Curing a candle with a wooden wick is a crucial step often overlooked by many candle enthusiasts. The curing process allows the fragrance oils to fully bind with the wax, ensuring a stronger and more consistent scent throw when the candle is burned. For candles with wooden wicks, the curing time can vary depending on factors such as the type of wax used, the fragrance oil concentration, and the desired scent intensity. Generally, it is recommended to let these candles cure for at least 2 weeks, though some artisans suggest extending this period to 4 weeks for optimal results. Proper curing not only enhances the aromatic experience but also improves the overall performance of the wooden wick, ensuring a clean and even burn.

| Characteristics | Values |

|---|---|

| Curing Time for Wooden Wick Candles | 1-2 weeks (minimum) for optimal performance and scent throw |

| Purpose of Curing | Allows wax and fragrance to fully bind, ensuring even burn and scent |

| Factors Affecting Curing Time | Type of wax, fragrance load, room temperature, humidity |

| Signs of Proper Curing | Hard, smooth surface; no wet spots; strong cold throw (scent when unlit) |

| Consequences of Insufficient Curing | Poor scent throw, tunneling, uneven burn, or wick issues |

| Storage During Curing | Cool, dry place away from direct sunlight or heat sources |

| Testing After Curing | Burn for 1-2 hours to ensure proper wick performance and scent release |

| Longer Curing Benefits | Enhanced scent throw and improved burn quality (up to 4 weeks) |

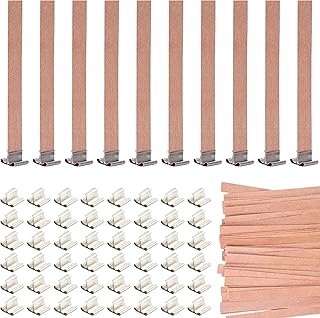

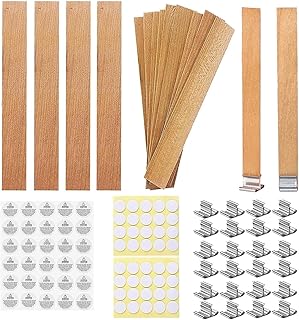

Explore related products

What You'll Learn

- Ideal Curing Time: 24-48 hours for optimal scent throw and burn performance

- Factors Affecting Curing: Wax type, fragrance oil, and room temperature influence curing duration

- Signs of Proper Curing: Hardened wax, strong scent, and clean burn indicate readiness

- Wooden Wick Preparation: Ensure wick is trimmed and centered before curing begins

- Accelerating Curing Process: Warm room temperature and good air circulation speed up curing

Ideal Curing Time: 24-48 hours for optimal scent throw and burn performance

Curing a candle with a wooden wick isn’t just a waiting game—it’s a science. The ideal curing time of 24–48 hours is rooted in the chemistry of fragrance oils and wax. During this period, the scent molecules fully bind to the wax, ensuring an even and potent aroma release when burned. Skipping or shortening this step can result in a weak scent throw, as the fragrance remains partially trapped within the wax. Think of it as marinating meat: the longer it sits, the deeper the flavor penetrates.

To maximize burn performance, follow these steps: place the candle in a cool, dry area away from direct sunlight or drafts. Cover it loosely with a lid or cloth to retain moisture while allowing air circulation. Avoid moving or disturbing the candle during this time, as it can disrupt the curing process. For best results, use a thermometer to ensure the room temperature remains between 65°F and 75°F, as extreme temperatures can affect curing.

A common misconception is that longer curing times always yield better results. While 24–48 hours is optimal, extending beyond 48 hours offers diminishing returns. After this window, the wax and fragrance reach equilibrium, and further curing won’t enhance performance. Over-curing can even lead to surface cracking or frosting, detracting from the candle’s appearance. Balance is key—enough time to bond, but not so much that it becomes counterproductive.

Finally, consider the practical benefits of proper curing. A well-cured candle burns more evenly, reducing tunneling and extending its lifespan. The wooden wick, when paired with cured wax, crackles softly and maintains a steady flame. This not only enhances the sensory experience but also ensures safety, as a properly cured candle is less likely to produce excessive smoke or soot. Patience in curing pays off in both performance and enjoyment.

Woodpecker Tongue Length: Unbelievable Facts About Their Unique Anatomy

You may want to see also

Explore related products

Factors Affecting Curing: Wax type, fragrance oil, and room temperature influence curing duration

The curing time for a candle with a wooden wick is not a one-size-fits-all scenario. It's a delicate dance influenced by the unique characteristics of your chosen materials and environment. Let's break down the key players: wax type, fragrance oil, and room temperature.

