Seasoning milled wood is a crucial process that involves reducing its moisture content to an optimal level for use in construction, furniture making, or other applications. The time it takes for milled wood to season depends on several factors, including the wood species, initial moisture content, thickness of the wood, and the seasoning method used. Air drying, the most common method, can take anywhere from several months to a few years, with hardwoods typically requiring more time than softwoods. Kiln drying, a faster alternative, can season wood in a matter of days to weeks, depending on the kiln's settings and the wood's characteristics. Properly seasoned wood ensures stability, durability, and resistance to warping or cracking, making the seasoning process a vital step in woodworking.

| Characteristics | Values |

|---|---|

| Time to Season Milled Wood | 6 months to 2 years (varies based on species, thickness, and climate) |

| Factors Affecting Drying Time | Wood species, thickness, moisture content, humidity, temperature |

| Softwood Drying Time | Typically 6–12 months |

| Hardwood Drying Time | Typically 1–2 years |

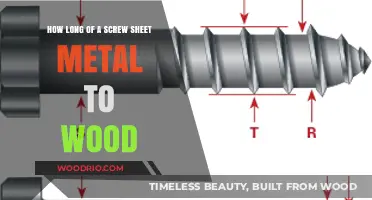

| Thickness Impact | Thicker boards take longer to season than thinner ones |

| Air Drying vs. Kiln Drying | Air drying: 6–24 months; Kiln drying: 1–4 weeks |

| Optimal Moisture Content | 6–12% for indoor use; 12–15% for outdoor use |

| Climate Influence | Warmer, drier climates speed up seasoning; humid climates slow it down |

| Storage Conditions | Stacked with stickers, under cover, good airflow |

| Signs of Properly Seasoned Wood | Stable weight, no cracks, dull surface, easy to work with |

Explore related products

What You'll Learn

- Factors Affecting Drying Time: Moisture content, wood type, and environment impact seasoning duration significantly

- Air Drying vs. Kiln Drying: Air drying takes months; kiln drying speeds up the process to weeks

- Optimal Moisture Levels: Wood is seasoned when moisture content drops below 12-15%

- Seasoning Time by Wood Type: Hardwoods take 1-2 years; softwoods season in 6-12 months

- Signs of Properly Seasoned Wood: Lightweight, dull color, and cracks indicate well-seasoned wood

Factors Affecting Drying Time: Moisture content, wood type, and environment impact seasoning duration significantly

The initial moisture content of wood is a critical determinant of how long it will take to season. Freshly cut timber, known as green wood, can contain up to 100% moisture content relative to its dry weight. For example, oak typically starts at 60-80% moisture content, while pine can be even higher. The rule of thumb is that wood loses moisture at a rate of about 4-8% per year under ideal conditions. Therefore, a piece of oak with 60% moisture content could take 7.5 to 15 years to air-dry naturally. Kiln-drying accelerates this process, reducing seasoning time to weeks by controlling temperature and humidity, but it requires precise monitoring to avoid warping or cracking.

Wood type plays a pivotal role in seasoning duration due to variations in density, grain structure, and natural oils. Hardwoods like maple and walnut are denser and take longer to dry than softwoods like cedar or fir. For instance, maple can take 1-2 years per inch of thickness to air-dry, while cedar may only require 6-12 months. Additionally, woods with high resin content, such as cedar, dry more quickly due to their natural resistance to moisture absorption. Understanding these differences allows woodworkers to plan projects effectively, ensuring the wood is stable and ready for use without risking shrinkage or distortion.

Environmental conditions are the wildcard in the seasoning process, influencing both the speed and quality of drying. Humidity levels below 60% and temperatures between 60-90°F (15-32°C) are ideal for air-drying. Storing wood in a well-ventilated area with consistent airflow is essential; stacking boards with spacers allows air to circulate, preventing mold and uneven drying. In regions with high humidity or frequent rainfall, kiln-drying or using a dehumidifier becomes necessary. For outdoor seasoning, covering the wood with a waterproof tarp while leaving the sides exposed can protect it from rain while still allowing moisture to escape.

Practical tips can significantly reduce seasoning time and improve outcomes. For air-drying, cut wood to its intended thickness before seasoning, as thicker pieces take exponentially longer to dry. Seal the ends of logs or boards with a commercial end-grain sealer or latex paint to minimize moisture loss from these areas, which dry 10-20 times faster than the sides. Regularly inspect wood for cracks or warping, especially during the first few months. If using a kiln, maintain a gradual temperature increase—no more than 10°F (5°C) per hour—to avoid internal stress. Combining these strategies ensures wood seasons efficiently, retaining its structural integrity for long-term use.

Jordyn Woods' Dating Timeline: How Long Has She Been Coupled Up?

