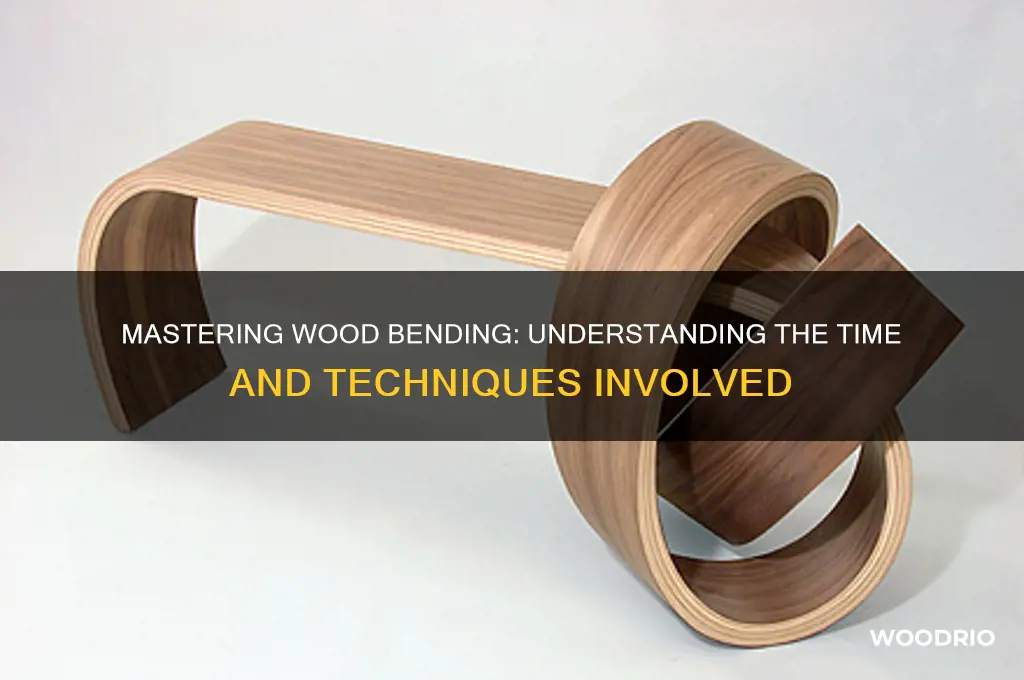

Bending wood is a versatile woodworking technique that allows artisans and craftsmen to create curved shapes and intricate designs, but the time required to achieve the desired bend varies significantly depending on several factors. The duration can range from a few minutes to several hours or even days, influenced by the type of wood, its moisture content, the bending method employed (such as steam bending, kerf bending, or laminating), and the complexity of the curve. For instance, steam bending, which involves heating the wood with steam to make it pliable, can take anywhere from 15 minutes to an hour, while laminating thin strips of wood around a form may require drying time that extends over multiple days. Understanding these variables is crucial for planning and executing wood bending projects effectively.

Explore related products

What You'll Learn

Wood Species and Grain

The time it takes to bend wood is not solely determined by the bending method but is significantly influenced by the wood species and its grain orientation. Different wood species have varying levels of flexibility and responsiveness to bending techniques due to their unique cellular structures and natural properties. For instance, woods like oak and maple are known for their strength and hardness, making them more challenging to bend compared to softer species such as pine or cedar. Understanding these inherent characteristics is crucial for woodworkers aiming to achieve precise bends without compromising the wood's integrity.

When considering grain orientation, the direction of the wood fibers plays a pivotal role in the bending process. Wood bends most easily along the grain, as the fibers can stretch and compress more readily in this direction. Bending across the grain is far more difficult and often results in splitting or cracking. To optimize bending time and success, woodworkers must carefully select the grain direction in relation to the intended bend. For example, a piece of wood intended for a curved chair leg should be oriented so that the grain runs parallel to the curve, allowing for a smoother and more controlled bend.

