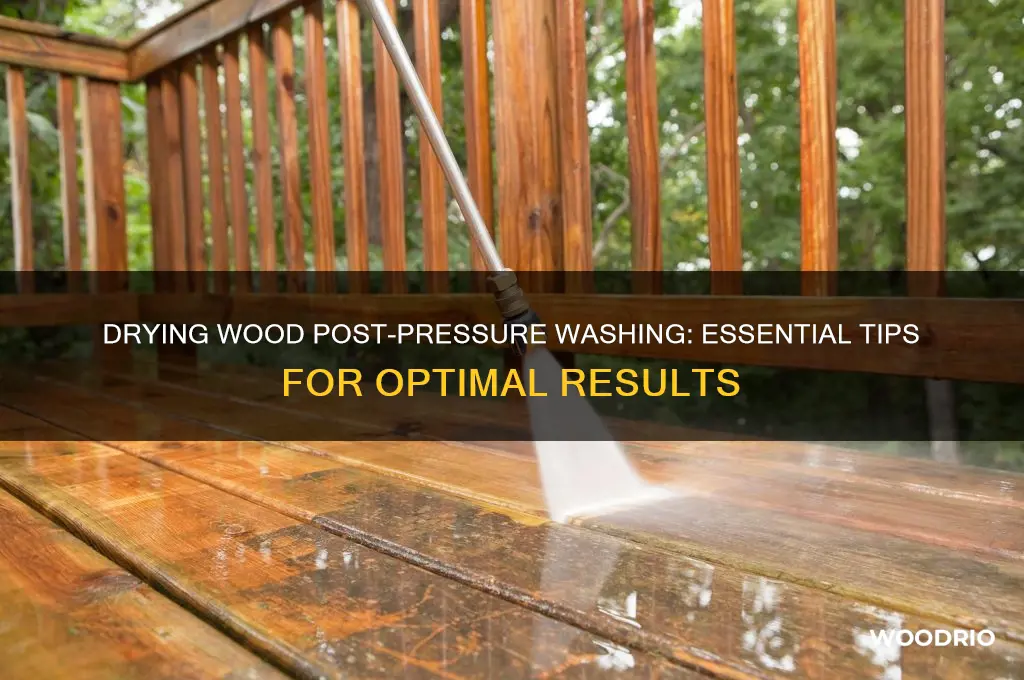

After pressure washing wood, it’s crucial to allow it to dry thoroughly before applying any finishes, stains, or sealants to prevent moisture-related issues like warping, mold, or uneven absorption. The drying time can vary significantly depending on factors such as humidity, temperature, airflow, and the type of wood. In ideal conditions—warm, dry weather with good ventilation—wood may dry within 24 to 48 hours. However, in cooler or more humid environments, it could take several days or even a week. To ensure the wood is fully dry, check for signs such as a consistent color throughout the surface and a lack of dampness when touched. Patience during this process is key to maintaining the wood’s integrity and achieving the best results for any subsequent treatments.

| Characteristics | Values |

|---|---|

| Drying Time After Pressure Washing | 24 to 48 hours (depending on weather conditions and wood type) |

| Optimal Weather Conditions | Sunny, low humidity, and good airflow |

| Wood Type Influence | Softer woods (e.g., pine) dry faster than harder woods (e.g., oak) |

| Moisture Content Goal | Wood should reach 12-15% moisture content before sealing or staining |

| Testing Dryness | Press a drop of water onto the wood; if it beads, it’s still wet |

| Avoiding Mold/Mildew | Ensure wood is completely dry to prevent mold or mildew growth |

| Sealing/Staining Timing | Apply sealant or stain only after wood is thoroughly dry |

| Seasonal Considerations | Longer drying times in humid or rainy seasons |

| Surface Preparation | Clean debris and ensure surface is smooth before drying |

| Professional Recommendation | Consult manufacturer guidelines for specific wood treatments |

Explore related products

What You'll Learn

Ideal drying time for different wood types

Pressure-washed wood requires tailored drying times based on its species, density, and intended use. Softwoods like pine or cedar, with their porous structure, typically dry within 24 to 48 hours under optimal conditions (low humidity, warm temperatures, and good airflow). These woods absorb and release moisture quickly, making them forgiving for outdoor projects like decks or fences. However, rushing the process can lead to warping or splitting, so monitor moisture levels with a wood moisture meter, aiming for 12-15% moisture content before sealing or staining.

