Wood filler is a versatile product used to repair imperfections in wood surfaces, such as cracks, holes, and gouges, but its longevity depends on several factors, including the type of filler, application technique, and environmental conditions. Generally, water-based wood fillers can last for several years when stored properly in a cool, dry place and sealed tightly to prevent drying out, while solvent-based fillers may have a longer shelf life due to their chemical composition. Once applied, the durability of wood filler also relies on proper preparation of the wood surface, adequate drying time, and the application of a protective finish, such as paint or varnish, to shield it from moisture, temperature fluctuations, and wear. When used correctly and maintained well, wood filler can provide a long-lasting repair, often lasting as long as the surrounding wood itself.

| Characteristics | Values |

|---|---|

| Shelf Life (Unopened) | Typically 1-2 years, depending on brand and storage conditions. |

| Shelf Life (Opened) | 6 months to 1 year, if stored properly in a sealed container. |

| Drying Time (Air Dry) | 15 minutes to 2 hours, depending on depth of application and humidity. |

| Curing Time (Full Hardness) | 24-48 hours for most wood fillers. |

| Durability (Indoor Use) | Can last indefinitely if properly applied and maintained. |

| Durability (Outdoor Use) | 5-10 years, depending on exposure to weather and UV rays. |

| Water Resistance | Varies by product; some are water-resistant after curing. |

| Paintability | Most wood fillers can be painted or stained after drying. |

| Sandability | Easily sanded once fully cured. |

| Shrinkage | Minimal to none, depending on the product. |

| Storage Requirements | Store in a cool, dry place, away from direct sunlight. |

| Compatibility with Wood Types | Works with most wood types, but check product specifications. |

| Odor | Low to moderate odor during application; dissipates after drying. |

| Environmental Impact | Varies; some products are low-VOC or eco-friendly. |

Explore related products

$14.19 $16.8

What You'll Learn

Shelf life of wood filler

Wood filler, a staple in woodworking and home repair, doesn’t last indefinitely. Most water-based wood fillers have a shelf life of 1 to 2 years when stored properly in a cool, dry place with the lid tightly sealed. Solvent-based fillers, while more durable, typically last 2 to 3 years under the same conditions. Once opened, both types degrade faster due to exposure to air and moisture, with usability dropping significantly after 6 months to a year. Always check for signs of spoilage, such as hardening, separation, or mold, before use.

Proper storage is critical to maximizing the shelf life of wood filler. Store containers in a temperature-controlled environment, ideally between 50°F and 75°F (10°C and 24°C), to prevent freezing or excessive heat, which can alter the product’s consistency. Avoid placing filler in damp areas like basements or garages without climate control, as humidity accelerates spoilage. For partially used containers, wipe the rim clean before sealing and consider adding a layer of plastic wrap under the lid to minimize air exposure.

If you’re unsure whether your wood filler is still usable, perform a simple test before applying it to a project. Scoop a small amount onto a scrap surface and attempt to spread it. Fresh filler should be pliable and easy to work with, while spoiled filler may be crumbly, dry, or lumpy. Additionally, check for unusual odors or discoloration, which indicate bacterial growth or chemical breakdown. When in doubt, discard the product to avoid compromising your work.

For those who use wood filler infrequently, consider purchasing smaller containers or single-use pouches to reduce waste. Bulk purchases may seem cost-effective, but they often lead to unused product expiring before it’s fully consumed. Alternatively, mix only the amount needed for a specific task to minimize leftover filler. If you must store excess, label the container with the date of opening to track its age and usability over time.

Extending the life of wood filler isn’t just about storage—it’s also about mindful usage. Avoid introducing contaminants like dirt or paint into the container by using clean tools for application. If you’re working on a large project, transfer small amounts to a separate container instead of repeatedly opening the main supply. These practices not only preserve the filler’s quality but also ensure consistent results across multiple applications.

Masterbuilt Wood Chips Lifespan: How Long Do They Last?

