Treated wood posts are a popular choice for various outdoor applications, including fencing, decking, and landscaping, due to their durability and resistance to decay, insects, and moisture. The lifespan of treated wood posts can vary significantly depending on several factors, such as the type of treatment, environmental conditions, and maintenance practices. Generally, pressure-treated wood posts can last anywhere from 20 to 40 years or more when properly installed and maintained. Factors like soil type, exposure to water, and climate play a crucial role in determining their longevity. For instance, posts in wet or humid environments may deteriorate faster than those in drier regions. Regular inspections and preventive measures, such as sealing cuts and ensuring proper drainage, can help maximize their lifespan. Understanding these variables is essential for anyone considering treated wood posts for their projects.

Explore related products

What You'll Learn

Factors affecting treated wood post lifespan

Treated wood posts are a staple in construction and landscaping, prized for their durability. However, their lifespan varies widely—from 10 to 40 years—depending on several critical factors. Understanding these can help maximize their longevity and ensure they perform as expected.

Treatment Type and Retention Level

The effectiveness of treated wood hinges on the preservative chemicals used and their retention level. Common treatments include chromated copper arsenate (CCA), alkaline copper quaternary (ACQ), and copper azole. ACQ and copper azole are widely used today due to CCA’s phase-out in residential applications. Retention levels, measured in pounds of preservative per cubic foot (pcf), dictate resistance to decay and insects. For example, ground-contact posts typically require a retention of 0.40 pcf, while above-ground posts may need only 0.25 pcf. Always verify the treatment type and retention level when purchasing to match the intended use.

Environmental Exposure

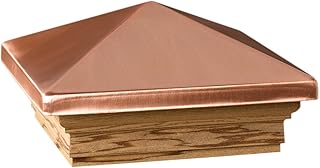

Moisture is the primary enemy of treated wood posts. Posts installed in direct contact with soil or water are at higher risk of decay due to constant moisture exposure. Even above-ground posts can suffer if exposed to frequent rain or humidity without proper drainage. UV radiation also accelerates surface degradation, causing cracking and splitting over time. To mitigate this, consider using post caps to reduce water infiltration and applying UV-resistant sealants every 2–3 years. For ground-contact posts, ensure proper grading and drainage to minimize soil moisture.

Installation Practices

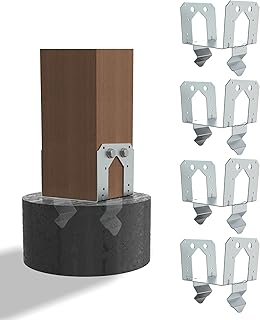

Improper installation can drastically shorten a post’s lifespan. For ground-contact posts, dig holes deep enough to meet local building codes, typically 1/3 of the post’s height below ground. Use gravel or crushed stone at the base to improve drainage. Avoid burying untreated portions of the post, as this can lead to rot. For fence posts, ensure they are set plumb and braced securely to withstand wind and lateral pressure. Poorly installed posts are more susceptible to shifting, cracking, and premature failure.

Maintenance and Aftercare

Regular maintenance extends the life of treated wood posts. Inspect posts annually for signs of damage, such as cracks, splinters, or insect activity. Reapply water-repellent sealants or stains as needed, especially after the initial treatment wears off. For posts in high-moisture areas, consider using a borate-based wood preservative to enhance resistance to fungi and insects. Promptly repair or replace damaged posts to prevent further deterioration. Neglecting maintenance can halve the expected lifespan of even the best-treated wood.

Wood Species and Quality

The base wood species plays a significant role in post durability. Southern yellow pine is commonly used due to its natural resistance to decay and its ability to absorb preservatives effectively. Other species, like cedar or redwood, have inherent resistance but may not perform as well when treated. Ensure the wood is free from defects like knots or splits, which can compromise structural integrity. High-quality, properly treated wood from reputable suppliers will always outperform inferior alternatives, regardless of treatment type.

By addressing these factors—treatment type, environmental exposure, installation practices, maintenance, and wood quality—you can significantly enhance the lifespan of treated wood posts. Tailoring these considerations to your specific project ensures long-lasting performance and reduces the need for premature replacements.

Cedar Wood Durability: How Long It Lasts Outdoors and Why

You may want to see also

Explore related products

Common treatment types and durability

Pressure-treated wood posts dominate the market due to their enhanced resistance to rot, insects, and decay. This process involves forcing preservatives deep into the wood fibers under high pressure, ensuring thorough penetration. Common chemicals used include alkaline copper quaternary (ACQ), copper azole (CA), and chromated copper arsenate (CCA), though CCA has been largely phased out for residential use due to health concerns. ACQ and CA are environmentally friendlier alternatives, with ACQ being the most widely used due to its low toxicity and effectiveness against fungi and termites. The lifespan of pressure-treated wood posts typically ranges from 20 to 40 years, depending on factors like soil contact, moisture exposure, and climate. For optimal durability, ensure posts are rated for ground contact if they’ll be buried, as these contain higher preservative concentrations.