You may want to see also

Explore related products

Air Drying vs. Kiln Drying: Air drying takes months; kiln drying speeds up the process to weeks

Milled wood requires seasoning to reduce moisture content, ensuring stability and durability in construction or craftsmanship. The time this process takes hinges largely on the method chosen: air drying or kiln drying. Air drying, the traditional approach, relies on natural conditions—sunlight, wind, and temperature fluctuations—to evaporate moisture. This method can take anywhere from 6 months to 2 years, depending on wood species, thickness, and climate. For instance, softwoods like pine may dry in 6–12 months, while hardwoods like oak can take up to 24 months. Air drying is cost-effective and environmentally friendly but demands patience and space.

Kiln drying, on the other hand, accelerates seasoning by placing wood in a controlled environment where temperature and humidity are precisely regulated. This method reduces drying time to 2–6 weeks, making it ideal for commercial operations or projects with tight deadlines. Kiln drying also minimizes the risk of warping, splitting, or insect infestation, as the process can be tailored to the wood’s specific needs. However, it requires specialized equipment and consumes energy, increasing costs. For example, a kiln can dry 1-inch thick hardwood boards in 3–4 weeks, compared to 12–18 months for air drying.

Choosing between the two methods depends on project requirements and resources. Air drying suits hobbyists, small-scale builders, or those prioritizing sustainability, while kiln drying is better for large-scale production or time-sensitive projects. A practical tip: if air drying, stack wood with stickers (spacers) between layers to promote airflow, and cover the pile to protect it from rain while allowing ventilation. For kiln drying, monitor moisture levels regularly using a moisture meter to avoid over-drying, which can weaken the wood.

In summary, air drying offers affordability and eco-friendliness but demands time, while kiln drying provides speed and precision at a higher cost. Understanding these trade-offs ensures the right choice for your wood seasoning needs.

Measuring Wood Length: Understanding Standard Sizes and Custom Cuts

You may want to see also

Explore related products

Optimal Moisture Levels: Wood is seasoned when moisture content drops below 12-15%

Wood seasoning is a delicate balance, and the key to unlocking its structural stability lies in achieving the right moisture content. The magic number? Below 12-15%. At this threshold, wood transitions from a pliable, dimensionally unstable material to a robust, reliable resource for construction, furniture, and craftsmanship. Exceeding this range invites warping, cracking, and decay, while falling short can lead to brittleness and reduced workability.

To measure moisture content accurately, invest in a reliable moisture meter. These tools provide instant readings, allowing you to monitor progress during seasoning. For milled wood, aim for a target moisture content that matches your local climate’s equilibrium moisture content (EMC), typically 9-12% in most regions. This ensures the wood neither absorbs excess moisture nor dries excessively once in use.

Seasoning time varies based on wood species, thickness, and environmental conditions. Softwoods like pine may reach optimal levels in 6-12 months, while denser hardwoods such as oak can take 1-2 years. Stack milled wood stickers (spacers) to promote airflow, and store it in a covered, well-ventilated area. Accelerate drying by splitting larger pieces or using a kiln, but beware: rapid drying can cause internal stresses.

Practical tip: Seal the ends of milled wood with a moisture-resistant sealant to prevent rapid end-grain drying, which contributes disproportionately to moisture loss and can lead to splits. Regularly rotate and inspect the stack to ensure even drying. Patience is paramount—rushing the process risks compromising the wood’s integrity.

In conclusion, achieving moisture levels below 12-15% is the cornerstone of successful wood seasoning. By combining precise measurement, strategic stacking, and environmental awareness, you can transform raw milled wood into a durable, high-quality material ready for any project.

The Enduring Legacy of Wood Framing: A Historical Perspective

You may want to see also

Explore related products

Seasoning Time by Wood Type: Hardwoods take 1-2 years; softwoods season in 6-12 months

The density of wood directly influences its seasoning time, with hardwoods and softwoods exhibiting distinct timelines. Hardwoods, such as oak, maple, and walnut, possess a tighter grain structure and higher moisture content, necessitating a longer seasoning period of 1–2 years. In contrast, softwoods like pine, cedar, and spruce have a looser grain and lower moisture content, allowing them to season more rapidly, typically within 6–12 months. This disparity underscores the importance of understanding wood type when planning projects that require properly seasoned lumber.

For those seeking to expedite the seasoning process, softwoods present a practical advantage. A homeowner planning to build a raised garden bed, for instance, might opt for cedar due to its natural resistance to rot and relatively quick seasoning time. By selecting a softwood, they can ensure the wood is ready for use within a single growing season, minimizing delays in their project. Conversely, a furniture maker crafting a dining table from hardwood would need to account for the extended seasoning period, potentially sourcing wood that has already been seasoned to avoid structural issues like warping or cracking.

