Spalting in green wood is a fascinating process where fungi colonize the wood, creating unique patterns and colors, highly prized in woodworking. The time it takes for green wood to spalt varies significantly, typically ranging from a few weeks to several months, depending on factors such as wood species, moisture content, temperature, and the presence of spalting fungi. Ideal conditions for spalting include a moisture content of 30-50%, temperatures between 60-80°F (15-27°C), and proper airflow to encourage fungal growth without causing decay. While spalting enhances aesthetic appeal, it weakens the wood, so timing and control are crucial to achieve the desired results without compromising structural integrity.

| Characteristics | Values |

|---|---|

| Ideal Temperature Range | 60°F to 80°F (15°C to 27°C) |

| Optimal Humidity Level | 40% to 60% |

| Typical Time for Spalted Wood | 2 to 8 weeks (varies based on wood type, conditions, and desired effect) |

| Wood Types That Spalt Easily | Maple, Birch, Beech, Poplar, and other hardwoods |

| Fungal Activity Required | Yes (specific fungi like Trametes versicolor and Stereum hirsutum) |

| Oxygen Requirement | Minimal (anaerobic conditions preferred for certain fungi) |

| Moisture Content Needed | 20% to 30% (green wood typically starts at 30% to 50%) |

| Risk of Over-Spalting | High (can lead to wood decay if left too long) |

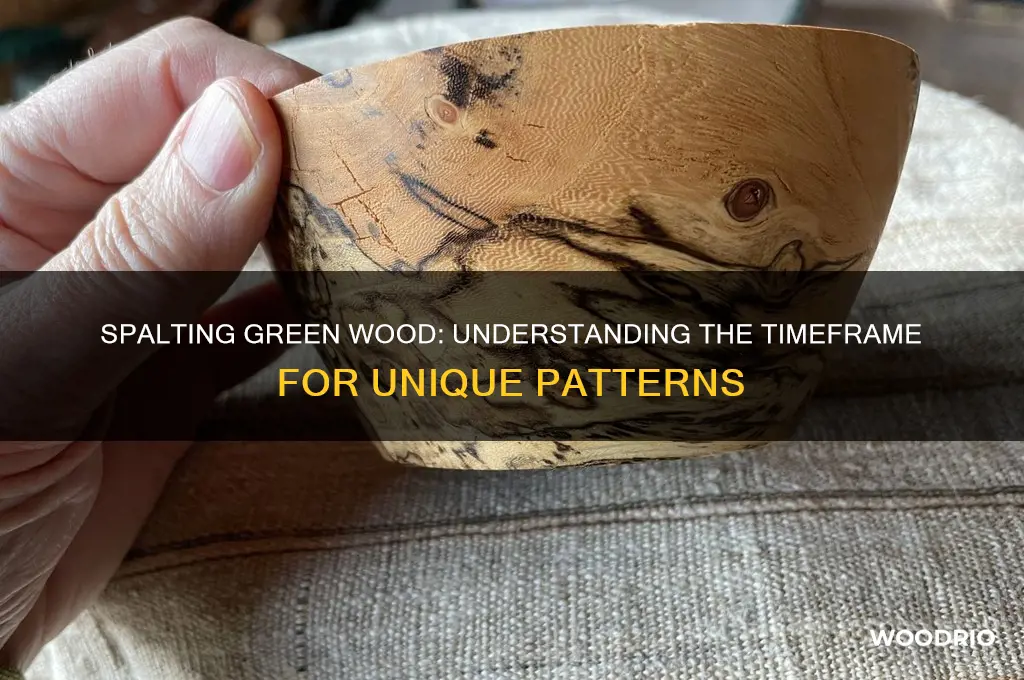

| Visual Indicators of Spalting | Dark lines (zonate lines), color changes, and unique patterns |

| Prevention of Decay | Kiln drying or air drying after desired spalting effect is achieved |

| Common Uses of Spalted Wood | Furniture, decorative items, turned objects, and woodworking projects |

Explore related products

What You'll Learn

Ideal Conditions for Spalt

Spalting thrives in a delicate balance of moisture, temperature, and time. Aim for a wood moisture content between 30% and 50%—too dry, and fungi won’t colonize; too wet, and rot takes over. Green wood, freshly cut and still saturated, is ideal because it retains this moisture range naturally. For best results, seal the wood in a plastic bag or container to maintain humidity, but puncture small holes to allow air exchange, as spalting fungi are aerobic. Monitor the wood periodically; if it feels dry to the touch, lightly mist it with water to restore moisture without oversaturating.

