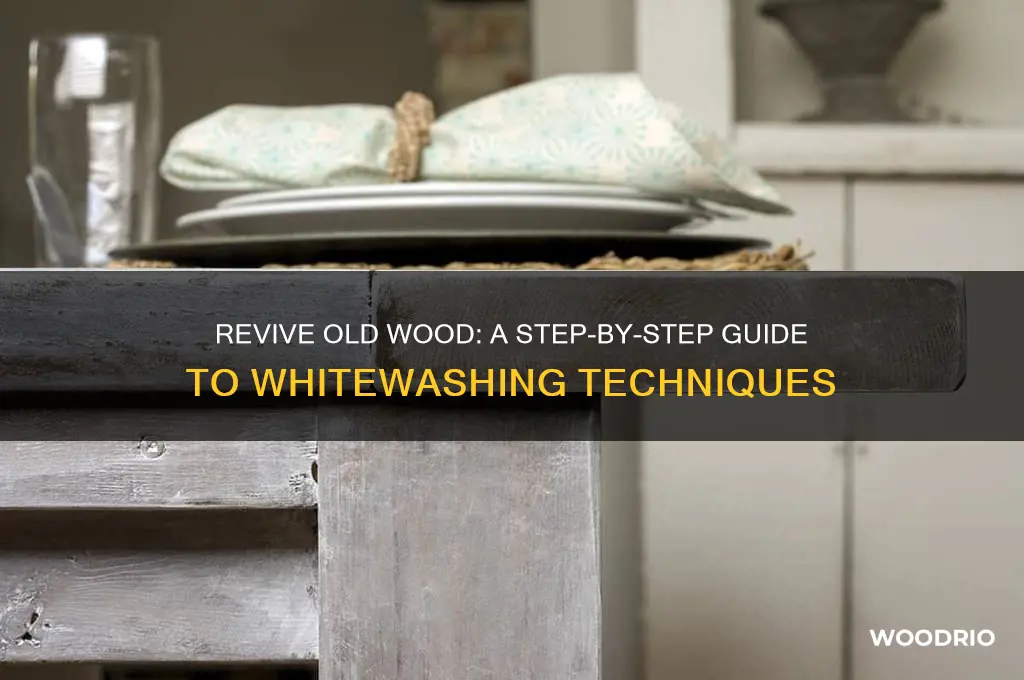

Whitewashing old wood is a timeless technique that breathes new life into weathered or outdated wooden surfaces while preserving their natural texture and character. This method involves applying a thin, opaque layer of paint mixed with water, allowing the wood grain to subtly show through, creating a rustic yet elegant finish. Ideal for furniture, walls, or flooring, whitewashing not only enhances the aesthetic appeal but also protects the wood from wear and tear. The process is straightforward, requiring minimal tools and materials, making it a popular choice for DIY enthusiasts and professionals alike. Whether aiming for a vintage farmhouse look or a modern minimalist vibe, mastering the art of whitewashing can transform old wood into a stunning focal point.

| Characteristics | Values |

|---|---|

| Purpose | To lighten and preserve old wood while maintaining its natural texture. |

| Materials Needed | White latex paint, water, paintbrush, sandpaper, cloth, wood cleaner. |

| Paint-to-Water Ratio | Typically 1:1 or 1:2 (paint:water), depending on desired opacity. |

| Preparation Steps | Clean wood, sand lightly, remove dust. |

| Application Method | Apply whitewash with a brush, wipe excess for desired effect. |

| Drying Time | 2-4 hours between coats; fully dry in 24 hours. |

| Number of Coats | 1-3 coats, depending on desired finish. |

| Finish Options | Matte, semi-gloss, or distressed (by sanding after drying). |

| Protection | Seal with polyurethane or wax for durability. |

| Best Wood Types | Pine, oak, or any porous wood; not ideal for dense woods like teak. |

| Indoor/Outdoor Use | Suitable for both, but outdoor wood requires weather-resistant sealant. |

| Eco-Friendly Option | Use non-toxic, water-based paints and sealants. |

| Cost | Low to moderate, depending on materials and scale of project. |

| Skill Level Required | Beginner-friendly; minimal experience needed. |

| Maintenance | Reapply sealant every 1-2 years for outdoor wood. |

| Common Mistakes | Applying too thick a coat, not sanding properly, or skipping cleaning. |

