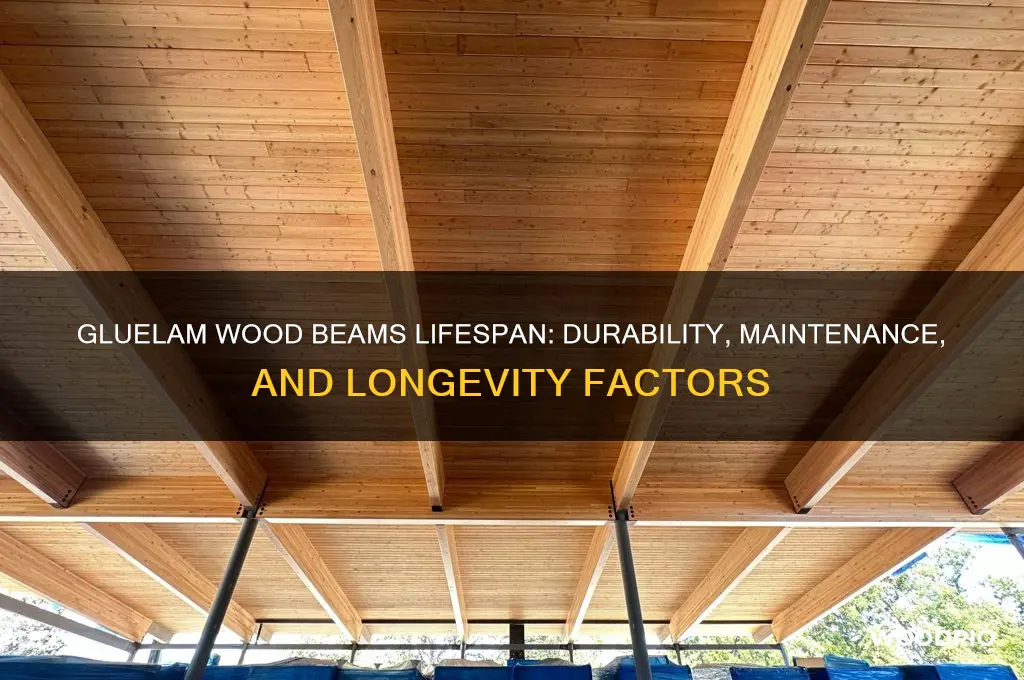

Gluelam wood beams, known for their strength, durability, and versatility, are a popular choice in construction for both residential and commercial projects. These engineered wood products are made by bonding layers of timber with adhesives, creating a material that can span long distances and support heavy loads. A common question among builders, architects, and homeowners is how long gluelam wood beams should last. The lifespan of gluelam beams depends on several factors, including the quality of the materials, the manufacturing process, environmental conditions, and proper maintenance. When installed and cared for correctly, gluelam beams can last for decades, often exceeding 50 years or more, making them a reliable and sustainable option for structural applications. Understanding the factors that influence their longevity is essential for maximizing their performance and ensuring long-term structural integrity.

| Characteristics | Values |

|---|---|

| Expected Lifespan (Indoor) | 50-100+ years (with proper maintenance and environmental conditions) |

| Expected Lifespan (Outdoor) | 20-50 years (dependent on exposure to weather, treatment, and maintenance) |

| Durability (Treated Gluelam) | Increased resistance to moisture, insects, and decay |

| Maintenance Requirements | Regular inspections, sealing, and protective coatings |

| Environmental Factors | Humidity, temperature fluctuations, and UV exposure affect longevity |

| Structural Integrity | Maintained if not subjected to excessive loads or mechanical damage |

| Resistance to Warping/Cracking | High, due to laminated layers distributing stress evenly |

| Fire Resistance | Treated gluelam can have improved fire resistance |

| Sustainability | Renewable resource with lower carbon footprint compared to steel/concrete |

| Warranty Period | Typically 10-30 years, depending on manufacturer and usage conditions |

Explore related products

What You'll Learn

Factors affecting gluelam lifespan

Gluelam beams, engineered for strength and durability, can last 50 years or more in optimal conditions. However, their lifespan hinges on several critical factors that influence their performance over time. Understanding these factors is essential for maximizing their longevity in various applications.