Heat-treated wood, often marketed as thermally modified wood, offers a chemical-free alternative to traditional treatments. This process involves heating the wood to high temperatures in a controlled environment, which alters its cellular structure to resist moisture absorption and decay. While heat-treated wood is less prone to warping and splitting, its durability against insects and fungi is generally lower than pressure-treated options. Lifespan varies widely, from 15 to 30 years, depending on environmental conditions. This treatment is ideal for above-ground applications where chemical exposure is a concern, such as garden structures or decking. However, it’s not recommended for ground contact without additional protective measures, like concrete bases or gravel beds.

Creosote-treated wood, commonly used for utility poles and marine pilings, is known for its extreme durability in harsh environments. Creosote is a tar-based preservative that provides exceptional resistance to fungi, insects, and moisture. However, its use is restricted to industrial and agricultural applications due to its toxicity and strong odor. Posts treated with creosote can last 40 to 60 years, making them one of the longest-lasting options available. When handling creosote-treated wood, wear protective gear, including gloves and a mask, to avoid skin and respiratory irritation. This treatment is not suitable for residential projects involving frequent human contact.

For those seeking eco-friendly options, natural treatments like borate-treated wood provide a middle ground between chemical preservatives and untreated wood. Borates are mineral salts that act as a natural fungicide and insecticide, leaching out of the wood when exposed to moisture. While effective for interior or covered exterior applications, borate-treated wood is not recommended for ground contact or areas with high humidity, as its lifespan drops significantly under these conditions. Expect 10 to 20 years of service life in ideal conditions. To maximize durability, apply a waterproof sealant to reduce moisture penetration and reapply borate solutions periodically if the wood is exposed to the elements.

Comparing these treatments, pressure-treated wood remains the most versatile and cost-effective option for most applications, while heat-treated and borate-treated wood cater to specific needs like chemical avoidance or interior use. Creosote, though highly durable, is limited to industrial settings. When selecting a treatment type, consider the post’s intended use, environmental exposure, and maintenance requirements. Proper installation, such as ensuring adequate drainage and using gravel or concrete bases, can significantly extend the lifespan of any treated wood post. Regular inspections for signs of wear or damage will also help identify issues before they compromise the post’s integrity.

Wood Wicks vs. Cotton: Which Burns Longer and Why?

You may want to see also

Explore related products

$26.41 $27.79

Environmental impact on post longevity

The lifespan of treated wood posts is significantly influenced by environmental factors, which can either accelerate deterioration or enhance durability. Moisture, for instance, is a primary culprit. Prolonged exposure to water, whether from rainfall, humidity, or soil saturation, can lead to rot and decay, even in pressure-treated wood. Posts installed in areas with poor drainage or high water tables are particularly vulnerable. To mitigate this, ensure proper grading and drainage around the posts, and consider using gravel or crushed stone as a base to improve water runoff. Additionally, applying a waterproof sealant every 2–3 years can provide an extra layer of protection.

Temperature fluctuations also play a critical role in post longevity. Extreme heat can cause wood to warp, crack, or splinter, while freezing temperatures can exacerbate moisture-related issues by causing wood fibers to expand and contract. In regions with harsh winters, posts should be installed at least 6 inches above ground level to minimize direct contact with snow and ice. For added resilience, choose wood treated with micronized copper azole (MCA) or alkaline copper quat (ACQ), which offer superior resistance to temperature-induced degradation. Regular inspections during seasonal transitions can help identify early signs of damage, allowing for timely repairs.

Soil composition and chemistry are often overlooked but can dramatically affect post durability. Acidic soils, common in regions with high rainfall, can accelerate corrosion of the metal fasteners used in post installation. Alkaline soils, on the other hand, may cause treated wood to lose its preservative properties more quickly. Conducting a soil test before installation can help determine the pH level and guide appropriate treatment choices. For acidic soils, consider using stainless steel or galvanized hardware, while posts in alkaline soils may benefit from additional borate treatments.

Sunlight exposure is another environmental factor that can shorten the life of treated wood posts. UV rays break down the lignin in wood, leading to discoloration, brittleness, and structural weakness over time. Posts installed in open, sunny areas should be painted or stained with a UV-resistant product to block harmful rays. Reapply this protective coating every 1–2 years, depending on sun exposure intensity. Alternatively, using a post cap can shield the end grain, which is particularly susceptible to UV damage.

Finally, biological activity in the surrounding environment can pose a threat to treated wood posts. Termites, fungi, and bacteria thrive in warm, moist conditions and can compromise even the most robustly treated wood. To deter these organisms, maintain a clear perimeter around posts, removing debris, mulch, or vegetation that could retain moisture. For high-risk areas, consider installing physical barriers like termite shields or using wood treated with additional insecticides. Regularly inspect posts for signs of infestation, such as hollowed wood or mud tubes, and address issues promptly to prevent further damage.

By understanding and addressing these environmental factors, you can significantly extend the lifespan of treated wood posts, ensuring they remain functional and structurally sound for decades.

Sealing Pressure Treated Wood: Optimal Timing for Long-Lasting Protection

You may want to see also

Explore related products

Maintenance tips to extend lifespan

Treated wood posts, when properly maintained, can last 20 to 40 years or more, depending on environmental conditions and care. However, without regular maintenance, their lifespan can be significantly shortened. The key to maximizing durability lies in proactive measures that protect against moisture, pests, and weathering.