Hardwoods such as oak or teak demand patience due to their denser grain. Expect drying times of 72 hours to a week, even in ideal conditions. Their natural oils and tighter cell structure resist moisture absorption, slowing evaporation. For hardwood decks or furniture, avoid shortcuts—premature sealing traps moisture, causing mold or finish failure. If time is a constraint, elevate the wood on racks to promote airflow, and use a fan or dehumidifier to expedite drying without compromising quality.

Exotic woods like ipe or mahogany introduce additional complexity. Their high density and natural oils can extend drying to 1-2 weeks, even in dry climates. These woods are prized for durability but require meticulous care. Test small sections with a moisture meter, ensuring uniformity before proceeding. For tropical hardwoods, partial shade during drying prevents surface checking from rapid evaporation, preserving their aesthetic appeal and structural integrity.

Green or freshly milled wood is a special case, often requiring weeks to months of air-drying before pressure washing is even considered. If pressure washing is necessary early, limit water exposure and allow extended drying—up to 3 weeks for softwoods and 4-6 weeks for hardwoods. Kiln-dried wood, while pre-dried, still needs 48-72 hours post-washing to equilibrate, as pressure washing reintroduces moisture. Always prioritize gradual drying to avoid internal stress, which can lead to long-term damage.

Practical tips across all wood types include avoiding direct sunlight during peak hours to prevent surface drying faster than the interior, which causes cracking. For large projects, stagger washing and drying in sections to manage workflow. In humid climates, consider a moisture-curing sealant after drying to protect against future water absorption. Ultimately, the ideal drying time is less about the clock and more about the wood’s readiness—patience ensures longevity and performance.

Optimal Firewood Drying Time: How Long Should Wood Season?

You may want to see also

Explore related products

Factors affecting wood drying speed after pressure washing

Wood absorbs water like a sponge during pressure washing, and its drying time hinges on several interrelated factors. Moisture content is the primary determinant—the more saturated the wood, the longer it takes to dry. Pressure washing can drive water deep into the grain, especially in softer woods like pine or cedar. Hardwoods like oak or teak, with denser fibers, may repel water more effectively but still require adequate drying time. Understanding the wood’s initial moisture level, often measured with a moisture meter (ideal range: 12–15% for outdoor use), provides a baseline for estimating drying duration.

Environmental conditions play a pivotal role in accelerating or hindering the drying process. Direct sunlight acts as a natural dehydrator, evaporating surface moisture rapidly, but prolonged exposure can cause warping or cracking. Humidity levels are equally critical—in climates with relative humidity above 60%, drying time can double or triple. Optimal drying occurs in temperatures between 70–85°F (21–29°C) with low humidity and gentle airflow. For faster results, position the wood in a well-ventilated area, using fans or open windows to circulate air without creating drafts that could unevenly dry the surface.

The thickness and density of the wood directly correlate with drying speed. A 1-inch thick board will dry in 2–3 days under ideal conditions, while a 2-inch plank may require 5–7 days. Thicker pieces retain moisture internally, necessitating longer drying periods to prevent rot or mold. Density matters too—softwoods dry faster due to larger pores, while hardwoods, though slower, often achieve a more uniform finish. To expedite drying, consider sanding the wood lightly after pressure washing to open the grain and allow moisture to escape more efficiently.

Surface treatment and preparation can significantly influence drying time. Applying a water-repellent sealant prematurely traps moisture, leading to bubbling or peeling. Instead, wait until the wood is completely dry (test by pressing a drop of water—if it beads, it’s dry; if it absorbs, wait longer). Pre-treating wood with a mildew-resistant solution before pressure washing can reduce drying time by minimizing water absorption. For decks or fences, ensure proper spacing between boards (¼–½ inch gaps) to allow airflow and prevent moisture buildup.

