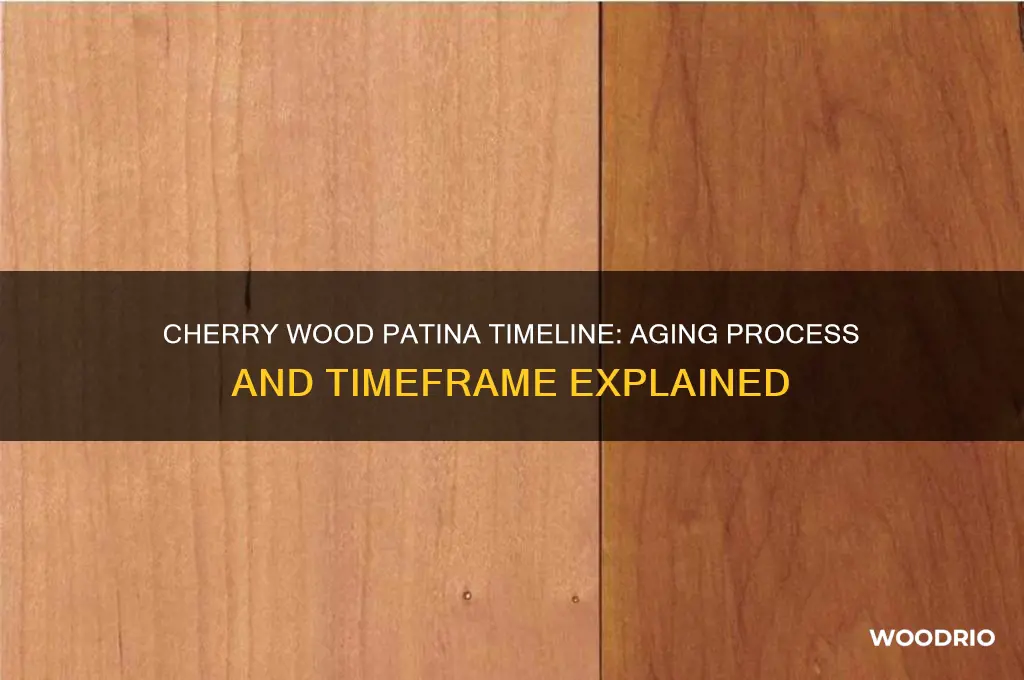

Cherry wood is renowned for its rich, warm tones and ability to develop a beautiful patina over time, a process that enhances its natural beauty and depth. The patina, characterized by a darkening and mellowing of the wood’s color, is influenced by factors such as exposure to light, humidity, and air. Typically, cherry wood begins to show noticeable patina within a few months to a year, with significant transformation occurring over 5 to 10 years. However, achieving a fully matured patina can take several decades, making it a gradual yet rewarding process for furniture makers, woodworkers, and enthusiasts alike. Understanding the timeline and conditions that contribute to this natural aging process is essential for appreciating and preserving the unique character of cherry wood.

| Characteristics | Values |

|---|---|

| Time to Develop Patina | 5 to 10 years (varies based on exposure to light and environmental conditions) |

| Initial Color Change | Light reddish-brown to deeper reddish-brown within the first 1-2 years |

| Final Patina Color | Rich, dark reddish-brown or amber hue |

| Factors Affecting Patina Speed | UV light exposure, humidity, temperature, and air circulation |

| Indoor vs. Outdoor Patina | Indoor: 5-10 years; Outdoor: 1-3 years (due to increased UV exposure) |

| Maintenance Impact | Regular cleaning and oiling can slow down patina development |

| Wood Grain Visibility | Patina enhances the natural grain and texture of cherry wood |

| Reversibility | Patina is permanent and cannot be reversed without refinishing |

| Common Uses for Patina Cherry Wood | Furniture, cabinetry, flooring, and decorative woodwork |

Explore related products

What You'll Learn

Factors affecting patina speed

Cherry wood's transformation into a rich, reddish-brown patina is a process influenced by several key factors, each playing a unique role in determining how quickly this aging effect occurs. One of the most significant variables is exposure to light, particularly ultraviolet (UV) rays. Direct sunlight accelerates the oxidation of the wood’s surface, breaking down its natural pigments and revealing deeper tones. For instance, a cherry wood table placed near a sunny window will develop patina faster than one kept in a dimly lit room. To control this, consider using UV-filtering window films or rotating furniture periodically to ensure even exposure.

