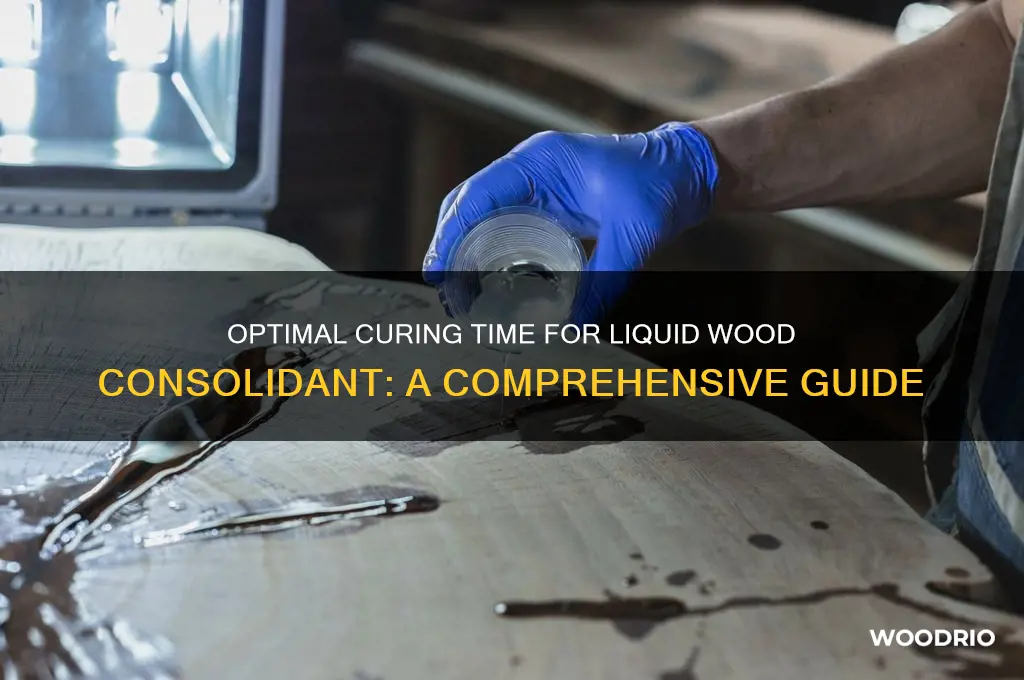

When using liquid wood consolidant to restore and strengthen damaged or decaying wood, it is crucial to allow sufficient curing time for optimal results. The curing process typically takes 24 to 48 hours under normal conditions, but this can vary depending on factors such as humidity, temperature, and the thickness of the application. In cooler or more humid environments, curing may take longer, while warmer and drier conditions can expedite the process. It is essential to follow the manufacturer’s guidelines and avoid subjecting the treated wood to stress or moisture until the consolidant has fully cured. Proper curing ensures the product penetrates deeply and bonds effectively, restoring the wood’s structural integrity and longevity.

Explore related products

$49.34 $59.99

What You'll Learn

Recommended Cure Times

Liquid wood consolidant cure times vary depending on environmental conditions, but a standard recommendation is to allow 24 to 48 hours for initial curing. This timeframe ensures the consolidant penetrates the wood fibers adequately, stabilizing and hardening the material. Humidity levels play a critical role; higher humidity can extend cure times, while drier conditions may accelerate the process. Always check the manufacturer’s guidelines, as some products specify longer periods, such as 72 hours, for optimal results.

For best results, apply the consolidant in thin, even coats, allowing each layer to cure fully before adding another. Overapplication can lead to prolonged cure times and uneven absorption. If working on large or deeply deteriorated wood surfaces, consider a second application after the initial cure period. This two-step approach ensures maximum penetration and strength, particularly in severely damaged areas. Patience during this phase is key to achieving a durable, long-lasting repair.

Temperature significantly impacts cure times, with warmer environments (65°F to 85°F) promoting faster drying. Below 50°F, the curing process slows dramatically, and the consolidant may not fully harden. Avoid applying the product in direct sunlight or extreme heat, as this can cause rapid surface drying while trapping moisture beneath, leading to blistering or uneven curing. For outdoor projects, plan applications during mild, dry weather to ensure consistent results.

After the recommended cure time, test the wood’s readiness by lightly pressing the surface with a fingernail or blunt tool. If the area feels hard and resistant, it’s ready for sanding or finishing. If it remains tacky or soft, allow additional time for curing. Once fully cured, the wood can be sanded, painted, or stained as needed. Proper curing not only enhances the consolidant’s effectiveness but also ensures the wood’s structural integrity for years to come.