You may want to see also

Explore related products

Drying time for wood filler

Wood filler drying time varies significantly based on factors like brand, environmental conditions, and application thickness. Most water-based wood fillers dry to the touch within 15 to 30 minutes but require 2 to 4 hours for a full cure. Solvent-based fillers, while less common due to their strong odors and longer drying times, can take 1 to 2 hours to dry and up to 8 hours to cure fully. Always check the manufacturer’s instructions, as these times can differ widely. For instance, DAP Plastic Wood dries in 30 minutes but needs 2 hours for a solid cure, while Minwax High-Performance Wood Filler takes 15 minutes to dry and 2 hours to cure.

Environmental conditions play a critical role in drying time. Humidity levels above 60% can double drying time, while temperatures below 50°F (10°C) may prevent proper curing altogether. Optimal conditions for wood filler application are a temperature range of 65°F to 85°F (18°C to 29°C) with humidity below 50%. If working in less-than-ideal conditions, consider using a portable heater or dehumidifier to expedite the process. Thicker applications also require more time to dry; a 1/4-inch layer may take twice as long as a thin coat.

Accelerating drying time without compromising quality is possible with a few practical tips. Sanding the surface before application ensures better adhesion, reducing the risk of cracking during curing. Applying thin layers and allowing each to dry completely before adding another can prevent prolonged drying times. For urgent projects, using a hairdryer on a low setting or placing the workpiece near a fan can speed up surface drying, but avoid excessive heat, which can cause bubbling or uneven curing.

Comparing wood fillers reveals that two-part epoxy fillers, like those from J-B Weld, cure faster in thicker applications due to their chemical reaction but are less flexible than traditional fillers. Water-based fillers are user-friendly and eco-conscious but may shrink slightly during drying. Solvent-based fillers offer superior hardness but are less forgiving in terms of working time. Choosing the right type depends on your project’s needs—epoxy for structural repairs, water-based for indoor finishing, and solvent-based for high-durability applications.

Understanding drying time is crucial for achieving a professional finish. Rushing the process can lead to sanding difficulties, paint adhesion issues, or structural weaknesses. Patience ensures the filler bonds securely with the wood, extending the lifespan of the repair. For example, a hastily dried filler may crack under stress, while a properly cured one can last decades. Always plan your project timeline to allow for adequate drying, especially when layering filler, stain, or sealant. This small investment of time pays off in durability and aesthetics.