Lastly, seasonal considerations cannot be overlooked. Pressure washing in spring or fall may extend drying time due to cooler temperatures and higher humidity. Summer provides ideal conditions but risks overheating the wood. Winter washing is inadvisable unless followed by immediate indoor drying. Plan pressure washing projects during dry, mild weather, and always check the forecast to avoid rain, which can re-saturate the wood and reset the drying clock. Patience is key—rushing the process compromises the wood’s integrity, while proper drying ensures longevity and aesthetic appeal.

How Long Does It Take to Make Wood Sink?

You may want to see also

Explore related products

Signs wood is fully dried and ready

Wood that has been pressure washed needs adequate time to dry before it can be safely stained, sealed, or used for its intended purpose. The drying time can vary depending on factors like humidity, temperature, and the wood’s density, but there are clear signs to look for that indicate it’s fully dried and ready. One of the most reliable indicators is the wood’s moisture content, which should ideally be below 15% for most outdoor applications. You can measure this using a moisture meter, a tool that provides an accurate reading of the wood’s internal moisture levels. If you don’t have a meter, visual and tactile cues can also guide you.

A fully dried piece of wood will feel cool to the touch, not damp or warm, which suggests residual moisture. Run your hand over the surface—if it feels smooth and free of any tackiness, it’s likely dry. Another test is to observe the wood’s appearance. Dry wood will regain its original color, often lightening from the darkened, wet state it was in after pressure washing. Splinters or raised grain that occurred during cleaning should have smoothed out as the wood fibers contracted. If the wood still looks dark or feels rough, it needs more time to dry.

For a more practical approach, consider the weight of the wood. Wet wood is significantly heavier than dry wood. If you can safely lift and compare the piece to a similar dry one, the difference will be noticeable. Additionally, dry wood will not leave water stains or moisture marks when placed on a surface. Test this by setting a small section of the wood on a dry, absorbent material like paper towel for a few hours—if no moisture transfers, it’s ready.

Environmental conditions play a critical role in drying time. In hot, dry climates, wood may dry within 24 to 48 hours, while humid or cooler conditions can extend this to several days or even a week. To expedite drying, ensure the wood is placed in a well-ventilated area with direct sunlight if possible. Elevating the wood off the ground using blocks or a rack can also prevent moisture absorption from below. Patience is key—rushing the process can lead to mold, warping, or poor adhesion of finishes.

Finally, trust your instincts. If the wood passes the visual, tactile, and weight tests, and environmental conditions have been favorable, it’s likely ready. However, when in doubt, err on the side of caution and allow more time. Properly dried wood ensures longevity and performance, whether it’s part of a deck, fence, or furniture. By recognizing these signs, you can confidently proceed with the next steps in your project.

Baby Wood Ducks' Stay Duration: A Complete Growth Timeline

You may want to see also

Explore related products

Risks of using wood before it’s completely dry

Pressure-washed wood may appear dry to the touch within hours, but its core moisture content can remain elevated for days or even weeks. This hidden moisture poses significant risks if the wood is used prematurely. One immediate consequence is warping and cracking. As the wood dries unevenly, internal stresses build, causing it to twist, cup, or split. For example, a freshly pressure-washed deck board installed before it’s fully dry might develop unsightly gaps or raised edges within weeks, compromising both appearance and safety.

Another critical risk is mold and mildew growth. Moist wood provides an ideal environment for fungi to thrive, especially in humid climates. Even if the surface feels dry, residual moisture trapped within the fibers can foster spore development. This not only damages the wood but also poses health risks, particularly for individuals with allergies or respiratory conditions. A study by the Forest Products Laboratory found that wood with a moisture content above 20% is highly susceptible to fungal colonization, underscoring the importance of thorough drying.

