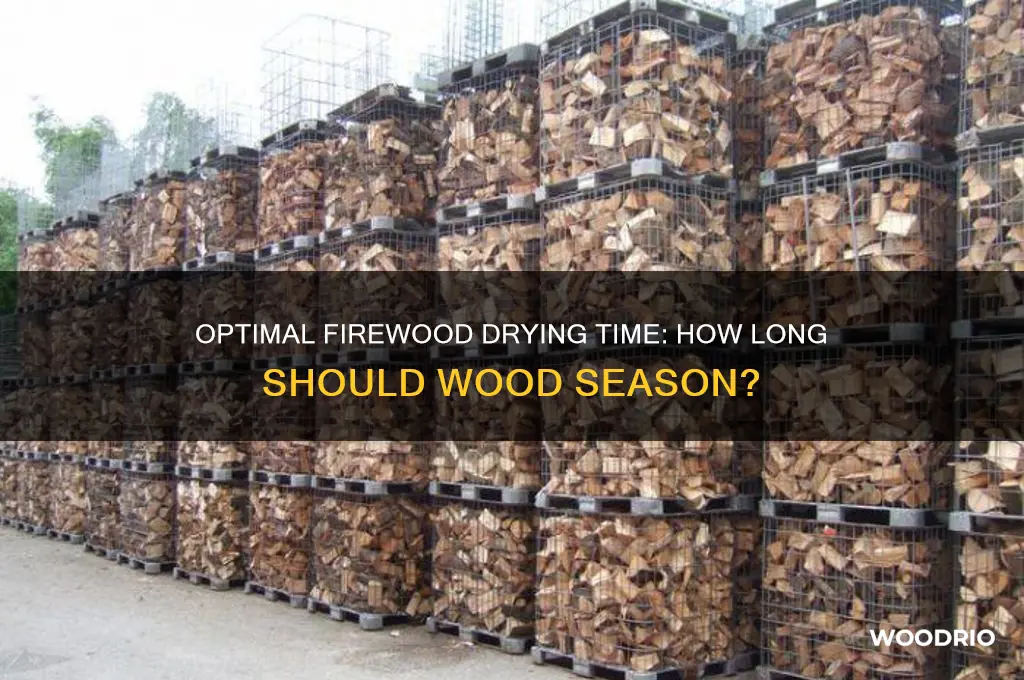

Drying wood properly is crucial for efficient and safe firewood use, as burning wet or unseasoned wood can lead to reduced heat output, increased creosote buildup in chimneys, and higher emissions. The time required for wood to dry, or season, depends on factors such as the wood species, initial moisture content, environmental conditions, and the size of the logs. Softwoods typically dry faster, often within 6 to 12 months, while hardwoods can take 12 to 24 months or longer. Ideal drying conditions include splitting the wood into smaller pieces, stacking it in a well-ventilated area protected from rain, and ensuring it is exposed to sunlight and airflow. Properly seasoned firewood should have a moisture content of around 20% or less, which can be verified using a moisture meter for accuracy.

| Characteristics | Values |

|---|---|

| Ideal Moisture Content | 20% or less |

| Drying Time (Air Drying) | 6 months to 2 years, depending on wood type and conditions |

| Drying Time (Kiln Drying) | 2–7 days |

| Wood Type (Hardwoods) | Longer drying time (e.g., oak, maple: 1–2 years) |

| Wood Type (Softwoods) | Shorter drying time (e.g., pine, spruce: 6–12 months) |

| Splitting Effect | Speeds up drying by increasing surface area |

| Stacking Method | Properly stacked with airflow (e.g., crisscross or using pallets) |

| Storage Conditions | Covered, off the ground, and in a well-ventilated area |

| Seasoning Indicators | Cracks in ends, lighter weight, and dull appearance |

| Moisture Meter Use | Recommended to ensure wood is below 20% moisture content |

| Environmental Factors | Drier climates and higher temperatures reduce drying time |

| Green Wood Burning Risk | Inefficient combustion, creosote buildup, and increased emissions |

Explore related products

What You'll Learn

- Moisture Content Levels: Ideal firewood has 20% moisture; higher levels require longer drying times

- Seasoning Timeframe: Most wood needs 6–12 months to dry properly for efficient burning

