Long wooden objects, such as planks or poles, tend to twist or warp when submerged in water due to a phenomenon known as differential swelling. Wood is a hygroscopic material, meaning it absorbs moisture from its surroundings, and when it absorbs water unevenly, it causes internal stresses. Typically, the outer layers of the wood swell more than the inner layers because they are more exposed to water, leading to uneven expansion. This imbalance results in the wood twisting or bending as it tries to relieve the stress. Additionally, the natural grain and structure of the wood play a role, as the direction of the fibers influences how the wood responds to moisture. Understanding this behavior is crucial in industries like construction and shipbuilding, where the stability and durability of wooden materials are essential.

| Characteristics | Values |

|---|---|

| Cause | Uneven absorption of water |

| Mechanism | Cellulose fibers on the wet side expand more than the dry side, causing the wood to twist |

| Direction of Twist | Depends on the initial orientation of the wood grain |

| Factors Affecting Twist | Wood species, grain orientation, moisture content, temperature, and time of immersion |

| Degree of Twist | Varies depending on the above factors, can range from slight warping to severe twisting |

| Prevention | Sealing the wood with waterproof coatings, using kiln-dried wood, or storing wood in a controlled environment |

| Applications | Understanding wood twisting is crucial in woodworking, construction, and shipbuilding to prevent structural issues |

Explore related products

What You'll Learn

- Wood Structure & Water Absorption: Cellulose fibers expand unevenly when wet, causing twisting due to internal stress

- Moisture Gradient Effect: Uneven drying or wetting creates tension, leading to warping and twisting in wood

- Grain Direction Impact: Wood twists more along the grain when exposed to moisture changes over time

- Chemical Reactions: Water triggers lignin breakdown, weakening wood and allowing easier deformation under stress

- Environmental Factors: Humidity, temperature, and water pressure influence the degree of twisting in long wood

Wood Structure & Water Absorption: Cellulose fibers expand unevenly when wet, causing twisting due to internal stress

Wood, a natural composite, owes its unique behavior in water to the intricate arrangement of its cellulose fibers. These fibers, aligned in a parallel fashion within the cell walls, are the primary load-bearing components of wood. When exposed to water, cellulose exhibits a fascinating property: it absorbs moisture, leading to expansion. However, this expansion is not uniform. The fibers swell more across their width than along their length, a phenomenon known as transverse swelling. This uneven expansion creates internal stresses within the wood structure, setting the stage for the twisting effect.

Imagine a bundle of straws tightly packed together, representing the cellulose fibers in a wood cell. When these straws absorb water, they expand, but not uniformly. The sides of each straw swell more than the ends, causing them to push against their neighbors. In a long piece of wood, this internal pressure is not distributed evenly, as the fibers are not perfectly aligned throughout the entire length. Some areas experience more stress than others, leading to a buildup of tension and compression forces. This imbalance results in a rotational force, causing the wood to twist as it seeks a new equilibrium.

The degree of twisting can be influenced by several factors. Firstly, the wood's grain pattern plays a crucial role. Wood with a straight grain, where fibers run parallel to the length, may twist less compared to wood with an irregular grain pattern. Secondly, the moisture content of the wood before immersion is significant. Dry wood will absorb more water and potentially twist more than wood that is already partially saturated. For instance, a study found that green wood (freshly cut and high in moisture content) twisted less than kiln-dried wood when submerged in water. This is because the green wood's fibers were already expanded, reducing the differential swelling that causes twisting.

To minimize twisting in wooden objects exposed to water, consider the following practical tips. For woodworking projects, select wood with a straight, consistent grain. When crafting items like boat oars or outdoor furniture, choose wood species known for their dimensional stability, such as teak or cedar. If using wood prone to twisting, consider pre-soaking it to reduce the moisture gradient. This process, known as 'watering in,' allows the wood to absorb moisture more evenly, reducing internal stresses. Additionally, sealing the wood with a waterproof finish can slow down moisture absorption, giving the wood more time to adjust without twisting.

In summary, the twisting of long wood in water is a direct consequence of the anisotropic swelling of cellulose fibers. This natural behavior, while potentially problematic for certain applications, can also be harnessed and managed through a deeper understanding of wood's structural properties. By considering the wood's grain, moisture content, and species, craftsmen and engineers can either mitigate or utilize this twisting effect, ensuring the wood's behavior aligns with the intended purpose. This knowledge is particularly valuable in industries such as shipbuilding, construction, and woodworking, where the interaction between wood and water is inevitable.