Using partially dried wood in structural applications, such as framing or furniture, can lead to long-term instability. Wood expands and contracts with changes in moisture content, a process known as dimensional change. If wood is fixed in place while still damp, it will shrink as it dries, potentially weakening joints or causing fasteners to loosen. For instance, a wooden fence post installed before drying may shift or lean over time, requiring costly repairs.

Finally, finishes and treatments applied to damp wood are ineffective and short-lived. Paint, stain, or sealant cannot properly adhere to a moist surface, leading to peeling, blistering, or discoloration. Manufacturers typically recommend a moisture content of 12–15% for optimal finish application. Ignoring this guideline not only wastes materials but also leaves the wood vulnerable to weathering and decay.

To mitigate these risks, allow pressure-washed wood to air-dry completely before use. In ideal conditions (low humidity, good airflow, and moderate temperatures), this process takes 2–7 days for surface drying and up to 4 weeks for deeper layers. Use a moisture meter to confirm the wood’s readiness, aiming for a reading below 15%. Patience in this stage ensures the wood’s durability, safety, and aesthetic appeal.

Seasoning Mulberry Wood: Understanding the Timeframe for Optimal Results

You may want to see also

Explore related products

Tips to speed up the drying process effectively

After pressure washing wood, the drying time can vary significantly based on factors like humidity, temperature, and wood type. Typically, it takes 24 to 48 hours for wood to dry completely under ideal conditions, but this can extend to several days in damp or cool environments. Speeding up this process not only saves time but also prevents potential issues like mold or warping. Here’s how to do it effectively.

Optimize Airflow with Strategic Placement

Position the wood in a well-ventilated area where air can circulate freely on all sides. Elevate it off the ground using wooden blocks or a drying rack to prevent moisture absorption from the surface below. If indoors, use fans to create cross-ventilation, directing airflow across the wood rather than straight at it to avoid uneven drying. For outdoor drying, choose a shaded area with indirect sunlight to prevent rapid evaporation, which can cause cracking.

Leverage Heat Without Overdoing It

Controlled heat accelerates evaporation but must be applied carefully. A space heater set on low can raise the ambient temperature, but keep it at least 3 feet away to avoid scorching. Alternatively, use a dehumidifier to reduce moisture in the air, particularly in humid climates. For larger projects, consider a portable heater with a thermostat to maintain a consistent temperature between 70°F and 80°F, ideal for speeding up drying without damaging the wood.

Pre-treat Wood for Faster Results

Before pressure washing, apply a wood sealant or water-repellent treatment to minimize water absorption. After washing, lightly sand the surface to open the grain, allowing moisture to escape more easily. For decks or fences, use a squeegee to remove excess water immediately after washing, reducing the overall drying time. Avoid oil-based treatments until the wood is completely dry, as they can trap moisture and prolong drying.

Monitor Humidity and Timing

Use a moisture meter to track the wood’s moisture content, aiming for a reading below 15% for most applications. If humidity exceeds 60%, consider moving the wood indoors or using a dehumidifier. In cooler climates, plan pressure washing during warmer parts of the day to take advantage of higher temperatures. For urgent projects, tent the wood with a breathable tarp to create a microclimate, but ensure it’s not airtight to prevent condensation buildup.

By combining these strategies, you can significantly reduce drying time while maintaining the integrity of the wood. Patience remains key, but with these tips, you’ll strike the right balance between speed and quality.

Wood Rot Timeline: How Long Does House Wood Last?

You may want to see also

Frequently asked questions

Allow the wood to dry for at least 48 hours, but ideally 72 hours, to ensure it is completely dry before applying stain or sealant.

Yes, you can speed up drying by using fans, ensuring good airflow, and placing the wood in direct sunlight, but avoid using heat sources like hair dryers, as they can damage the wood.

No, staining or sealing damp wood can trap moisture, leading to peeling, mold, or mildew. Always wait until the wood is fully dry.

Test the wood by pressing a small area with your finger or using a moisture meter. If it feels dry to the touch and the meter reads below 15% moisture content, it’s ready.

Yes, denser woods like oak take longer to dry than softer woods like pine. Additionally, humid or cold weather can extend drying time, while dry, sunny conditions speed it up.