A comparative analysis of wood species reveals that some, like walnut and cherry, offer a balance between strength and flexibility, making them ideal for moderate bending applications. These species can typically be bent within 30 minutes to 2 hours, depending on the thickness and the bending method used. In contrast, denser woods such as teak or mahogany may require longer steaming times, often exceeding 2 hours, to achieve the necessary pliability. Softer woods like basswood or aspen can often be bent in under 30 minutes with minimal preparation, but they may lack the durability needed for certain structural applications.

For practical implementation, woodworkers should follow specific steps to ensure successful bending. First, assess the wood species and grain orientation to determine the most suitable bending technique. Steaming is commonly used for harder woods, while laminating or kerfing may be more appropriate for thicker pieces. Second, apply heat or moisture evenly to avoid warping or uneven bending. For steaming, maintain a temperature of 212°F (100°C) for the recommended duration based on the wood species. Finally, clamp the wood in the desired shape immediately after bending and allow it to cool or dry completely before removing the clamps. This ensures the wood retains its new form without springing back.

In conclusion, the interplay between wood species and grain orientation is a critical factor in determining how long it takes to bend wood. By selecting the right wood and aligning the grain properly, woodworkers can significantly reduce bending time and improve the quality of the finished piece. Whether working with hardwoods or softwoods, understanding these principles allows for more efficient and effective bending, ultimately enhancing the craftsmanship of wooden creations.

Wood Chip Decomposition Timeline: Factors Affecting Breakdown in Nature

You may want to see also

Explore related products

Bending Methods (Steam, Heat, etc.)

Wood bending is an art that hinges on the method chosen, each with its own timeline and nuances. Steam bending, for instance, typically requires 30 minutes to 2 hours of steaming time, depending on the wood thickness and species. Hardwoods like oak or maple demand longer steaming—up to 2 hours—while softer woods like pine may need only 30–45 minutes. The key is maintaining a consistent temperature of 180–212°F (82–100°C) to soften the lignin, the natural glue in wood fibers. Once steamed, the wood must be bent and clamped within 1–2 minutes before it cools and hardens, making timing critical.

Heat bending, often done with a heat gun or strip heater, offers a faster alternative, especially for thinner pieces. Applying heat directly to the wood for 5–15 minutes softens it enough for bending. This method is ideal for small projects like chair backs or cabinet doors. However, caution is essential: overheating can scorch or weaken the wood. A heat gun should be held 6–12 inches away, moving constantly to distribute heat evenly. Unlike steam bending, heat bending allows for immediate manipulation, reducing the risk of the wood cooling too quickly.

For those without access to steam or heat tools, cold bending with laminations is a viable option. This involves cutting the wood into thin strips, soaking them in water for 24–48 hours to increase flexibility, and then gluing them together in the desired curve. While this method is time-consuming—requiring days for soaking and drying—it’s accessible and effective for gradual bends. The takeaway? Cold bending trades speed for simplicity, making it suitable for hobbyists or small-scale projects.

Chemical bending, though less common, uses solvents like ammonia to break down lignin, allowing wood to bend after 24–72 hours of exposure. This method is unpredictable and often reserved for experimental or artistic projects due to the toxicity and variability of results. While it offers unique possibilities, it’s not practical for precise or structural work. Each bending method, therefore, balances time, tools, and technique, demanding careful consideration of the project’s scale and purpose.

Perfect Bonfire Prep: Optimal Wood Drying Time for Crackling Fires

You may want to see also

Explore related products

Thickness and Moisture Content

Wood thickness plays a pivotal role in determining how long it takes to bend. Thinner pieces, such as 1/4-inch or 3/8-inch stock, bend more readily under heat or moisture because they have less material to resist the applied force. Thicker pieces, like 1-inch or greater, require significantly more time and energy to achieve the same result. For instance, a 1/4-inch oak strip might bend within 15–30 minutes when steamed, while a 1-inch strip of the same wood could take 2–3 hours under identical conditions. Always consider the thickness-to-width ratio; a wide, thin piece will bend more easily than a narrow, thick one due to reduced internal stress.

