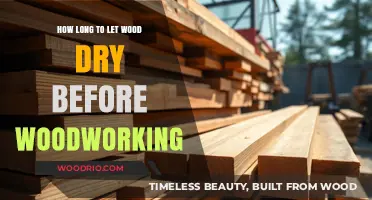

When working with balsa wood, understanding how long to let it dry is crucial for achieving optimal results in your projects. Balsa wood is naturally lightweight and porous, which makes it absorbent but also prone to warping or cracking if not dried properly. After applying glue, finishes, or exposing it to moisture, allowing sufficient drying time is essential. Typically, balsa wood requires 24 to 48 hours to dry completely in a well-ventilated, room-temperature environment, though this can vary based on humidity levels, the thickness of the wood, and the amount of moisture present. Patience during the drying process ensures the wood retains its structural integrity and is ready for further crafting or finishing.

| Characteristics | Values |

|---|---|

| Drying Time (Air Drying) | 1-3 weeks (varies based on thickness, humidity, and temperature) |

| Drying Time (Kiln Drying) | 2-5 days (controlled environment, faster than air drying) |

| Moisture Content After Drying | 8-12% (ideal for woodworking and stability) |

| Factors Affecting Drying Time | Thickness of wood, humidity levels, temperature, airflow |

| Signs of Properly Dried Balsa | Lightweight, no warping, consistent color, no damp smell |

| Recommended Humidity for Drying | 50-70% relative humidity |

| Optimal Drying Temperature | 60-80°F (15-27°C) |

| Risk of Drying Too Quickly | Cracking, warping, or splitting |

| Storage After Drying | Store in a cool, dry place away from direct sunlight |

| Rehydration Possibility | Minimal; balsa wood does not reabsorb moisture easily once fully dried |

Explore related products

What You'll Learn

Ideal drying time for balsa wood glue applications

Balsa wood, prized for its lightweight yet sturdy nature, is a favorite among model builders and hobbyists. When gluing balsa wood, the drying time isn’t just a waiting game—it’s a critical factor in the strength and durability of your project. Most wood glues, such as PVA (white glue) or cyanoacrylate (super glue), require specific conditions to cure effectively. For PVA glue, a thin application on balsa wood typically dries to the touch within 15–30 minutes, but full curing takes 24 hours. Cyanoacrylate dries almost instantly but needs 1–2 hours to reach maximum strength. Always follow the manufacturer’s guidelines, as drying times can vary based on humidity, temperature, and glue type.

The ideal drying time for balsa wood glue applications hinges on both the glue used and the project’s structural demands. For lightweight models like airplanes, where joints bear minimal stress, a 1–2 hour drying period for cyanoacrylate or 24 hours for PVA is sufficient. However, for load-bearing structures, such as bridges or heavy-duty frames, extending the drying time to 48 hours ensures maximum bond strength. Accelerating drying with heat or fans can weaken the bond, so patience is key. Clamping or using tape to hold pieces together during drying prevents misalignment and ensures a tight fit.

Humidity and temperature play a significant role in drying times. In high-humidity environments, PVA glue may take up to 48 hours to fully cure, while low humidity can cause the glue to dry too quickly, leading to a brittle bond. Ideal conditions are 65–75°F (18–24°C) with 40–60% humidity. If working in suboptimal conditions, consider using epoxy glues, which are more forgiving and cure consistently across a wider range of temperatures and humidity levels. Epoxy typically takes 4–6 hours to set and 24 hours to fully cure, making it a reliable choice for balsa wood projects in variable environments.

Practical tips can streamline the drying process and improve results. Apply glue sparingly to balsa wood, as excess moisture can warp the lightweight material. Sanding the surfaces before gluing increases adhesion by creating a rougher texture for the glue to grip. For complex assemblies, work in stages, allowing each section to dry fully before adding more pieces. Labeling drying times on your workspace can help track progress and prevent premature handling. Finally, store glues properly—uncapped bottles or tubes can dry out, leading to inconsistent drying times in future applications.

In summary, the ideal drying time for balsa wood glue applications depends on glue type, project requirements, and environmental conditions. PVA glue requires 24–48 hours for full curing, while cyanoacrylate reaches maximum strength in 1–2 hours. Epoxy offers a middle ground with a 4–6 hour set time and 24-hour cure. By understanding these factors and employing practical techniques, you can ensure strong, lasting bonds in your balsa wood projects. Patience and precision are your greatest tools in achieving professional results.