Wax Type: Different waxes have distinct curing needs. Soy wax, known for its clean burn and eco-friendliness, typically requires a longer curing period of 1-2 weeks. This allows the fragrance to fully bind with the wax, ensuring a strong, even scent throw. Paraffin wax, on the other hand, cures more rapidly, often within 3-5 days, due to its denser molecular structure. For a unique, rustic aesthetic, consider beeswax, which may take up to 2 weeks to cure fully, but rewards you with a natural, sweet aroma and a longer burn time.

Fragrance Oil Concentration: The amount of fragrance oil you use directly impacts curing time. A general rule of thumb is to use 6-10% fragrance oil by weight of the wax. However, if you're aiming for a more subtle scent, reducing the concentration to 4-6% can shorten curing time by a couple of days. Conversely, a higher concentration, around 12%, may require an additional week of curing to prevent fragrance oil from pooling or sweating out of the wax.

Room Temperature and Humidity: Curing is a temperature-sensitive process. Ideal curing conditions range from 65-75°F (18-24°C). In cooler environments, curing may take longer, as the wax molecules move more slowly, hindering the fragrance binding process. In warmer climates, be cautious not to exceed 80°F (27°C), as this can cause the wax to soften excessively, potentially leading to sweating or cracking. Humidity levels also play a role; aim for a relative humidity of 40-60% to prevent moisture from affecting the curing process.

Practical Tips for Optimal Curing: To expedite curing, consider placing your candles in a well-ventilated area with consistent temperature and humidity. Avoid direct sunlight or drafts, which can cause uneven curing. For a more controlled environment, use a curing room or enclosure with a thermostat and humidistat. If you're short on time, a gentle warm air flow from a fan or heater can help accelerate the process, but be cautious not to overheat the wax.

The Waiting Game: While it may be tempting to light your candle immediately, patience is key. A fully cured candle not only ensures a better scent throw and burn quality but also extends the life of your wooden wick. As a general guideline, allow at least 1 week for paraffin wax, 1-2 weeks for soy wax, and up to 2 weeks for beeswax. However, always trust your senses – if the candle still emits a strong, unburned fragrance oil scent, it may require additional curing time. By understanding the interplay between wax type, fragrance oil, and room temperature, you can fine-tune your curing process, ultimately creating candles that burn brighter, smell better, and last longer.

Termite Wood Damage Timeline: How Quickly Do They Consume Wood?

You may want to see also

Explore related products

Signs of Proper Curing: Hardened wax, strong scent, and clean burn indicate readiness

A candle with a wooden wick requires a specific curing process to ensure optimal performance and longevity. The curing time can vary depending on factors such as the type of wax, fragrance load, and container size. However, a general guideline is to allow the candle to cure for at least 7-14 days before use. During this period, the wax and fragrance oils undergo a crucial transformation, leading to the development of key indicators that signal proper curing.

Observation and Analysis: As the curing process progresses, the wax will gradually harden, transforming from a soft, pliable state to a firm, rigid texture. This hardening is essential, as it ensures the wax can withstand the heat generated by the wooden wick, preventing excessive melting and potential safety hazards. A properly cured candle will exhibit a smooth, even surface, free from cracks or air pockets, indicating a uniform distribution of fragrance and wax.

Instructive Guidance: To assess the scent strength, perform a simple "sniff test" after the initial curing period. A well-cured candle will emit a robust, true-to-life fragrance, filling the surrounding area with its aroma. If the scent seems faint or muted, allow the candle to cure for an additional 2-3 days, as the fragrance oils may still be binding with the wax. For optimal results, store the curing candle in a cool, dry place, away from direct sunlight and extreme temperatures, which can disrupt the curing process.

Comparative Insight: A clean burn is another critical sign of proper curing. When lit, a well-cured candle with a wooden wick should produce a steady, even flame with minimal smoking or sooting. In contrast, an under-cured candle may exhibit a flickering, uneven flame, accompanied by excessive smoke and residue. To ensure a clean burn, trim the wooden wick to approximately 1/4 inch before each use, removing any charred or burnt material that could impede the candle's performance.

Practical Tips and Takeaways: To expedite the curing process, consider using a fan or gentle air circulation to promote even fragrance distribution and wax hardening. However, avoid excessive airflow, which can cause the wax to dry out or crack. Additionally, keep in mind that the curing time may vary depending on the specific candle formulation and environmental conditions. As a general rule, larger candles or those with higher fragrance loads may require an extended curing period of up to 21 days. By recognizing the signs of proper curing – hardened wax, strong scent, and clean burn – you can ensure your candle with a wooden wick is ready to provide a safe, enjoyable, and long-lasting experience.