Discover Darrick Wood Swimming Pool's Length and Facilities Guide

You may want to see also

Explore related products

$15.99

Factors Affecting Cure Time

Liquid wood consolidant cure times are not set in stone; they fluctuate based on several environmental and application factors. Temperature plays a pivotal role, with ideal curing occurring between 60°F and 80°F (15°C and 27°C). Below 50°F (10°C), the curing process slows dramatically, potentially doubling the standard 24-hour initial cure time. Conversely, excessive heat above 90°F (32°C) can cause rapid surface drying, leading to uneven penetration and weaker consolidation. Humidity levels also matter—high humidity accelerates curing by promoting moisture evaporation, while low humidity can delay it, requiring up to 48 hours for full consolidation.

Application technique directly impacts cure time as well. Over-saturation of the wood can prolong curing, as excess consolidant takes longer to penetrate and stabilize. Manufacturers typically recommend applying the product in thin, even coats, allowing each layer to dry for 4–6 hours before reapplication. For severely deteriorated wood, multiple applications may be necessary, extending the total cure time to 3–5 days. Diluting the consolidant beyond the recommended ratio (usually 1:1 with water) can also hinder curing, as it reduces the active solid content needed for effective consolidation.

Wood type and condition are critical determinants of cure time. Softwoods like pine absorb consolidants more quickly than hardwoods like oak, often curing within 24 hours. However, aged or weathered wood with deep cracks and voids may require additional time for the consolidant to penetrate fully, sometimes up to 72 hours. Pre-treating the wood by cleaning and lightly sanding it can improve absorption rates, reducing overall cure time. For best results, test a small area first to gauge how the wood responds to the consolidant and adjust the curing schedule accordingly.

Ventilation and airflow are often overlooked but essential factors. Adequate air circulation helps evaporate moisture from the consolidant, speeding up the curing process. In enclosed spaces, using fans or opening windows can reduce cure time by up to 25%. However, excessive airflow can cause the surface to dry too quickly, trapping moisture beneath and compromising adhesion. Striking a balance is key—ensure the area is well-ventilated but avoid direct drafts on the treated surface.

Finally, the specific product formulation influences cure time. Some liquid wood consolidants contain additives that accelerate curing, while others prioritize deep penetration over speed. Always refer to the manufacturer’s guidelines, which often provide a curing range (e.g., 24–48 hours) rather than a fixed time. For example, a product like Abatron WoodEpox may require 8–12 hours per coat, while a faster-acting consolidant like PC Products Liquid Wood might cure in 6–8 hours. Understanding these nuances ensures optimal results and avoids premature sanding or recoating, which can damage the treated wood.

Acclimating Engineered Wood: Essential Timeframe for Perfect Installation Results

You may want to see also

Explore related products

$135.27 $160.49

Testing for Full Cure

Liquid wood consolidant hardens by reacting with wood fibers, forming a durable polymer matrix. Testing for full cure requires understanding this chemical process, which varies based on factors like humidity, temperature, and application thickness. A common misconception is that surface dryness indicates full cure, but the reaction continues deeper within the wood. To assess cure accurately, focus on both surface and subsurface conditions.

Step-by-Step Testing Method:

- Surface Hardness Test (24–48 hours post-application): Press a fingernail or blunt tool into the treated area. If no indentation remains, the surface has hardened. However, this only confirms initial curing.

- Subsurface Probe (72 hours+): Insert a toothpick or thin wooden skewer into the wood at a 45-degree angle. If it penetrates easily or feels gummy, the consolidant hasn’t fully cured. Repeat this test daily until resistance is consistent.

- Moisture Meter Reading (5–7 days): Use a moisture meter to check the wood’s moisture content. Fully cured consolidant should stabilize moisture levels, typically below 15%.

Cautions: Avoid relying solely on time-based estimates, as curing times range from 3 days to 2 weeks depending on environmental conditions. High humidity (>60%) or low temperatures (<60°F) can double curing time. Overloading the wood with excessive consolidant (e.g., applying more than 10% of the wood’s weight) can also delay curing and lead to surface cracking.

Practical Tips: For critical projects, test a small, inconspicuous area first. Accelerate curing by maintaining airflow with fans or dehumidifiers, but avoid direct heat sources, which can cause uneven hardening. If unsure, err on the side of caution—allowing an extra 2–3 days ensures the consolidant reaches maximum strength before sanding, painting, or finishing.

