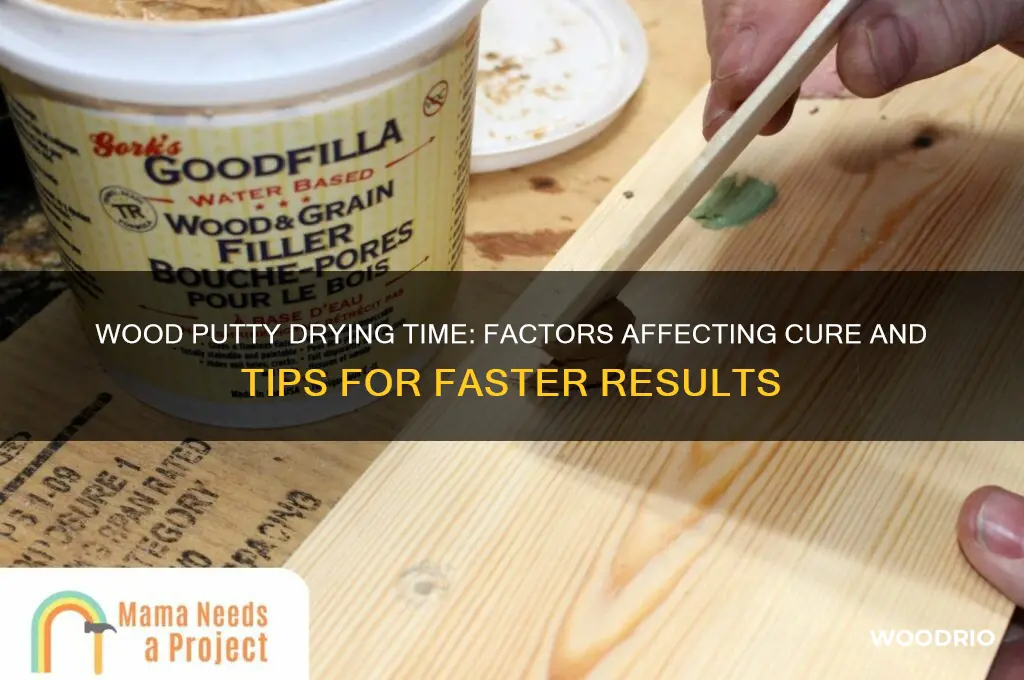

Wood putty is a versatile material commonly used for filling holes, cracks, and imperfections in wood surfaces, but understanding its drying time is crucial for achieving a smooth and durable finish. The drying time of wood putty can vary significantly depending on factors such as the type of putty, environmental conditions, and the thickness of the application. Typically, water-based wood putties dry faster, often within 1 to 2 hours, while oil-based or solvent-based putties may take anywhere from 4 to 24 hours or longer to fully cure. Humidity, temperature, and ventilation also play a role, with warmer and drier conditions accelerating the drying process. It’s essential to follow the manufacturer’s instructions and allow sufficient drying time before sanding, painting, or staining to ensure the best results.

| Characteristics | Values |

|---|---|

| Drying Time (Surface Dry) | 2-4 hours (varies by brand and environmental conditions) |

| Full Cure Time | 24-48 hours (for most water-based wood putties) |

| Solvent-Based Putty Cure Time | 8-12 hours (surface dry), 24-72 hours (full cure) |

| Temperature Impact | Faster drying in warm, dry conditions; slower in cold or humid areas |

| Humidity Impact | High humidity prolongs drying time |

| Application Thickness | Thicker applications increase drying time |

| Brand Variations | Drying times differ by manufacturer (check product label for specifics) |

| Sanding Readiness | Can be sanded after 2-4 hours (when fully hardened) |

| Paintability | Can be painted after 4-6 hours (ensure fully dry) |

| Reapplication Time | Additional layers can be applied after initial layer is dry (2-4 hours) |

| Storage Impact | Properly stored putty may have longer shelf life but drying times remain consistent |

Explore related products

What You'll Learn

Factors Affecting Drying Time

Wood putty drying time isn't a fixed number; it's a dynamic process influenced by several key factors. Understanding these variables empowers you to plan your project effectively and avoid frustration.

