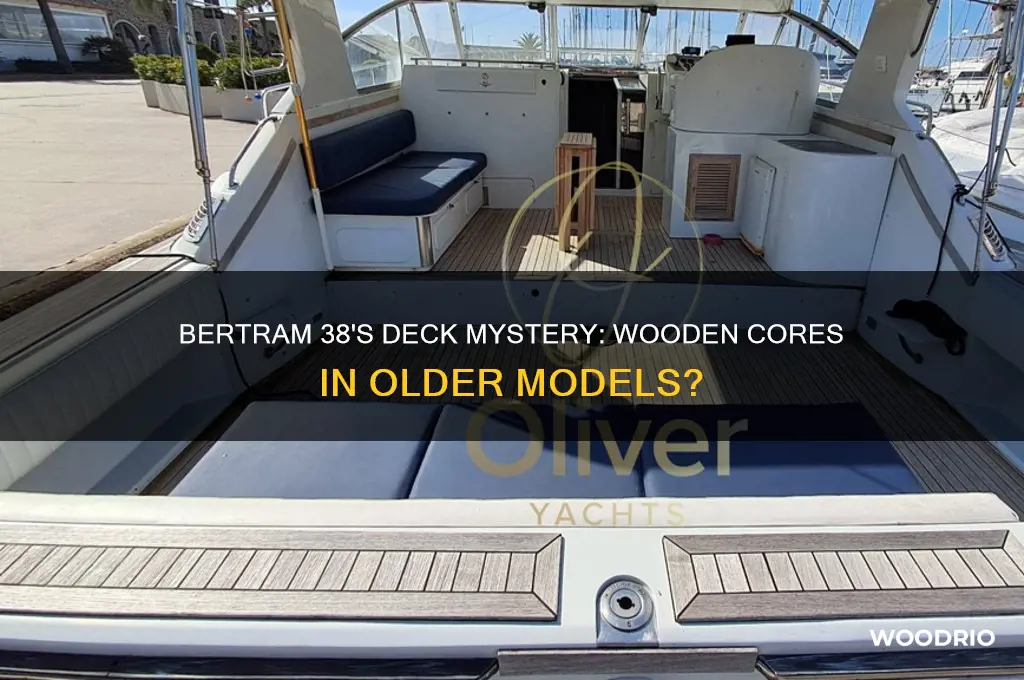

The Bertram 38, a legendary sportfishing yacht, has long been celebrated for its durability and performance, but questions often arise about its construction, particularly regarding the materials used in its deck cores. Early models of the Bertram 38, produced in the 1960s and 1970s, indeed featured wooden deck cores, typically made from marine-grade plywood, which was a standard practice in boatbuilding at the time. This design choice provided structural integrity and a solid foundation for the fiberglass exterior. However, as technology and materials evolved, later models transitioned to more modern core materials, such as balsa or foam, to reduce weight and improve resistance to moisture. Understanding the construction of the old Bertram 38, including its wooden deck cores, offers valuable insights into the evolution of boatbuilding techniques and the enduring legacy of this iconic vessel.

| Characteristics | Values |

|---|---|

| Deck Core Material | The older Bertram 38 models (pre-1980s) typically had wooden deck cores, often made of plywood or marine-grade wood. |

| Construction Era | Wooden deck cores were common in Bertram 38s built before the 1980s. |

| Later Models | Post-1980s models transitioned to fiberglass or composite deck cores for improved durability and reduced maintenance. |

| Purpose of Wooden Cores | Wooden cores provided structural integrity and insulation but were prone to rot and water damage over time. |

| Maintenance Requirements | Wooden deck cores required regular inspection, sealing, and potential replacement due to moisture exposure. |

| Modern Alternatives | Modern Bertram 38s and similar boats use fiberglass or foam cores, which are lighter, more durable, and less maintenance-intensive. |

| Historical Significance | Wooden deck cores are a hallmark of classic Bertram 38 construction, reflecting traditional boatbuilding techniques. |

| Restoration Considerations | Restoring a Bertram 38 with a wooden deck core involves careful inspection and potential replacement of rotted sections. |

| Weight Impact | Wooden cores added significant weight compared to modern materials, affecting performance and fuel efficiency. |

| Market Value | Well-maintained Bertram 38s with original wooden deck cores may hold higher value among classic boat enthusiasts. |

Explore related products

What You'll Learn

- Original Construction Materials: Examines the materials used in the old Bertram 38's deck construction

