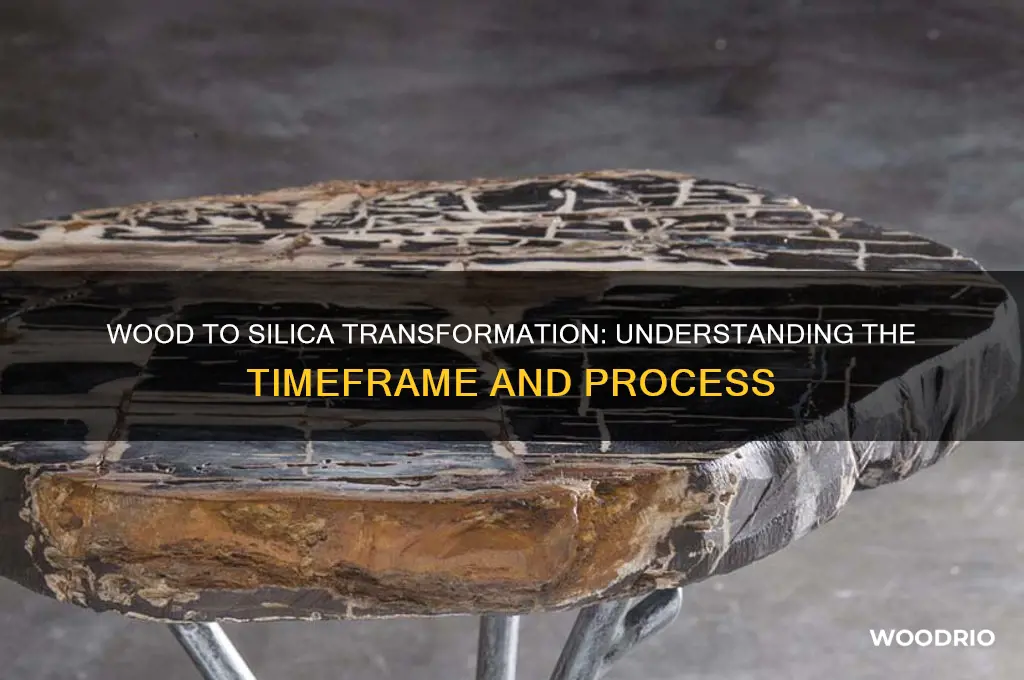

The transformation of wood into silica, a process known as silicification, is a fascinating natural phenomenon that occurs over geological timescales. This process involves the gradual replacement of the organic material in wood with silica, typically through the infiltration of silica-rich groundwater. The duration of this transformation can vary significantly, ranging from thousands to millions of years, depending on factors such as the silica concentration in the surrounding environment, the permeability of the wood, and the geological conditions. Understanding the timeline and mechanisms behind wood silicification not only sheds light on Earth's geological history but also has implications for fields like paleontology, archaeology, and materials science.

| Characteristics | Values |

|---|---|

| Process Name | Silicification or Permineralization |

| Timeframe | Thousands to millions of years (varies based on conditions) |

| Key Factors Influencing Speed | Temperature, pH, silica concentration, burial depth, pressure |

| Optimal Conditions | Anaerobic (oxygen-free) environments, high silica availability |

| Examples in Nature | Petrified forests (e.g., Arizona's Petrified Forest National Park) |

| Initial Stage | Cellulose and lignin degradation, silica infiltration into cell walls |

| End Result | Wood structure preserved as silica (chalcedony or quartz) |

| Common Silica Sources | Volcanic ash, groundwater rich in dissolved silica |

| Preservation Quality | Depends on silica purity and uniformity of replacement |

| Scientific Significance | Provides insights into ancient ecosystems and geological history |

Explore related products

What You'll Learn

- Factors Affecting Silicification: Temperature, pressure, pH, and mineral content influence wood-to-silica transformation rates

- Natural Silicification Process: Occurs over centuries to millennia in sedimentary environments with silica-rich water

- Artificial Silicification Methods: Accelerated processes using heat, chemicals, or pressure to convert wood to silica

- Role of Microorganisms: Bacteria and fungi can mediate silica precipitation in wood structures over time

- Examples of Silicified Wood: Fossilized wood like petrified wood showcases complete silica transformation over millions of years

Factors Affecting Silicification: Temperature, pressure, pH, and mineral content influence wood-to-silica transformation rates

The transformation of wood into silica, a process known as silicification, is not a simple or quick event. It occurs under specific geological conditions, often taking thousands to millions of years. However, the rate at which this transformation happens can vary significantly based on several key factors: temperature, pressure, pH, and mineral content. Understanding these factors is crucial for geologists, paleontologists, and materials scientists studying fossilization and mineralization processes.

