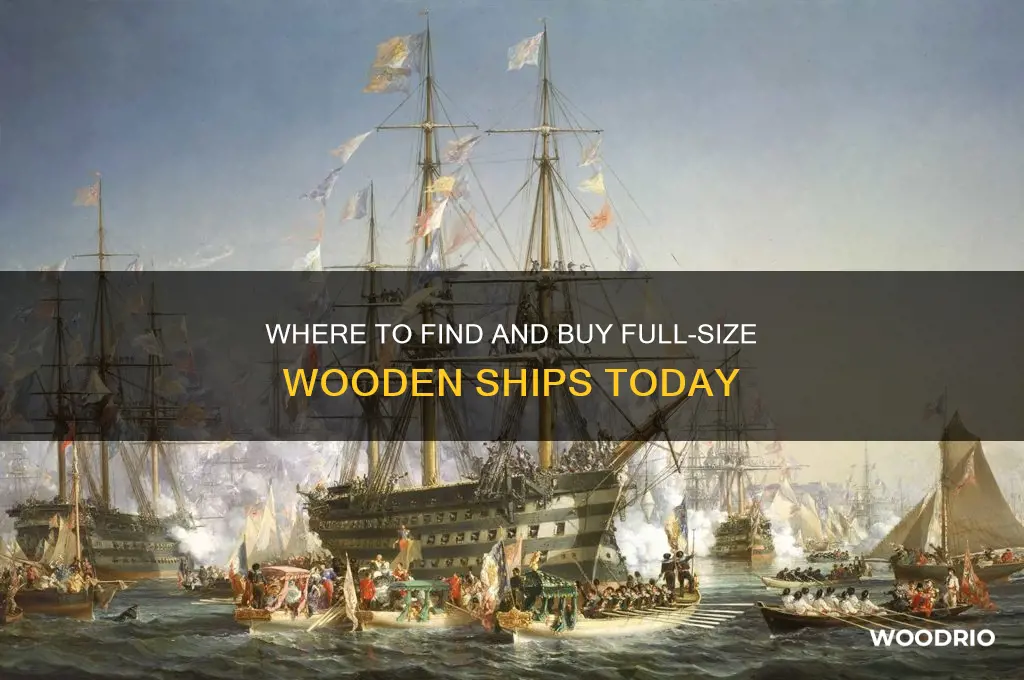

The era of full-size wooden ships, once the backbone of maritime exploration and trade, has largely faded into history, replaced by modern steel vessels designed for efficiency and durability. However, the question of whether you can still buy full-size wooden ships today sparks curiosity about the intersection of tradition, craftsmanship, and contemporary demand. While large wooden ships are no longer mass-produced for commercial or military purposes, they can still be commissioned as bespoke projects, often for luxury yachts, historical replicas, or cultural preservation. Additionally, restored vintage wooden ships are occasionally available for purchase, appealing to collectors and enthusiasts who value their timeless beauty and historical significance. Though rare and costly, the market for full-size wooden ships persists, driven by a niche appreciation for maritime heritage and artisanal craftsmanship.

| Characteristics | Values |

|---|---|

| Availability | Yes, full-size wooden ships are still available for purchase, though they are less common than modern fiberglass or steel vessels. |

| Types | Sailing ships, tall ships, classic yachts, traditional fishing boats, and custom-built wooden vessels. |

| Builders | Specialized shipyards and craftsmen who focus on traditional wooden boatbuilding techniques. Examples include Van der Graaf (NL), Sterling Yachts (USA), and various custom builders worldwide. |

| Cost | Varies widely based on size, design, and craftsmanship. Prices can range from $500,000 to several million dollars for custom-built or historic vessels. |

| Materials | High-quality hardwoods such as teak, mahogany, oak, and cedar are commonly used. Modern epoxy resins and composites may be incorporated for durability. |

| Maintenance | Requires regular maintenance, including varnishing, caulking, and protection against rot and marine organisms. Annual costs can be significant. |

| Durability | With proper care, wooden ships can last for decades or even centuries. Historic wooden ships like the Cutty Sark and USS Constitution are still preserved. |

| Customization | Highly customizable in terms of design, size, and features, allowing for unique and personalized vessels. |

| Market | Niche market, primarily catering to enthusiasts, collectors, and those seeking a classic or traditional aesthetic. |

| Environmental Impact | Generally considered more sustainable than fiberglass or steel boats due to the use of renewable materials, though maintenance products may have environmental concerns. |

| Usage | Sailing, leisure, charter services, historical reenactments, and as showpieces in maritime museums or private collections. |

| Regulations | Subject to maritime safety regulations, which may vary by country. Wooden ships must meet specific standards for seaworthiness. |

| Popularity | Less popular than modern materials but experiencing a resurgence in interest due to their aesthetic appeal and historical significance. |

