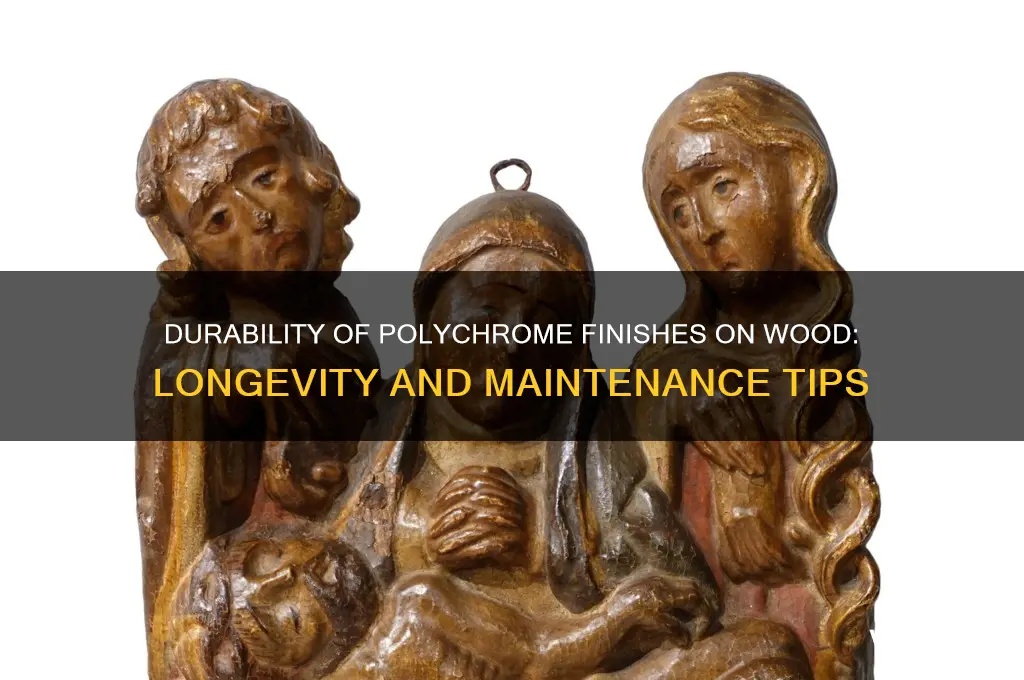

Polychrome, the decorative technique of applying multiple colors to a surface, has been used for centuries to enhance the beauty of wooden objects, from intricate sculptures to architectural elements. When applied to wood, polychrome can create stunning visual effects, but its longevity depends on various factors, including the materials used, the application method, and the environmental conditions it is exposed to. Understanding how long polychrome holds up on wood is essential for preserving historical artifacts, maintaining the integrity of contemporary artworks, and ensuring the durability of decorative finishes in both indoor and outdoor settings. Factors such as humidity, temperature fluctuations, UV exposure, and physical wear can significantly impact the lifespan of polychrome on wood, making proper conservation and maintenance practices crucial for its long-term preservation.

Explore related products

$36.99 $64.5

What You'll Learn

Climate Impact on Polychrome Durability

Polychrome finishes on wood, characterized by their vibrant, multi-colored layers, are particularly vulnerable to climatic conditions. Humidity, temperature fluctuations, and UV exposure act as silent adversaries, accelerating degradation. In tropical regions, where relative humidity often exceeds 70%, the wood beneath the polychrome absorbs moisture, causing it to expand and contract. This movement fractures the paint layers, leading to flaking and delamination. Conversely, arid climates with less than 30% humidity can cause the wood to shrink, creating gaps between the paint and substrate. Monitoring local humidity levels and maintaining indoor environments between 40-60% relative humidity can mitigate these effects, preserving the integrity of the polychrome for decades.

Temperature extremes further exacerbate the fragility of polychrome finishes. In regions with temperature swings exceeding 30°C (86°F) between day and night, such as desert areas, the thermal stress causes the paint to crack and peel. Prolonged exposure to temperatures above 40°C (104°F) accelerates the oxidation of pigments, dulling their vibrancy. For outdoor polychrome structures, applying a UV-resistant varnish with a minimum SPF 50 rating can provide a protective barrier. Indoor pieces should be kept in temperature-controlled spaces, ideally between 18-22°C (64-72°F), to minimize thermal stress and extend the lifespan of the finish.

