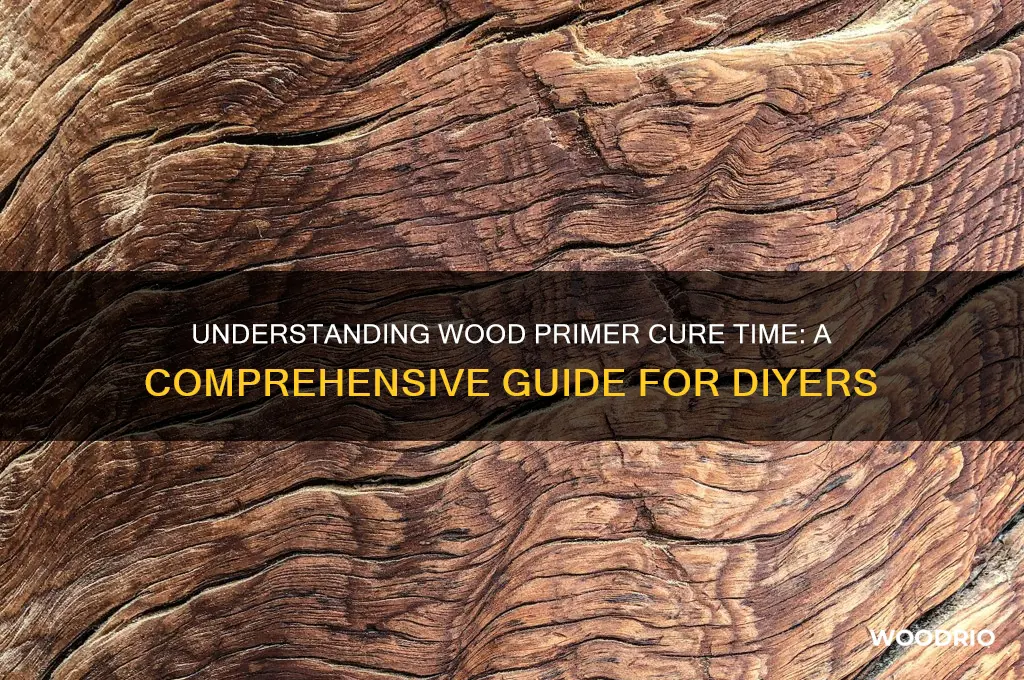

When preparing wood surfaces for painting or staining, applying a wood primer is a crucial step to ensure proper adhesion and durability of the finish. One common question that arises during this process is how long the cure time for wood primer is, as it directly impacts the timeline of the project. The cure time for wood primer can vary depending on factors such as the type of primer used, humidity levels, temperature, and ventilation. Generally, oil-based wood primers may take anywhere from 24 to 48 hours to cure, while water-based or latex primers typically cure within 1 to 4 hours, though it's recommended to wait at least 2 hours before applying subsequent coats or the final finish. Always refer to the manufacturer's instructions for specific guidance on cure times and optimal conditions for the best results.

Explore related products

$59.99

What You'll Learn

- Primer Type Influence: Oil-based primers cure slower than water-based, affecting overall drying time significantly

- Humidity Impact: High humidity prolongs cure time, while low humidity speeds up the drying process

- Temperature Effects: Warmer temperatures accelerate curing, colder temperatures slow it down considerably

- Wood Porosity: Dense wood takes longer to absorb primer, extending the cure time needed

- Coat Thickness: Thicker primer coats require more time to cure fully compared to thin layers

Primer Type Influence: Oil-based primers cure slower than water-based, affecting overall drying time significantly

The curing time of wood primer is a critical factor in any painting project, and the type of primer you choose plays a pivotal role in this process. Oil-based primers, known for their durability and stain-blocking properties, typically require a longer curing period compared to their water-based counterparts. This extended curing time is a result of the primer's chemical composition and the way it interacts with the wood surface.

Understanding the Curing Process:

Oil-based primers undergo a chemical reaction as they dry, forming a hard, protective film. This process is slower due to the evaporation of solvents and the oxidation of oils, which can take several hours to days. For instance, a common oil-based wood primer might recommend a minimum of 4 hours for touch dry and up to 24 hours for a full cure before applying the topcoat. In contrast, water-based primers dry through evaporation, a faster process that often allows for a second coat within 2-4 hours and a full cure within 24 hours.

Practical Implications:

The choice between oil and water-based primers should consider the project's timeline and environmental conditions. Oil-based primers are ideal for projects where a robust, long-lasting finish is required, such as exterior woodwork or high-moisture areas. However, the longer curing time means planning ahead to avoid rushing the process, which can compromise the primer's effectiveness. For quick turnarounds or interior projects with less exposure to elements, water-based primers offer a faster solution without sacrificing quality.

Tips for Optimal Results:

- Surface Preparation: Ensure the wood is clean, dry, and smooth before priming. Sanding and removing any dust or debris will promote better adhesion and a more even cure.