Humidity and temperature also play critical roles in patina development. Higher humidity levels can speed up the process by promoting moisture absorption, which softens the wood fibers and allows for quicker chemical reactions. However, excessive moisture can lead to warping or mold, so maintaining a balanced environment—ideally between 40–60% humidity—is essential. Temperature fluctuations, especially in environments with significant seasonal changes, can further accelerate patina by expanding and contracting the wood, exposing new layers to oxidation.

The finish applied to the wood is another decisive factor. Unfinished cherry wood will patina faster than sealed or varnished pieces, as protective coatings act as barriers against oxygen and light. For those seeking a quicker patina, opting for a light oil finish or wax can provide minimal protection while still allowing the wood to breathe and age naturally. Conversely, if slowing the process is the goal, a high-quality polyurethane or lacquer finish can significantly delay patina formation.

Finally, human interaction and environmental pollutants can subtly influence patina speed. Frequent handling or cleaning with harsh chemicals can strip away natural oils, exposing the wood to faster oxidation. Similarly, airborne pollutants in urban areas may react with the wood’s surface, altering its patina timeline. To mitigate this, use gentle, pH-neutral cleaners and avoid over-polishing, as this can remove the very layers that contribute to the patina’s depth and character.

Understanding these factors allows for greater control over cherry wood’s patina process, whether the goal is to hasten its transformation or preserve its original hue. By manipulating light exposure, environmental conditions, finishes, and maintenance practices, one can tailor the aging process to suit specific aesthetic preferences or functional needs.

Maximizing Wood Pellet Storage: How Long Do They Last?

You may want to see also

Explore related products

Role of environmental conditions

Cherry wood's patina development is a symphony conducted by environmental conditions, each factor playing a distinct role in the timing and character of its transformation. Humidity, for instance, acts as the tempo, dictating the speed of the process. In regions with high humidity, such as coastal areas, cherry wood tends to patina more rapidly due to increased moisture content. This moisture accelerates the oxidation process, causing the wood to darken and develop its characteristic warm, reddish-brown hue within 5 to 10 years. Conversely, in arid climates, the patina may take 15 years or more to fully manifest, as the lack of moisture slows the chemical reactions responsible for color change.

Light exposure is another critical conductor in this environmental orchestra. Direct sunlight, rich in ultraviolet (UV) rays, intensifies the patina process by breaking down surface lignin and tannins. This results in a deeper, richer color but can also lead to uneven fading if the wood is exposed inconsistently. For optimal patina development, aim for balanced light exposure—filtered or indirect sunlight is ideal. If using cherry wood indoors, position it near north-facing windows to minimize harsh UV rays while still allowing natural light to enhance the patina.

Temperature fluctuations also play a subtle yet significant role. Extreme temperature swings, particularly in outdoor applications, can cause the wood to expand and contract, accelerating surface wear and patina formation. In temperate climates with mild seasonal changes, cherry wood may develop a more uniform patina over time. To mitigate the effects of temperature, consider acclimating the wood to its environment before installation and applying a protective finish to stabilize moisture levels.

Air quality and pollutants introduce an unpredictable element to the patina timeline. In urban areas with higher levels of airborne chemicals or pollutants, cherry wood may patina faster due to increased chemical reactions with the wood’s surface. Conversely, in cleaner environments, the process may proceed more slowly but with greater clarity and depth. For those seeking to control patina development, monitoring indoor air quality and using air purifiers can help maintain a consistent environment.

Finally, the interplay of these environmental factors creates a unique patina for each piece of cherry wood. While general timelines exist, the specific conditions of your location will ultimately determine the pace and character of the transformation. By understanding and manipulating these variables—humidity, light, temperature, and air quality—you can guide the patina process to achieve the desired aesthetic. Whether you’re crafting furniture, cabinetry, or decorative elements, embracing the role of environmental conditions ensures that your cherry wood ages gracefully, telling its own story through its patina.

