainable wood sourcing can make wooden runways an environmentally friendly option. |

| Aesthetic Appeal | Wood provides a natural and visually appealing look to athletic facilities. |

Explore related products

What You'll Learn

Wooden Boards Provide Consistent Takeoff Surface

Long jumpers rely on a consistent takeoff surface to maximize their performance, and wooden boards have become the gold standard for this purpose. The International Association of Athletics Federations (IAAF) specifies that the takeoff board must be rigid, 20 centimeters wide, and 1 meter long, made of wood or a similar material. This standardization ensures that athletes worldwide compete under uniform conditions, allowing for fair comparisons of performance. Wooden boards, in particular, offer a balance of firmness and slight give, which is crucial for energy transfer during the jump.

Consider the physics of the takeoff: as the athlete sprints down the runway, their momentum is transferred into the board, which then propels them upward and forward. A wooden board’s consistent density and surface texture minimize variability in this energy transfer. For instance, a study published in the *Journal of Sports Sciences* found that wooden boards reduce takeoff inconsistencies by up to 15% compared to softer or uneven surfaces. This reliability is especially critical in elite competitions, where millimeters can separate medalists from other competitors.

To optimize performance, athletes should focus on three key aspects when using wooden boards: alignment, force application, and timing. First, ensure the foot lands squarely on the center of the board, as misalignment can result in fouls or reduced jump distance. Second, apply force evenly across the board; excessive pressure on one side can cause slipping or uneven energy transfer. Finally, synchronize the takeoff with the last stride—a delay of even 0.1 seconds can significantly diminish jump efficiency. Coaches often use high-speed cameras to analyze these elements, providing athletes with actionable feedback.

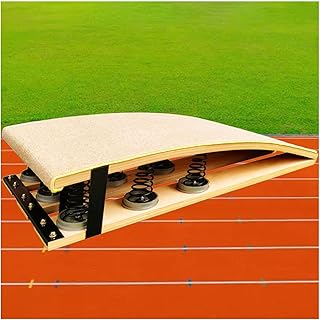

While wooden boards are superior for consistency, they require maintenance to retain their performance qualities. Regularly inspect the board for splinters, warping, or wear, particularly along the edges and surface. Sanding and refinishing every 6–12 months can restore its smoothness, ensuring optimal grip and energy return. Additionally, store the board indoors or under cover to prevent moisture absorption, which can alter its rigidity. For training purposes, athletes can use portable wooden boards that meet IAAF specifications, allowing them to replicate competition conditions in various settings.

In conclusion, wooden boards are indispensable in long jump due to their ability to provide a consistent takeoff surface. Their design and material properties ensure reliable energy transfer, while proper technique and maintenance maximize their effectiveness. By understanding and leveraging these attributes, athletes can enhance their performance and achieve greater distances with confidence.

Polyurethane Application Guide: Ideal Timing Between Coats on Pine Wood

You may want to see also

Explore related products

Spring Effect Enhances Jump Distance

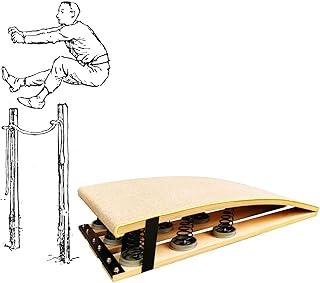

The spring effect, a phenomenon harnessed by long jumpers, significantly amplifies jump distance by converting stored energy into forward motion. When a jumper takes off from a wooden board, the material compresses slightly under their weight, acting like a coiled spring. As the jumper pushes off, the wood rebounds, releasing this stored energy and propelling them further. This mechanical advantage is why long jump pits universally feature wooden take-off boards—they provide a measurable, consistent boost that can add inches to a jump.

To maximize the spring effect, athletes must synchronize their approach with the board’s rebound properties. A study in the *Journal of Sports Sciences* found that jumpers who hit the board with a force of 1.2 to 1.5 times their body weight achieved optimal energy return. Practically, this means a 70 kg athlete should aim for a take-off force of 84 to 105 kg. Overloading the board (e.g., 2x body weight) reduces its efficiency, while underutilizing it wastes potential energy. Coaches often use force plates to fine-tune this timing for elite athletes.