Analyzing the seasoning process reveals that environmental factors play a crucial role, regardless of wood type. Proper stacking, adequate airflow, and protection from direct moisture are essential for both hardwoods and softwoods. For example, hardwoods should be stacked with stickers (spacers) between layers to promote even drying, while softwoods benefit from being stored in a well-ventilated, covered area to prevent rapid moisture loss that could lead to splitting. These practices ensure that the wood reaches its optimal moisture content (typically 12–15% for indoor use) within the expected timeframe.

A comparative perspective highlights the trade-offs between hardwoods and softwoods in seasoning. While softwoods season faster, they are generally less durable and more prone to dents and scratches, making them less ideal for high-traffic applications. Hardwoods, despite their longer seasoning time, offer superior strength and longevity, justifying the wait for projects requiring resilience and aesthetic appeal. For instance, a hardwood like cherry would be preferred for cabinetry, whereas a softwood like spruce might suffice for framing in a low-stress environment.

Instructively, woodworkers and DIY enthusiasts can use moisture meters to monitor the seasoning progress of both hardwoods and softwoods. For hardwoods, aim for a moisture content below 12% for indoor projects, while softwoods should stabilize around 15% for optimal performance. Regularly checking the moisture levels and adjusting storage conditions accordingly can help prevent issues like mold growth or uneven drying. By tailoring the approach to the specific wood type, craftsmen can ensure the material is ready for use at the right time, balancing efficiency with quality.

Off! Deep Woods Tick Protection Duration: How Long Does It Last?

You may want to see also

Explore related products

Signs of Properly Seasoned Wood: Lightweight, dull color, and cracks indicate well-seasoned wood

Wood seasoning is a patient art, and recognizing when it’s done right can save you from warped projects or inefficient fires. One of the most immediate signs of properly seasoned wood is its weight. Freshly cut wood, or "green" wood, is heavy with moisture, often weighing up to 50% more than its dry counterpart. As it seasons, the wood releases this moisture, becoming noticeably lighter. For example, a hardwood like oak, which typically weighs around 70 pounds per cubic foot when green, will drop to about 40 pounds per cubic foot when fully seasoned. If you can easily lift a log that once felt cumbersome, it’s a strong indicator that the seasoning process is complete.

Color is another telltale sign, though it’s subtler and varies by species. Freshly milled wood often has a vibrant, almost wet appearance, with rich hues that seem to glow. As it dries, the color dulls, shifting toward a more muted, matte tone. For instance, maple transitions from a creamy white to a softer, almost grayish shade, while cherry wood loses its deep red vibrancy and takes on a more subdued, brownish hue. This change isn’t just aesthetic—it’s a visual cue that the wood’s moisture content is decreasing, a key step in the seasoning process.

Cracks, often viewed as flaws, are actually a sign of progress in wood seasoning. As moisture escapes, the wood shrinks, and fine cracks, known as checks, may appear on the surface or ends of the logs. These cracks are most prominent in hardwoods like hickory or ash, which tend to dry unevenly. While severe cracking can indicate overly rapid drying, small, hairline fractures are normal and even desirable. They show that the wood is releasing moisture evenly, a critical factor in preventing warping or splitting in finished projects.

To test for seasoning, consider the wood’s intended use. For firewood, a moisture content below 20% is ideal—you can verify this with a moisture meter, aiming for a reading between 15% and 20%. For woodworking, the target is often lower, around 8% to 12%, depending on the climate. A simple trick is the "knock test": well-seasoned wood produces a sharp, clear sound when struck, while green wood sounds dull and thudding. Pair this with the visual and weight cues, and you’ll confidently identify wood that’s ready for use.

Finally, remember that seasoning time varies widely—softwoods like pine may dry in 6 to 12 months, while dense hardwoods like teak can take 2 to 3 years. Stack wood off the ground, allow airflow between pieces, and protect it from rain to expedite the process. By recognizing the signs of lightweight, dull color, and controlled cracking, you’ll ensure your wood is not just dry, but properly seasoned for its purpose.

Wood Shrimp Lifespan: Understanding Their Survival in Captivity and the Wild

You may want to see also

Frequently asked questions

Milled wood typically takes 6 to 12 months to season, depending on factors like wood species, thickness, humidity, and airflow.

Yes, denser hardwoods like oak or maple take longer to season (12+ months), while softer woods like pine season faster (6-9 months).

Yes, milled wood can be seasoned indoors, but it may take slightly longer (8-14 months) due to controlled humidity and temperature conditions.

Yes, thicker pieces of milled wood take longer to season (up to 18 months for 2+ inches), while thinner pieces (under 1 inch) may season in 3-6 months.

Stack milled wood with spacers for airflow, store it in a dry, well-ventilated area, and use a moisture meter to monitor progress, potentially reducing seasoning time by 20-30%.