- Wood Type Differences: Hardwoods dry slower (12+ months) vs. softwoods (6–9 months)

- Splitting and Stacking: Split logs dry faster; stack in a dry, sunny, well-ventilated area

- Kiln Drying Option: Speeds up drying to 2–3 weeks but requires specialized equipment

Moisture Content Levels: Ideal firewood has 20% moisture; higher levels require longer drying times

Freshly cut wood, often called "green wood," can contain moisture levels upwards of 50%. This high moisture content makes it inefficient and problematic for burning. Ideal firewood has a moisture content of around 20%, a level that ensures clean, efficient combustion. At 20%, the wood burns hotter, produces less smoke, and minimizes creosote buildup in chimneys, reducing fire hazards.

Achieving this 20% moisture level isn’t instantaneous. Drying time depends on the wood’s initial moisture content and environmental conditions. For instance, wood with 40% moisture might take 6–12 months to air-dry under optimal conditions (well-ventilated, covered storage). Wood with 60% moisture could require 18–24 months. Hardwoods like oak or maple generally dry slower than softwoods like pine due to their denser structure.

To expedite drying, stack wood in a single row, allowing air circulation on all sides. Use a raised platform to prevent ground moisture absorption, and cover the stack with a tarp, leaving the sides open for airflow. For those with higher moisture wood, consider a moisture meter to monitor progress. If the meter reads above 25%, continue drying; below 20%, the wood is ready for use.

Burning wood with higher moisture content isn’t just inefficient—it’s wasteful. Wet wood produces less heat, more smoke, and contributes to chimney damage. For example, burning wood at 50% moisture can reduce heat output by up to 30% compared to properly seasoned wood. The extra energy required to evaporate the moisture also means you’re burning more wood for less warmth.

In regions with high humidity or frequent rainfall, drying times will naturally extend. In such cases, supplement air-drying with a kiln or solar dryer to control temperature and humidity. While these methods require investment, they ensure consistent results, particularly for those relying on firewood as a primary heat source. Patience and monitoring are key—rushing the process compromises both efficiency and safety.

Southern Pine Wood Durability: Lifespan and Longevity Explained

You may want to see also

Explore related products

$39.89

Seasoning Timeframe: Most wood needs 6–12 months to dry properly for efficient burning

Freshly cut wood, often called "green" wood, contains a significant amount of moisture, typically ranging from 30% to 60% of its weight. This moisture acts as a barrier to efficient burning, as it requires energy to evaporate before the wood can combust effectively. The process of reducing this moisture content to around 20% or less is known as seasoning. For most types of wood, this process takes between 6 to 12 months, depending on factors like the wood species, climate, and storage conditions.

Steps to Optimize Seasoning Time:

- Split the Wood: Cutting logs into smaller pieces increases the surface area exposed to air, accelerating drying. Aim for lengths of 12–18 inches and thicknesses that allow air to circulate freely.

- Store Properly: Stack wood in a single row or a crisscross pattern to promote airflow. Use a raised platform to prevent ground moisture absorption and cover the stack with a tarp, leaving the sides open for ventilation.

- Choose the Right Location: Place the woodpile in a sunny, well-ventilated area. Avoid damp or shaded spots that slow drying.

Cautions to Avoid:

- Overstacking: Piling wood too high or densely restricts airflow, prolonging drying time.

- Indoor Drying: Bringing green wood indoors traps moisture in your living space and increases humidity.

- Using Unseasoned Wood: Burning wood with high moisture content leads to inefficient combustion, creosote buildup in chimneys, and increased smoke emissions.

Comparative Insight:

Softwoods like pine or spruce dry faster, often within 6 months, due to their lower density and resin content. Hardwoods such as oak or maple, with denser fibers, typically require the full 12 months. Knowing the wood type helps in planning and managing your firewood supply effectively.

Practical Tip:

Test wood readiness by weighing a piece and comparing it to its original weight. Properly seasoned wood should be significantly lighter. Alternatively, knock two pieces together—a sharp, ringing sound indicates dryness, while a dull thud suggests remaining moisture.