Wooden Warship Durability: Factors Affecting Their Lifespan and Preservation

You may want to see also

Explore related products

Impact of wood finishing techniques

Cherry wood's journey to a rich, amber patina is a process influenced significantly by the finishing techniques applied. The choice of finish not only affects the wood's appearance but also its rate of patina development. For instance, oil-based finishes like tung or linseed oil penetrate deeply, allowing the wood to breathe and darken naturally over time. These finishes typically enhance the patina within 5–10 years, depending on exposure to light and air. Conversely, polyurethaney or lacquer forms a protective barrier that slows down the patina process, often delaying noticeable changes for 10–15 years. Understanding these differences is crucial for anyone aiming to control the aesthetic evolution of cherry wood.

To accelerate the patina process, consider using reactive finishes that chemically interact with the wood. For example, ammonia fumes can darken cherry wood rapidly, mimicking years of natural aging in just a few hours. This method involves placing the wood in an enclosed space with ammonia, allowing the fumes to react with the wood’s tannins. However, caution is essential: ammonia fuming requires proper ventilation and protective gear to avoid health risks. Another technique is applying iron acetate, which reacts with the wood’s tannins to create a dark, aged appearance almost instantly. These methods are ideal for projects requiring a quick, uniform patina but should be reserved for experienced finishers due to their complexity.

For those seeking a more gradual, hands-off approach, natural aging combined with a wax or shellac finish is ideal. Wax allows the wood to darken freely while providing minimal protection, making it perfect for furniture or decor where patina is the desired outcome. Shellac, a breathable finish, offers slightly more protection while still permitting the wood to develop its natural color over time. Both finishes require periodic reapplication to maintain their protective qualities but allow the patina to emerge within 3–7 years under normal indoor conditions. This method is best suited for enthusiasts who appreciate the organic, evolving beauty of cherry wood.

Comparing finishing techniques reveals a trade-off between preservation and patina development. Modern finishes like catalyzed lacquers or water-based polyurethanes prioritize durability, often at the expense of the wood’s natural aging process. While these finishes protect against moisture and wear, they can inhibit the chemical reactions necessary for patina formation, delaying it by decades. On the other hand, traditional finishes like boiled linseed oil or Danish oil strike a balance, offering moderate protection while fostering patina development. For optimal results, consider the intended use of the wood: high-traffic items may require durable finishes, while decorative pieces can benefit from patina-friendly options.

In practice, combining techniques can yield tailored results. For example, applying a thin coat of shellac as a sealer before finishing with Danish oil can enhance both protection and patina potential. This layered approach allows the wood to darken naturally while adding a subtle sheen. Additionally, periodic exposure to sunlight can expedite the patina process, as UV rays break down the wood’s surface and accelerate color changes. However, prolonged sun exposure can cause uneven fading, so strategic placement and rotation of the wood piece are recommended. By experimenting with these methods, craftsmen can achieve a patina that aligns with their vision, whether it’s a quick transformation or a slow, graceful aging process.

Wooden Matches Lifespan: Factors Affecting Durability and Storage Tips

You may want to see also

Explore related products

Natural vs. accelerated patina methods

Cherry wood's journey to a rich, amber patina is a process both revered and expedited by craftsmen and enthusiasts alike. Naturally, this transformation can span decades, with the wood gradually darkening under the influence of oxygen and light. However, for those seeking quicker results, accelerated methods offer a shortcut, albeit with trade-offs in authenticity and depth. Understanding the nuances between these approaches is key to achieving the desired finish.

Analytical Perspective:

Natural patina development in cherry wood relies on chemical reactions between the wood’s tannins and environmental factors like UV light and air exposure. This process typically begins within months but takes 10–20 years to fully mature, depending on conditions. Accelerated methods, such as applying ammonia fuming or tung oil treatments, can condense this timeline to days or weeks. However, these techniques often produce a uniform surface lacking the subtle variations and depth achieved through natural aging. For instance, ammonia fuming requires careful application—a 1:1 ratio of household ammonia to water, applied in a well-ventilated area—to avoid overexposure, which can darken the wood unnaturally.