UV radiation is another critical factor in polychrome deterioration, particularly in regions with high solar exposure. In areas receiving over 2,000 hours of sunlight annually, such as the Mediterranean or southwestern United States, UV rays break down the chemical bonds in paint binders, causing colors to fade and surfaces to become brittle. To combat this, limit direct sunlight exposure by using UV-filtering glass for display cases or positioning objects away from windows. For outdoor pieces, reapplication of a UV-protective coating every 2-3 years is essential to maintain colorfastness and structural stability.

The interplay between climate and pollutants intensifies the degradation of polychrome finishes, especially in urban environments. Airborne pollutants like sulfur dioxide and nitrogen oxides react with moisture to form acids, which corrode paint layers. In cities with high pollution levels, such as Delhi or Mexico City, polychrome surfaces may deteriorate within 5-10 years without intervention. Regular cleaning with a soft brush and distilled water can remove surface contaminants, while applying a barrier coat of calcium carbonate-based varnish every 5 years provides additional protection against acid rain.

Finally, microclimates within buildings can significantly impact polychrome durability. Areas with poor ventilation, such as basements or attics, often experience condensation, fostering mold growth that degrades both wood and paint. Installing dehumidifiers in these spaces and ensuring adequate airflow can prevent moisture accumulation. For high-value polychrome artifacts, investing in environmental monitoring systems that track humidity, temperature, and light levels allows for proactive adjustments, ensuring the finish remains intact for generations. By understanding and addressing these climatic factors, one can significantly prolong the life of polychrome on wood.

Minwax Wood Filler Drying Time: Quick Guide for Perfect Results

You may want to see also

Explore related products

Indoor vs. Outdoor Longevity

Polychrome finishes on wood face dramatically different lifespans depending on their environment. Indoor applications, shielded from UV radiation, temperature fluctuations, and moisture, can retain vibrancy for decades, even centuries, with proper care. The 15th-century polychrome altarpieces in European churches, for instance, showcase enduring pigments thanks to controlled climates and minimal handling. Outdoor polychrome, however, battles relentless degradation. Sunlight fades colors, rain leaches pigments, and temperature swings cause wood to expand and contract, cracking the paint. Even with modern sealants, outdoor polychrome rarely surpasses 10–15 years without significant restoration.

To maximize outdoor longevity, prioritize preparation and protection. Begin by using a wood species resistant to warping, like cedar or cypress. Apply a primer specifically formulated for exterior use, followed by multiple thin coats of high-quality, UV-resistant paint. Seal the surface with a marine-grade varnish, reapplied annually. For added durability, consider incorporating a sacrificial layer of wax or oil-based sealant that can be refreshed more frequently. Despite these measures, expect to refinish outdoor polychrome every 5–7 years in moderate climates, and more often in harsher conditions.

Indoor polychrome demands a different approach, emphasizing preservation over constant renewal. Avoid placing finished pieces near heat sources, windows, or areas of high humidity, as these accelerate deterioration. Dust regularly with a soft brush to prevent particulate buildup, and clean gently with a damp cloth using mild, non-abrasive soap. For antique or valuable pieces, consult a conservator before attempting repairs. While indoor polychrome can theoretically last indefinitely, its lifespan hinges on consistent, mindful maintenance.

The contrast between indoor and outdoor longevity underscores the importance of matching technique to environment. Outdoor polychrome is inherently ephemeral, a fleeting art form that requires acceptance of its transient nature. Indoor polychrome, by contrast, is an investment in permanence, a testament to craftsmanship that can span generations. Understanding these distinctions allows artisans and enthusiasts to set realistic expectations and tailor their methods accordingly, ensuring the beauty of polychrome endures—whether for a season or a century.