- Wooden Core Presence: Investigates if wooden cores were standard in the Bertram 38's deck

- Structural Integrity: Analyzes how wooden cores impacted the deck's strength and durability

- Maintenance Challenges: Discusses potential issues with wooden cores in marine environments

- Modern Comparisons: Compares old Bertram 38 decks to newer models' construction methods

Original Construction Materials: Examines the materials used in the old Bertram 38's deck construction

The Bertram 38, a legendary sportfishing yacht, has long been celebrated for its durability and performance. Central to its construction is the deck, a critical component that withstands the rigors of offshore fishing. Examining the original materials used in the Bertram 38’s deck construction reveals a blend of traditional craftsmanship and innovative engineering. Early models, particularly those built in the 1960s and 1970s, featured wooden deck cores, typically marine-grade plywood, encapsulated in fiberglass. This combination provided structural integrity while maintaining a manageable weight, essential for a vessel designed for speed and stability.

Marine-grade plywood, often chosen for its resistance to moisture and rot, was the backbone of the deck’s core. This material was meticulously laminated with layers of fiberglass and resin, creating a composite structure that balanced strength and flexibility. The fiberglass not only protected the wood from the harsh marine environment but also added rigidity to the deck. This construction method was a hallmark of Bertram’s early designs, reflecting the era’s best practices in boatbuilding. However, it’s important to note that not all Bertram 38s were identical; variations in construction techniques and materials existed, particularly as production evolved over the years.

One of the key advantages of the wooden core was its ability to dampen vibrations, providing a smoother ride in choppy waters—a feature highly valued by anglers. However, this design was not without its drawbacks. Over time, water intrusion could compromise the wood, leading to delamination or rot if not properly maintained. Owners of older Bertram 38s often face the challenge of inspecting and repairing these cores, a task that requires careful attention to detail. Modern restoration techniques, such as core replacement with closed-cell foam or advanced composites, offer alternatives to the original wood, though purists may prefer to preserve the boat’s authenticity.

For those considering restoration or maintenance, understanding the original construction materials is crucial. Inspecting the deck for signs of moisture intrusion, such as soft spots or blistering, should be a priority. If the wooden core is compromised, removing the affected areas and replacing them with modern materials can extend the boat’s lifespan while maintaining its structural integrity. However, this process demands precision and expertise, as improper repairs can lead to further damage. Consulting with a marine surveyor or experienced boatbuilder is highly recommended.

In conclusion, the Bertram 38’s wooden deck cores represent a testament to the ingenuity of its original design. While this construction method has its challenges, it remains a defining feature of the boat’s heritage. Whether preserving the original materials or opting for modern upgrades, understanding the intricacies of the deck’s construction is essential for maintaining this iconic vessel’s performance and longevity.

Are Old Wooden Boxes Valuable? Unlocking Their Hidden Worth

You may want to see also

Explore related products

Wooden Core Presence: Investigates if wooden cores were standard in the Bertram 38's deck

The Bertram 38, a legendary sportfishing yacht, has long been celebrated for its durability and performance. However, the construction of its deck, particularly the presence of wooden cores, remains a topic of interest among enthusiasts and restorers. Historical records and expert insights reveal that earlier models of the Bertram 38, produced in the 1960s and early 1970s, often incorporated wooden cores in their decks. These cores, typically made of marine-grade plywood, were encapsulated in fiberglass to provide structural integrity and reduce weight. This design choice was common in the era, balancing strength with the technological limitations of the time.

To determine if a Bertram 38 has a wooden deck core, owners can perform a simple inspection. Start by tapping the deck surface with a rubber mallet or a knuckle; a hollow sound may indicate delamination or a void, suggesting the presence of a wooden core. For a more definitive assessment, drill a small, inconspicuous hole through the fiberglass layer. If wood shavings appear, the core is likely wooden. Caution: Always consult a marine surveyor before drilling to avoid damaging critical areas. This method is particularly useful for buyers or restorers evaluating the condition of an older vessel.

While wooden cores were standard in early Bertram 38s, their longevity depends on proper maintenance. Moisture intrusion is the primary enemy, as it can cause rot and delamination. Owners should inspect hatches, hardware mounts, and deck penetrations annually for signs of water infiltration. Applying a high-quality marine sealant to these areas can prevent moisture from reaching the core. Additionally, monitoring the deck’s stiffness and addressing soft spots promptly can extend the life of the wooden core. For those considering restoration, replacing the wooden core with modern materials like closed-cell foam or composite panels is an option, though it requires professional expertise.