Explore related products

What You'll Learn

- Preparing the Wood Surface: Clean, sand, and repair any damage before starting the whitewashing process

- Choosing the Right Paint: Select a suitable white paint or whitewash solution for wood surfaces

- Applying the Whitewash: Use a brush or rag to apply thin, even coats of whitewash

- Achieving Desired Opacity: Control the number of coats to balance wood grain visibility and coverage

- Sealing the Finish: Apply a clear sealant to protect the whitewashed wood from wear and tear

Preparing the Wood Surface: Clean, sand, and repair any damage before starting the whitewashing process

Before you even think about applying that whitewash, your wood needs a spa day. Think of it as prepping a canvas before painting – a clean, smooth surface is key to a flawless finish. Dirt, grime, and old finishes will sabotage your efforts, leaving you with a streaky, uneven mess.

Imagine trying to paint a masterpiece on a dusty, cracked wall – not ideal, right?

The Cleaning Ritual: Start by banishing dust and cobwebs with a dry brush or vacuum. For stubborn dirt, a damp cloth with mild soap and water works wonders. Avoid harsh chemicals that might damage the wood's natural beauty. Remember, you're aiming for a clean slate, not a chemical bath.

Rinse thoroughly and allow the wood to dry completely before moving on.

Sanding: The Secret to Smoothness: Once clean, it's time to address texture. Sanding smooths out rough patches, splinters, and old paint, creating a uniform surface for the whitewash to adhere to. Start with a medium-grit sandpaper (around 120 grit) to tackle imperfections, then graduate to a finer grit (220 grit) for a silky finish. Always sand in the direction of the wood grain – going against it will leave unsightly scratches.

Think of it as exfoliating your wood, revealing its natural radiance.

Repairing the Past: Before you can move forward, address any past injuries. Fill cracks, holes, or gaps with a wood filler that matches the color of your wood. Allow it to dry completely and sand it smooth, ensuring a seamless repair. This step is crucial for a professional-looking finish, preventing the whitewash from pooling in imperfections.

By meticulously cleaning, sanding, and repairing, you're laying the foundation for a stunning whitewashed transformation. This preparatory work might seem tedious, but it's the difference between a DIY disaster and a Pinterest-worthy masterpiece. Remember, patience and attention to detail are your secret weapons in this wood-revival mission.

Hydrangea Macrophylla: Blooming on New or Old Wood Explained

You may want to see also

Explore related products

Choosing the Right Paint: Select a suitable white paint or whitewash solution for wood surfaces

The opacity of your chosen paint or whitewash solution will dramatically affect the final look of your wood. A high-opacity white paint will almost entirely obscure the wood grain, creating a crisp, modern finish. Conversely, a low-opacity whitewash allows the natural grain and texture to show through, resulting in a more rustic, weathered appearance. Consider the desired aesthetic before selecting your product.

For a true whitewash effect, opt for a lime-based solution. Traditionally, whitewashing involved mixing slaked lime with water to create a thin, milky liquid. This method not only lightens the wood but also acts as a natural preservative, deterring insects and mold. Modern limewash products are readily available and often come pre-mixed for convenience. They typically require dilution with water at a ratio of 1:1 to 1:4, depending on the desired opacity.

If you prefer a more controlled application and a wider range of white shades, latex paint is a suitable choice. Choose a flat or matte finish to maintain a natural, understated look. For a whitewashed effect with paint, dilute it with water at a 1:2 ratio. This technique allows the wood grain to peek through while providing more coverage than a traditional whitewash. Remember, the more water you add, the more transparent the paint becomes.

Chalk paint has gained popularity for its ability to adhere to various surfaces, including wood, without extensive preparation. Its matte finish and slight texture contribute to a charming, vintage look. When using chalk paint for whitewashing, consider mixing it with a clear wax or a small amount of water to achieve the desired consistency and opacity. This method is particularly forgiving for beginners, as it requires minimal sanding and priming.

When selecting your white paint or whitewash, always test the product on a small, inconspicuous area of the wood. This step is crucial to ensure the color and opacity meet your expectations. Allow the test area to dry completely, as the color may lighten significantly. Additionally, consider the wood's age and condition; older, more porous wood may absorb more of the solution, affecting the final shade. By carefully choosing and testing your paint or whitewash, you can achieve a beautiful, customized finish that enhances the character of your old wood.