Choosing the Right Wood Screw Length for Your Project

You may want to see also

Explore related products

Factors affecting balsa wood drying speed and efficiency

Balsa wood, prized for its lightweight and workable nature, requires careful drying to maintain its structural integrity and usability. The speed and efficiency of this process hinge on several interrelated factors, each demanding attention for optimal results.

Moisture Content and Initial Wetness: The starting point matters. Freshly cut balsa, with its high moisture content (often exceeding 50%), will take significantly longer to dry than wood that has already air-dried to a moderate level. Think of it as wringing out a soaked towel versus a damp one – the former requires far more effort.

Environmental Conditions: Imagine drying clothes on a sunny day versus a humid, cloudy one. Temperature, humidity, and airflow are the drying trifecta. Higher temperatures accelerate evaporation, while low humidity allows moisture to escape more readily. Adequate airflow, whether natural or aided by fans, ensures moisture doesn't become trapped within the wood fibers.

Wood Thickness and Density: Picture a thick steak versus a thin slice – the thicker piece takes longer to cook through. Similarly, thicker balsa boards or denser sections within a piece will dry more slowly than thinner or less dense areas. This uneven drying can lead to warping or cracking if not managed carefully.

Drying Method: Air drying, kiln drying, and solar drying each have their pros and cons. Air drying is slow but gentle, kiln drying is faster but requires specialized equipment, and solar drying leverages sunlight but can be inconsistent. The chosen method directly impacts drying speed and the potential for defects.

Desired End Use: A balsa model airplane wing demands different drying characteristics than a wooden sculpture. The intended use dictates the acceptable moisture content range and, consequently, the drying duration. For structural applications, lower moisture content is crucial for strength and stability, necessitating a longer drying period.

Control and Monitoring: Think of drying balsa as baking a cake – you wouldn't leave it unattended in the oven. Regularly monitoring moisture content with a moisture meter allows for adjustments to drying conditions and prevents overdrying, which can make the wood brittle.

By understanding these factors and their interplay, woodworkers can optimize the drying process, ensuring balsa wood reaches its full potential for strength, workability, and longevity.

Oven Drying Wood: Optimal Time for Perfect Results Explained

You may want to see also

Explore related products

Best practices for air-drying balsa wood projects

Balsa wood, prized for its lightweight yet sturdy nature, demands careful handling during the drying process to maintain its structural integrity. Air-drying, a preferred method for many hobbyists and professionals, requires patience and precision. The drying time for balsa wood typically ranges from 2 to 6 weeks, depending on factors like humidity, temperature, and wood thickness. Thinner pieces (under ¼ inch) may dry in as little as 10–14 days, while thicker sections (over ½ inch) can take up to 8 weeks. Understanding these timelines is crucial, but equally important are the practices that ensure even drying and prevent warping or cracking.

One of the most effective strategies for air-drying balsa wood is stacking and spacing. Arrange the wood pieces in a single layer, ensuring they are not stacked directly on top of one another. Use stickers—thin, uniform strips of wood—between layers to promote airflow. For optimal results, place the stack in a well-ventilated area with consistent air circulation. Avoid overcrowding, as this can trap moisture and lead to uneven drying. If possible, elevate the stack off the ground using a drying rack or wooden slats to prevent moisture absorption from the floor.

Humidity and temperature control are critical factors in the drying process. Balsa wood dries best in environments with 40–60% relative humidity and temperatures between 60–80°F (15–27°C). High humidity slows drying and increases the risk of mold, while low humidity can cause the wood to dry too quickly, leading to cracks. Consider using a dehumidifier or humidifier to maintain ideal conditions. For those in humid climates, placing a fan near the drying stack can aid in moisture evaporation, but avoid direct airflow, which can cause uneven drying.

A lesser-known but highly effective practice is periodic flipping of the wood pieces. Every 3–5 days, rotate and flip the balsa wood to ensure all sides dry evenly. This simple step prevents warping and promotes uniform moisture loss. Additionally, inspect the wood regularly for signs of mold or discoloration. If mold appears, gently sand the affected area and relocate the wood to a drier environment. Consistency in monitoring and adjusting the drying conditions is key to achieving a flawless finish.