Let's delve into the elements that dictate how quickly your wood putty transforms from a pliable paste to a solid, durable repair.

The Putty Itself: A Matter of Composition

Not all wood putties are created equal. Oil-based putties, for instance, generally dry slower than water-based alternatives. This is because oil takes longer to evaporate compared to water. Additionally, the specific additives and fillers within the putty can impact drying time. Some putties are formulated for quick drying, ideal for time-sensitive projects, while others prioritize a longer working time for intricate repairs. Always consult the manufacturer's instructions for specific drying time estimates based on the product you've chosen.

Environmental Conditions: Nature's Role in the Process

Temperature and humidity play a crucial role in wood putty drying. Higher temperatures accelerate drying by increasing the rate of evaporation. Aim for a workspace temperature between 65°F and 85°F (18°C and 29°C) for optimal results. Humidity, on the other hand, slows drying. In humid environments, moisture in the air competes with the putty's solvents for evaporation, prolonging the drying process. Consider using a dehumidifier or working in a well-ventilated area to mitigate humidity's effects.

Application Thickness: Less is More (Sometimes)

The thickness of your putty application directly correlates with drying time. A thin layer will dry significantly faster than a thick glob. For larger repairs, consider applying multiple thin layers, allowing each layer to dry completely before adding the next. This not only speeds up drying but also reduces the risk of cracking or shrinkage.

Ventilation: The Power of Airflow

Adequate ventilation is essential for efficient drying. Good airflow helps carry away moisture vapor, expediting the evaporation process. Open windows, use fans, or work in a well-ventilated area to promote air circulation around the repaired area.

Accelerating the Process: When Time is of the Essence

If you're facing a tight deadline, there are ways to hasten drying. A hairdryer on a low heat setting can gently warm the putty, accelerating evaporation. However, exercise caution to avoid overheating, which can cause bubbling or cracking. For oil-based putties, a heat lamp positioned at a safe distance can also be effective. Remember, these methods should be used sparingly and with care to prevent damage to the wood or putty.

Wood Glue Drying Time: Quick Guide to Curing Durations

You may want to see also

Explore related products

Recommended Drying Conditions

Wood putty drying times vary widely, but optimal conditions can significantly expedite the process. Temperature plays a pivotal role, with most wood putties curing fastest between 65°F and 75°F (18°C to 24°C). Below 50°F (10°C), drying slows dramatically, and humidity levels above 60% can extend drying times by up to 50%. For instance, a putty that dries in 2 hours under ideal conditions might take 4–6 hours in a damp, cool environment. To maximize efficiency, ensure the workspace is within this temperature range and use a dehumidifier if necessary.

Humidity isn’t the only environmental factor to consider—airflow matters too. Stagnant air traps moisture, prolonging drying. Positioning a fan near the repaired area can reduce drying time by 20–30%. However, avoid direct, forceful air, as it can cause the putty to dry unevenly or crack. A gentle, consistent breeze is ideal. For small repairs, a desktop fan on low setting works well, while larger projects may benefit from a floor fan placed 3–4 feet away.

Light exposure can also influence drying, particularly for water-based wood putties. UV rays from sunlight can accelerate surface drying, but this often leads to a brittle finish. Instead, opt for indirect, bright indoor lighting to promote even curing. If working outdoors, cover the area with a thin cloth to filter sunlight while still allowing air circulation. This balance ensures the putty dries uniformly without compromising its structural integrity.

Finally, the thickness of the applied putty directly impacts drying time. A thin layer (1/16 inch or less) typically dries within 1–2 hours, while a 1/4-inch layer can take 4–6 hours or more. To speed up drying for thicker applications, apply the putty in multiple thin coats, sanding lightly between layers. This not only reduces drying time but also ensures a smoother, more professional finish. Always follow the manufacturer’s guidelines, as some putties have specific layering recommendations.