Durability of Wooden Railroad Ties: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Wooden Wick Preparation: Ensure wick is trimmed and centered before curing begins

Trimming and centering a wooden wick before curing is a critical step often overlooked in candle making. Unlike cotton wicks, wooden wicks require precise preparation to ensure optimal burn performance. A wick that’s too long can cause excessive smoke or flame height, while one that’s off-center may lead to uneven wax pooling. This initial step sets the foundation for a clean, efficient burn and extends the life of the candle.

Steps for Proper Wick Preparation:

- Trim the Wick: Use sharp scissors or wick trimmers to cut the wooden wick to approximately ¼ inch (6 mm) above the wax surface. This length ensures the flame remains controlled without smoldering.

- Center the Wick: Secure the wick in place using a centering tool or adhesive dots. If using a mold, attach the wick tab to the bottom and thread the wick through a wick holder to keep it upright and centered during pouring.

- Verify Alignment: Double-check that the wick is straight and centered after pouring the wax. Gently adjust if necessary, but avoid disturbing the wax surface.

Cautions to Consider:

Avoid trimming the wick too short, as this can prevent proper flame ignition. Similarly, over-centering or forcing the wick into position can damage the wax or wick structure. Wooden wicks are more rigid than cotton, so handle them with care to maintain their integrity.

Proper wooden wick preparation is a small but impactful detail in the candle-making process. By trimming and centering the wick before curing, you ensure a safer, more consistent burn and enhance the overall quality of the finished product. This step, though simple, is a cornerstone of professional candle craftsmanship.

Engineered Wood Durability: Lifespan, Maintenance, and Longevity Explained

You may want to see also

Explore related products

Accelerating Curing Process: Warm room temperature and good air circulation speed up curing

Warm room temperatures, ideally between 70°F and 75°F (21°C and 24°C), significantly accelerate the curing process of candles with wooden wicks. At these temperatures, the wax molecules move more freely, allowing them to settle and bond more efficiently. Avoid exceeding 80°F (27°C), as excessive heat can cause the wax to sweat or separate, compromising the candle’s structure. Pair this warmth with good air circulation—think a quiet fan on low or a well-ventilated room—to ensure even curing. Stagnant air traps moisture and slows the process, while gentle airflow promotes uniform hardening.

The science behind this method lies in the balance of heat and airflow. Warmth reduces the wax’s viscosity, enabling it to release trapped air bubbles and adhere to the container more effectively. Meanwhile, air circulation prevents the formation of a humid microclimate around the candle, which can delay curing. For optimal results, place candles on a raised surface, like a wire rack, to allow air to flow beneath them. Avoid drafts or direct heat sources, as these can cause uneven curing or warping.

Practical application of this technique can cut curing time nearly in half. A standard soy or paraffin candle with a wooden wick typically requires 2–4 weeks to cure fully, but under ideal warm and airy conditions, this can be reduced to 7–10 days. Monitor the candles daily for signs of readiness: a hardened surface, even color, and a wick that stands upright without leaning. If the wick appears soft or the wax feels tacky, extend the curing period slightly, even with accelerated conditions.

One common mistake is assuming that higher temperatures will yield faster results. While warmth is beneficial, overheating can degrade the wax’s fragrance throw and texture. Similarly, overdoing airflow—such as using a high-powered fan—can introduce dust or disrupt the wick’s position. Strike a balance by maintaining consistent warmth and gentle circulation. For those in cooler climates, a space heater or seedling mat can provide controlled warmth without overheating.

Incorporating this accelerated curing method not only saves time but also enhances the candle’s performance. Properly cured candles burn cleaner, last longer, and deliver a stronger scent. For small-batch makers or hobbyists, this approach allows for quicker turnaround without sacrificing quality. Remember, curing is as crucial as the pouring process itself—it’s the final step in crafting a candle that burns beautifully and safely.

Cholla Wood Durability: Lifespan, Care, and Longevity Explained

You may want to see also

Frequently asked questions

A candle with a wooden wick should cure for at least 24 to 48 hours before its first use to allow the wax to fully stabilize and ensure optimal burn performance.

Yes, the curing time can vary depending on the wax type. Soy wax typically requires 1 to 2 weeks for full curing, while paraffin wax may cure faster, within 24 to 48 hours.

While you can use it sooner, it’s best to wait until the candle is fully cured to ensure a clean, even burn and maximize its fragrance throw.

A fully cured candle will have a consistent texture, and the fragrance will be evenly distributed. The surface may appear slightly matte or smoother, indicating it’s ready for use.