Durability of Wooden Workboats: Lifespan and Replacement Timeline Explored

You may want to see also

Explore related products

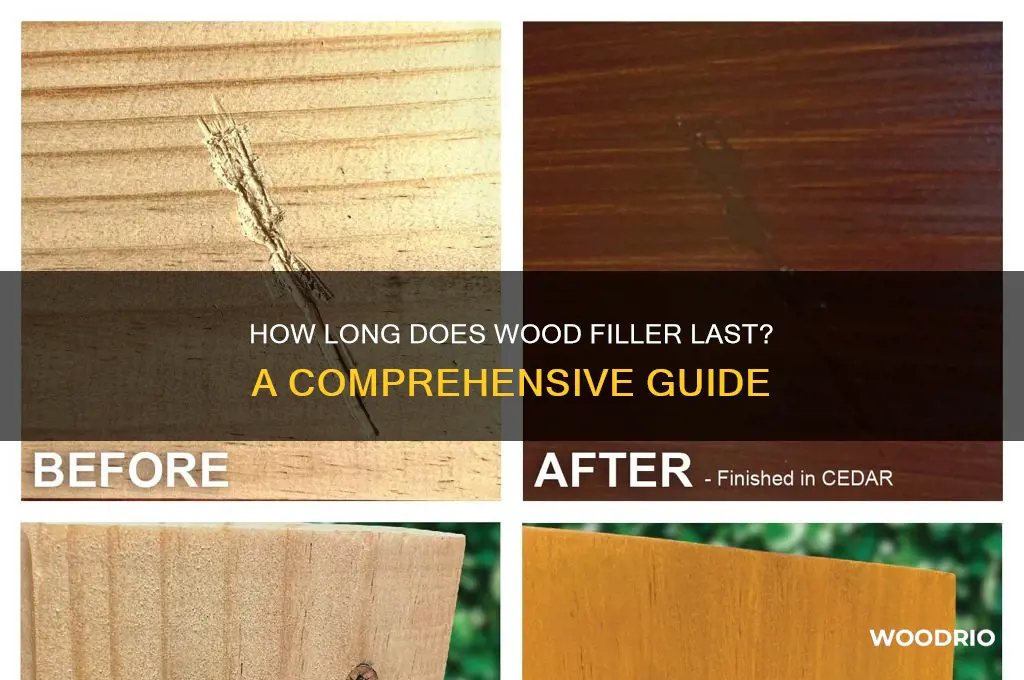

Durability after application

Wood filler, once applied and cured, can last for decades under ideal conditions, but its durability hinges on several factors. Exposure to moisture is the primary adversary; fillers in damp environments, such as bathrooms or exterior surfaces, degrade faster due to swelling, cracking, or mold growth. Even water-resistant formulas, like epoxy-based fillers, require proper sealing with paint or varnish to maintain longevity. For instance, a wood filler used indoors on a window frame may last 15–20 years, while the same product on an outdoor deck might fail within 5 years without adequate protection.

The type of wood filler significantly influences its post-application resilience. Solvent-based fillers, though harder and more durable, can shrink or crack over time as the solvent evaporates. Water-based fillers, while easier to work with, are generally less robust and more prone to wear in high-traffic areas. For structural repairs, two-part epoxy fillers offer superior strength and moisture resistance, making them ideal for load-bearing applications like furniture joints or flooring gaps. Always follow manufacturer guidelines for mixing ratios (e.g., 1:1 for epoxy) to ensure maximum durability.

Surface preparation is critical to extending the lifespan of wood filler. Sanding the wood to a rough texture (80–120 grit) and cleaning away dust or debris ensures better adhesion. Applying thin layers rather than a single thick coat reduces the risk of cracking during curing. For example, filling a deep hole in a hardwood floor should be done in ¼-inch increments, allowing each layer to dry fully before sanding and adding the next. This method prevents internal stress that could lead to failure over time.

Environmental conditions play a silent but decisive role in durability. Extreme temperature fluctuations cause wood and filler to expand and contract at different rates, leading to gaps or detachment. UV exposure, particularly in outdoor applications, can cause discoloration and brittleness in fillers lacking UV stabilizers. In regions with harsh winters, using a flexible wood filler designed to withstand freeze-thaw cycles can prevent premature deterioration. Regular maintenance, such as reapplying sealant every 2–3 years, further safeguards against environmental wear.

Finally, the intended use of the repaired wood dictates the necessary durability level. High-traffic areas like stair treads or tabletops require harder, more impact-resistant fillers, while decorative moldings may prioritize ease of sanding over strength. For instance, a latex-based filler is sufficient for filling nail holes in a painted door frame but would fail quickly under the weight of a heavy table leg. Matching the filler’s properties to the application ensures both longevity and functionality, turning a temporary fix into a lasting solution.

Drying Wood Slices: Timeframe, Techniques, and Tips for Perfect Results

You may want to see also

Explore related products

Factors affecting longevity

Wood filler durability hinges on environmental conditions, application techniques, and material composition. Exposure to moisture, temperature fluctuations, and UV radiation accelerates degradation. For instance, fillers used outdoors without proper sealing may crack or shrink within six months, while indoor applications can last over five years. To maximize longevity, choose fillers designed for specific environments—exterior-grade products often contain additives resistant to weather extremes.