Understanding Wood Warping: Factors Affecting Timeframe and Prevention Tips

You may want to see also

Explore related products

Maintenance Tips for Preservation

Polychrome finishes on wood, with their vibrant layers of paint and glaze, are breathtaking but fragile. Their longevity hinges on proactive care, as environmental factors and handling can accelerate deterioration.

Understanding the Enemy: What Threatens Polychrome

Polychrome’s primary adversaries are moisture, sunlight, temperature fluctuations, and physical contact. Humidity causes wood expansion and contraction, cracking the paint layers. UV rays fade pigments and embrittle varnish. Abrupt temperature shifts create micro-fractures, while dust and oils from touch degrade surfaces. Even well-intentioned cleaning without proper knowledge can cause irreversible damage.

Proactive Preservation: A Step-by-Step Maintenance Routine

- Environmental Control: Maintain relative humidity between 45–55% and temperatures around 68–72°F. Use dehumidifiers or silica gel packets in display cases. Avoid direct sunlight; use UV-filtering glass or curtains.

- Gentle Cleaning: Dust with a soft, dry brush or microfiber cloth weekly. For stubborn grime, lightly mist a cloth with distilled water mixed with 1–2 drops of mild, pH-neutral soap (like Castile), wiping along the grain. Never saturate the wood.

- Inspections: Annually examine for flaking paint, cracks, or insect activity. Document changes with photographs for conservation records.

When to Call a Professional: Red Flags and Repairs

DIY fixes often worsen polychrome damage. Seek a conservator if you notice:

- Lifting or flaking paint layers.

- Structural instability in the wood substrate.

- Discoloration from previous restorations.

Professionals use reversible materials like wax-resin adhesives and retouch pigments matched to the original palette, ensuring integrity.

Preventive Measures: Handling and Display

Always wear nitrile gloves when moving polychrome objects to avoid oil transfer. Use padded supports in display cases to minimize vibration. For larger pieces, install seismic mounts to protect against accidental knocks. Label storage areas with environmental guidelines to ensure consistent care.

By combining vigilance, controlled conditions, and expert intervention, polychrome on wood can endure for centuries, retaining its original splendor. Preservation is not passive—it’s an ongoing commitment to honoring the craftsmanship of the past.

Ground Contact Wood Durability: Lifespan and Preservation Tips Explained

You may want to see also

Explore related products

$28 $29.63

Wood Type and Polychrome Adhesion

The durability of polychrome finishes on wood is significantly influenced by the type of wood used. Hardwoods like oak and maple, with their dense grain structure, provide a more stable surface for paint adhesion compared to softwoods such as pine or cedar, which tend to be more porous and resinous. This inherent difference in wood composition directly impacts how well polychrome layers bond and how long they last. For instance, the natural oils in cedar can cause paint to peel over time, while oak’s tight grain ensures a smoother, more durable finish. Understanding this relationship is crucial for anyone aiming to preserve or restore polychrome woodwork.

To maximize adhesion, preparation is key. Softwoods require more meticulous sanding and priming to seal their porous surfaces and neutralize resins that might repel paint. A high-quality oil-based primer, applied in thin, even coats, can create a barrier that enhances paint grip. For hardwoods, while less prep work is needed, ensuring the surface is free of dust and debris remains essential. In both cases, using a fine-grit sandpaper (220-grit or higher) between coats can improve mechanical adhesion. These steps, though time-consuming, are non-negotiable for long-lasting results.

Environmental factors further complicate the wood type and polychrome adhesion equation. Softwoods, often used in exterior applications, are more susceptible to moisture absorption, which can cause paint to crack or blister. Applying a water-repellent sealant before priming can mitigate this risk. Hardwoods, while more stable, are not immune to environmental stress—prolonged exposure to UV rays can fade polychrome finishes, regardless of wood type. Regular maintenance, such as re-sealing every 2–3 years and touch-ups as needed, can extend the life of the finish.

A comparative analysis of historical polychrome woodwork reveals that hardwoods consistently outperform softwoods in terms of longevity. For example, 18th-century oak altarpieces with polychrome detailing often retain their vibrancy, while contemporary pine furniture pieces show signs of flaking within decades. This disparity underscores the importance of material selection in conservation efforts. When restoring or creating new polychrome pieces, choosing the right wood type based on its intended use and environmental exposure can make the difference between a finish that lasts generations and one that deteriorates prematurely.