- Environmental Control: Curing times can be influenced by temperature and humidity. Oil-based primers may cure slower in cold or humid conditions, so consider using a space heater or dehumidifier to create an optimal environment.

- Application Technique: Apply primers in thin, even coats to prevent dripping and promote faster drying. Use high-quality brushes or rollers suitable for the primer type to ensure a smooth finish.

Comparative Analysis:

The difference in curing times between oil and water-based primers highlights the importance of matching the primer to the project's specific needs. While oil-based primers offer superior protection and are ideal for challenging environments, their longer curing time requires careful planning. Water-based primers, with their quicker drying times, are more versatile and user-friendly, making them a popular choice for DIY enthusiasts and professionals alike. Understanding these characteristics ensures that the chosen primer not only prepares the wood surface effectively but also aligns with the project's timeline and requirements.

Understanding Wood Shrinkage: Factors Affecting Drying Time and Dimensional Changes

You may want to see also

Explore related products

Humidity Impact: High humidity prolongs cure time, while low humidity speeds up the drying process

High humidity acts as a brake on the curing process of wood primer, significantly extending the time it takes for the primer to fully harden. This is because moisture in the air hinders the evaporation of solvents within the primer, a crucial step in the curing process. Imagine trying to dry a wet towel on a damp day – the excess moisture in the air slows down the drying process. Similarly, high humidity levels create an environment where the primer struggles to release its solvents, leading to a longer cure time.

In practical terms, this means that if you're priming wood in a humid environment, you'll need to factor in additional drying time. For instance, a primer that typically cures within 2-4 hours in dry conditions might take 6-8 hours or even longer in high humidity. This extended cure time is not just an inconvenience; it can impact the overall quality of your project. Rushing the process by applying subsequent coats too soon can lead to a weak bond, adhesion issues, and a less durable finish.

The opposite is true in low humidity conditions. With less moisture in the air, solvents evaporate more rapidly, accelerating the curing process. This can be advantageous when time is of the essence, allowing you to complete your project faster. However, it's crucial to monitor the primer closely to avoid over-drying, which can lead to a brittle finish.

In regions with naturally low humidity, such as desert climates, you might find that primers cure within the lower end of the recommended time frame or even slightly faster. This can be beneficial for professional painters or DIY enthusiasts working on time-sensitive projects. However, it's essential to follow the manufacturer's guidelines and not assume that faster drying always equates to a fully cured primer.

Understanding the humidity impact on cure time is crucial for achieving optimal results when priming wood. In high humidity, patience is key; allow ample time for the primer to cure fully before proceeding with the next steps. Consider using fans or dehumidifiers to improve air circulation and reduce moisture levels, especially in enclosed spaces. Conversely, in low humidity, monitor the primer closely to prevent over-drying and ensure a smooth, durable finish. By factoring in humidity levels and adjusting your approach accordingly, you can ensure a successful wood priming project, regardless of the environmental conditions.

Understanding 2x4 Wood Dimensions: Length, Uses, and Practical Tips

You may want to see also

Explore related products

$25.07

$16.63 $19.99

Temperature Effects: Warmer temperatures accelerate curing, colder temperatures slow it down considerably

Temperature plays a pivotal role in the curing process of wood primer, acting as a catalyst or inhibitor depending on its level. Warmer temperatures, typically above 70°F (21°C), significantly accelerate the chemical reactions within the primer, reducing cure times by up to 50%. For instance, a primer that might take 4 hours to dry at 75°F (24°C) could be touch-dry in just 2 hours at 85°F (29°C). This is particularly beneficial for professionals or DIY enthusiasts working on tight schedules, as it allows for faster project completion and reduced downtime between coats.

Conversely, colder temperatures below 50°F (10°C) can dramatically slow curing, often doubling or even tripling the recommended dry time. At 40°F (4°C), a primer that normally cures in 2 hours might take 6 hours or more. This delay is due to the sluggish chemical reactions in cooler conditions, which hinder the evaporation of solvents and the cross-linking of polymers. For outdoor projects or garage workshops in colder climates, this means planning ahead is essential—applying primer during the warmest part of the day or using space heaters (with proper ventilation) can mitigate delays.

The ideal temperature range for most wood primers falls between 60°F and 85°F (15°C to 29°C), where curing is both efficient and predictable. Within this range, manufacturers’ recommended cure times are most accurate, ensuring proper adhesion and durability. For example, a high-quality oil-based primer might cure to a hard, recoatable finish in 2–4 hours at 70°F (21°C), while a water-based primer could be ready in as little as 1 hour under the same conditions. Always check the product label for specific temperature guidelines, as some primers may have narrower optimal ranges.