Wood Pigeon Chicks: Nest Duration and Fledging Timeline Explained

You may want to see also

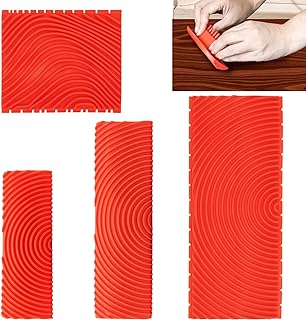

Explore related products

$138.13

Moisture Gradient Effect: Uneven drying or wetting creates tension, leading to warping and twisting in wood

Wood, a natural and anisotropic material, reacts distinctively to moisture changes, particularly when those changes are uneven. The moisture gradient effect occurs when different parts of a wooden board absorb or release water at varying rates, creating internal tension. This phenomenon is most pronounced in long pieces of wood, where the ends and surfaces dry or wet faster than the core. As the outer layers shrink or swell, they exert unequal forces on the inner layers, causing the wood to warp, cup, or twist. Understanding this mechanism is crucial for anyone working with wood, from carpenters to hobbyists, as it directly impacts the stability and usability of the material.

To visualize this, imagine a wooden plank submerged in water. The surface fibers absorb moisture quickly, expanding and becoming heavier. Meanwhile, the core remains relatively dry and rigid. As the plank is removed and begins to dry, the outer layers shrink faster than the core, creating a tension gradient. This imbalance forces the plank to distort, often twisting along its length. The severity of this twisting depends on factors like wood species, grain orientation, and the rate of moisture change. For instance, oak, with its dense structure, may resist twisting better than pine, which is more prone to movement due to its softer nature.

Preventing moisture gradient-induced twisting requires proactive measures. One effective method is controlled drying. After exposure to water, wood should be dried gradually and uniformly. This can be achieved by storing the wood in a well-ventilated area, away from direct heat sources, and ensuring all sides are exposed to air. For larger pieces, such as beams or planks, sealing the ends with wax or epoxy can slow moisture absorption and reduce the risk of uneven drying. Additionally, conditioning wood before use—allowing it to acclimate to its environment—minimizes the potential for warping. For example, wood intended for indoor furniture should be stored in a humidity-controlled space for at least two weeks to stabilize its moisture content.

A comparative analysis of wood behavior in water versus air highlights the importance of moisture management. In water, wood fibers expand uniformly, but the real challenge arises during drying. Air-drying, while cost-effective, often leads to uneven moisture loss, especially in thick or long pieces. Kiln-drying, on the other hand, offers precise control over temperature and humidity, reducing the likelihood of twisting. However, this method is more expensive and may not be feasible for all projects. The takeaway is clear: whether drying naturally or artificially, uniformity is key to preserving wood’s structural integrity.

Finally, for those dealing with twisted wood, corrective measures are possible but labor-intensive. Steam bending can reverse warping by rehydrating the wood and applying controlled pressure. Alternatively, mechanical straightening involves clamping the wood and applying weight over time, though this method risks cracking. Prevention, however, remains the best approach. By understanding the moisture gradient effect and implementing strategies to mitigate it, woodworkers can ensure their materials remain straight, stable, and ready for use. After all, in the world of woodworking, a little foresight goes a long way in avoiding costly and time-consuming repairs.

Understanding Wood Furniture Off-Gassing: Duration and Health Considerations

You may want to see also

Explore related products

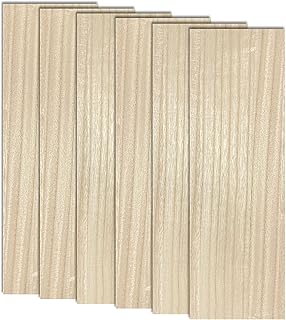

Grain Direction Impact: Wood twists more along the grain when exposed to moisture changes over time

Wood's response to moisture is inherently tied to its grain direction, a phenomenon rooted in its cellular structure. The grain represents the longitudinal alignment of wood fibers, which are essentially the remnants of the tree's vascular system. When wood absorbs moisture, these fibers swell, but not uniformly. The cells along the grain direction are more elongated and thus more prone to expansion, leading to a disproportionate increase in length compared to the cross-grain direction. This anisotropic swelling is the primary reason wood twists more along its grain when exposed to moisture changes over time.