Environmental Exposure: The Arch-Nemesis of Gluelam

Moisture is the primary threat to gluelam’s lifespan. Prolonged exposure to humidity above 20% or direct water contact can degrade the adhesive bonds, leading to delamination or fungal growth. UV radiation, common in outdoor applications, breaks down the wood’s lignin, causing surface cracking and weakening. For instance, gluelam used in uncovered bridges or pergolas may degrade within 20–30 years without proper sealing or shading. To mitigate this, apply a high-quality, UV-resistant sealant every 3–5 years and ensure adequate drainage to prevent water pooling.

Load and Structural Design: Balancing Strength and Stress

Gluelam’s lifespan is directly tied to how well it handles applied loads. Overloading, even marginally, accelerates fatigue and can cause premature failure. For example, a beam designed for a 1.5 safety factor may fail within 15 years if subjected to loads exceeding its capacity by 20%. Always adhere to engineering specifications and conduct regular inspections for signs of stress, such as cracking or warping. Retrofitting with additional supports or reducing loads can extend lifespan significantly.

Material Quality and Manufacturing: The Foundation of Durability

The quality of raw materials and manufacturing processes determines gluelam’s baseline durability. Low-grade timber or inadequate adhesive application can reduce lifespan by up to 40%. Look for gluelam certified to standards like APA EWS or EN 14080, which ensure proper bonding and moisture resistance. For critical applications, specify phenol-formaldehyde adhesives, which offer superior moisture resistance compared to urea-formaldehyde alternatives.

Maintenance and Protective Measures: Proactive Preservation

Regular maintenance is non-negotiable for maximizing gluelam’s lifespan. Inspect beams annually for cracks, discoloration, or insect activity. Treat infestations immediately with borate-based preservatives, which penetrate wood fibers to deter pests. In high-moisture environments, consider integrating vapor barriers or using pressure-treated end seals to prevent water absorption. Proper ventilation and temperature control (ideally between 10°C and 25°C) further safeguard against degradation.

Application-Specific Considerations: Tailoring for Context

Different applications demand tailored strategies. For example, gluelam in marine environments requires copper-based preservatives to resist saltwater corrosion, while interior beams benefit from humidity control systems to maintain moisture levels below 15%. In seismic zones, incorporate flexible joints to reduce stress during movement. By aligning design, materials, and maintenance with the specific demands of the application, gluelam can consistently achieve its maximum potential lifespan.

Cedar Wood's Moth-Repelling Power: Duration and Effectiveness Explained

You may want to see also

Explore related products

Maintenance tips for longevity

Gluelam wood beams, when properly maintained, can last for decades, even centuries, rivaling the lifespan of steel or concrete in certain applications. However, their longevity hinges on proactive care that mitigates environmental stressors and structural wear. Below are targeted maintenance strategies to maximize their durability.

Moisture Management: The Non-Negotiable Priority

Wood’s arch-nemesis is moisture, which fosters rot, warping, and delamination. Gluelam beams in exterior or humid environments require a two-pronged defense: sealants and ventilation. Apply a high-quality, UV-resistant wood sealant every 3–5 years, ensuring full coverage on end grains and exposed surfaces. For beams in enclosed spaces, maintain relative humidity below 50% using dehumidifiers or proper airflow. Inspect annually for cracks or peeling sealant, addressing issues immediately to prevent water infiltration.

Structural Inspections: Early Detection Saves Lifespans

Regular inspections identify issues before they compromise integrity. Annually, examine beams for signs of insect damage (powdered wood, pinholes), fungal growth (discoloration, softness), or mechanical stress (cracks, splinters). Use a moisture meter to check for hidden dampness, targeting areas near joints or fasteners. For beams supporting heavy loads, consult a structural engineer every 5–10 years to assess deflection and load capacity, particularly in older installations or after environmental events like earthquakes.

Protective Coatings: Beyond Aesthetics

While sealants address moisture, protective coatings add layers of defense. Fire-retardant treatments are mandatory in commercial or high-risk residential settings, reducing flammability by up to 90%. For beams exposed to chemicals or abrasions, apply epoxy coatings, which provide a hard, chemical-resistant barrier. Reapply coatings according to manufacturer guidelines—typically every 5–7 years for fire retardants and 10+ years for epoxies, depending on exposure severity.

