Wood shellac, a natural resin derived from the lac bug, has been used for centuries as a protective finish for wood surfaces. Its durability and aesthetic appeal make it a popular choice for furniture, flooring, and decorative items. However, the longevity of wood shellac depends on various factors, including the quality of application, environmental conditions, and maintenance. Typically, a well-applied shellac finish can last anywhere from 5 to 10 years before showing signs of wear, such as yellowing, cracking, or chipping. Regular maintenance, like gentle cleaning and occasional reapplication, can extend its lifespan, ensuring the wood remains protected and visually appealing. Understanding these factors is key to maximizing the durability of a shellac finish.

| Characteristics | Values |

|---|---|

| Durability | 1-3 years (with proper maintenance) |

| Lifespan on High-Traffic Areas | 6 months to 1 year |

| Lifespan on Low-Traffic Areas | 2-3 years |

| Resistance to Heat | Low (can soften or melt under high heat) |

| Resistance to Water | Poor (not waterproof, can be water-resistant with multiple coats) |

| Resistance to Alcohol | Poor (can dissolve or damage the finish) |

| Maintenance Required | Regular reapplication (every 1-3 years) |

| Drying Time | 30 minutes to 2 hours between coats |

| Number of Coats Recommended | 3-5 coats for optimal protection |

| Environmental Factors Affecting Lifespan | Humidity, temperature, and exposure to sunlight can shorten lifespan |

| Suitability for Outdoor Use | Not recommended (not UV-resistant or weatherproof) |

| Ease of Repair | Easy (can be touched up or reapplied as needed) |

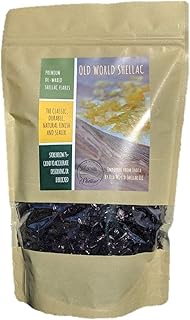

Explore related products

What You'll Learn

Shellac durability on wood surfaces

Shellac, a natural resin derived from the lac bug, has been used for centuries as a protective finish on wood surfaces. Its durability, however, is often a subject of debate among woodworkers and DIY enthusiasts. When applied correctly, shellac can provide a robust, long-lasting finish that enhances the wood’s natural beauty. The key to maximizing its lifespan lies in understanding its properties and application techniques. For instance, shellac is alcohol-soluble, which means it dries quickly but also requires careful handling to avoid over-thinning or uneven application. A typical shellac finish, when applied in 3-4 coats with proper sanding between layers, can last anywhere from 5 to 10 years on low-traffic wood surfaces like cabinets or decorative furniture.

To ensure optimal durability, the preparation of the wood surface is critical. Start by sanding the wood to a smooth, even finish, removing any rough spots or previous finishes. Wipe the surface clean with a tack cloth to eliminate dust. When applying shellac, use a high-quality brush or sprayer to achieve an even coat. Dilute the shellac with denatured alcohol in a ratio of 1:1 for a thinner, more penetrable finish, or use it straight for a thicker, more protective layer. Allow each coat to dry for at least 30 minutes before sanding lightly with 400-grit sandpaper. This process not only ensures adhesion but also builds a resilient barrier against moisture and wear.

One common misconception is that shellac is not suitable for high-traffic areas or surfaces exposed to heat and moisture. While it’s true that shellac is less resistant to heat and alcohol compared to modern finishes like polyurethane, it can still perform well in kitchens or dining tables with proper care. For example, applying a wax topcoat over shellac can add an extra layer of protection against spills and scratches. Additionally, shellac’s ability to be easily repaired makes it a practical choice for furniture that may endure wear over time. Simply reapply shellac to damaged areas, and it will blend seamlessly with the existing finish.

Comparing shellac to other wood finishes highlights its unique advantages. Unlike polyurethane, which can yellow over time, shellac maintains its clarity, making it ideal for light-colored woods like maple or birch. It’s also more environmentally friendly than synthetic finishes, as it’s derived from natural sources and emits fewer volatile organic compounds (VOCs). However, shellac’s susceptibility to water and alcohol means it’s less suitable for outdoor use or surfaces frequently exposed to liquids. For such applications, consider a more water-resistant finish like varnish or epoxy.

In conclusion, the durability of shellac on wood surfaces depends largely on application technique, surface preparation, and the specific demands of the environment. By following best practices—such as proper sanding, careful dilution, and strategic use of topcoats—shellac can provide a beautiful, long-lasting finish that rivals modern alternatives. Whether you’re restoring antique furniture or finishing a new woodworking project, shellac remains a versatile and timeless choice for those who appreciate its natural charm and ease of use.

Timbor Wood Treatment Durability: Longevity and Protection Explained

You may want to see also

Explore related products

Factors affecting shellac lifespan

Shellac's durability on wood hinges on a delicate interplay of environmental factors, application techniques, and inherent material properties. Sunlight, a silent adversary, accelerates degradation through UV radiation, causing shellac to yellow and brittle over time. In high-traffic areas, physical wear and tear become the primary concern, as friction from use can scrape away the protective layer. Humidity levels play a dual role: excessive moisture softens shellac, inviting damage, while arid conditions lead to cracking. Understanding these vulnerabilities is the first step in maximizing shellac's lifespan.