Temperature plays a pivotal role in silicification, acting as a catalyst for the chemical reactions involved. Higher temperatures generally accelerate the process by increasing the mobility of silica-rich fluids. For instance, in hydrothermal environments where temperatures range from 100°C to 300°C, wood can silicify within a few thousand years. Conversely, in cooler environments, such as shallow groundwater systems with temperatures below 25°C, the process may take millions of years. This temperature-dependent rate highlights the importance of geothermal gradients in determining how quickly organic material transforms into silica.

Pressure, often coupled with temperature, also significantly influences silicification. Elevated pressures, typically found in deep sedimentary basins or along fault zones, enhance the solubility of silica in aqueous solutions. This increased solubility allows silica to permeate wood tissues more effectively, speeding up the replacement of organic matter with silica. For example, wood buried at depths greater than 1 kilometer, where pressures exceed 20 MPa, can silicify more rapidly than wood in near-surface environments. However, excessive pressure can also crush the wood, preserving less structural detail in the final silica replica.

PH levels in the surrounding environment are another critical factor, as they affect the stability and mobility of silica. Silicification is most efficient in slightly acidic to neutral conditions (pH 6–7), where silica is highly soluble and can readily infiltrate wood tissues. In highly acidic environments (pH < 5), silica may precipitate too quickly, forming crusts rather than detailed cellular replacements. Conversely, in alkaline conditions (pH > 8), silica solubility decreases, slowing the silicification process. Monitoring and controlling pH in experimental settings can thus provide insights into optimizing silica formation.

Mineral content in the surrounding sediment or fluid is equally important, as it determines the availability of silica and other necessary elements. High concentrations of dissolved silica, often derived from volcanic activity or weathering of silicate minerals, are essential for rapid silicification. Additionally, the presence of certain minerals, such as quartz or opal, can serve as direct sources of silica. For example, wood buried in silica-rich volcanic ash layers can silicify within tens of thousands of years, whereas wood in silica-poor environments may take significantly longer. Practical applications of this knowledge include selecting silica-rich substrates for experimental fossilization studies.

In summary, the wood-to-silica transformation is a complex process influenced by temperature, pressure, pH, and mineral content. By manipulating these factors, scientists can better understand the mechanisms of silicification and potentially replicate the process in controlled environments. Whether studying ancient fossils or developing new materials, recognizing the interplay of these variables is key to unlocking the secrets of this remarkable geological phenomenon.

Drying Hickory Wood: Optimal Time for Perfect Seasoning and Use

You may want to see also

Explore related products

Natural Silicification Process: Occurs over centuries to millennia in sedimentary environments with silica-rich water

Wood's transformation into silica, a process known as silicification, is a remarkable natural phenomenon that unfolds over vast timescales. This process, occurring in sedimentary environments rich in silica, highlights the intricate interplay between organic materials and mineral-laden waters. The journey from wood to silica is not merely a quick chemical reaction but a gradual, centuries-long process that preserves intricate details of the original organic structure. Understanding this timeline offers insights into the Earth's geological processes and the conditions necessary for such transformations.

In sedimentary environments, silica-rich water plays a pivotal role in the silicification of wood. Groundwater, often saturated with dissolved silica from volcanic rocks or silicate minerals, permeates buried wood. Over time, the silica precipitates out of the water, replacing the organic cell walls of the wood with microscopic quartz crystals. This replacement occurs at a glacial pace, typically spanning centuries to millennia, depending on factors such as temperature, pH, and the concentration of silica in the water. For instance, wood buried in geothermal areas with high silica concentrations may silicify faster than that in cooler, less mineralized environments.

The process begins with the infiltration of silica-rich water into the wood’s cellular structure. As the silica precipitates, it replicates the wood’s original texture, including growth rings and even cellular details. This preservation is so precise that paleontologists and geologists often study silicified wood to understand ancient ecosystems. However, achieving this level of detail requires specific conditions: the wood must be buried quickly to prevent decay, and the surrounding environment must remain stable over long periods. Practical tips for identifying silicified wood include looking for a glass-like luster and tapping it to produce a high-pitched ring, characteristic of its quartz composition.

Comparatively, silicification contrasts with other fossilization processes like carbonization or permineralization. While carbonization leaves behind thin carbon films and permineralization fills voids with minerals, silicification replaces the organic material entirely with silica, preserving three-dimensional structures. This uniqueness makes silicified wood invaluable for scientific study. For enthusiasts or collectors, silicified wood can be found in regions with a history of volcanic activity or silica-rich sedimentary basins, such as the Yellowstone area in the U.S. or the Petrified Forest in Arizona.