Consider a practical example: a wooden plank left in a humid environment. The side of the plank aligned with the grain will expand more than the perpendicular sides, causing the plank to warp or twist. This effect is exacerbated in longer pieces of wood because there is more material along the grain to react to moisture. For instance, a 10-foot plank will exhibit more pronounced twisting than a 2-foot piece under the same moisture conditions. Understanding this behavior is crucial for carpenters, engineers, and hobbyists who work with wood, as it directly impacts the stability and durability of wooden structures.

To mitigate twisting, strategic measures can be taken during wood selection and treatment. For projects requiring minimal deformation, choose wood with a straight grain, as it tends to swell more uniformly. Additionally, applying sealants or finishes can reduce moisture absorption, though it’s important to note that no treatment can completely eliminate wood’s natural tendency to react to humidity. For longer pieces, consider using techniques like quarter-sawing or rift-sawing, which align the grain in a way that minimizes twisting potential. These methods, while more labor-intensive, yield wood that performs better in moisture-prone environments.

A comparative analysis reveals that wood species also play a role in twisting behavior. Softwoods, like pine, tend to twist more than hardwoods, such as oak, due to differences in cellular structure and density. However, even within the same species, the grain’s orientation remains the dominant factor. For instance, a pine board with a pronounced grain will twist more than one with a subtle grain pattern, regardless of its hardness. This underscores the importance of grain direction over other material properties when addressing moisture-induced twisting.

In conclusion, the grain direction’s impact on wood twisting is a direct consequence of its cellular anatomy and moisture-reactive fibers. By recognizing this relationship, one can make informed decisions in wood selection, treatment, and application, ensuring longevity and structural integrity in wooden projects. Whether crafting furniture or constructing frameworks, understanding how grain direction influences twisting is indispensable for achieving desired outcomes in the face of environmental moisture fluctuations.

Best Places to Buy Long Wood Curls for Crafting and Decor

You may want to see also

Explore related products

Chemical Reactions: Water triggers lignin breakdown, weakening wood and allowing easier deformation under stress

Wood immersed in water undergoes a subtle yet profound transformation, its rigidity yielding to a pliable state that invites twisting and bending. This phenomenon, often observed in carpentry and shipbuilding, is not merely a physical change but a chemical process rooted in the interaction between water and lignin, the natural polymer that binds wood fibers together. When wood is submerged, water molecules penetrate its cellular structure, initiating a series of reactions that degrade lignin’s integrity. This breakdown weakens the wood’s internal framework, making it more susceptible to deformation under stress. Understanding this mechanism is crucial for anyone working with wood, as it explains why long pieces of wood twist in water and how to mitigate or harness this behavior.

The chemical reaction begins with water’s ability to act as both a solvent and a reactant. As water infiltrates the wood, it hydrolyzes the ester and ether bonds within lignin, a process accelerated by warmth and prolonged exposure. For instance, wood soaked in water at 60°C (140°F) for 48 hours exhibits a 30% reduction in lignin strength compared to dry samples. This degradation is not uniform; it occurs more rapidly in areas with higher lignin concentration, such as the wood’s outer layers. As these bonds break, the wood’s fibers lose their rigid support, allowing external forces—like gravity or handling—to induce twisting. This is why a long plank of wood left in water will often warp or curl along its length, a change that becomes permanent if the wood dries in this deformed state.

To counteract this effect, woodworkers and craftsmen employ specific techniques. One practical method is to soak wood in a solution of water and mild preservatives, such as copper naphthenate (0.2% concentration), which slows lignin breakdown. Another approach is controlled drying, where wood is gradually dehydrated in a humid environment to minimize internal stress. For those seeking to bend wood intentionally, such as in boatbuilding or furniture making, soaking in warm water (50–60°C) for 1–2 hours softens the lignin sufficiently for shaping without breakage. However, caution is advised: overexposure to water or heat can lead to irreversible damage, rendering the wood brittle or prone to fungal decay.