Consider the application process as a critical determinant of longevity. Thinning shellac with the correct ratio of denatured alcohol—typically 1:1 for seal coats and 3:1 for finish coats—ensures even penetration and adhesion. Over-thinning weakens the film, while under-thinning results in a blotchy, uneven surface prone to chipping. Multiple thin coats, allowing 30 minutes drying time between applications, outperform a single thick coat by providing a more resilient barrier. Sanding lightly with 400-grit paper between coats enhances adhesion, but over-sanding risks removing too much material, compromising thickness.

The type of wood and its preparation cannot be overlooked. Porous woods like oak absorb shellac more readily, requiring additional coats for uniform coverage. Non-porous woods like maple demand meticulous surface preparation—cleaning with mineral spirits and light sanding—to ensure shellac grips effectively. Contaminants such as oils or waxes act as barriers, preventing proper bonding. For best results, apply shellac to bare wood or over a compatible sealer, avoiding water-based products that repel its alcohol base.

Maintenance practices significantly extend shellac's life. Periodic reapplication of a thin maintenance coat every 1-2 years in high-use areas restores protection. For furniture, avoid placing shellacked surfaces near heat sources or in direct sunlight, and use coasters to prevent water rings. Cleaning should be done gently with a soft cloth dampened in mild soap and water, followed by immediate drying. Harsh chemicals or abrasive cleaners strip away the finish, necessitating full reapplication.

Finally, the intended use of the shellacked piece dictates its expected lifespan. Decorative items stored indoors can retain their finish for decades, while tabletops or floors subjected to daily use may require refinishing every 5-7 years. In commercial settings, where wear is intensified, shellac may last only 2-3 years before showing signs of distress. By tailoring application and care to the specific demands of the environment, one can optimize shellac's performance, balancing its natural beauty with practical durability.

Understanding Wood Dust Settling Time: Factors and Practical Tips

You may want to see also

Explore related products

$17.99 $18.99

Proper application for longevity

Shellac's durability hinges on meticulous application, a process demanding precision and patience. The first step is surface preparation, a critical phase often overlooked. Wood must be clean, dry, and free from any previous finishes or contaminants. Sanding is essential, starting with a coarse grit (120-150) to remove imperfections, followed by finer grits (180-220) for a smooth finish. This ensures shellac adheres properly, preventing premature wear and peeling.

The application technique significantly impacts longevity. Shellac is typically dissolved in alcohol, creating a liquid solution known as 'cut.' A common ratio is 1 pound of shellac flakes to 1 gallon of denatured alcohol, resulting in a 1-lb cut. For most wood projects, a 1.5 to 2-lb cut is ideal, offering a balance between ease of application and durability. Apply thin coats using a natural-bristle brush or a cloth, allowing each coat to dry completely (approximately 30 minutes to 1 hour) before adding the next. Multiple thin coats are superior to a single thick one, as they reduce the risk of drips and ensure even coverage.

Environmental conditions play a pivotal role in the application process. Shellac should be applied in a well-ventilated area, with temperatures between 65°F and 85°F (18°C and 29°C). High humidity can prolong drying times and affect the finish's clarity, while extreme heat may cause the shellac to dry too quickly, leading to a cloudy appearance. Maintaining optimal conditions ensures the shellac cures properly, enhancing its protective qualities and aesthetic appeal.

A often-overlooked aspect is the sealing of the wood's end grain. End grain absorbs shellac at a different rate, which can lead to an uneven finish. To mitigate this, apply a thicker coat of shellac to the end grain or seal it with a wood sealer before the initial application. This simple step can significantly extend the life of the finish, particularly in furniture or flooring where end grain is exposed.

Finally, the number of coats applied directly correlates with durability. For high-traffic areas or items subjected to frequent use, a minimum of four to six coats is recommended. Each additional coat increases the shellac's resistance to scratches, stains, and moisture. After the final coat, allow the shellac to cure fully, which can take up to 48 hours. This curing period is crucial, as it hardens the shellac, maximizing its protective capabilities and ensuring the finish lasts for years.

Wood Pigeon Lifespan: Understanding Their Average Life Expectancy

You may want to see also

Explore related products

Shellac maintenance and care tips

Shellac, a natural resin derived from lac bugs, has been a staple in wood finishing for centuries, prized for its rich luster and protective qualities. However, its longevity depends heavily on maintenance and care. Unlike synthetic finishes, shellac is sensitive to heat, moisture, and alcohol, which can degrade its integrity over time. Proper care can extend its lifespan from a few years to several decades, making it a viable choice for both antique restoration and modern woodworking.

One critical aspect of shellac maintenance is protecting it from moisture. Shellac is hygroscopic, meaning it absorbs water, which can cause it to swell, crack, or lose its sheen. To mitigate this, avoid placing shellac-finished items in humid environments, such as bathrooms or near dishwashers. If exposure is unavoidable, apply a thin coat of wax or a moisture-resistant topcoat like polyurethane over the shellac. For daily care, wipe spills immediately with a soft, dry cloth, and never use abrasive cleaners or scrubbers, as they can scratch the surface.