Comparatively, later Bertram 38 models transitioned to non-wood core materials, such as balsa or PVC, to address durability concerns. This shift reflects advancements in marine construction technology and changing industry standards. However, the wooden cores in older models are not inherently problematic if well-maintained. They offer a classic, time-tested design that, with care, can remain functional for decades. For purists, preserving the original wooden core is a way to honor the boat’s heritage, while pragmatists may opt for modern upgrades. Ultimately, understanding the core material is essential for informed decision-making in maintenance, restoration, or purchase.

The Enigmatic Stranger: Unveiling Merlin's Mystical Woods Encounter

You may want to see also

Explore related products

Structural Integrity: Analyzes how wooden cores impacted the deck's strength and durability

Wooden cores in the decks of older Bertram 38s were not merely a design choice but a structural necessity that balanced strength, weight, and durability. These cores, typically made from marine-grade plywood, were encapsulated in fiberglass to create a composite structure. This hybrid design leveraged the natural stiffness and shear strength of wood while benefiting from the moisture resistance and low maintenance of fiberglass. However, the effectiveness of this system depended heavily on the quality of encapsulation. If water infiltrated the wood due to cracks or poor lamination, the core could rot, compromising the deck’s integrity. Regular inspections for soft spots or delamination were critical to maintaining structural soundness, as even a small area of decay could spread rapidly in a marine environment.

To assess the impact of wooden cores on deck strength, consider their role in distributing loads. Wood’s natural ability to absorb and dissipate stress made it an ideal core material for high-traffic areas like the deck of a sportfishing boat. For instance, when anchoring or fighting a large catch, the deck endured significant point loads. A wooden core provided a more forgiving surface compared to solid fiberglass, reducing the risk of hairline cracks or structural fatigue over time. However, this advantage came with a trade-off: wood’s susceptibility to moisture required meticulous maintenance, such as resealing deck hardware annually and monitoring for signs of water intrusion around hatches or cleats.

A comparative analysis highlights the durability challenges of wooden cores versus modern alternatives like foam or balsa. While foam cores are lighter and non-absorbent, they lack the shear strength of wood, making them less suitable for heavy-duty applications like the Bertram 38’s deck. Balsa, though lightweight and rot-resistant, is more brittle and prone to crushing under concentrated loads. Wooden cores, when properly maintained, offered a middle ground—durable enough for decades of use but demanding vigilance to prevent water damage. Owners of older Bertram 38s often report that decks with intact wooden cores remain structurally sound after 30+ years, provided they’ve been proactively cared for.

For those restoring a Bertram 38 with a wooden-cored deck, the key to preserving structural integrity lies in three steps: inspection, repair, and prevention. Start by probing the deck for soft spots using a sharp tool; any give indicates water intrusion. Delaminated areas should be cut out, the core replaced with marine plywood, and the patch re-glassed with epoxy resin for superior moisture resistance. Finally, apply a high-quality non-skid coating and inspect all through-deck fittings for leaks. While labor-intensive, this process ensures the deck retains its original strength and longevity, honoring the boat’s classic design while addressing its inherent vulnerabilities.

Unveiling Gage Wood's Age: A Comprehensive Look at His Life

You may want to see also

Explore related products

Maintenance Challenges: Discusses potential issues with wooden cores in marine environments

Wooden deck cores in marine environments, such as those found in older Bertram 38s, present unique maintenance challenges due to their susceptibility to moisture absorption. Unlike modern composite materials, wood is inherently porous, allowing water to penetrate its cellular structure. Over time, this can lead to swelling, warping, and eventual rot, compromising the structural integrity of the deck. Regular inspections are critical, particularly after exposure to heavy rain, saltwater spray, or prolonged humidity. Early detection of soft spots or discoloration can prevent more extensive damage, but the process demands vigilance and a keen eye for subtle changes in the deck’s texture and appearance.

One of the most significant issues with wooden cores is their reaction to temperature fluctuations and UV exposure. In marine settings, decks are constantly subjected to harsh sunlight, which accelerates the breakdown of wood fibers and protective coatings. This degradation not only weakens the material but also increases its vulnerability to moisture infiltration. Applying UV-resistant sealants and marine-grade varnishes can mitigate this, but these treatments require frequent reapplication—typically every 6 to 12 months, depending on exposure levels. Neglecting this maintenance regimen can result in costly repairs or even necessitate a full deck replacement.

