The question of whether burnt wood lasts longer is a fascinating intersection of traditional practices and material science. Pyrolysis, the process of burning wood in the absence of oxygen, alters its chemical composition, creating a hardened outer layer known as char or charcoal. This treatment can enhance wood's resistance to decay, insects, and moisture, potentially extending its lifespan. Historically, techniques like Shou Sugi Ban in Japan and similar methods in Scandinavia have utilized burning as a preservative. However, the durability of burnt wood depends on factors such as the depth of charring, the type of wood, and environmental exposure. While burnt wood can indeed last longer under certain conditions, excessive charring may compromise its structural integrity, making the balance between preservation and strength critical to its longevity.

| Characteristics | Values |

|---|---|

| Durability | Burnt wood, specifically charred or treated through processes like Shou Sugi Ban, can last significantly longer than untreated wood. The burning process creates a protective layer that resists rot, insects, and moisture. |

| Moisture Resistance | The charred layer acts as a barrier, reducing water absorption and minimizing the risk of decay and fungal growth. |

| Insect Resistance | The burnt surface deters insects like termites and beetles, which are less likely to feed on charred wood. |

| UV Resistance | Charred wood has improved resistance to UV radiation, reducing the effects of weathering and color fading. |

| Maintenance | Requires less maintenance compared to untreated wood due to its enhanced resistance properties. |

| Aesthetic Appeal | Offers a unique, weathered look that is highly valued in architectural and decorative applications. |

| Environmental Impact | The process is eco-friendly, as it uses natural materials and does not require chemical treatments. |

| Fire Resistance | Paradoxically, the charred layer can provide some fire resistance, as the outer layer is already burnt and less likely to ignite further. |

| Cost | Initial treatment costs may be higher, but long-term savings are achieved due to reduced maintenance and replacement needs. |

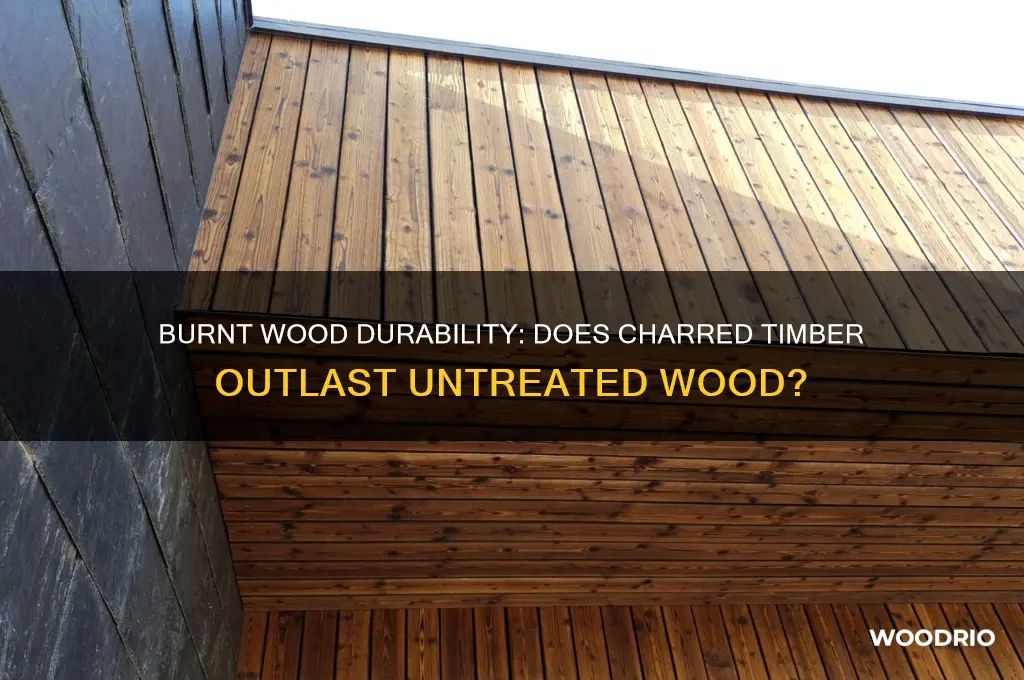

| Application | Commonly used in exterior cladding, fencing, and decorative elements due to its durability and aesthetic appeal. |

Explore related products

What You'll Learn

Natural Preservation Methods

Burnt wood, often referred to as charred or scorched wood, has been used for centuries as a natural preservation method. The process, known as Shou Sugi Ban in Japanese tradition, involves burning the surface of wood to create a protective layer that enhances durability. This method not only extends the lifespan of the wood but also adds a unique aesthetic appeal. By carbonizing the surface, the wood becomes resistant to pests, moisture, and rot, making it an ideal choice for outdoor structures like fencing, siding, and decking.