Another key to preserving shellac is minimizing its exposure to heat and sunlight. Prolonged heat can cause shellac to melt or become sticky, while UV rays can fade its color and weaken its structure. Keep shellac-finished furniture away from radiators, fireplaces, and direct sunlight. If the piece is in a sunny area, consider using UV-filtering window films or rotating the item periodically to ensure even exposure. For added protection, reapply a thin layer of shellac every 3–5 years, especially on high-traffic surfaces like tabletops.

For repairs, shellac’s solubility in alcohol is both a blessing and a challenge. Small scratches or worn areas can be touched up by applying a fresh coat of shellac, but care must be taken not to dissolve the existing finish. Use a fine brush or cloth to apply the shellac sparingly, allowing each coat to dry completely before adding another. For deeper damage, lightly sand the area with 400-grit sandpaper, clean the surface with denatured alcohol, and then reapply shellac in thin, even layers. Always test a small, inconspicuous area first to ensure compatibility.

Finally, consider the environment in which shellac-finished pieces are used. Shellac is not suitable for outdoor furniture or areas with extreme temperature fluctuations, as these conditions accelerate its deterioration. For indoor use, maintain a stable environment with moderate humidity (40–50%) and temperature (65–75°F). Regularly dusting with a microfiber cloth and occasional polishing with a shellac-safe product, such as a paste wax, will keep the finish looking vibrant. With thoughtful care, shellac can retain its beauty and functionality for generations, blending timeless elegance with practical durability.

Wood Glue Drying Time: Essential Tips Before Routing Your Project

You may want to see also

Explore related products

Comparing shellac to other finishes

Shellac, derived from the resin secretions of the lac bug, has been a staple in wood finishing for centuries. Its longevity, however, is often questioned when compared to modern alternatives like polyurethane, varnish, and lacquer. While shellac can last anywhere from 1 to 5 years depending on exposure and maintenance, its durability is inherently tied to its natural composition. Unlike synthetic finishes, shellac is soluble in alcohol, making it more susceptible to damage from water and heat. This vulnerability raises the question: how does shellac stack up against other finishes in terms of longevity and performance?

Consider polyurethane, a go-to finish for high-traffic surfaces like floors and countertops. Polyurethane forms a hard, plastic-like coating that resists scratches, stains, and moisture far better than shellac. A properly applied polyurethane finish can last 10–15 years, significantly outperforming shellac in durability. However, polyurethane lacks the warmth and depth that shellac imparts to wood, making it less desirable for fine furniture or antiques. Additionally, polyurethane requires careful application to avoid bubbles and drips, whereas shellac is more forgiving due to its thinner consistency and faster drying time.

Varnish, another popular finish, strikes a middle ground between shellac and polyurethane. Oil-based varnishes can last 5–10 years, offering better water resistance than shellac while still enhancing the wood’s natural beauty. However, varnish takes longer to dry and cure, often requiring multiple coats and extended drying times. Shellac, on the other hand, can be applied in multiple thin coats within hours, making it ideal for quick projects. For restoration work, shellac’s compatibility with older finishes and its ability to be easily repaired with another coat give it an edge over varnish.

Lacquer, known for its fast-drying properties and high-gloss finish, is often compared to shellac due to their shared solvent-based nature. However, lacquer is more durable and resistant to heat and chemicals, lasting up to 10 years in optimal conditions. Unlike shellac, lacquer requires spraying for a smooth finish, which can be impractical for DIYers without proper equipment. Shellac’s brushability and ease of application make it a more accessible choice for hobbyists and small-scale projects, despite its shorter lifespan.

In practice, the choice between shellac and other finishes depends on the intended use and aesthetic goals. For a dining table that will see frequent spills and heat exposure, polyurethane or lacquer would be more suitable. For a vintage desk or decorative piece that prioritizes appearance and ease of repair, shellac remains a compelling option. To extend shellac’s life, apply a maintenance coat annually and avoid placing shellacked items in direct sunlight or near heat sources. While it may not outlast its synthetic counterparts, shellac’s unique blend of beauty, versatility, and historical authenticity ensures its place in the world of wood finishing.

Wood Gorilla Glue Drying Time: Quick Guide to Perfect Bonding

You may want to see also

Frequently asked questions

Wood shellac can last between 1 to 5 years, depending on factors like exposure to sunlight, moisture, and wear.

Yes, shellac is more durable indoors and can last up to 5 years, while exterior applications may only last 1 to 2 years due to weather exposure.

Yes, shellac can be reapplied as needed, and regular maintenance can significantly extend its lifespan.

Higher-quality shellac tends to last longer, with premium products offering better resistance to wear and environmental factors.

Yes, sealing shellac with a more durable finish like polyurethane can enhance its longevity, especially in high-traffic or outdoor areas.