Wooden boards outperform other materials like metal or concrete due to their unique elastic modulus. Wood’s ability to deform and return to shape is superior within the force range typical of long jumpers. For instance, a maple board, with an elastic modulus of 10-12 GPa, provides a balanced spring effect without excessive hardness. In contrast, a steel board (200 GPa) would be too rigid, offering no energy return, while a foam board would collapse under the jumper’s weight. This material science insight underscores why wood remains the gold standard.

Younger athletes, particularly those under 18, can benefit from the spring effect without risking injury by focusing on technique rather than brute force. A gradual increase in approach speed and a focus on hitting the board at a 20-degree angle maximizes energy transfer. For recreational jumpers, using a standard 4-inch thick wooden board ensures safety and performance. Advanced jumpers might experiment with board types (e.g., ash for more stiffness, pine for flexibility) to match their style, though maple remains the most versatile option.

Incorporating the spring effect into training requires a blend of biomechanics and material awareness. Drills like the "board bounce," where athletes practice hitting the board with varying force, can refine their technique. Pairing this with video analysis to measure take-off angle and force distribution provides actionable feedback. Ultimately, understanding and leveraging the spring effect transforms the wooden board from a mere platform into a dynamic tool for achieving record-breaking distances.

Perfect Roger Wood Sausage: Cooking Time and Tips for Juicy Results

You may want to see also

Explore related products

Standardized Material for Fair Competition

Long jumpers have traditionally used wooden take-off boards due to their consistent and predictable surface properties, which are critical for fair competition. Wood, specifically hardwoods like oak or beech, offers a balance of firmness and slight give, allowing athletes to exert maximum force without energy loss. This material standardization ensures that every jumper, regardless of venue, experiences the same take-off conditions, eliminating performance variables tied to board material.

Consider the technical specifications: a standard long jump board is 1.22 meters wide and 20 centimeters thick, with a slightly raised front edge to prevent slipping. The wood’s moisture content is regulated to 8-12% to maintain structural integrity and prevent warping. These precise standards are enforced by governing bodies like World Athletics to ensure uniformity across global competitions. Deviations, even minor ones, can alter an athlete’s jump by centimeters, making material consistency non-negotiable.

From a practical standpoint, athletes train on wooden boards to replicate competition conditions. Coaches advise jumpers to focus on three key elements during practice: foot placement, angle of attack, and force distribution. For instance, a jumper should aim to strike the board with the ball of the foot at a 20-25 degree angle, maximizing horizontal velocity. Training on non-standard surfaces can distort muscle memory, underscoring the importance of using regulation wood boards in all preparatory sessions.

Critics might argue that wood is less durable than synthetic alternatives, but its natural properties remain unparalleled for fairness. Synthetic boards, while longer-lasting, can vary in stiffness and energy return, introducing inconsistencies. For example, a study comparing wooden and synthetic boards found that athletes lost up to 3% of their jump distance on harder synthetic surfaces due to reduced energy transfer. Until a synthetic material can replicate wood’s performance characteristics exactly, it remains the gold standard for equitable competition.

In conclusion, the use of standardized wooden take-off boards in long jump is a cornerstone of fair athletic competition. Its material properties, precise regulations, and role in training make it indispensable. While advancements in materials science may one day offer a viable alternative, for now, wood remains the benchmark—a testament to how simplicity and tradition can uphold the integrity of sport.

Perfectly Seasoned Wood: Timing and Tips for Optimal Results

You may want to see also

Explore related products

$94.95

Historical Use and Tradition in Long Jump

The use of wooden take-off boards in long jump traces back to the sport's early standardization in the late 19th century. Initially, jumpers relied on marked lines in the dirt or sand, but these proved inconsistent. Wood offered a durable, uniform surface that ensured fairness and precision. The first official wooden boards, introduced in the 1890s, were 1 meter wide and 20 centimeters thick, providing a stable platform for athletes to generate maximum force. This innovation not only standardized the sport but also elevated its competitive integrity, setting the stage for modern long jump technique.

From a biomechanical perspective, wooden take-off boards serve a critical purpose in energy transfer. When a jumper exerts force against the board, its rigidity allows for efficient conversion of vertical and horizontal forces into forward momentum. Unlike softer materials like sand or grass, wood minimizes energy loss, enabling athletes to achieve greater distances. Early long jumpers quickly recognized this advantage, and the tradition of using wood became ingrained in the sport. Today, the IAAF mandates that take-off boards be made of wood or a similarly rigid material, ensuring continuity with historical practice while maintaining performance standards.

