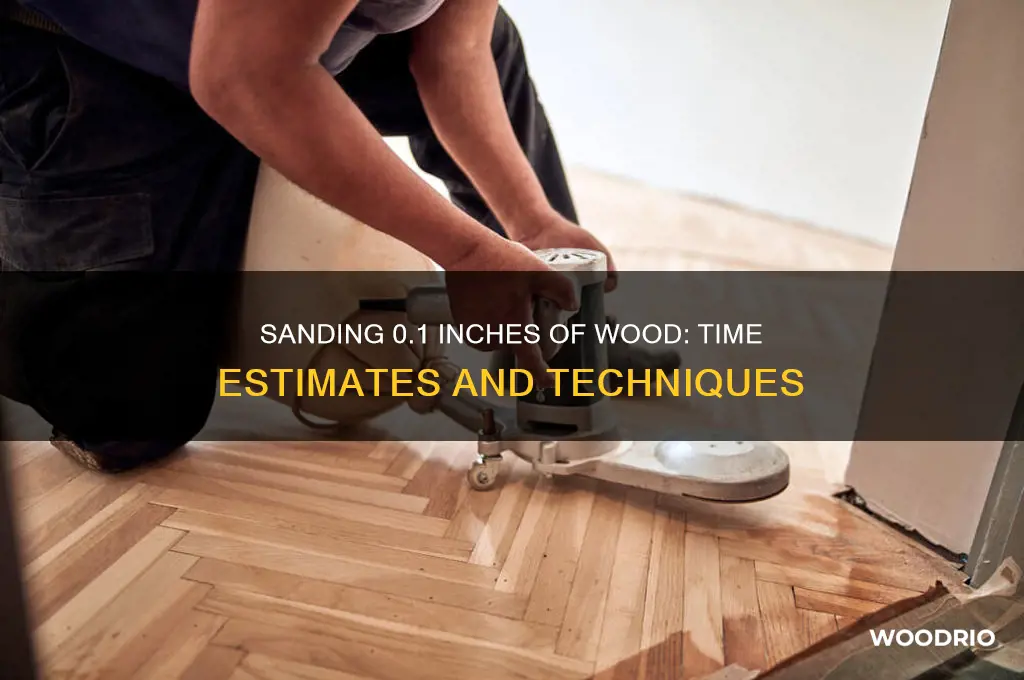

Sanding 0.1 inches of wood is a task that requires careful consideration of the tools, techniques, and time involved. The duration can vary significantly depending on factors such as the type of wood, the grit of sandpaper used, the power and efficiency of the sander, and the desired finish. For example, softer woods like pine may sand more quickly than harder woods like oak. Using a coarse grit initially can speed up material removal but will require additional time with finer grits to achieve a smooth finish. Hand sanding is generally slower but offers more control, while power sanders can expedite the process but may require more caution to avoid uneven results. On average, sanding 0.1 inches of wood could take anywhere from a few minutes to several hours, making it essential to plan accordingly and prioritize both efficiency and precision.

| Characteristics | Values |

|---|---|

| Time to Sand 0.1 inch of Wood | Varies based on wood type, grit, tool, and technique (approx. 1-4 hrs) |

| Wood Type | Softer woods (pine) sand faster; harder woods (oak) take longer |

| Sanding Tool | Belt sander: fastest (15-30 mins); orbital/hand sanding: slower (2-4 hrs) |

| Grit Progression | Coarse (40-60 grit) to fine (120+ grit) increases time |

| Surface Condition | Rough/uneven surfaces require more time |

| Wood Grain | Against the grain increases sanding time |

| Dust Management | Efficient dust collection reduces clogging, saving time |

| User Experience | Beginners may take longer than experienced users |

| Thickness Consistency | Uniform thickness reduces sanding time |

| Moisture Content | Dry wood sands faster than damp wood |

Explore related products

$32 $37.99

What You'll Learn

Grit Selection for Efficiency

Sanding 0.1 inches of wood is no small feat, and the grit sequence you choose can dramatically affect both the time and effort required. Starting with a coarse grit, such as 40 or 60, removes material quickly but leaves deep scratches. Progressing through medium grits (100–150) and finishing with fine grits (220 and above) ensures a smooth surface. Skipping grits or using too fine a grit too early can lead to inefficiency, as finer grits clog and wear out faster when used on rough surfaces.

Consider the wood species and its hardness when selecting grits. Softer woods like pine may require fewer passes with coarser grits, while harder woods like oak demand more aggressive grits and patience. For example, starting with 80-grit on oak and transitioning to 120-grit before finishing with 220-grit is a practical sequence. Conversely, pine might only need 100-grit followed by 180-grit and 220-grit. Matching grit to wood type minimizes unnecessary sanding and extends abrasive life.