Explore related products

What You'll Learn

Availability of full-size wooden ships in modern markets

Full-size wooden ships, once the backbone of maritime trade and exploration, are now rare commodities in modern markets. While their historical significance is undeniable, their availability today is limited to specialized niches. For those seeking to purchase or commission such vessels, understanding the current landscape is crucial. The primary sources for full-size wooden ships are custom shipbuilders, restoration projects, and private sales of existing vessels. These avenues cater to a niche market of enthusiasts, collectors, and organizations dedicated to preserving maritime heritage.

Custom shipbuilders remain the most reliable option for acquiring a full-size wooden ship. These craftsmen specialize in traditional techniques, often using modern tools to enhance precision and durability. However, commissioning such a project is a significant investment, with costs ranging from hundreds of thousands to millions of dollars, depending on size, design, and materials. Prospective buyers should be prepared for lengthy construction timelines, typically spanning several years. For instance, a 100-foot wooden sailing vessel might require 2–5 years to complete, involving meticulous craftsmanship and adherence to historical accuracy.

Restored wooden ships occasionally enter the market, offering a more immediate but equally costly alternative. These vessels are often salvaged from historical contexts, such as abandoned harbors or museum collections, and undergo extensive refurbishment. Restoration projects demand expertise in both maritime history and conservation, as preserving the ship’s authenticity while ensuring seaworthiness is paramount. Buyers should conduct thorough inspections and consult maritime surveyors to assess structural integrity and compliance with modern safety standards.

Private sales of existing wooden ships are less common but can provide opportunities for those willing to search diligently. Online platforms, maritime auctions, and specialized brokers occasionally list such vessels, often at prices reflecting their historical value or restoration needs. However, buyers must exercise caution, as these ships may require significant maintenance or repairs. Engaging a maritime attorney to review ownership documents and a surveyor to evaluate the ship’s condition is advisable to avoid costly pitfalls.

In conclusion, while full-size wooden ships are not readily available in mainstream markets, they can still be acquired through custom shipbuilding, restoration projects, or private sales. Each pathway presents unique challenges and costs, requiring careful planning, research, and investment. For those passionate about maritime history and craftsmanship, the pursuit of a wooden ship remains a rewarding endeavor, albeit one reserved for the dedicated few.

Buying Muir Woods Pass Same Day: What You Need to Know

You may want to see also

Explore related products

$30.35

Cost and maintenance of purchasing wooden ships today

Wooden ships, once the backbone of maritime trade and exploration, remain a niche but viable option for enthusiasts and collectors today. However, purchasing a full-size wooden ship is not a decision to be taken lightly. The initial cost can range from $500,000 to several million dollars, depending on the ship’s size, historical significance, and condition. For example, a restored 19th-century schooner might fetch upwards of $2 million, while a smaller, less ornate vessel could be acquired for closer to $500,000. These prices reflect not only the craftsmanship but also the rarity of such vessels in today’s market.

Beyond the purchase price, maintenance is a significant consideration. Wooden ships require meticulous care to prevent deterioration from water, insects, and rot. Annual maintenance costs typically range from $50,000 to $150,000, depending on the ship’s size and the extent of necessary repairs. This includes regular inspections, caulking, painting, and treating the wood with preservatives. For instance, a full hull inspection and recaulking can cost $30,000–$50,000 alone. Additionally, storing the ship in a dry dock or covered facility can add $10,000–$30,000 annually to upkeep expenses.

For those considering a wooden ship as an investment, it’s essential to weigh the emotional and historical value against the financial burden. While these vessels can appreciate over time, particularly if they hold historical significance, the market is limited. Maintenance costs can erode potential returns, making it more of a passion project than a lucrative venture. Prospective buyers should also factor in insurance, which can cost $10,000–$50,000 annually, depending on the ship’s value and intended use.