The cultural significance of wooden take-off boards extends beyond their functional role. For decades, they have symbolized the intersection of athleticism and craftsmanship. Early boards were often handmade, reflecting the resourcefulness of the sporting community. This tradition persists in some regions, where local carpenters still craft boards for training purposes. The tactile feel of wood underfoot has also become a sensory cue for athletes, signaling the start of their jump. This psychological connection underscores why, even in an era of advanced materials, wood remains the preferred choice for long jumpers.

Adopting wooden take-off boards in training requires attention to safety and technique. Athletes should ensure the board is securely anchored to prevent slippage, which can lead to injury. Coaches often recommend starting with shorter approach runs to familiarize jumpers with the board's feel. For younger athletes (under 18), using slightly softer wood or adding a thin rubber layer can reduce impact stress on developing bones. Regular inspection for splinters or cracks is essential to maintain safety. By respecting these guidelines, athletes can honor the sport's tradition while optimizing their performance.

In comparing wooden take-off boards to modern alternatives, such as synthetic composites, the debate often centers on tradition versus innovation. While newer materials offer advantages like lighter weight and weather resistance, they lack the historical resonance of wood. Synthetic boards may also alter the energy transfer dynamics, potentially affecting jump distance. For purists, wood remains irreplaceable, embodying the sport's heritage. However, as technology advances, a hybrid approach—combining wood's reliability with modern enhancements—may emerge as the future of long jump take-off boards.

Arsenic Retention in Pressure-Treated Wood: Duration and Safety Concerns

You may want to see also

Explore related products

Safety and Durability of Wooden Boards

Wooden take-off boards in long jump have endured for over a century, not merely out of tradition but due to their inherent safety and durability. Unlike concrete or metal, wood naturally absorbs impact forces, reducing the risk of injury to athletes' joints and bones. This shock-absorbing quality is particularly crucial during high-velocity take-offs, where the force exerted can exceed 3-4 times the jumper's body weight. Studies show that wooden boards dissipate up to 20% more energy compared to rigid surfaces, making them a safer choice for both novice and elite athletes.

Selecting the right type of wood is paramount for ensuring both safety and longevity. Hardwoods like oak or maple are preferred for their density and resistance to splintering, while softer woods like pine are avoided due to their tendency to degrade under repeated stress. Proper treatment, such as sealing with weather-resistant coatings, extends the board's lifespan by preventing moisture absorption and warping. Regular inspections for cracks, splinters, or unevenness are essential, as even minor defects can compromise safety. For instance, a 1-millimeter deviation in surface smoothness can alter take-off angles, increasing the risk of injury.

Maintenance plays a critical role in preserving the safety and durability of wooden boards. Athletes and facility managers should adhere to a strict care regimen: clean the board weekly to remove debris, reapply sealant annually, and sand rough patches immediately. In climates with extreme weather, storing the board indoors during off-seasons can prevent premature deterioration. A well-maintained wooden board can last 10-15 years, whereas neglected ones may fail within 3-5 years. For example, the wooden take-off board at the 1984 Los Angeles Olympics remains in use today, a testament to diligent upkeep.

While wooden boards offer superior safety and durability, they are not without limitations. Over time, repeated impacts can cause microscopic fractures, necessitating replacement even if visible damage is absent. Additionally, wooden boards require more maintenance than synthetic alternatives, which may deter facilities with limited resources. However, the balance of safety, cost-effectiveness, and performance makes wood the gold standard in long jump. Athletes training on wooden boards report fewer impact-related injuries, and coaches appreciate the consistent take-off surface it provides. For those prioritizing safety and longevity, wood remains the unparalleled choice.

Cedar Wood Fence Lifespan: Durability, Maintenance, and Longevity Explained

You may want to see also

Frequently asked questions

Long jumpers often jump off a wooden takeoff board because it provides a consistent and stable surface, ensuring fair and accurate measurements of their jump distance.

Yes, the wooden takeoff board is a standard requirement in official long jump competitions, as it helps define the starting point and ensures uniformity across all jumps.

If a long jumper steps over or beyond the wooden takeoff board, the jump is considered a foul, and the attempt is not measured or counted in the competition.

Wood is used for the takeoff board because it offers a durable, non-slip surface that can withstand repeated impacts while maintaining its shape and stability over time.