Aimee Lou Wood's Age: Unveiling the Youthful Star's Birth Year

You may want to see also

Explore related products

$38.99

Applying the Whitewash: Use a brush or rag to apply thin, even coats of whitewash

The application of whitewash to old wood is a delicate balance between artistry and technique. Using a brush or rag to apply thin, even coats is crucial, as it allows the wood's natural grain to show through while achieving the desired weathered or rustic look. A brush offers more control, especially in detailed areas, while a rag can provide a softer, more uniform finish. The choice of tool depends on the project's aesthetic goals and the wood's condition.

Instructively, start by dipping your brush or rag into the whitewash mixture, which typically consists of a 1:2 ratio of paint to water, though this can be adjusted for opacity. Wring out excess liquid to avoid drips, as too much moisture can raise the wood grain or cause uneven coverage. Apply the whitewash in the direction of the grain, using long, smooth strokes. Allow each coat to dry completely, which usually takes 2-4 hours, before assessing the need for additional layers. Two to three thin coats are often sufficient, but this depends on the desired effect and the wood's absorbency.

Comparatively, brushes are ideal for projects requiring precision, such as furniture or decorative pieces, where you want to highlight specific details. Rags, on the other hand, are better suited for larger, more uniform surfaces like walls or floors, where consistency is key. For example, a brush might be used to whitewash an old wooden table, emphasizing its intricate carvings, while a rag could be employed to treat a barn door, creating a seamless, aged appearance. The tool choice also influences the texture: brushes can leave subtle brushstrokes, adding character, while rags produce a smoother finish.

Persuasively, mastering the application of thin, even coats is essential for achieving professional results. Thick layers can obscure the wood's natural beauty and lead to peeling or cracking over time. By working in stages, you maintain control over the final look, ensuring the whitewash enhances rather than overwhelms the wood. Additionally, this method allows for easy correction of mistakes—a light sanding between coats can fix imperfections without starting over. Patience and attention to detail are your greatest allies in this process.

Descriptively, imagine the transformation as you apply each coat: the wood gradually lightens, its texture becoming more pronounced, yet softened by the translucent wash. The first coat may appear uneven, but subsequent layers build depth and consistency. With each stroke, you're not just painting—you're reviving the wood's story, blending its history with your vision. Whether using a brush or rag, the technique is as much about feel as it is about appearance, requiring a gentle hand and an eye for balance. The end result is a piece that feels both timeless and intentionally crafted.

Trumpet Vine Blooming Secrets: Old Wood vs. New Growth Explained

You may want to see also

Explore related products

Achieving Desired Opacity: Control the number of coats to balance wood grain visibility and coverage

The opacity of your whitewash is a delicate dance between revealing the wood's character and achieving the desired coverage. Too much paint, and you'll lose the grain's beauty; too little, and the wood's imperfections might overshadow your vision. This balance is where the art of whitewashing truly shines.

The Layering Technique: A Step-by-Step Approach

Begin with a single coat of whitewash, allowing it to dry completely. This initial layer serves as a base, providing a subtle hint of color while still showcasing the wood's natural texture. For a more pronounced effect, consider a 1:4 ratio of paint to water, ensuring the mixture is thin enough to penetrate the wood without obscuring its details. After the first coat, assess the opacity—is the wood grain still visible, or does it need more coverage?

Building Opacity with Precision

Each additional coat of whitewash increases opacity, gradually transforming the wood's appearance. For a more opaque finish, apply a second coat, but with a slightly thicker consistency (adjust the paint-to-water ratio to 1:3). This layer will start to unify the wood's color while still allowing some grain to peek through. The key is to work in thin layers, as this technique provides better control over the final look. For instance, a third coat with a 1:2 ratio can be used to target specific areas that require more coverage, ensuring the overall effect remains nuanced.

Avoiding Common Pitfalls

Over-application is a common mistake when aiming for the perfect opacity. Too many thick coats can result in a heavy, uneven finish, hiding the wood's natural charm. Instead, opt for multiple thin layers, allowing each to dry before adding the next. This method ensures a more consistent and controllable outcome. Additionally, consider the wood's age and condition; older wood may absorb more paint, requiring additional coats to achieve the same opacity as newer wood.

Tailoring Opacity to Your Vision

The beauty of whitewashing lies in its versatility. For a rustic, weathered look, one or two coats might suffice, allowing the wood's history to shine through. In contrast, a more modern aesthetic could demand a higher level of opacity, achieved through additional layers. By carefully controlling the number of coats and their consistency, you can customize the final appearance to suit your style. This tailored approach ensures that the whitewashed wood becomes a unique, personalized element in your space.