Practical tips for managing temperature effects include monitoring humidity levels, as high humidity can exacerbate slow curing in cold conditions. In warmer environments, ensure adequate ventilation to prevent solvent buildup, which can lead to bubbling or uneven drying. For cold-weather applications, consider using primers formulated for low-temperature performance, which contain additives to enhance curing at lower temperatures. Finally, avoid applying primer in direct sunlight or extreme heat, as this can cause rapid surface drying while the underlying layers remain wet, leading to poor adhesion and cracking.

In summary, understanding temperature’s impact on wood primer curing allows for better planning and execution of projects. By working within optimal temperature ranges and adjusting techniques for warmer or colder conditions, you can achieve professional results regardless of the climate. Always prioritize the manufacturer’s guidelines and adapt your approach to ensure the primer cures properly, as this is critical for the long-term performance and appearance of the finished wood surface.

Minwax Wood Putty Drying Time: A Comprehensive Guide for Woodworkers

You may want to see also

Explore related products

Wood Porosity: Dense wood takes longer to absorb primer, extending the cure time needed

Dense woods like maple or oak present a unique challenge when it comes to priming. Their tight grain structure resists primer absorption, effectively slowing down the curing process. Imagine pouring water on a sponge versus a block of wood—the sponge soaks it up instantly, while the wood takes its time. This analogy illustrates why dense woods require extended cure times; the primer needs more time to penetrate the surface and form a solid bond.

To optimize primer application on dense wood, consider these steps: first, lightly sand the surface to create micro-abrasions, enhancing primer adhesion. Second, apply thin, even coats rather than a single thick layer, which can lead to uneven drying and prolonged cure times. Third, ensure proper ventilation and maintain a consistent temperature (ideally 70–80°F) to facilitate even curing. For example, a dense oak surface might require 4–6 hours between coats, compared to 2–3 hours for softer pine.

The science behind this lies in the wood’s cellular structure. Dense woods have fewer air pockets, reducing the primer’s ability to permeate quickly. This slower absorption means the solvent in the primer evaporates at a different rate than the binder hardens, potentially weakening the finish if rushed. Manufacturers often recommend waiting 24–48 hours before sanding or applying a topcoat on dense woods, ensuring the primer fully cures for maximum durability.

Practical tip: Test a small, inconspicuous area to gauge cure time. If the primer remains tacky after the recommended drying period, allow additional time. Rushing this step can result in peeling or poor adhesion, undermining the entire project. Patience is key when working with dense woods—think of it as an investment in longevity rather than a delay.

In comparison, softwoods like pine or cedar absorb primer more readily due to their open grain, often curing within 2–4 hours between coats. This contrast highlights the importance of understanding wood porosity. By tailoring your approach to the wood type, you ensure a professional finish that stands the test of time. Always refer to the primer manufacturer’s guidelines, but remember: dense woods demand extra time and attention.

Wood Glue Paper Mache Drying Time: A Comprehensive Guide

You may want to see also

Explore related products

Coat Thickness: Thicker primer coats require more time to cure fully compared to thin layers

The thickness of your wood primer coat directly impacts curing time. A thin, even layer allows solvent evaporation and moisture release to occur more rapidly, leading to faster curing. Conversely, thicker coats trap solvents and moisture, slowing down the process. This principle applies to both oil-based and latex primers, though oil-based primers generally require longer curing times regardless of thickness.

Imagine a sponge soaked in water. A thin layer of sponge will dry faster than a thick one because the water has less material to penetrate. The same concept applies to primer on wood.

For optimal results, aim for a primer coat thickness of approximately 2-3 mils (thousandths of an inch). This can be achieved with a high-quality brush or roller, ensuring even coverage without excessive buildup. Thicker coats, exceeding 4 mils, can significantly extend curing time, potentially doubling or tripling the recommended timeframe.

For example, a primer with a stated curing time of 2 hours for a thin coat might require 4-6 hours or more for a thick coat to fully cure.

Several factors influence the impact of coat thickness on curing time. Humidity levels play a crucial role, with higher humidity slowing down solvent evaporation. Temperature also affects curing, with warmer temperatures generally accelerating the process. Proper ventilation is essential, as it facilitates solvent release and promotes faster drying.

To ensure proper curing and adhesion, always follow the manufacturer's instructions regarding recommended coat thickness and drying times. If in doubt, err on the side of thinner coats, allowing each layer to dry completely before applying the next. This patient approach will ultimately lead to a more durable and long-lasting finish.

Aging Martin Top Wood: Understanding the Timeframe for Optimal Tone

You may want to see also

Frequently asked questions

The cure time for wood primer typically ranges from 2 to 4 hours for drying to the touch, but full cure can take 24 to 48 hours, depending on the product and environmental conditions.

Yes, high humidity and low temperatures can significantly extend cure time, while warm, dry conditions can speed it up. Always check the manufacturer’s instructions for specific recommendations.

No, applying a second coat before the first is fully cured can lead to bubbling, peeling, or improper adhesion. Wait the recommended time (usually 2-4 hours) before applying additional coats.