Application precision directly impacts how well wood filler withstands time. Overfilling or under-sanding creates weak spots prone to chipping. Follow manufacturer guidelines for mixing ratios and drying times; improper mixing can lead to incomplete curing, reducing lifespan by up to 50%. Sanding in stages—starting with 120-grit and finishing with 220-grit—ensures a smooth, bonded surface. Proper preparation, like cleaning the wood with a damp cloth and letting it dry, enhances adhesion and durability.

The type of wood and its condition influence filler performance. Softwoods like pine absorb moisture more readily, causing filler to expand and contract unevenly. Hardwoods like oak provide a more stable base but require deeper filling for cracks, increasing material stress. Pre-treat damaged wood with a wood hardener to stabilize the substrate, especially in high-traffic areas. For aged or rotted wood, consider epoxy-based fillers, which offer superior strength and moisture resistance compared to latex or solvent-based options.

Maintenance practices play a critical role in extending wood filler life. Regularly inspect filled areas for signs of wear, particularly in humid or outdoor settings. Reapply sealant annually to protect against moisture intrusion. For minor cracks, touch up with matching filler and reseal immediately. Avoid harsh chemicals or abrasive cleaners that can erode the filler’s surface. With proactive care, even budget-friendly fillers can rival premium products in longevity, often lasting three to four years in demanding conditions.

Drying Wet Seasoned Wood: Understanding the Timeframe for Optimal Results

You may want to see also

Explore related products

Storage tips for wood filler

Wood filler, when stored correctly, can last for years, but its shelf life hinges on how well you preserve it. Exposure to air is the primary culprit behind dried-out, unusable filler. To combat this, always seal the container tightly after use, pressing out excess air if possible. For partially used tubes, consider transferring the remaining filler to an airtight container, like a small glass jar with a rubber gasket lid. This simple step can extend the product’s usability significantly, ensuring it remains pliable for future repairs.

Temperature and humidity play a critical role in wood filler storage. Extreme heat can cause the filler to dry out prematurely, while cold temperatures may alter its consistency. Aim to store it in a cool, dry place, ideally between 50°F and 75°F (10°C and 24°C). Avoid areas prone to moisture, such as basements or garages without climate control, as humidity can introduce mold or affect the filler’s adhesion properties. A climate-controlled workshop or indoor storage closet is ideal for maintaining optimal conditions.

For those who use wood filler infrequently, portion control can prevent waste. Instead of opening a large container, consider purchasing smaller tubes or dividing bulk filler into individual portions stored in sealed bags or small containers. Label each portion with the date and type of filler to track its age and suitability for specific projects. This method not only preserves the filler but also ensures you have the right amount ready for small repairs without risking the entire batch.

Lastly, inspect your wood filler regularly, especially if it’s been stored for a while. Check for signs of drying, hardening, or unusual odors, which indicate it’s past its prime. If the filler has separated or developed a skin, it may still be salvageable by mixing it thoroughly or adding a small amount of water (for water-based fillers) or solvent (for solvent-based fillers) to restore consistency. However, if it crumbles or fails to adhere, it’s time to replace it. Proper storage and periodic checks will maximize the lifespan of your wood filler, ensuring it’s ready whenever you need it.

Elmer's Wood Filler Drying Time: When Can You Drill Safely?

You may want to see also

Frequently asked questions

Wood filler typically lasts 1 to 2 years once opened if stored properly in a cool, dry place with the lid tightly sealed.

Unopened wood filler can last 3 to 5 years if stored in its original packaging and kept in a controlled environment away from extreme temperatures.

Wood filler has gone bad if it becomes hard, crumbly, or develops a foul odor. If it doesn’t mix smoothly or adhere properly, it’s likely expired.

Yes, you can extend its lifespan by storing it in an airtight container, removing excess air, and keeping it in a cool, dry place away from moisture.

Using expired wood filler is not recommended, as it may not adhere properly, dry correctly, or provide the desired finish, compromising the quality of your project.