Inspect and Clean Regularly

Begin by inspecting posts annually for signs of wear, such as cracks, splinters, or discoloration. Use a stiff brush or pressure washer (on low setting) to remove dirt, debris, and mildew, which can trap moisture and accelerate decay. Pay special attention to areas where posts meet the ground or hardware, as these are prone to water accumulation. For posts in humid climates, consider cleaning twice a year to prevent fungal growth.

Reapply Water Repellent or Stain

Every 2–3 years, reapply a water-repellent sealant or wood stain to create a barrier against moisture. Choose a product with UV protection to guard against sun damage, especially for posts exposed to direct sunlight. For best results, ensure the wood is clean and dry before application, and follow the manufacturer’s instructions for coverage rates (typically 100–150 square feet per gallon). This simple step can add 5–10 years to a post’s life.

Address Hardware and Attachments

Loose or corroded hardware can create entry points for moisture and weaken structural integrity. Tighten screws, bolts, and brackets annually, replacing any rusted or damaged pieces with galvanized or stainless steel alternatives. If posts support fences or structures, ensure proper drainage by sloping the ground away from the base to prevent water pooling.

Prevent Pest Infestation

Termites and carpenter ants pose a significant threat to treated wood. Reduce risk by keeping the surrounding area clear of wood debris, leaves, and standing water. For added protection, apply a wood preservative with insecticidal properties every 3–5 years. If infestation is suspected, consult a pest control professional immediately to prevent further damage.

By implementing these maintenance practices, you can significantly extend the lifespan of treated wood posts, ensuring they remain functional and aesthetically pleasing for decades. The investment in time and materials is minimal compared to the cost of premature replacement.

Stardew Valley Wood Chipper Efficiency: Time to Process Wood Explained

You may want to see also

Explore related products

Comparing treated wood to alternatives

Treated wood posts, when properly installed and maintained, can last 20 to 40 years, depending on factors like soil conditions, moisture exposure, and treatment type. Pressure-treated wood, infused with preservatives like chromated copper arsenate (CCA) or alkaline copper quaternary (ACQ), resists rot, insects, and fungal decay. However, this longevity pales in comparison to alternatives like steel, composite materials, and concrete, which can endure 50 years or more with minimal maintenance. While treated wood offers a balance of cost and durability, its lifespan is inherently finite, making it a mid-tier choice in the spectrum of post materials.

Consider steel posts, for instance, which boast a lifespan of 50 to 70 years, largely due to their resistance to moisture, pests, and weathering. Galvanized steel, coated with a protective zinc layer, is particularly resilient, though it can corrode in highly acidic or saline environments. Unlike treated wood, steel requires no chemical treatments and is fully recyclable at the end of its life. However, steel posts are more expensive upfront and can conduct heat, making them less ideal for certain applications like fencing in hot climates. For those prioritizing longevity and sustainability, steel is a compelling alternative.

Composite materials, made from a blend of recycled wood fibers and plastic, offer another durable option, typically lasting 30 to 50 years. These posts are resistant to rot, warping, and insect damage, and they require minimal upkeep beyond occasional cleaning. While composites are more expensive than treated wood, their longer lifespan and low maintenance needs can offset the initial cost over time. However, they are not as strong as steel or concrete and may not be suitable for heavy-duty applications like retaining walls. For projects where aesthetics and ease of maintenance are key, composites shine.

Concrete posts, often used in agricultural and industrial settings, can last 50 years or more, thanks to their sheer durability and resistance to environmental stressors. They are impervious to rot, insects, and moisture, making them ideal for wet or humid conditions. However, concrete is heavy and difficult to install, requiring specialized equipment and labor. It also lacks the natural aesthetic of wood or the versatility of composites. For applications where strength and permanence are paramount, concrete is unmatched, but its practicality is limited by its weight and cost.

In choosing between treated wood and its alternatives, consider the specific demands of your project. Treated wood is cost-effective and versatile but requires periodic inspection and potential replacement within a few decades. Steel offers superior longevity and sustainability but at a higher price point. Composites balance durability and aesthetics but may not suit heavy-duty uses. Concrete provides unmatched strength but is cumbersome and expensive to install. Each material has its place, and the best choice depends on your priorities: budget, lifespan, maintenance, and environmental impact.

Mastering Smoke Flavor: Optimal Soaking Time for Wood Chunks

You may want to see also

Frequently asked questions

Treated wood posts can last anywhere from 20 to 40 years or more, depending on factors like the type of treatment, environmental conditions, and maintenance.

Yes, the lifespan varies. Posts used in ground contact, like fence posts, typically last 15–20 years, while those used above ground, like deck supports, can last 40+ years.

Exposure to moisture, soil conditions, insect damage, and lack of proper installation or maintenance can significantly reduce the lifespan of treated wood posts.

Yes, periodic reapplication of wood preservatives, proper sealing, and ensuring good drainage can help extend the lifespan of treated wood posts.