Instructive Approach:

To accelerate patina, start by sanding cherry wood to 220-grit for a smooth surface. Apply a mixture of equal parts ammonia and water using a spray bottle, ensuring even coverage. Allow the wood to react for 15–30 minutes, then neutralize with a vinegar solution to halt the process. For a milder effect, tung oil can be applied in thin coats, with each layer deepening the color over 2–3 days. Always test on a scrap piece first to gauge the intensity. Natural patina, on the other hand, requires patience and minimal intervention—simply expose the wood to indirect sunlight and allow time to work its magic.

Comparative Insight:

While accelerated methods deliver quick results, they often sacrifice the nuanced character of natural patina. For example, ammonia fuming can create a flat, monochromatic finish, whereas natural aging produces a dynamic interplay of light and dark tones. Additionally, accelerated techniques may alter the wood’s texture or require more maintenance. Natural patina, though slower, enhances the wood’s inherent beauty without compromising its integrity, making it ideal for heirloom pieces or traditional craftsmanship.

Descriptive Takeaway:

Imagine a naturally patinated cherry wood table, its surface alive with warm, golden hues that deepen gracefully over time, each mark and shade telling a story. Contrast this with an accelerated finish, which, while striking, may appear artificially uniform, lacking the organic depth of its natural counterpart. The choice between methods ultimately hinges on the desired outcome—speed and control versus timeless, unhurried elegance. Whether you opt for patience or expediency, understanding these processes ensures the patina reflects your vision.

Louie's Endurance: Standing with the Wood for How Long?

You may want to see also

Explore related products

Cherry wood patina timeline examples

Cherry wood's transformation into a rich, reddish-brown patina is a process that captivates woodworkers and enthusiasts alike. This natural aging phenomenon, influenced by light exposure, oxygen, and moisture, unfolds over years, not weeks or months. Understanding the timeline and factors at play allows for informed decisions when working with this prized hardwood.

While the exact duration varies, cherry wood typically begins to show noticeable patina development within 2-5 years of exposure to natural light. This initial phase is characterized by a subtle lightening of the wood's surface, followed by a gradual shift towards a warmer, pinkish hue. Think of it as the wood's initial blush, a hint of the deeper tones to come.

Accelerating the Process: For those seeking a more expedited patina, controlled exposure to sunlight remains the most effective method. Placing cherry wood furniture near windows or outdoors (with proper protection from direct rain) can significantly shorten the timeline. However, it's crucial to remember that excessive sunlight can lead to uneven fading and potential cracking. Caution: Avoid using heat guns or chemical accelerators, as these methods often result in unnatural and undesirable coloration.

Comparative Perspective: Compared to other woods like oak or maple, cherry's patina development is relatively swift. Oak, for instance, can take decades to achieve a similar depth of color. This makes cherry a popular choice for furniture and cabinetry where a desirable aged appearance is desired within a reasonable timeframe.

Maintaining the Patina: Once the desired patina is achieved, regular maintenance is key to preserving its beauty. Tip: Use a high-quality, non-yellowing furniture wax or oil to protect the wood from moisture and scratches while enhancing its natural luster. Avoid harsh chemicals or abrasive cleaners that can strip away the patina.

Embracing the Journey: The beauty of cherry wood lies not only in its final patina but also in the journey it takes to get there. Each piece tells a unique story, marked by the passage of time and the environment it inhabits. By understanding the patina timeline and employing thoughtful care, you can ensure that your cherry wood treasures continue to evolve and enrich your space for generations to come.

Gloss Drying Time on Wood: Factors Affecting Cure and Finish

You may want to see also

Frequently asked questions

Cherry wood typically begins to develop a patina within 6 months to 1 year, with noticeable changes in color and depth occurring over 2 to 5 years.

Exposure to light, especially UV rays, humidity, temperature, and the wood’s natural oils are key factors that influence the speed of patina development.

Yes, patina development can be accelerated by increasing exposure to sunlight, using tung oil or other finishes, and maintaining consistent humidity levels.

Yes, cherry wood’s patina continues to evolve, with color deepening and richness increasing for up to 20 years or more, depending on environmental conditions.