Finally, modern advancements in paint technology offer solutions to bridge the gap between wood types. Acrylic-based paints, for instance, adhere well to both hardwoods and softwoods due to their flexible nature and low VOC content. However, they may not provide the same depth of color as traditional oil-based paints. For those committed to using oil-based polychrome, incorporating a bonding agent into the primer can enhance adhesion on problematic woods like pine. By combining traditional techniques with contemporary materials, artisans and restorers can achieve durable, visually striking results on any wood type.

Drying Fresh Milled Wood: Understanding the Timeframe for Optimal Results

You may want to see also

Explore related products

Aging Effects on Color and Finish

Polychrome finishes on wood, characterized by multiple colors and intricate designs, are susceptible to aging effects that alter both their vibrancy and structural integrity. Exposure to ultraviolet (UV) light, a primary culprit, causes pigments to fade over time, particularly in reds, blues, and yellows. For instance, a 19th-century polychrome altarpiece exposed to decades of sunlight may exhibit muted tones where once vivid hues existed. To mitigate this, consider applying UV-resistant coatings or relocating the piece away from direct sunlight. However, complete prevention is impossible, as even museum-grade preservation efforts cannot entirely halt the natural degradation process.

The finish itself, often composed of varnishes or lacquers, undergoes physical changes as it ages. Oxidation, a chemical reaction with oxygen, can cause the surface to become brittle, cracked, or yellowed. Humidity fluctuations exacerbate this, as wood expands and contracts, leading to flaking or peeling layers. A practical tip for homeowners is to maintain a stable indoor environment—ideally 40-50% humidity and 68-72°F—to minimize stress on the wood and finish. Regular inspection for early signs of wear, such as hairline cracks or dulling, allows for timely intervention before irreversible damage occurs.

Comparing indoor and outdoor polychrome applications reveals stark differences in longevity. Outdoor pieces, like decorative garden furniture or architectural elements, face additional challenges from rain, temperature extremes, and pollutants. Water infiltration can dissolve soluble pigments or cause mold growth beneath the finish, while freeze-thaw cycles accelerate cracking. Indoor pieces, though shielded from these elements, are not immune to aging. Dust accumulation, cleaning methods, and even air quality play roles in finish deterioration. For example, abrasive cleaning agents can strip away protective layers, while airborne chemicals may react with the finish over time.

To preserve polychrome wood effectively, adopt a proactive maintenance routine. Dust surfaces gently with a soft brush or microfiber cloth, avoiding harsh chemicals. For deeper cleaning, use a mild soap solution applied sparingly with a damp cloth, followed by thorough drying. Every 5-10 years, assess the need for refinishing, particularly if the surface appears dull or damaged. When refinishing, match the original materials and techniques as closely as possible to maintain authenticity. For historical pieces, consult a conservator to ensure preservation standards are met.

In conclusion, aging effects on polychrome wood are inevitable but manageable. Understanding the mechanisms of degradation—UV exposure, oxidation, humidity, and environmental factors—enables targeted interventions. By combining environmental control, gentle maintenance, and periodic restoration, the lifespan of polychrome finishes can be extended, preserving their beauty and historical value for future generations.

Perfect Grilling: Soaking Wooden Skewers for Safe, Tasty Results

You may want to see also

Frequently asked questions

Polychrome on wood can last for decades to centuries, depending on factors like environmental conditions, quality of materials, and maintenance.

Yes, polychrome can fade due to exposure to sunlight, humidity, and temperature fluctuations, but proper sealing and protection can slow this process.

Outdoor exposure significantly shortens the lifespan of polychrome due to weather, UV rays, and moisture, often requiring more frequent touch-ups or reapplication.

Yes, deteriorated polychrome can often be restored by professionals through cleaning, repairing, and reapplying pigments and protective coatings.

To prolong its life, keep the wood in a stable environment, avoid direct sunlight, apply protective finishes, and regularly inspect for damage or wear.