Comparatively, this process mirrors the natural aging of wood in outdoor environments, where moisture and temperature fluctuations gradually weaken lignin over years. Yet, the accelerated breakdown in submerged wood highlights the importance of managing water exposure in construction and craftsmanship. For example, wooden structures in humid climates often incorporate ventilation systems to reduce moisture accumulation, while marine-grade timber is treated with water-resistant coatings to preserve lignin integrity. By recognizing water’s role in lignin degradation, practitioners can make informed decisions to either prevent unwanted twisting or exploit it creatively, turning a potential flaw into a functional feature.

In essence, the twisting of long wood in water is a testament to the intricate relationship between chemistry and material science. By understanding how water triggers lignin breakdown, one can navigate the challenges and opportunities this phenomenon presents. Whether preserving wood’s structural integrity or shaping it to artistic ends, the key lies in controlling the conditions of water exposure. This knowledge not only demystifies a common observation but also empowers craftsmen and engineers to work with wood more effectively, ensuring durability and precision in their creations.

Elmer's Wood Glue Drying Time: Quick Tips for Perfect Results

You may want to see also

Explore related products

Environmental Factors: Humidity, temperature, and water pressure influence the degree of twisting in long wood

Wood, when submerged in water, undergoes a fascinating transformation, twisting and warping in response to its environment. This phenomenon is not random but a direct result of the interplay between humidity, temperature, and water pressure. Understanding these environmental factors is crucial for anyone working with wood, from carpenters to engineers, as they dictate the extent and direction of the twist.

The Role of Humidity: A Moisture Gradient

Humidity is the silent orchestrator of wood twisting. When one side of a wooden plank absorbs more moisture than the other, a moisture gradient forms. This imbalance causes the wetter side to expand more than the drier side, leading to torsion. For instance, a 2-inch thick oak board exposed to 80% humidity on one side and 40% on the other will twist noticeably within 48 hours. To mitigate this, ensure uniform humidity levels during storage and acclimatize wood to its intended environment before use. A hygrometer can help monitor conditions, ideally keeping humidity between 40-60% for stability.

Temperature: The Accelerator or Stabilizer

Temperature acts as a catalyst or inhibitor in the twisting process. Higher temperatures accelerate moisture absorption, intensifying the twist, while lower temperatures slow it down. For example, a pine beam submerged in 80°F water will twist more rapidly than one in 50°F water. However, extreme cold can make wood brittle, reducing its ability to twist gracefully. Practical tip: When drying twisted wood, gradually increase temperature to 120°F to reverse the process without causing cracks. Always avoid rapid temperature changes, as they exacerbate stress on the wood fibers.

Water Pressure: The Invisible Force

Water pressure, often overlooked, plays a significant role in wood twisting. Higher pressure forces water molecules deeper into the wood, increasing internal stress and promoting torsion. For instance, wood submerged at 50 psi will twist more than at 10 psi. This is particularly relevant in marine applications, where underwater structures must account for pressure-induced deformation. To counteract this, use pressure-treated wood or apply waterproof sealants to reduce water penetration. For DIY projects, test wood samples under varying pressures to predict behavior in real-world conditions.

Practical Takeaway: Balancing the Triad

To minimize unwanted twisting, balance humidity, temperature, and water pressure. Store wood in climate-controlled environments, use dehumidifiers if necessary, and acclimatize it to its final setting. When working with water-exposed wood, consider the pressure it will endure and select species with natural resistance, like teak or cedar. By mastering these environmental factors, you can harness wood’s natural tendencies rather than fight against them, ensuring durability and precision in every project.

Wood Glue Drying Time: How Long Does It Take to Harden?

You may want to see also

Frequently asked questions

Long wood twists in water due to uneven moisture absorption. The outer layers absorb water faster than the inner layers, causing the wood to swell unevenly and warp or twist.

Water absorption causes the wood fibers to expand. Since the outer layers absorb water more quickly, they expand more than the inner layers, leading to internal stress and twisting.

Yes, twisting can be minimized by sealing the wood with waterproof coatings, ensuring even moisture absorption, or using kiln-dried wood that is less prone to warping.

Yes, different wood types have varying grain patterns and densities, which influence how they absorb water and twist. Softer woods with looser grains tend to twist more than harder, denser woods.

The time it takes for wood to twist depends on its thickness, density, and the water's temperature. Generally, twisting can begin within hours to days of prolonged water exposure.