To apply this technique, start by selecting a suitable wood type, such as cedar or pine, which are known for their natural resilience. Secure the wood in a well-ventilated area and use a propane torch or controlled fire to evenly char the surface. The goal is to achieve a consistent, dark layer without causing excessive damage to the wood’s structural integrity. After burning, allow the wood to cool, then brush off loose charcoal particles. Finish by applying a natural oil, like linseed or tung oil, to seal the surface and enhance its water resistance. This process can double or even triple the wood’s lifespan, depending on environmental conditions.

While Shou Sugi Ban is effective, it’s not the only natural preservation method. Another approach involves treating wood with natural extracts, such as copper sulfate or borax solutions. These substances act as fungicides and insecticides, preventing decay and infestation. To treat wood with copper sulfate, dissolve 1 pound of the compound in 1 gallon of water, then apply the solution generously to the wood’s surface. Allow it to dry completely before use. This method is particularly useful for wooden structures in humid or insect-prone areas, though it lacks the aesthetic transformation of burnt wood.

Comparing these methods reveals trade-offs. Burnt wood offers both preservation and visual appeal but requires careful execution to avoid over-charring. Natural chemical treatments, on the other hand, are simpler to apply but may not provide the same longevity or aesthetic impact. For those prioritizing appearance and tradition, Shou Sugi Ban is the clear choice. For practicality and ease, natural extracts are more suitable. Regardless of the method, both approaches demonstrate how natural preservation techniques can significantly extend the life of wood without relying on synthetic chemicals.

Incorporating these methods into modern construction or restoration projects not only honors traditional practices but also aligns with sustainable building principles. By using locally sourced wood and natural treatments, builders can reduce environmental impact while creating durable, long-lasting structures. Whether charring wood for a rustic finish or treating it with mineral solutions for functionality, these techniques prove that natural preservation methods remain highly effective in contemporary applications.

Wood Filler Drying Time: When to Sand for Smooth Results

You may want to see also

Explore related products

Fire-Induced Chemical Changes

Fire transforms wood through a series of chemical reactions, primarily pyrolysis, which breaks down cellulose, hemicellulose, and lignin—the main components of wood. At temperatures between 200°C and 300°C, cellulose decomposes into char, releasing volatile gases like methane and hydrogen. Lignin, more heat-resistant, decomposes at higher temperatures (300°C–400°C), leaving behind a carbon-rich residue. This process alters the wood’s structure, reducing its moisture content and increasing its density. The resulting char layer acts as a barrier against further degradation, which is why burnt wood often exhibits enhanced durability.

To understand the practical implications, consider the traditional Japanese technique of *yakisugi* (burnt cedar). Wood is exposed to controlled flames for 10–30 seconds, then quickly cooled. This surface carbonization creates a hydrophobic layer that repels water and resists insect infestation. Studies show that *yakisugi*-treated wood can last 80–100 years, compared to untreated cedar’s 15–20-year lifespan. The key lies in the fire’s ability to remove organic compounds susceptible to decay, leaving behind a more stable, carbon-dominated structure.

However, not all fire-induced changes are beneficial. Over-charring weakens wood by reducing its cellulose and hemicellulose content, making it brittle. For optimal results, control the temperature (250°C–350°C) and duration (15–30 seconds per side) during burning. Use a propane torch or controlled flame for precision, and avoid open fires that can lead to uneven charring. After treatment, seal the wood with a natural oil to enhance moisture resistance without compromising the char layer’s integrity.

Comparing burnt wood to chemically treated alternatives reveals its eco-friendly advantage. Pressure-treated lumber relies on toxic preservatives like copper azole, which leach into the environment over time. Burnt wood, in contrast, uses no chemicals and relies solely on natural processes. For outdoor applications like fencing or cladding, fire-treated wood is a sustainable choice, though it requires periodic re-burning every 10–15 years to maintain its protective layer.