Patience is key in seasoning firewood. While 6–12 months may seem lengthy, the payoff is cleaner, hotter burns and reduced risk of chimney fires. Properly dried wood not only heats more efficiently but also extends the life of your fireplace or wood stove. Plan ahead, and you’ll reap the benefits of well-seasoned firewood all winter long.

Seasoning Gumball Wood: Understanding the Timeframe for Optimal Results

You may want to see also

Explore related products

$46.99

Wood Type Differences: Hardwoods dry slower (12+ months) vs. softwoods (6–9 months)

The drying time for firewood is not a one-size-fits-all scenario; it's a tale of two distinct categories: hardwoods and softwoods. Imagine you've just chopped down a tree, and you're eager to know when you can cozy up by the fireplace. Well, the clock starts ticking differently depending on the wood type. Hardwoods, with their dense and robust nature, demand patience, requiring a minimum of 12 months to dry adequately. In contrast, softwoods, being less dense, are the sprinters of the firewood world, ready for use in as little as 6 to 9 months.

The Science Behind the Split

Hardwoods, like oak and maple, have a higher density and lower sap content, which slows moisture evaporation. This density acts as a barrier, trapping water within the wood fibers. Softwoods, such as pine and spruce, have larger cells and higher resin content, allowing moisture to escape more rapidly. Think of it as a race where hardwoods are marathon runners, steady but slow, while softwoods are sprinters, quick out of the gate. This biological difference is why stacking and seasoning hardwoods require a longer commitment.

Practical Tips for Faster Results

If you’re short on time, opt for softwoods like cedar or fir, which can be ready for burning in under a year. For hardwood enthusiasts, strategic stacking is key. Split logs into smaller pieces to increase surface area, and stack them in a sunny, well-ventilated area. Cover the top with a tarp to protect from rain while allowing airflow. For both types, use a moisture meter to ensure wood is below 20% moisture content before burning—a critical step to avoid inefficient fires and creosote buildup.

Comparative Burn Quality

While softwoods dry faster, they burn quicker and produce less heat compared to hardwoods. Hardwoods, despite their longer drying time, offer a hotter, longer-lasting burn, making them ideal for overnight fires or colder months. Softwoods are perfect for kindling or quick, short-term warmth. Understanding this trade-off helps you plan your firewood supply based on your needs and climate.

Avoiding Common Pitfalls

One mistake many make is underestimating the drying time, especially with hardwoods. Burning wet wood not only produces less heat but also releases harmful pollutants and can damage your chimney. Always err on the side of caution and give hardwoods at least a full year to season. For softwoods, resist the temptation to use them too early—wait the full 6–9 months to ensure they’re safe and efficient to burn. Patience, in this case, is not just a virtue but a necessity.

Durability of Wood Mowing Strips: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Splitting and Stacking: Split logs dry faster; stack in a dry, sunny, well-ventilated area

Freshly cut wood, or "green" wood, contains a high moisture content, typically between 30% and 50%. This moisture must be reduced to around 20% or less for efficient and safe burning. The drying process, known as seasoning, can take anywhere from six months to two years, depending on various factors such as wood type, initial moisture content, and environmental conditions. However, proper splitting and stacking techniques can significantly accelerate this timeline.

Splitting logs is a critical step in expediting the drying process. When wood is split, the exposed surfaces increase, allowing moisture to evaporate more rapidly. A log with a diameter of 12 inches, for instance, can take up to two years to dry, whereas splitting it into 4-inch pieces can reduce the drying time to as little as six months. Use a sharp axe or hydraulic splitter to ensure clean cuts, minimizing damage to the wood fibers. Aim for pieces that are 3 to 6 inches in diameter, as these sizes strike a balance between surface area exposure and structural integrity.

Once split, the way you stack the wood plays a pivotal role in its drying efficiency. Stack logs in a single row, off the ground, to promote airflow from all sides. A simple method is to use pallets or railroad ties as a base, ensuring the wood is at least 4 inches above the ground. Arrange the pieces in a crisscross pattern for stability, allowing gaps between logs for air circulation. Avoid stacking wood directly against walls or under overhangs, as these areas can trap moisture. Instead, choose a sunny, well-ventilated spot where rainwater cannot reach the pile.