Temperature plays a critical role in spalting speed and quality. Ideal conditions range from 60°F to 75°F (15°C to 24°C), mirroring the fungi’s preferred environment. Colder temperatures slow the process, while heat above 85°F (29°C) can kill the fungi. Avoid direct sunlight, as it dries the wood and raises temperatures unpredictably. For controlled spalting, store the wood in a shaded, temperature-stable area like a garage or basement. If your climate is too cold, consider using a heating pad set on low to maintain optimal warmth without overheating.

Not all wood species spalt equally, and some are more resistant to rot. Hardwoods like maple, beech, and birch are excellent choices due to their dense structure, which slows decay while allowing fungi to penetrate. Softwoods like pine or cedar are riskier, as they decompose faster. Select freshly cut logs or branches, ensuring they’re free of cracks or damage that could invite unwanted bacteria. Experiment with different species to observe how their grain patterns and natural defenses influence spalting outcomes.

Time is both an ally and an adversary in spalting. Green wood typically begins to show spalting patterns within 2–4 weeks under ideal conditions, but full development can take 2–3 months. Regularly inspect the wood for signs of rot or mold, which indicate the process has gone too far. Once desired patterns emerge, halt spalting by drying the wood in a kiln or air-drying it to below 20% moisture content. Patience is key—rushing the process risks ruining the wood, while neglecting it allows decay to dominate.

Finally, safety must guide your spalting efforts. Wear gloves and a mask when handling spalted wood, as fungal spores can cause respiratory irritation or allergic reactions. Work in a well-ventilated area, and avoid spalting wood intended for food contact or indoor use without proper sealing. While spalting transforms wood into a stunning material, it’s a natural process that requires respect for both the craft and its potential hazards. With care, you can create unique, visually striking pieces that showcase nature’s artistry.

Eco Wood Weathering: Timeframe for Achieving a Natural Grey Patina

You may want to see also

Explore related products

Wood Types and Spalt Speed

The speed at which green wood spalts varies dramatically by species, with some woods like maple and beech showing visible spalt patterns within 2-4 weeks, while denser hardwoods such as oak or walnut may require 6-12 weeks to achieve similar results. This disparity is primarily due to differences in cellular structure and natural defenses against fungi, which are the catalysts for spalting. For instance, maple’s loose grain structure allows fungi to penetrate quickly, accelerating the process, whereas oak’s higher tannin content slows fungal growth, delaying spalt development.

To optimize spalting speed, select wood species with a balance of permeability and moisture retention. Birch and poplar are excellent choices for beginners, as they spalt within 3-6 weeks under ideal conditions (60-70% humidity, 70-75°F). For faster results, thin logs or planks (1-2 inches thick) are recommended, as they allow moisture and fungi to penetrate more evenly. Avoid overly dense woods like teak or mahogany, which may take months to spalt and often produce inconsistent patterns due to their natural resistance to decay.

Environmental control is critical for accelerating spalting, regardless of wood type. Maintain a consistent temperature range of 70-75°F and humidity above 60% to encourage fungal activity without promoting rot. Use a humidity dome or sealed container with a small vent to regulate moisture levels. Introduce spalt fungi by placing wood in contact with spore-rich materials like decaying leaves or previously spalted wood, but avoid overcrowding to prevent mold. Monitor the process weekly, as over-spalting can weaken the wood structure.