In the art of whitewashing, achieving the desired opacity is a process of patience and precision. Through careful layering and an understanding of the paint's behavior, you can create a finish that enhances the wood's natural beauty while adding a touch of your own creative vision. This technique is a testament to the transformative power of paint, where control and creativity converge.

Nandina Pruning Guide: Does It Leaf on Old Wood?

You may want to see also

Explore related products

Sealing the Finish: Apply a clear sealant to protect the whitewashed wood from wear and tear

A protective sealant is the unsung hero of any whitewashing project, ensuring your hard work stands the test of time. After meticulously applying the whitewash and achieving the desired aesthetic, sealing the wood becomes a critical step to preserve its beauty. This final layer acts as a shield, guarding against the daily onslaught of scratches, stains, and moisture that can deteriorate the finish. Without it, your whitewashed wood may succumb to wear and tear, losing its charm prematurely.

The Sealing Process: A Step-by-Step Guide

Begin by selecting a clear sealant suitable for wood, such as polyurethane or polycrylic. These sealants are available in various finishes, from matte to gloss, allowing you to customize the final look. For instance, a matte finish provides a subtle, natural appearance, while a gloss finish adds a sleek, modern touch. Once you've chosen your sealant, ensure the whitewashed wood is clean and dry. Any dust or debris can become permanently trapped under the sealant, marring the surface.

Application techniques vary, but a common method is to use a brush or a clean, lint-free cloth. Apply the sealant in thin, even coats, following the wood grain. Typically, two to three coats are recommended, allowing each layer to dry completely before adding the next. This process might take several hours or even days, depending on the sealant and environmental conditions. Patience is key; rushing can lead to an uneven finish or bubbles.

Cautions and Considerations

While sealing is essential, it's not without its pitfalls. Over-application can result in a thick, uneven surface, detracting from the wood's natural beauty. Always follow the manufacturer's instructions regarding application and drying times. Additionally, be mindful of the wood's age and condition. Older wood may require more gentle treatment, and certain sealants might not adhere well to aged surfaces. Testing the sealant on a small, inconspicuous area first is a wise precaution.

The Long-Term Benefits

Sealing your whitewashed wood is an investment in its longevity. It not only protects against physical damage but also helps resist UV fading, ensuring the color remains vibrant. This is particularly important for outdoor furniture or décor, where sunlight and weather can quickly degrade unprotected wood. With proper sealing, your whitewashed pieces can retain their allure for years, becoming timeless additions to your space.

In essence, sealing is the final, crucial step in the whitewashing process, transforming a vulnerable surface into a durable, long-lasting finish. It's a simple yet powerful technique that ensures your craftsmanship endures, allowing you to enjoy the beauty of whitewashed wood for generations.

Natalie Wood's Age in The Searchers: A Surprising Fact

You may want to see also

Frequently asked questions

Whitewashing is a technique that involves applying a diluted paint or lime mixture to wood, creating a translucent finish that highlights the wood's natural grain while adding a soft, aged appearance.

You’ll need white paint (latex or chalk paint), water, a paintbrush or roller, sandpaper, a clean cloth, and optionally a sealant for protection.

Yes, sand the wood lightly to remove any rough spots or old finishes, clean it with a damp cloth to remove dust, and ensure it’s dry before applying the whitewash.

Mix 1 part white paint with 3 parts water, apply the mixture with a brush or roller in the direction of the grain, and wipe off excess with a cloth for the desired opacity.

Yes, sealing is recommended to protect the finish. Use a clear matte or satin sealant, applying it evenly with a brush or spray after the whitewash has dried completely.

![Chalk Pure Paint - for Furniture, Crafts, Home Decor - All-in-One – DIY – Eco-Friendly (Vintage [White]), (33.81 oz)](https://m.media-amazon.com/images/I/71D8FahUGhL._AC_UL320_.jpg)

![Shabby Chic Chalk Furniture Paint: Luxurious Chalk Finish Craft Paint for Home Decor, DIY, Wood Cabinets - All-in-One Paints with Rustic Matte Finish [Antique White] - (8.5 oz Covers 32 sf)](https://m.media-amazon.com/images/I/61CWkXJu9LL._AC_UL320_.jpg)