A practical tip for reducing maintenance costs is to hire a dedicated shipwright or maritime specialist who can perform routine tasks and identify issues before they escalate. For example, addressing minor wood rot early can save thousands compared to replacing entire sections of the hull. Additionally, joining a maritime preservation society can provide access to resources, expertise, and potential cost-sharing opportunities for restoration projects.

In conclusion, owning a full-size wooden ship is a commitment that demands both financial resources and dedication. While the allure of preserving maritime history is undeniable, buyers must carefully evaluate the ongoing costs and logistical challenges. By approaching the purchase with a clear understanding of these factors, enthusiasts can ensure their wooden ship remains a source of pride rather than a financial burden.

Buying Wooden Blinds Individually: Single Options for Custom Window Treatments

You may want to see also

Explore related products

Locations where full-size wooden ships are still sold

Full-size wooden ships, once the backbone of maritime trade and exploration, are now rare but not extinct. For those seeking to purchase these majestic vessels, specific locations around the globe still cater to this niche market. Coastal regions with deep-rooted shipbuilding traditions, such as the Baltic Sea area in Scandinavia and the Mediterranean ports of Italy and Greece, remain key hubs. These areas not only preserve the craftsmanship required to build wooden ships but also house shipyards that continue to produce and sell them, often blending traditional techniques with modern engineering.

For prospective buyers, Southeast Asia offers another viable option. Countries like Indonesia, Thailand, and the Philippines have long histories of wooden boat construction, particularly for fishing and tourism. Here, full-size wooden ships are often handcrafted using local timber, making them more affordable compared to European counterparts. However, buyers should be aware of potential challenges, such as verifying the legality of the wood used and ensuring compliance with international maritime standards.

In North America, the Pacific Northwest stands out as a region where wooden shipbuilding thrives, thanks to its abundant timber resources and skilled artisans. Shipyards in Washington and Oregon specialize in custom-built wooden vessels, ranging from traditional schooners to modern yachts. While prices can be higher due to labor costs, the quality and craftsmanship often justify the investment. Prospective buyers should plan to visit these shipyards in person to discuss specifications and timelines, as custom builds can take several months to complete.

For those interested in restored or vintage wooden ships, auction houses and maritime museums in the United Kingdom and the United States occasionally list full-size vessels for sale. These ships often come with historical significance, making them attractive to collectors and enthusiasts. However, buyers must factor in maintenance costs, as older wooden ships require regular upkeep to preserve their structural integrity. Engaging a marine surveyor to assess the ship’s condition before purchase is a practical step to avoid unforeseen expenses.

Finally, online platforms and specialized brokers have emerged as convenient avenues for locating full-size wooden ships worldwide. Websites dedicated to maritime sales often feature listings from various countries, allowing buyers to compare options without geographical constraints. When using these platforms, it’s essential to request detailed documentation, including proof of ownership, maintenance records, and compliance with safety regulations. While the digital marketplace broadens accessibility, due diligence remains crucial to ensure a sound investment.

Best Places to Buy Mesquite Wood for Smoking and Grilling

You may want to see also

Explore related products

Historical vs. modern demand for wooden ships

The demand for full-size wooden ships has shifted dramatically from historical peaks to modern niche interest. In the 18th and 19th centuries, wooden ships were the backbone of global trade, exploration, and naval warfare. Thousands of shipwrights labored in bustling shipyards, crafting vessels from oak, pine, and teak. Today, the market for full-size wooden ships is minuscule by comparison, driven primarily by restoration projects, luxury yachts, and historical recreations. While the scale of demand has shrunk, the craftsmanship and artistry involved remain unparalleled, preserving a legacy that modern materials cannot replicate.

For those considering purchasing a full-size wooden ship, understanding the modern market is essential. Unlike historical times, when wooden ships were mass-produced for practicality, today’s wooden vessels are often bespoke creations or meticulously restored antiques. Prices can range from $500,000 for a restored classic to over $10 million for a custom-built wooden yacht. Maintenance is a significant consideration; wooden ships require regular care, including caulking, painting, and protection against rot and marine borers. Modern buyers must weigh the aesthetic and historical value against the ongoing costs and labor-intensive upkeep.