Moisture content is the silent orchestrator of wood bending success. Green wood, with a moisture content of 20% or higher, bends almost effortlessly due to its pliable cell walls. Air-dried wood (8–12% moisture) requires steaming or soaking to reintroduce moisture, typically taking 1–2 hours to reach optimal flexibility. Kiln-dried wood (6–8% moisture) is the most challenging; it demands prolonged steaming (2–4 hours) or repeated soaking and clamping cycles to achieve the necessary plasticity. A moisture meter is an essential tool here—aim for 25–30% moisture content for most bending operations, as this range strikes the balance between flexibility and structural integrity.

The interplay between thickness and moisture content cannot be overlooked. A thick piece of wood, even when properly moistened, will always take longer to bend than a thinner one due to its greater mass and density. For example, a 3/4-inch maple board might require 90 minutes of steaming, while a 1/2-inch board of the same species could be ready in 45 minutes. To expedite the process, consider kerfing (making shallow cuts along the inside of the bend) for thicker pieces, but be cautious—this weakens the wood and is best reserved for structural applications where strength is less critical.

Practical tips can streamline the bending process. For thicker wood, pre-heat or pre-soak only the bending area to minimize warping in non-critical sections. Use a steam box with a consistent temperature of 212°F (100°C) for even moisture penetration. When bending by lamination, alternate thin layers of high-moisture wood with thicker, drier pieces to reduce overall bending time. Always allow bent wood to dry gradually under clamping pressure—rushing this step can lead to spring-back or cracking, undoing hours of careful work.

In conclusion, thickness and moisture content are interdependent variables that dictate the timeline for bending wood. Thinner pieces bend faster but offer less structural strength, while thicker pieces demand patience and precision. Moisture content acts as the catalyst, with green wood bending quickest and kiln-dried wood requiring the most intervention. By mastering these factors and employing strategic techniques, woodworkers can achieve elegant curves and complex shapes with confidence and efficiency.

Wood Pilings Lifespan: Factors Affecting Durability and Longevity

You may want to see also

Explore related products

Required Tools and Equipment

Bending wood is a craft that demands precision, patience, and the right tools. Without the proper equipment, even the most skilled woodworker will struggle to achieve clean, consistent bends. The essential toolkit for wood bending includes a heat source, such as a steam box or bending iron, to soften the wood fibers. A steam box, typically made of insulated wood or metal, requires a heat source like a steam generator or kettle to produce steam at temperatures around 212°F (100°C). Alternatively, a bending iron, heated to 350°F (177°C), offers a more localized approach for smaller projects. Both methods effectively prepare the wood for bending, but the choice depends on the scale and complexity of the project.

Once the wood is heated, clamps and formers become indispensable. Clamps secure the wood in its desired shape while it cools and sets, ensuring the bend retains its form. Wooden or metal formers, shaped to the curve or angle needed, act as molds around which the wood is bent. For intricate bends, such as those in chair legs or musical instruments, custom-made formers are often necessary. Additionally, a spray bottle with water or a damp cloth can help maintain moisture levels during bending, preventing the wood from drying out too quickly and cracking.

Safety equipment is equally critical, as working with heat and steam poses risks. Heat-resistant gloves protect hands from burns when handling hot wood or tools, while safety goggles shield eyes from steam and wood splinters. A well-ventilated workspace is essential to avoid inhaling steam or fumes, particularly when using a steam box. For those using a bending iron, a fire extinguisher should be nearby to address any accidental fires caused by overheating.

For advanced projects, additional tools like a thickness planer or bandsaw may be required to prepare the wood. A thickness planer ensures uniform wood thickness, which is crucial for even bending, while a bandsaw allows for precise cuts to create kerfs or relief cuts. These cuts reduce stress on the wood during bending, making it easier to achieve tight curves without breakage. While not always necessary, these tools elevate the quality and complexity of the final piece.

In summary, bending wood is as much about the tools as the technique. From heat sources and clamps to safety gear and specialized equipment, each item plays a unique role in the process. Investing in the right tools not only saves time but also ensures the longevity and precision of your work. Whether you’re a novice or a seasoned woodworker, understanding and utilizing these tools will transform your wood bending projects from amateur attempts to professional masterpieces.