Comparing species reveals that softwoods like pine or cedar spalt poorly due to their resinous defenses, often resulting in dull, uneven patterns. In contrast, fruitwoods such as cherry or apple spalt rapidly (4-8 weeks) and produce vibrant colors due to their sugar content, which feeds fungi. Exotic woods like purpleheart or wenge are less predictable, as their density and chemical composition can either inhibit or enhance spalting depending on conditions. Experimentation with small samples is key to understanding how each species responds.

For practical application, pair faster-spalting woods with time-sensitive projects, such as using beech for decorative veneers or maple for turned bowls. Slower-spalting woods like walnut are better suited for long-term projects where deeper, more complex patterns are desired. Always stabilize spalted wood with a resin or oil finish to prevent further decay, as the spalting process weakens the material. By matching wood type to project timeline and controlling conditions, crafters can reliably achieve desired spalt effects without unnecessary delays.

Wood Foundation Lifespan: Durability, Factors, and Longevity Explained

You may want to see also

Moisture and Temperature Roles

Spalting, the process by which fungi colonize wood, creating unique patterns and colors, hinges critically on moisture and temperature. These two factors act as the gatekeepers of fungal activity, dictating whether spalting occurs, its speed, and the final aesthetic outcome. Understanding their interplay is essential for anyone seeking to control or accelerate the spalting process.

Green wood, by definition, contains a high moisture content, typically above 20%. This moisture is the lifeblood of spalting fungi, providing the necessary environment for their growth and metabolism. However, too much moisture can lead to undesirable outcomes. Excess water can drown the fungi, preventing them from accessing the wood's nutrients and halting the spalting process altogether. Conversely, insufficient moisture will starve the fungi, leaving the wood untouched. The ideal moisture range for spalting typically falls between 20% and 40%, with 30% often considered optimal.

Temperature plays a dual role in spalting. Firstly, it directly influences fungal growth rates. Most spalting fungi thrive in temperate conditions, with an ideal range between 60°F and 80°F (15°C and 27°C). Below this range, fungal activity slows significantly, while temperatures above 90°F (32°C) can be detrimental, potentially killing the fungi. Secondly, temperature affects the wood's moisture content. Higher temperatures accelerate evaporation, potentially drying the wood too quickly and halting spalting. Conversely, cooler temperatures slow evaporation, allowing for a more controlled moisture environment.

Maintaining the delicate balance between moisture and temperature is key to successful spalting. This often involves a combination of techniques. Storing wood in a humid environment, such as a sealed container with damp sawdust, helps maintain optimal moisture levels. Controlling ambient temperature through heating or cooling systems ensures the fungi remain within their preferred range. Regular monitoring of both moisture content and temperature is crucial, allowing for adjustments to be made as needed.

While controlling moisture and temperature can accelerate spalting, it's important to remember that the process is inherently unpredictable. Different wood species, fungal strains, and environmental conditions can lead to vastly different results. Patience and experimentation are key, as the beauty of spalting lies in its unique and often unexpected outcomes. By understanding the roles of moisture and temperature, woodworkers can create the ideal conditions for spalting, increasing the likelihood of achieving stunning and distinctive patterns in their projects.

Polyurethane Application Guide: Ideal Timing Between Coats on Pine Wood

You may want to see also

Signs of Proper Spalting

Spalting is a natural process where fungi colonize wood, creating unique patterns and colors. However, not all spalting is desirable. Proper spalting enhances the wood’s aesthetic without compromising its structural integrity. The first sign of successful spalting is the presence of zonate lines, which are dark, thin lines formed by fungal colonization. These lines should be distinct yet evenly distributed, indicating a healthy fungal interaction rather than decay. If the lines appear blotchy or sparse, the spalting process may be uneven or incomplete.

Another critical indicator is the coloration of the wood. Properly spalted wood often displays vibrant hues of blue, green, brown, or black, depending on the fungal species present. For example, *Chlorociboria* fungi produce striking blue-green shades, while *Perenniporia* species create darker, more earthy tones. Avoid wood with dull or muddy colors, as this suggests excessive decay or improper moisture control during spalting. Aim for colors that are rich and well-defined, enhancing the wood’s natural beauty.