Historically, wooden ships were built for function, not luxury. Merchant vessels like East Indiamen and naval warships like frigates were designed to withstand harsh conditions and carry heavy loads. In contrast, modern wooden ships often prioritize comfort and aesthetics. Luxury wooden yachts, for instance, feature state-of-the-art interiors, advanced navigation systems, and eco-friendly coatings to protect the wood. This shift reflects a change in demand from utility to exclusivity, catering to a wealthy clientele who value tradition and craftsmanship over cost-efficiency.

A key takeaway from the historical vs. modern demand comparison is the role of technology. In the past, wooden ships were the only viable option due to limited materials and engineering knowledge. Today, steel, aluminum, and fiberglass dominate shipbuilding for their durability and lower maintenance. However, advancements in wood treatment and design have allowed wooden ships to remain relevant, albeit in a specialized market. For enthusiasts, this blend of tradition and innovation offers a unique opportunity to own a piece of maritime history while enjoying modern conveniences.

Finally, the cultural and educational value of wooden ships cannot be overlooked. Historical recreations, such as the *HMS Victory* or *Cutty Sark*, serve as living museums, educating the public about naval history and craftsmanship. Modern demand for such projects is driven by preservation societies, governments, and private collectors committed to safeguarding maritime heritage. For potential buyers, investing in a full-size wooden ship is not just a financial decision but a contribution to cultural continuity, bridging the gap between historical significance and modern appreciation.

Prefab Wood Garage Door Bottom: Buying Options and Installation Tips

You may want to see also

Explore related products

Custom-built wooden ships: options and manufacturers

The art of crafting full-size wooden ships persists, though it’s a niche market dominated by custom builders. Unlike mass-produced vessels, custom wooden ships are tailored to the buyer’s vision, blending traditional craftsmanship with modern technology. Manufacturers like *Rockport Marine* in Maine and *Van der Graaf* in the Netherlands specialize in this field, offering everything from classic schooners to modern yachts with wooden hulls. These ships aren’t just functional; they’re heirlooms, often commissioned by enthusiasts who value heritage and individuality.

Choosing a manufacturer requires careful consideration of expertise and materials. For instance, *Burrard Yachts* in Canada uses sustainably sourced teak and mahogany, ensuring durability and ethical sourcing. Meanwhile, *Spirit Yachts* in the UK combines wood with carbon fiber for lightweight, high-performance vessels. Prospective buyers should assess the builder’s portfolio, focusing on projects similar to their vision. A site visit to inspect craftsmanship and discuss timelines is crucial, as builds can take 18–36 months, depending on complexity.

Customization options are vast, from rigging systems to interior layouts. Traditionalists might opt for gaff rigs and hand-carved joinery, while modernists could prefer hydraulic systems and minimalist designs. Costs vary widely—a 50-foot wooden sailboat starts at $1.5 million, with luxury models exceeding $5 million. Maintenance is a commitment; wooden ships require annual inspections and refinishing to prevent rot and warping. However, with proper care, they can outlast their fiberglass counterparts by decades.

For those seeking a unique vessel, custom wooden ships offer unparalleled charm and character. They’re not just boats but statements of craftsmanship and personal taste. While the process demands time, investment, and patience, the result is a one-of-a-kind masterpiece that sails into history. Whether for private use or as a charter vessel, these ships are a testament to the enduring allure of wood in maritime design.

Choosing the Right Wood: A Buyer's Guide for Quality and Value

You may want to see also

Frequently asked questions

Yes, full-size wooden ships are still available for purchase, though they are less common than modern steel or fiberglass vessels. Custom builders and shipyards specializing in traditional craftsmanship continue to construct wooden ships for enthusiasts, collectors, and historical recreations.

Available types include tall ships, sailing yachts, fishing vessels, and replicas of historical ships. Some builders also create custom designs tailored to the buyer’s specifications, blending traditional techniques with modern amenities.

The cost varies widely depending on size, design, materials, and craftsmanship. Prices can range from hundreds of thousands to several million dollars, with custom-built or historically accurate ships often being the most expensive.

While wooden ships may require more maintenance than modern materials, they are still practical for specific uses, such as leisure sailing, historical exhibitions, or educational purposes. Advances in wood treatment and construction techniques have improved their durability and longevity.