In conclusion, fire-induced chemical changes can significantly extend wood’s lifespan when applied correctly. By understanding the science behind pyrolysis and adopting techniques like *yakisugi*, you can harness fire’s transformative power to create durable, environmentally friendly materials. Always prioritize safety and precision during the burning process to avoid structural damage or uneven results.

Woodpeckers' Long Beaks: Do They Really Eat Wood?

You may want to see also

Explore related products

Durability Against Decay

Burnt wood, often referred to as charred or scorched wood, exhibits remarkable resistance to decay, a phenomenon rooted in the chemical transformation of its surface. When wood is exposed to controlled burning, the process of pyrolysis occurs, breaking down hemicellulose and cellulose while leaving behind a carbon-rich layer. This carbonized surface acts as a barrier, significantly reducing the wood’s susceptibility to moisture absorption, fungal growth, and insect infestation—primary culprits of decay. Historical examples, such as the centuries-old shou sugi ban technique from Japan, demonstrate that this method can extend wood’s lifespan by decades, even in harsh outdoor conditions.

To maximize durability against decay, the burning process must be carefully executed. The ideal temperature range for pyrolysis is between 200°C and 300°C (392°F to 572°F), applied for 5 to 15 minutes depending on the wood species and thickness. Over-charring can compromise structural integrity, while under-charring may leave the wood vulnerable. After burning, the wood should be cooled slowly and brushed to remove loose ash, followed by a protective oil or sealant application to enhance moisture resistance. This method is particularly effective for softwoods like pine or cedar, which are naturally more prone to decay.

A comparative analysis reveals that burnt wood outperforms untreated wood in decay resistance by up to 50% in humid environments. While pressure-treated wood relies on chemical preservatives that may leach over time, the durability of burnt wood stems from its inherent physical and chemical changes. However, burnt wood is not invincible; it remains susceptible to mechanical wear and UV degradation. Combining charring with UV-resistant finishes or strategic placement in shaded areas can mitigate these limitations, ensuring longevity in both structural and decorative applications.

For practical implementation, burnt wood is ideal for exterior cladding, fencing, and garden structures where exposure to moisture and pests is high. Maintenance is minimal, requiring only periodic re-sealing every 3 to 5 years. Homeowners and builders should note that while the initial charring process requires precision, the long-term benefits in reduced maintenance and replacement costs make it a cost-effective choice. By understanding the science and application of this ancient technique, modern construction can harness its durability to combat decay sustainably.

How Durable Are Molded Wood Toilet Seats? Longevity Explained

You may want to see also

Explore related products

$25

Resistance to Pests

Burnt wood, often referred to as charred or scorched wood, exhibits a remarkable resistance to pests, a trait that has been leveraged in traditional construction techniques like Shou Sugi Ban for centuries. The process of burning wood creates a protective layer that deters insects such as termites, ants, and beetles, which are common culprits in wood degradation. This layer, known as the char, acts as a physical and chemical barrier, making it difficult for pests to penetrate the wood’s surface. For instance, termites, which rely on cellulose as their primary food source, find the carbonized layer unpalatable and are less likely to infest treated wood.

To maximize pest resistance, the burning process must be carefully controlled. A temperature range of 350°C to 400°C (662°F to 752°F) is ideal for creating a deep char without compromising the wood’s structural integrity. Shallow burns may not provide sufficient protection, while excessive heat can cause the wood to become brittle. After burning, the wood should be cooled slowly and then sealed with a natural oil or sealant to lock in the protective layer and prevent moisture absorption, which could attract pests over time.

Comparatively, untreated wood is highly susceptible to pest infestations, especially in humid or tropical climates. For example, a study comparing untreated pine to charred pine found that the latter showed no signs of termite damage after five years of exposure, while the former was severely compromised. This highlights the efficacy of burning as a pest-resistant treatment, particularly for outdoor structures like fences, decking, and siding. However, it’s essential to note that while burnt wood resists many pests, it is not entirely immune to all wood-boring insects, especially if the char layer is damaged or improperly applied.