Texture is equally important. Properly spalted wood retains a smooth, intact surface despite fungal activity. Run your hand over the wood—it should feel solid with minimal softness or crumbling. If the wood feels spongy or crumbly, the spalting has likely progressed into decay, rendering it unsuitable for most woodworking projects. Regularly inspect the wood during the spalting process to ensure it remains structurally sound.

Finally, timing plays a crucial role in achieving proper spalting. Green wood typically begins to spalt within 2–4 weeks under ideal conditions (high humidity, 70–80°F temperatures). However, the process can take 3–6 months to fully develop desirable patterns. Monitor the wood weekly, especially during the first month, to catch any signs of excessive decay early. Patience is key—rushing the process or leaving it unchecked can ruin the wood.

To ensure proper spalting, maintain a humidity level of 60–80% and protect the wood from direct sunlight. Wrapping it in breathable materials like burlap or placing it in a controlled environment, such as a greenhouse, can help regulate conditions. Always work with hardwoods like maple, beech, or birch, as they spalt more predictably than softwoods. With careful observation and control, you can achieve beautifully spalted wood that is both visually stunning and structurally reliable.

How Long Does a Cord of Wood Last Before Decay?

You may want to see also

Preventing Over-Spalting Risks

Spalting, the process where fungi colonize wood, creating unique patterns, is a delicate balance. Left unchecked, it can lead to over-spalting, compromising the wood's structural integrity. Understanding the timeline and implementing preventive measures are crucial for achieving the desired aesthetic without sacrificing strength.

While the spalting process can begin within days of wood being exposed to moisture and fungi, the ideal duration for achieving desirable patterns without over-spalting varies. Generally, green wood requires 4-8 weeks for initial spalting, but this is highly dependent on factors like wood species, moisture content, temperature, and fungal species present.

Hardwoods like maple and beech are more resistant to over-spalting compared to softer woods like basswood or poplar. Maintaining a moisture content of 20-30% is optimal for spalting, as higher levels can accelerate fungal growth and lead to decay. Regularly monitoring the wood's moisture content using a moisture meter is essential for controlling the process.

Controlling the Environment:

The key to preventing over-spalting lies in controlling the environment. Maintain a temperature range of 60-75°F (15-24°C), as higher temperatures accelerate fungal growth. Ensure adequate airflow around the wood to prevent stagnant moisture pockets, which can lead to rot. Consider using a humidifier or misting system to maintain consistent moisture levels, but avoid direct water contact with the wood.

Regularly inspect the wood for signs of excessive fungal growth, such as dark discoloration, soft spots, or a musty odor. If over-spalting is detected, immediately reduce moisture levels by increasing airflow and allowing the wood to dry slightly.

Intervention Techniques:

If over-spalting becomes apparent, intervention is necessary. One method is to kiln-dry the wood, which halts fungal growth but may also alter the spalting patterns. Alternatively, applying a fungicide solution (following manufacturer instructions and safety precautions) can inhibit further fungal activity. However, this may also affect the desired aesthetic.

The Art of Timing:

Preventing over-spalting is an art that requires close observation and timely intervention. By understanding the factors influencing spalting and implementing controlled environmental conditions, woodworkers can achieve stunning spalting patterns while preserving the wood's structural integrity. Remember, the goal is to guide the process, not control it entirely, allowing nature's artistry to shine through.

Boiling Chicken of the Woods: Optimal Cooking Time for Perfect Texture

You may want to see also

Frequently asked questions

Spalted wood is wood that has been colonized by fungi, creating unique dark lines and patterns. Green wood is used because its higher moisture content provides an ideal environment for fungal growth, which is essential for spalting.

The spalting process for green wood usually takes 4 to 8 weeks, depending on factors like temperature, humidity, and the type of wood and fungi involved.

Yes, spalting can be accelerated by maintaining optimal conditions: a temperature of 70–80°F (21–27°C), high humidity (around 80–100%), and proper airflow to encourage fungal growth without causing decay.

The wood is sufficiently spalted when distinct dark lines (zonate lines) and color changes are visible. Over-spalting can lead to decay, so monitor the wood regularly and dry it once the desired pattern is achieved.