Seasoning Beech Wood: Understanding the Timeframe for Optimal Results

You may want to see also

Explore related products

$24.95

Cooling and Setting Time

The cooling and setting phase is critical when bending wood, as it determines the final shape and stability of the piece. Once the wood has been heated and bent to the desired curve, it must cool gradually to retain its new form. Rapid cooling can cause the wood fibers to revert to their original shape or introduce unwanted stresses, leading to cracks or warping. For steam-bent wood, cooling times typically range from 30 minutes to 2 hours, depending on the thickness and species of the wood. Thicker pieces require more time to cool evenly, while denser hardwoods like oak or maple may take longer than softer woods like pine or cedar. Always allow the wood to cool naturally in the mold or jig, avoiding exposure to drafts or sudden temperature changes.

Analyzing the setting time reveals its importance in achieving a permanent bend. As the wood cools, the cellulose and lignin structures reset, locking the fibers into their new position. This process is influenced by humidity and ambient temperature—higher humidity can prolong setting time, while drier conditions may accelerate it. For optimal results, maintain a consistent environment during cooling. If using a jig, ensure it remains clamped securely until the wood is fully set. A practical tip is to test the bend’s stability by gently applying pressure after 1 hour of cooling; if it holds without springing back, the setting process is nearly complete. However, always err on the side of caution and allow the full recommended time for thicker or denser pieces.

Persuasively, investing time in proper cooling and setting is non-negotiable for professional-quality results. Skipping this step or rushing it can undermine hours of work, leading to pieces that lose their shape or fail structurally. For example, a steam-bent chair leg that hasn’t fully set may straighten over time, compromising both aesthetics and safety. To ensure success, plan your workflow to accommodate cooling time—overnight setting is ideal for complex bends. Additionally, consider using a moisture meter to monitor the wood’s hydration level during cooling, as excessive moisture can delay setting. Patience here isn’t just a virtue; it’s a requirement for craftsmanship.

Comparatively, cooling and setting times for wood bending differ significantly from those in metalworking or plastics manufacturing. While metal cools rapidly and plastics set almost instantly under heat, wood demands a slower, more deliberate approach. This distinction highlights the organic nature of wood and its sensitivity to environmental factors. Unlike synthetic materials, wood’s setting process involves natural polymers (lignin) reforming bonds, a reaction that cannot be rushed. Understanding this difference helps woodworkers avoid common pitfalls, such as applying metalworking techniques to wood, which often results in failure. By respecting wood’s unique properties, you can achieve bends that are both beautiful and durable.

Descriptively, the cooling and setting phase is a transformative period where the wood transitions from a pliable state to a rigid, permanent form. As the piece rests in its mold, the once-steamed fibers gradually tighten, their structure realigning under the constraints of the jig. The air around the wood grows cooler, and with it, the piece gains strength and stability. For the woodworker, this is a time of anticipation—a moment to step back and let nature and science work in harmony. By the end of this phase, the wood emerges not just bent, but reborn, ready to serve its new purpose with grace and resilience. Master this step, and you’ll unlock the full potential of wood bending.

Titebond Wood Glue Curing Time: A Comprehensive Guide for Woodworkers

You may want to see also

Frequently asked questions

Steam bending typically takes 30 minutes to 2 hours, depending on the wood species, thickness, and desired bend radius.

Laminating wood can take several hours to a day, including clamping and drying time, depending on the glue used and the complexity of the bend.

Kerf bending is relatively quick, often taking 15–30 minutes to cut the kerfs and bend the wood, though additional time may be needed for finishing.

Heat bending with a bending iron usually takes 5–15 minutes per piece, depending on the wood type and the heat applied.

![[Upgraded] RM&Co 1/4" Thick 4 Pack 12 Inch Large Wood Circles for Crafts, Blank Round Wooden Discs, DIY Craft Wood Rounds Cutouts for Door Hanger, Sign, Painting, Wood Burning, Christmas Home Decor](https://m.media-amazon.com/images/I/61SNVa5FhYL._AC_UL320_.jpg)