The environment in which you stack your wood is equally important. Direct sunlight helps accelerate evaporation, while good ventilation prevents moisture buildup. If possible, cover the top of the stack with a tarp or waterproof cover, leaving the sides open to allow air movement. In humid climates, consider using a moisture meter to monitor the wood’s progress, aiming for a reading of 20% or less before burning. Properly seasoned wood should be lighter in weight, have cracks at the ends, and produce a hollow sound when two pieces are knocked together.

By combining strategic splitting with thoughtful stacking, you can reduce the drying time of firewood significantly. This not only ensures a more efficient burning process but also minimizes creosote buildup in chimneys, reducing fire hazards. Remember, patience is key—even with optimal conditions, rushing the seasoning process can lead to inefficient burns and increased pollution. Follow these steps, and you’ll have a well-seasoned supply of firewood ready for the next heating season.

Maximizing Flavor: Apple Wood Chips Lifespan and Storage Tips

You may want to see also

Explore related products

Kiln Drying Option: Speeds up drying to 2–3 weeks but requires specialized equipment

Kiln drying slashes firewood seasoning time from months to just 2–3 weeks by controlling temperature, humidity, and airflow in a specialized chamber. This method is particularly advantageous for commercial operations or homeowners with immediate firewood needs, as it bypasses the lengthy air-drying process. However, the upfront investment in kiln equipment and operational costs—such as electricity or propane for heating—make it less accessible for casual users. For those with the resources, kiln drying ensures uniformly seasoned wood with moisture levels consistently below 20%, ideal for efficient burning.

The process begins by loading split firewood into the kiln, ensuring adequate spacing for air circulation. Kilns typically operate at temperatures between 120°F and 180°F (49°C–82°C), gradually increasing to avoid case-hardening (a dry exterior with moist interior). Humidity is monitored and adjusted to facilitate moisture release, while fans circulate air to prevent uneven drying. A critical step is the cooling phase, where the wood is slowly brought back to ambient temperature to avoid condensation and reabsorption of moisture. Properly managed, this method yields firewood ready for immediate use, eliminating the guesswork of air-drying.

For those considering kiln drying, the equipment itself is a significant barrier. Commercial kilns range from small, portable units costing $2,000–$5,000 to large-scale systems exceeding $20,000, depending on capacity and features. DIY enthusiasts can build a basic kiln using insulated panels, a heating element, and a dehumidifier, though this requires technical skill and careful calibration. Operational costs vary based on fuel type and local energy prices, with propane-fired kilns often being more cost-effective for rural users. Despite the expense, the ability to produce dry firewood year-round—even in humid climates—makes kiln drying a compelling option for serious wood suppliers.

A key advantage of kiln drying is its ability to eliminate pests, such as insects and fungi, which are eradicated by the high temperatures. This is particularly valuable for hardwoods like oak or hickory, which are prone to infestation during prolonged air-drying. Additionally, kiln-dried wood is lighter and easier to transport, reducing delivery costs for sellers. For homeowners, the convenience of purchasing kiln-dried firewood ensures a cleaner, more efficient burn with minimal creosote buildup in chimneys. However, the environmental impact of energy consumption must be weighed against these benefits, especially for small-scale users.

In conclusion, kiln drying is a game-changer for accelerating firewood seasoning, but it’s not a one-size-fits-all solution. Its efficiency and reliability come at a steep price, making it most suitable for commercial producers or dedicated individuals with high firewood demands. For those willing to invest, the result is a premium product that burns hotter, cleaner, and with less hassle than traditionally seasoned wood. Whether building or buying a kiln, careful planning and resource allocation are essential to maximize returns on this advanced drying technique.

Yellowjackets in the Woods: Understanding Their Seasonal Presence and Duration

You may want to see also

Frequently asked questions

Wood typically needs to dry for 6 months to 2 years, depending on the type of wood, moisture content, and drying conditions.

Freshly cut wood, also known as green wood, has a high moisture content and burns inefficiently, producing less heat and more smoke. It’s best to let it dry before use.

Properly dried firewood feels lighter, has cracks or checks on the ends, and makes a hollow sound when two pieces are knocked together. A moisture meter can also confirm it’s below 20% moisture content.

Yes, denser hardwoods like oak or hickory take longer to dry (1–2 years), while softer woods like pine or poplar dry faster (6–12 months).