In conclusion, the natural silicification of wood is a testament to the Earth’s ability to transform organic matter into enduring mineral forms. Occurring over centuries to millennia, this process requires specific sedimentary environments and silica-rich water to preserve wood’s intricate details. By understanding the conditions and timeline of silicification, we gain not only scientific insights but also a deeper appreciation for the geological processes that shape our planet. Whether for research or personal interest, exploring silicified wood offers a tangible connection to Earth’s ancient past.

Alaskan Wood Frogs: Survival Secrets of Their Frozen Hibernation

You may want to see also

Explore related products

Artificial Silicification Methods: Accelerated processes using heat, chemicals, or pressure to convert wood to silica

Under natural conditions, wood silicification takes millennia, relying on geological processes to replace organic matter with silica. However, artificial silicification methods offer a shortcut, leveraging heat, chemicals, or pressure to accelerate this transformation. These techniques are not only faster but also allow for greater control over the material’s properties, making them valuable in fields like biomimetic materials, preservation, and engineering. By mimicking nature’s processes in a lab setting, researchers can produce silica-wood composites in weeks or months rather than centuries.

One of the most effective artificial silicification methods involves the use of chemical solutions, particularly sodium silicate (Na₂SiO₃) combined with acid catalysts. In this process, wood is first treated with a sodium silicate solution, allowing the silica to penetrate the cellular structure. Subsequent immersion in an acid bath, such as acetic acid (CH₃COOH) at a concentration of 5–10%, triggers gelation, converting the silicate into a solid silica matrix. Temperature control is critical; maintaining the solution at 60–80°C enhances diffusion without causing thermal degradation. This method preserves the wood’s original texture while imbuing it with silica’s durability and heat resistance.

Heat and pressure can also be employed to expedite silicification, though they require precise calibration to avoid damaging the wood’s structure. Autoclave treatment at 150–200°C and 10–20 bar pressure, combined with a silica precursor like tetraethyl orthosilicate (TEOS), can achieve near-complete silicification in 24–48 hours. This high-pressure approach forces silica into the wood’s micropores, ensuring uniform distribution. However, caution must be exercised to prevent charring or collapse of the wood’s cellular framework, as excessive heat or pressure can lead to irreversible damage.

Comparatively, chemical methods offer greater control over the silica’s properties, while heat and pressure techniques prioritize speed. For instance, adjusting the pH or concentration of the silicate solution can tailor the silica’s density or porosity, making it suitable for specific applications like insulation or filtration. In contrast, pressure-based methods are ideal for large-scale production, where rapid turnaround is more critical than fine-tuning material characteristics. Both approaches, however, underscore the versatility of artificial silicification in transforming wood into a high-performance material.

Practical implementation of these methods requires careful planning and safety measures. When handling sodium silicate or acids, protective gear, including gloves and goggles, is essential to prevent skin and eye irritation. Additionally, ensuring proper ventilation during autoclave operations mitigates the risk of inhaling volatile compounds. For hobbyists or small-scale experiments, starting with low-cost materials like balsa wood and commercially available silica precursors can provide a hands-on understanding of the process without significant investment. With the right tools and precautions, artificial silicification opens up exciting possibilities for creating advanced materials from one of nature’s most abundant resources.

Mastering Wood Glue Clamping: Optimal Time for Strong, Durable Joints

You may want to see also

Explore related products

Role of Microorganisms: Bacteria and fungi can mediate silica precipitation in wood structures over time

Wood's transformation into silica is a fascinating process, but it's not a simple, linear journey. One of the key players in this metamorphosis is the microscopic world of bacteria and fungi. These microorganisms, often overlooked, hold the power to accelerate and mediate silica precipitation within wood structures, effectively turning organic matter into mineral over time.

The Microbial Mechanism

Bacteria and fungi secrete organic acids and enzymes as part of their metabolic processes. These secretions can dissolve silica-containing minerals present in the surrounding environment, such as soil or water. The dissolved silica (SiO2) is then transported into the wood's cellular structure, where it precipitates, forming solid silica deposits. This process, known as biomineralization, is a natural phenomenon that has been observed in various environments, from deep-sea hydrothermal vents to terrestrial ecosystems. For instance, certain species of bacteria, like *Bacillus* and *Pseudomonas*, have been identified as efficient silica-precipitating agents, capable of inducing silica formation within wood tissues.