Practical tips for homeowners and builders include inspecting burnt wood annually for cracks or wear, as these can expose the underlying wood to pests. Reapplying a protective sealant every 2–3 years can maintain the wood’s resistance. Additionally, combining burnt wood with other pest-deterrent measures, such as elevating structures off the ground or using gravel barriers, can further enhance durability. For those in high-pest-risk areas, consulting a pest control expert to identify specific local threats is advisable.

In conclusion, the resistance of burnt wood to pests is a significant advantage, particularly in regions where insect damage is prevalent. By understanding the science behind the process and following best practices for application and maintenance, individuals can effectively extend the lifespan of wooden structures while minimizing the need for chemical treatments. This natural, eco-friendly method not only preserves wood but also aligns with sustainable building practices, making it a valuable technique for modern construction.

Mastering Smoking: Optimal Wood Chip Soaking Time for Perfect Flavor

You may want to see also

Explore related products

Environmental Impact Factors

Burnt wood, often referred to as charred or scorched wood, has been used for centuries in various applications, from traditional Japanese *shou sugi ban* to modern architectural cladding. While its durability is a key selling point, the environmental impact of the burning process and the long-term effects of using burnt wood warrant careful consideration. The process of burning wood alters its chemical composition, reducing its biodegradability and potentially releasing harmful emissions if not managed properly. This raises questions about its sustainability in an era of heightened environmental awareness.

Analytical Perspective:

The carbonization process that occurs during wood burning creates a protective layer that enhances resistance to rot, pests, and weathering. However, this process releases volatile organic compounds (VOCs) and particulate matter, contributing to air pollution. For instance, burning 1 cubic meter of wood can release up to 1.5 kg of carbon monoxide and 0.5 kg of particulate matter (PM2.5), depending on the burning technique and wood type. While burnt wood’s extended lifespan reduces the need for frequent replacements, the immediate environmental cost of the burning process must be weighed against its long-term benefits.

Instructive Approach:

To minimize environmental impact, consider using controlled burning methods, such as low-oxygen pyrolysis, which reduces emissions by up to 70% compared to open-air burning. Additionally, sourcing wood from sustainably managed forests certified by organizations like the Forest Stewardship Council (FSC) ensures that the raw material is responsibly harvested. For DIY enthusiasts, using a propane torch or a specialized charring machine at temperatures between 200°C and 300°C for 10–15 minutes per side can achieve the desired effect while minimizing harmful emissions. Always conduct the process outdoors or in a well-ventilated area to avoid inhaling toxic fumes.

Comparative Insight:

Compared to untreated wood, burnt wood’s longevity reduces the demand for chemical preservatives like chromated copper arsenate (CCA), which leach toxic substances into the soil over time. However, burnt wood’s reduced biodegradability means it persists longer in landfills if not repurposed. In contrast, natural weathering processes for untreated wood are more environmentally benign but result in shorter lifespans. For example, untreated pine lasts 5–10 years outdoors, while burnt pine can endure for 30–50 years, significantly reducing replacement frequency and associated resource consumption.

Persuasive Argument:

Adopting burnt wood as a sustainable building material requires a lifecycle approach. While the burning process poses immediate environmental challenges, its durability offsets these by reducing the need for frequent replacements and associated deforestation. Governments and industries should incentivize low-emission burning technologies and promote the use of burnt wood in long-lasting applications, such as exterior siding or decking. By prioritizing innovation and responsible practices, burnt wood can become a cornerstone of eco-friendly construction, balancing durability with environmental stewardship.

Durability of Wood Windows: Lifespan, Maintenance, and Longevity Explained

You may want to see also

Frequently asked questions

Burnt wood, when properly treated through a process like Shou Sugi Ban, can last longer than untreated wood due to its increased resistance to rot, insects, and moisture.

Burning wood creates a protective charcoal layer that acts as a barrier against moisture, pests, and decay, enhancing its durability and lifespan.

Yes, burnt wood is more resistant to weathering, UV damage, and fungal growth, making it better suited for outdoor applications compared to untreated wood.

When done correctly, the burning process does not significantly weaken the wood. However, excessive charring can reduce its strength, so proper technique is essential.

Burnt wood can last 10–20 years or more in outdoor conditions, whereas untreated wood typically deteriorates within 5–10 years, depending on the environment.