Pest Prevention: A Proactive Stance

Termites and wood-boring beetles can silently undermine gluelam’s strength. Pre-treatment with borate solutions during installation creates a toxic barrier against insects, lasting up to 30 years. For existing beams, injectable insecticides or physical barriers like stainless-steel mesh deter infestations. Quarterly visual checks for frass (insect waste) or exit holes, coupled with professional pest inspections every 2–3 years, catch problems early.

Load and Movement Considerations: Avoiding Stress Fractures

Gluelam’s engineered strength assumes consistent loading conditions. Avoid exceeding design limits by redistributing heavy equipment or storage away from beam midspans, where stress is highest. For beams in dynamic environments (e.g., bridges), install movement joints to accommodate thermal expansion, reducing the risk of cracking. Reinforce connections with galvanized hardware to prevent corrosion-induced loosening, tightening fasteners every 3–5 years during inspections.

By integrating these maintenance practices, gluelam beams can transcend their expected 50–100-year lifespan, becoming generational investments rather than temporary solutions. The key lies in treating maintenance not as reactive repairs, but as a disciplined regimen that anticipates and neutralizes threats before they escalate.

Wood Bison Endangered Status: A Historical Overview of Their Conservation

You may want to see also

Explore related products

Environmental impact on durability

The durability of gluelam wood beams is significantly influenced by environmental factors, which can either extend or shorten their lifespan. Exposure to moisture, temperature fluctuations, and UV radiation are primary culprits in accelerating degradation. For instance, prolonged moisture exposure can lead to warping, cracking, or fungal growth, while UV radiation breaks down the wood’s lignin, causing brittleness and discoloration. In regions with high humidity or frequent rainfall, gluelam beams may require additional protective measures, such as sealants or coatings, to mitigate these effects. Conversely, arid climates with low humidity can reduce the risk of moisture-related damage but may still pose challenges due to extreme temperature variations.

To combat environmental wear, proactive maintenance is essential. Regular inspections should be conducted to identify early signs of damage, such as surface cracks or mold. Applying a high-quality wood preservative every 2–3 years can significantly enhance resistance to moisture and pests. For beams exposed to direct sunlight, UV-resistant coatings or paints are recommended to minimize surface degradation. In coastal areas, where saltwater exposure is a concern, using marine-grade sealants can provide an additional layer of protection. These measures not only preserve the structural integrity of the beams but also reduce the need for costly replacements.

Comparing gluelam’s performance in different environments reveals its adaptability but also highlights its limitations. In temperate climates with moderate humidity and temperature, gluelam beams can last upwards of 50 years with proper care. However, in tropical regions with high humidity and rainfall, their lifespan may be reduced to 20–30 years without adequate protection. Similarly, in desert environments, while moisture is less of a concern, the constant stress of thermal expansion and contraction can lead to fatigue over time. Understanding these regional variations allows for better material selection and maintenance planning, ensuring optimal performance across diverse settings.

A persuasive argument for investing in environmental protection measures lies in the long-term cost savings and sustainability benefits. While initial treatments and coatings may increase upfront costs, they significantly reduce the likelihood of premature failure and the need for frequent repairs. Additionally, gluelam’s renewable nature makes it an eco-friendly choice compared to steel or concrete, but only if its durability is maximized. By prioritizing environmental resilience, builders and homeowners can contribute to both economic efficiency and environmental conservation, making gluelam a viable option for generations to come.

Wood Pigeon Egg Hatching Timeline: What to Expect and When

You may want to see also

Explore related products

Typical lifespan expectations

Gluelam wood beams, engineered for strength and durability, typically boast a lifespan of 50 to 100 years when properly installed and maintained. This longevity stems from the material’s inherent resistance to warping, cracking, and splitting, coupled with its ability to bear heavy loads. Unlike solid timber, gluelam’s layered construction minimizes defects, ensuring consistent performance over decades. However, this lifespan isn’t set in stone—environmental factors, structural demands, and maintenance practices play pivotal roles in determining how long these beams will endure.

Environmental conditions significantly influence gluelam’s durability. In dry, well-ventilated interiors, such as those found in residential or commercial buildings, gluelam beams can easily reach the upper end of their lifespan. Conversely, exposure to moisture, extreme temperatures, or pests can accelerate degradation. For instance, gluelam used in outdoor structures like bridges or canopies requires protective treatments, such as sealants or preservatives, to combat weathering. Regular inspections and proactive maintenance, including resealing every 5–10 years, can mitigate these risks and extend the beam’s service life.