Accelerating the Transformation

The presence of microorganisms can significantly shorten the time required for wood to turn into silica. In natural settings, this process might take thousands of years, but under the right conditions, bacteria and fungi can expedite it. Laboratory experiments have demonstrated that silica precipitation in wood can occur within weeks to months when exposed to specific microbial communities. A study published in the *Journal of Geophysical Research: Biogeosciences* (2018) found that wood samples inoculated with a consortium of silica-precipitating bacteria showed substantial silica deposition after just 12 weeks. This highlights the potential for microbial intervention to accelerate the preservation and fossilization of wood.

Practical Applications and Considerations

Understanding the role of microorganisms in silica precipitation has practical implications for various fields. In archaeology and paleontology, this knowledge can aid in interpreting fossilized wood remains and estimating their age. For instance, the presence of specific microbial signatures within silica-rich wood fossils could provide insights into ancient environments and the microorganisms that inhabited them. Moreover, in materials science, harnessing microbial silica precipitation could lead to innovative methods for wood preservation and the development of bio-inspired composite materials. However, it's crucial to consider the potential environmental impact of introducing silica-precipitating microorganisms into ecosystems, as this could have unforeseen consequences on natural processes and biodiversity.

A Delicate Balance

The relationship between microorganisms and silica precipitation in wood is a delicate balance of biology and geology. While bacteria and fungi can mediate this transformation, the process is influenced by numerous factors, including pH, temperature, and the availability of silica. For optimal silica precipitation, a slightly acidic environment (pH 6-7) and temperatures between 20-30°C are generally favorable. Additionally, ensuring a sufficient supply of dissolved silica is crucial, as it directly impacts the rate and extent of precipitation. This intricate interplay between microorganisms and their environment underscores the complexity of natural processes and the challenges in replicating them for practical applications.

Crafting Wood Molds: Understanding the Time Investment Required

You may want to see also

Explore related products

Examples of Silicified Wood: Fossilized wood like petrified wood showcases complete silica transformation over millions of years

Wood's transformation into silica is a geological marvel, exemplified by petrified wood, a fossilized remnant of ancient forests. This process, known as silicification, occurs when wood is buried under sediment and groundwater rich in dissolved silica. Over millions of years, the organic material is gradually replaced by silica, preserving the wood's cellular structure in stunning detail. Petrified wood, found in places like Arizona's Petrified Forest National Park, showcases this transformation, with vibrant hues of red, yellow, and brown resulting from trace minerals like iron and manganese. Each piece tells a story of time, pressure, and chemistry, offering a tangible link to Earth's distant past.

To understand the timeline of silicification, consider the conditions required. The process begins when wood is rapidly buried, shielding it from decay. Groundwater then permeates the wood, depositing silica into its cellular cavities. This replacement occurs at a glacial pace, with estimates ranging from tens of thousands to millions of years. For instance, the petrified wood in Argentina’s Patagonia region is believed to be over 65 million years old, a testament to the endurance of this transformation. Practical observation of this process is impossible in a human lifespan, but studying existing specimens provides invaluable insights into the mechanisms at play.

One striking example of silicified wood is the Araucarioxylon arizonicum, a species prevalent in the Petrified Forest. Its preservation is so precise that scientists can identify its original tree rings and cellular structures. This level of detail is rare in fossilization, making silicified wood a prized subject for paleontologists and geologists. To observe this phenomenon firsthand, visit locations like the Lesbos Petrified Forest in Greece or the Huanglong Scenic Area in China, where silicified wood is displayed in situ. These sites offer a unique opportunity to witness the intersection of biology and geology.

For enthusiasts and collectors, identifying genuine petrified wood requires careful examination. Authentic pieces will exhibit a crystalline structure when cut or polished, with a weight significantly greater than ordinary wood. Avoid specimens with unnatural colors or uniformity, as these may be artificially treated. When handling petrified wood, remember that it is a fragile record of Earth’s history, deserving of respect and preservation. Whether for scientific study or aesthetic appreciation, silicified wood serves as a powerful reminder of nature’s patience and artistry.

Wood Deck Wet Sanding: Optimal Timing for Smooth, Refinished Surfaces

You may want to see also

Frequently asked questions

No, wood cannot naturally turn into silica. Silica formation typically requires inorganic processes involving minerals and geological conditions, not organic materials like wood.

Wood does not transform into silica under any natural or artificial conditions. Silica formation is unrelated to the decomposition or transformation of wood.

There are no known processes, natural or artificial, that can convert wood into silica. Silica is derived from silicon dioxide, which is not present in wood in a form that can be transformed.

No, wood does not play a role in silica formation. Silica forms through geological processes involving minerals, water, and heat, independent of organic materials like wood.