By controlling temperature, humidity, airflow, and application thickness, you can optimize drying conditions for wood putty. These adjustments not only save time but also enhance the quality of the repair. Whether you’re a professional woodworker or a DIY enthusiast, mastering these conditions ensures consistent, reliable results every time.

Plastic vs. Wooden Sheds: Which Material Offers Longer Durability?

You may want to see also

Explore related products

Accelerating Drying Process

Wood putty typically dries within 2 to 6 hours, depending on factors like humidity, temperature, and brand. However, when time is of the essence, accelerating the drying process becomes crucial. One effective method is to increase air circulation around the repaired area. Positioning a fan near the wood putty can significantly reduce drying time by promoting evaporation of moisture. Ensure the fan is set on a low to medium speed to avoid disturbing the putty’s surface. This simple technique can cut drying time by up to 50%, making it ideal for projects with tight deadlines.

Another practical approach involves adjusting the environmental conditions. Wood putty dries faster in warm, dry environments. If working indoors, raise the room temperature to around 70–75°F (21–24°C) using a space heater or by adjusting the thermostat. Pair this with a dehumidifier to reduce moisture in the air, as high humidity slows the drying process. For outdoor projects, choose a sunny day with low humidity and avoid applying putty during rainy or damp conditions. These adjustments can shave hours off the drying time, ensuring a quicker return to sanding or finishing.

For those seeking a more hands-on method, applying heat directly to the putty can expedite drying. A hairdryer set on low heat can be used to gently warm the area, but caution is essential to avoid overheating, which can cause cracking or discoloration. Hold the dryer 6–8 inches away from the surface and move it continuously to distribute heat evenly. This method is particularly effective for small repairs and can reduce drying time to as little as 30 minutes. However, it’s not recommended for large areas or delicate wood surfaces.

Lastly, consider using a fast-drying wood putty variant if time is a critical factor. Some brands offer specialized formulas designed to cure in as little as 15–30 minutes. These products often contain solvents or additives that accelerate drying, making them perfect for urgent repairs. Always follow the manufacturer’s instructions, as these putties may require specific application techniques or conditions. While they may be slightly more expensive, the time saved can outweigh the cost, especially for professionals or hobbyists working on multiple projects.

Incorporating these strategies—improving air circulation, optimizing environmental conditions, applying heat, or using fast-drying products—can dramatically reduce wood putty drying time. Each method has its advantages and limitations, so choose the one that best fits your project’s needs. By taking a proactive approach, you can ensure that your wood repairs are ready for the next step in no time, without compromising quality.

Durability of Wooden Condos: Lifespan and Maintenance Tips Revealed

You may want to see also

Explore related products

Checking if Putty is Dry

Wood putty drying times vary based on factors like brand, humidity, and application thickness, but checking if it’s dry requires more than glancing at the surface. A common mistake is assuming dryness when the top layer feels hard, only to discover the interior remains soft. To avoid this, press your fingernail gently into the putty. If it indents easily, it’s not fully cured. For a more precise test, use the "toothpick method": insert a toothpick into the putty. If it comes out clean without residue, the putty is dry. This method works because it tests the internal consistency, not just the surface.

Analyzing the drying process reveals why these methods are effective. Wood putty dries through solvent evaporation or chemical curing, depending on the type. Oil-based putties harden as oils polymerize, while water-based versions rely on water evaporation. Both processes occur from the outside in, creating a deceptive hard shell. The toothpick method exposes this by probing deeper layers, ensuring you don’t proceed with sanding or painting prematurely. Ignoring this step risks smearing uncured putty or compromising adhesion, undermining your repair work.

Persuasively, investing a few extra minutes to test dryness pays dividends in project quality. Rushing can lead to rework, wasting time and materials. For instance, if you sand partially dried putty, it can gum up sandpaper and leave an uneven surface. Similarly, painting over uncured putty may cause cracking or peeling. By systematically checking dryness, you ensure a smooth, durable finish. Think of it as a small step with a big impact—akin to letting paint cure fully before handling.