Finally, patience is paramount. Rushing the drying process by using heat sources like ovens or hairdryers can compromise the wood’s quality, causing it to become brittle or distorted. Instead, embrace the natural drying timeline and use this period to plan your next steps in the project. Once the wood feels consistently lightweight and no longer cool to the touch, it’s ready for use. Testing the moisture content with a wood moisture meter (aiming for 8–12%) can provide additional assurance. By following these best practices, you’ll ensure your balsa wood projects retain their strength, stability, and aesthetic appeal.

Reapplying Wood Finish: Timing Tips for Optimal Results and Durability

You may want to see also

Explore related products

Accelerating balsa wood drying with heat or fans

Balsa wood, prized for its lightweight and workable nature, requires careful drying to prevent warping, cracking, or mold. While air-drying can take weeks, applying heat or fans accelerates the process significantly. Heat increases molecular activity, driving moisture out faster, while fans enhance evaporation by moving stagnant air. However, both methods demand precision to avoid damaging the wood’s integrity.

Steps to Accelerate Drying with Heat:

- Prepare the Wood: Seal the ends of the balsa with wax or a moisture-resistant sealant to prevent end grain splitting.

- Set Up a Heat Source: Use a dehydrator set to 120–140°F (49–60°C) or an oven on its lowest setting with the door slightly ajar. For larger pieces, a kiln with controlled humidity is ideal.

- Monitor Closely: Check the wood every 2–3 hours. Balsa dries in 12–24 hours with heat, but over-drying can make it brittle.

- Cool Gradually: Remove the wood and let it cool slowly to room temperature to prevent shock.

Using Fans for Faster Drying:

Position industrial fans or household box fans around the wood, ensuring airflow is consistent but not forceful. Aim for a distance of 3–4 feet to avoid uneven drying. Combine fans with low heat (e.g., a space heater set to 80–90°F) for optimal results. This method reduces drying time from weeks to 3–5 days, depending on humidity levels.

Cautions and Trade-offs:

Heat risks scorching or weakening the wood if applied too intensely, while fans alone may be ineffective in high-humidity environments. Always maintain a relative humidity below 50% for best results. Test small pieces first to calibrate your setup.

Wood Filler Setting Time: Quick Guide to Drying and Curing

You may want to see also

Explore related products

Testing balsa wood moisture content for readiness

Balsa wood, prized for its lightweight and workable nature, requires careful moisture management to ensure structural integrity and longevity in projects. Testing its moisture content is crucial, as excess moisture can lead to warping, cracking, or mold growth. The ideal moisture level for balsa wood typically ranges between 6% and 8%, depending on the intended application and environmental conditions. Achieving this range ensures the wood is stable and ready for use.

One effective method for testing moisture content is using a pin-type moisture meter, which measures the electrical resistance between two pins inserted into the wood. For accurate results, insert the pins at least 1/4 inch deep into the thickest part of the wood, avoiding knots or resin pockets. Take multiple readings across different areas to account for variations. A digital display will show the moisture percentage, allowing you to determine if the wood is ready or needs further drying. This method is quick, reliable, and suitable for both hobbyists and professionals.

For those without access to a moisture meter, a simpler yet less precise method involves weighing the wood sample. First, weigh the balsa wood, then dry it in an oven at 212°F (100°C) for 24 hours. Weigh it again after cooling. The difference in weight, divided by the original weight, multiplied by 100, gives the moisture percentage. While this method is more time-consuming and destructive, it provides a clear indication of moisture levels, especially useful for larger batches.

Comparing these testing methods highlights their trade-offs. Pin-type meters offer convenience and repeatability but require an initial investment. The oven-dry method is cost-effective but sacrifices the wood sample. Choosing the right approach depends on project scale, budget, and precision needs. Regardless of method, consistent testing ensures balsa wood is optimally dried, safeguarding the quality of your craftsmanship.

Wood Hardener Drying Time: Quick Guide to Curing Process

You may want to see also

Frequently asked questions

Allow balsa wood to air dry for at least 24–48 hours in a well-ventilated area, depending on the thickness and humidity levels.

Yes, you can use a fan or place the wood in a warm, dry environment, but avoid direct heat sources like ovens or heaters, as they can warp or damage the wood.

Balsa wood is fully dry when it feels lightweight, is no longer cool to the touch, and shows no signs of moisture when tested with a moisture meter or by touch.

Always let balsa wood dry completely before sealing it to prevent trapping moisture inside, which can lead to warping or mold.

Improper drying can cause the wood to warp, crack, or weaken over time, compromising its structural integrity and usability in projects.