Another challenge lies in the difficulty of drying wooden cores once moisture has penetrated. Unlike surface-level water, which can be wiped away, internal moisture becomes trapped within the wood, fostering mold, mildew, and fungal growth. These organisms not only deteriorate the wood but also pose health risks to those aboard. To combat this, owners must ensure proper ventilation beneath the deck and consider installing moisture barriers during restoration projects. Additionally, using dehumidifiers in enclosed spaces, such as cabins or storage areas, can help maintain optimal humidity levels and reduce the risk of internal dampness.

Comparatively, wooden cores require more labor-intensive maintenance than their modern counterparts, such as foam or balsa cores. While foam cores are lightweight and resistant to water absorption, and balsa cores offer a balance of strength and buoyancy, wood demands a higher degree of care and expertise. For instance, repairing delaminated sections of a wooden core often involves removing damaged layers, treating the area with preservatives, and meticulously reapplying fiberglass or resin. This process is time-consuming and requires precision to ensure a seamless finish that can withstand the rigors of marine conditions.

In conclusion, maintaining wooden deck cores in a marine environment is a demanding but manageable task with the right approach. By prioritizing regular inspections, proactive waterproofing, and addressing moisture issues promptly, owners can extend the lifespan of their wooden decks. While the challenges are undeniable, the timeless aesthetic and historical authenticity of wooden cores in boats like the Bertram 38 often justify the effort. For those willing to invest the time and resources, preserving these classic features can be a rewarding endeavor that honors the vessel’s heritage.

Avery Woods' Husband's Age: Unveiling the Mystery Behind Their Love Story

You may want to see also

Explore related products

Modern Comparisons: Compares old Bertram 38 decks to newer models' construction methods

The Bertram 38, a legendary sportfishing yacht, has undergone significant transformations in its construction methods over the decades. One of the most notable changes lies in the deck construction, particularly the shift from wooden cores to modern materials. The original Bertram 38, introduced in the 1960s, featured a wooden deck core, which was a standard practice at the time. This traditional method provided a sturdy and reliable foundation but was prone to rot, delamination, and moisture absorption over time, especially in harsh marine environments.

In contrast, modern Bertram models and their contemporaries have adopted advanced composite materials, such as fiberglass with closed-cell foam cores or even carbon fiber reinforcements. These innovations offer superior durability, reduced weight, and enhanced resistance to water intrusion. For instance, the use of closed-cell foam cores, like Divinycell or Core-Cell, provides excellent strength-to-weight ratios while preventing water absorption, a common issue with wooden cores. This evolution in construction not only extends the lifespan of the vessel but also reduces maintenance requirements, making newer models more appealing to long-term owners.

From a practical standpoint, owners of older Bertram 38s with wooden deck cores should be vigilant for signs of deterioration, such as soft spots, swelling, or delamination. Regular inspections, particularly after exposure to moisture, are crucial. If issues are detected, repairs often involve cutting out the damaged wood and replacing it with modern materials, a process that, while costly, can restore the deck’s integrity. For those considering a purchase, newer models with advanced cores offer peace of mind, though they come at a premium price.

The comparison between old and new construction methods also highlights the trade-offs between tradition and innovation. While wooden cores evoke a sense of classic craftsmanship, they demand meticulous care and maintenance. Modern materials, on the other hand, prioritize performance and longevity, aligning with contemporary expectations of low-maintenance boating. Ultimately, the choice between an older Bertram 38 and a newer model depends on the owner’s priorities: nostalgia and restoration versus cutting-edge technology and convenience.

Natalie Wood's Age in West Side Story: A Surprising Fact

You may want to see also

Frequently asked questions

Yes, the original Bertram 38, produced in the 1960s and early 1970s, featured wooden deck cores, typically made of plywood, encapsulated in fiberglass.

Wooden deck cores were used for their strength, durability, and ease of construction at the time. They provided a solid foundation for the fiberglass layers.

Yes, if water infiltrates the fiberglass, the wooden core can rot over time, leading to structural issues. Proper maintenance and regular inspections are crucial.

The early models (1960s-early 1970s) had wooden cores, but later versions transitioned to foam or other materials as technology advanced.

You can tap the deck to listen for a solid sound (indicating wood) or consult the boat’s documentation. A professional surveyor can also confirm the core material.