Comparatively, checking wood putty dryness differs from testing other materials like paint or glue. Paint dries uniformly, so a surface test often suffices, but putty’s layered drying demands deeper inspection. Glue, on the other hand, bonds surfaces, so its readiness is tied to tackiness or clamp time. Putty’s role as a filler means its internal and external states must align for optimal results. This distinction highlights why generic drying advice falls short for putty and why specialized methods are essential.

Descriptively, the ideal conditions for putty drying include moderate temperatures (65–80°F) and low humidity. In such settings, most putties dry within 2–4 hours for light sanding and 8–12 hours for full curing. However, these are estimates, not guarantees. Factors like putty thickness, wood porosity, and airflow affect timing. For example, a thin layer in a well-ventilated room dries faster than a thick application in a damp basement. Always err on the side of caution and test dryness before proceeding, especially in less-than-ideal conditions.

Instructively, here’s a step-by-step guide to checking putty dryness: First, wait the minimum recommended drying time (check the product label). Next, perform the fingernail test by pressing lightly into the putty. If it feels firm, proceed to the toothpick test. Insert a toothpick at a 45-degree angle and twist gently. Clean withdrawal indicates dryness; residue means more time is needed. Finally, if both tests pass, lightly sand the area to confirm. If the putty sands smoothly without gumming, it’s ready for the next step. This methodical approach ensures accuracy and avoids common pitfalls.

Wood Duck Egg Hatching Timeline: Incubation Period Explained

You may want to see also

Explore related products

Drying Time by Putty Type

Wood putty drying times vary significantly based on the type of putty used, environmental conditions, and application thickness. Understanding these differences ensures efficient project completion and optimal results. For instance, oil-based wood putty typically dries within 2 to 6 hours, depending on humidity and temperature. It’s ideal for small repairs but requires longer curing times—up to 24 hours—before sanding or painting. In contrast, water-based wood putty dries faster, often within 30 minutes to 2 hours, making it a go-to choice for quick fixes. However, it’s less durable than oil-based options and may shrink slightly upon drying.

Epoxy wood putties stand out for their strength and moisture resistance, but they come with a trade-off: longer drying times. Most epoxy putties take 8 to 12 hours to dry and up to 24 hours to fully cure. This makes them unsuitable for time-sensitive projects but perfect for structural repairs. For outdoor applications, exterior-grade wood putties are formulated to withstand weather exposure, drying within 4 to 8 hours. Always check manufacturer guidelines, as some require specific temperature ranges (e.g., 65°F to 85°F) for optimal drying.

When working with solvent-based putties, expect drying times of 2 to 4 hours, but be cautious of strong fumes. These are best used in well-ventilated areas and are ideal for matching stained wood due to their transparency. Latex wood putties, on the other hand, dry in 15 to 30 minutes, making them excellent for minor imperfections. However, they lack the durability of oil or epoxy-based options and are prone to cracking under stress.

To expedite drying, control the environment. Use a fan or dehumidifier to reduce moisture, and maintain a consistent temperature. Thin applications dry faster than thick layers, so apply putty sparingly and build up as needed. For multi-step projects, plan ahead: allow each layer to dry completely before sanding or adding another coat. This prevents smudging and ensures a smooth finish.

In summary, choosing the right wood putty type depends on your project’s timeline, durability needs, and environmental conditions. Oil-based putties offer balance, water-based options provide speed, and epoxy delivers strength. Always follow product instructions and test drying times on a scrap piece of wood to avoid delays. With the right putty and preparation, achieving seamless wood repairs becomes a straightforward task.

Elle Woods' Class Skipping Habits: Uncovering Her Academic Absences

You may want to see also

Frequently asked questions

Wood putty usually takes 2 to 4 hours to dry to the touch, but it can take up to 24 hours to fully cure, depending on the brand, humidity, and temperature.

Yes, you can speed up drying by using a hairdryer on a low setting, increasing ventilation, or applying heat gently. However, avoid excessive heat as it may damage the wood or putty.

While wood putty may feel hard to the touch after a few hours, it is not fully cured. Wait at least 24 hours before sanding, painting, or applying finish for best results.