Structural demands also dictate gluelam’s longevity. Beams subjected to heavy loads or dynamic stresses, such as those in industrial settings or large-span structures, may experience fatigue over time. Engineers must account for these factors during design, ensuring the beams are not only strong enough for the initial load but also resilient to long-term stress. Retrofitting or reinforcing beams in high-demand applications can further prolong their usability, though this approach is more cost-effective when planned during the initial construction phase.

Comparatively, gluelam’s lifespan stacks up favorably against other structural materials. Steel, for example, may corrode without proper coatings, while concrete can crack under tension. Gluelam’s natural flexibility and resistance to decay make it a superior choice in many applications, particularly where aesthetics and sustainability are priorities. However, it’s essential to recognize that no material is immune to time and wear—gluelam’s longevity is a testament to its engineering, not immortality.

To maximize the lifespan of gluelam wood beams, follow these practical steps: ensure proper installation by certified professionals, protect beams from moisture with high-quality sealants, and conduct annual inspections for signs of damage or wear. For outdoor applications, consider using gluelam treated with preservatives or opting for species naturally resistant to decay. By combining thoughtful design, proactive maintenance, and informed material selection, gluelam beams can serve as reliable structural elements for generations.

Wood Duck Fledglings: Water Duration and Survival Insights

You may want to see also

Explore related products

Signs of gluelam deterioration

Gluelam beams, known for their strength and durability, are engineered to last decades under optimal conditions. However, environmental factors and structural stresses can accelerate deterioration. Recognizing early signs of degradation is crucial to prevent catastrophic failure. Here’s how to identify when gluelam beams may be compromised.

Visual Cracking and Delamination: Inspect beams for longitudinal cracks or separation between laminated layers, known as delamination. These defects often stem from moisture infiltration, which weakens the adhesive bonds. Cracks wider than 1/16 inch or delamination spanning more than 5% of the beam’s length warrant immediate attention. Use a bright light source to detect hairline fractures that might otherwise go unnoticed.

Moisture-Related Discoloration: Gluelam is susceptible to fungal decay and mold growth when exposed to prolonged moisture. Look for dark streaks, greenish patches, or a bleached appearance on the wood surface. These signs indicate water intrusion, which can compromise the beam’s structural integrity. Install moisture barriers and ensure proper ventilation to mitigate this risk, especially in humid climates or below-grade installations.

Warping and Deformation: Over time, gluelam beams may warp, twist, or sag due to uneven loading or environmental stress. Measure deflection using a straightedge or laser level; beams should not deviate more than L/240 of their span length (e.g., a 20-foot beam should not sag more than 1 inch). Deformation often signals adhesive failure or excessive load, requiring reinforcement or replacement.

Pest Infestation Evidence: Termites and wood-boring beetles can infiltrate gluelam, particularly if the wood was not properly treated during manufacturing. Inspect for small exit holes, frass (sawdust-like debris), or hollow-sounding sections when tapped. Apply borate-based treatments during installation to deter pests, and conduct annual inspections in high-risk areas.

Adhesive Bond Failure: The glue lines in gluelam are its Achilles’ heel. Overheating (above 150°F) or exposure to solvents can degrade the adhesive, leading to delamination. Test bond strength by gently prying a small section with a putty knife; if layers separate easily, the adhesive has failed. In such cases, the beam must be replaced, as repairs are rarely effective.

By monitoring these signs and addressing issues promptly, you can extend the lifespan of gluelam beams, typically designed to last 50–100 years in ideal conditions. Regular maintenance and proactive measures are key to preserving their structural integrity.

Elmer's Glue on Wood: Durability and Adhesion Time Explained

You may want to see also

Frequently asked questions

Glulam wood beams, when properly installed and maintained, can last 50 to 100 years or more in typical residential applications. Their durability depends on factors like exposure to moisture, pests, and structural loads.

Yes, glulam beams last longer indoors (50–100+ years) compared to outdoor use (20–50 years), as outdoor exposure to weather, UV rays, and moisture accelerates degradation without proper treatment and maintenance.

Glulam beams can match or exceed the lifespan of steel or concrete beams when protected from environmental factors. Steel may corrode, and concrete can crack, while glulam, with proper care, maintains its structural integrity for decades.