Wood Hardener Drying Time: Factors Affecting Cure and Dry Speed

You may want to see also

Explore related products

$61.77 $99

Accelerating Cure Process

Liquid wood consolidants typically require 24 to 48 hours to cure under ideal conditions, but this timeframe can be accelerated with strategic interventions. The cure process hinges on factors like temperature, humidity, and the product’s chemical composition. For instance, water-based consolidants cure faster in warm, dry environments, while solvent-based formulas may require additional ventilation to speed up evaporation. Understanding these variables is the first step in reducing downtime and maximizing efficiency.

To accelerate curing, start by optimizing environmental conditions. Maintain a temperature range of 70°F to 85°F (21°C to 29°C) and keep humidity below 50%. Use portable heaters or fans to create a consistent airflow, but avoid direct drafts that could disrupt the surface. For solvent-based products, ensure proper ventilation to prevent solvent trapping, which can prolong drying. If working indoors, consider a dehumidifier to control moisture levels, especially in humid climates.

Another effective method is to apply heat gently. Infrared lamps or heat guns can be used, but caution is critical—excessive heat can damage the wood or cause uneven curing. Maintain a distance of at least 12 inches and move the heat source continuously. For water-based consolidants, a hairdryer on a low setting can be sufficient. Always refer to the manufacturer’s guidelines, as some products may have specific temperature thresholds.

Incorporating additives can also expedite the process. Some manufacturers offer accelerators designed to reduce cure times by up to 50%. These additives are typically mixed into the consolidant at a ratio of 1:10 (accelerator to product). However, test on a small area first to ensure compatibility and avoid adverse reactions. Overuse of accelerators can compromise the consolidant’s strength, so follow dosage instructions meticulously.

Finally, consider the wood’s condition and preparation. Clean and dry the surface thoroughly before application, as contaminants can hinder absorption and curing. For aged or porous wood, pre-treat with a wood hardener to create a more receptive surface. While these steps may add initial time, they ultimately streamline the cure process by ensuring optimal adhesion and penetration. With careful planning and the right techniques, curing times can be significantly reduced without sacrificing quality.

Mastering Wood Aging: Optimal Time for Perfect Smoking Flavor

You may want to see also

Explore related products

Post-Cure Sanding & Finishing

Liquid wood consolidant, once cured, transforms into a hardened, stable surface, but it’s not ready for its final finish just yet. Post-cure sanding is essential to smooth out any raised grain, uneven areas, or excess product that may have accumulated during application. Start with a medium-grit sandpaper (120-150 grit) to level the surface, then progress to a finer grit (220 grit) for a smoother finish. Always sand in the direction of the wood grain to avoid scratches or damage. This step ensures that the wood is uniformly prepared for staining, sealing, or painting, enhancing both adhesion and appearance.

The timing of post-cure sanding is critical. Most liquid wood consolidants require 24 to 48 hours to cure fully, depending on humidity and temperature. However, it’s wise to test a small area first to ensure the product has hardened sufficiently. Premature sanding can smear the consolidant, while waiting too long may make it harder to work with. Once sanding is complete, thoroughly remove all dust with a tack cloth or vacuum to prevent particles from marring the final finish. This preparatory step is often overlooked but is key to achieving professional results.

Finishing after sanding requires careful product selection. Water-based finishes, such as polyurethane or polycrylic, are compatible with most liquid wood consolidants and dry quickly, typically within 2-4 hours between coats. Oil-based finishes offer deeper penetration and richer color but take longer to dry, often 8-12 hours per coat. Apply thin, even coats using a brush, roller, or sprayer, ensuring proper ventilation. For outdoor projects, choose a UV-resistant sealant to protect against weathering. Each coat should be lightly sanded (400 grit) and cleaned before the next application to ensure a smooth, durable finish.

A common mistake in post-cure finishing is overloading the wood with product, which can lead to a cloudy or uneven appearance. Instead, apply multiple thin coats, allowing each to dry completely. For added protection, consider incorporating a wood preservative or fungicide into the finish, especially for exterior or moisture-prone areas. Finally, inspect the finished surface under different lighting conditions to ensure consistency and address any imperfections. With proper sanding and finishing, liquid wood consolidant not only restores structural integrity but also enhances the wood’s natural beauty for years to come.

Driftwood vs. Stone: Which Natural Material Outlasts the Other?

You may want to see also

Frequently asked questions

Allow liquid wood consolidant to cure for at least 24 hours before sanding or painting, depending on humidity and temperature conditions.

No, wait until the first coat is fully cured (typically 24–48 hours) before applying a second coat to ensure proper adhesion and effectiveness.

While the wood may feel dry after 24 hours, it’s best to wait 48–72 hours for the consolidant to fully harden and stabilize the wood before heavy use.

High humidity can extend curing time, so allow up to 48–72 hours for the consolidant to fully cure in humid conditions.