Efficiency also hinges on the sanding tool and technique. Belt sanders excel at rapid material removal with coarse grits but can be aggressive, risking uneven surfaces. Orbital sanders, paired with medium to fine grits, offer control for smoother finishes. Hand sanding with fine grits (320–400) is ideal for final touches. Always sand with the grain to avoid tear-out and use consistent pressure to ensure even wear.

A common mistake is rushing the grit progression. Each grit should fully remove the scratches left by the previous one before moving to the next. Test the surface with your hand or a bright light to check for remaining scratches. Ignoring this step can lead to visible imperfections, forcing you to backtrack and resand. Patience in grit progression saves time in the long run.

Finally, consider the project’s purpose when selecting grits. Structural pieces may only need 120-grit for functionality, while furniture or decorative items might require 400-grit for a glass-smooth finish. Balancing grit selection with the desired outcome ensures efficiency without overworking the material. Always prioritize the end goal to avoid unnecessary labor.

Durability of Wood Clarinets: Lifespan, Care, and Maintenance Tips

You may want to see also

Explore related products

Hand vs. Power Sanding Time

Sanding 0.1 inches of wood by hand is a labor-intensive task that demands patience and precision. Using coarse grit sandpaper (60-80 grit), you’ll spend approximately 30–60 minutes per square foot, depending on the wood’s hardness and grain direction. Progressing to finer grits (120-220) for smoothing adds another 20–40 minutes per square foot. This method is ideal for small projects or delicate areas where control is critical, but it’s physically demanding and time-consuming for larger surfaces.

Power sanding slashes the time required dramatically, but the tool choice matters. A belt sander, aggressive and fast, can remove 0.1 inches in 5–10 minutes per square foot using a 60-grit belt. However, it’s prone to uneven surfaces if not handled skillfully. An orbital sander, slower but more forgiving, takes 10–15 minutes per square foot with 80-grit sandpaper. For precision, a detail sander or power hand sander offers better control but extends the time to 15–20 minutes per square foot. Power sanding is efficient but requires vigilance to avoid over-sanding or damaging the wood.

The trade-off between hand and power sanding isn’t just about speed—it’s about finish quality and project scale. Hand sanding yields a smoother, more uniform surface, especially with finer grits, but it’s impractical for large areas. Power sanding is faster and less physically taxing but risks leaving swirl marks or uneven patches if not used correctly. For projects requiring both speed and precision, a hybrid approach works best: power sand to remove the bulk, then hand sand for the final touch.

Practical tips can optimize your sanding time regardless of method. Always sand with the grain to prevent tear-out, and keep the surface flat by applying even pressure. For power sanding, move the tool in smooth, overlapping strokes to avoid gouges. When hand sanding, fold the paper to create a sharp edge for corners or use a sanding block for flat surfaces. Regularly check your progress with a straight edge or by running your hand over the wood to ensure uniformity.

In conclusion, the choice between hand and power sanding for removing 0.1 inches of wood hinges on your project’s size, desired finish, and time constraints. Hand sanding is meticulous and time-consuming but delivers superior control, while power sanding is efficient but requires skill to avoid mistakes. Combining both methods often yields the best results, balancing speed with precision for a professional finish.

Wood County Ohio Deed Retention: Understanding Record-Keeping Duration

You may want to see also

Explore related products

Wood Type Impact on Speed

The density and hardness of wood significantly influence sanding speed. Softwoods like pine or cedar, with their lower density, yield quickly to sandpaper, allowing you to remove 0.01 inches in as little as 10-15 minutes with a belt sander. Hardwoods, such as oak or maple, present a different challenge. Their dense grain structure resists abrasion, potentially doubling or tripling the time required to achieve the same depth removal. For example, sanding 0.01 inches off a hardwood surface might take 30-45 minutes or more, depending on the tool and grit used.

Consider the sanding process as a battle between abrasives and wood fibers. Softer woods, with their looser cell structure, surrender more readily, while harder woods demand persistence. This isn't just about time; it's about technique. When tackling hardwoods, start with a coarser grit (60-80) to break through the initial resistance, then progress to finer grits (120-220) for a smoother finish. For softwoods, you can often skip the coarser grits and start with a medium grit (100-150) to avoid over-sanding and creating uneven surfaces.

The type of sander also plays a role in how wood type affects speed. Orbital sanders, with their random-orbit action, are gentler and more versatile, making them suitable for both soft and hard woods. Belt sanders, with their aggressive linear motion, excel at rapid material removal on softwoods but can be unforgiving on hardwoods, leaving deep scratches if not handled carefully. For precise control, especially on hardwoods, a hand-held block plane followed by hand sanding might be the most efficient method, though it’s more labor-intensive.

Practical tip: Always test your sanding technique on a scrap piece of the same wood type to gauge the rate of material removal. This not only helps you estimate the time needed but also prevents over-sanding, which can ruin the workpiece. For hardwoods, consider using a lubricant like mineral oil or water to reduce friction and heat buildup, which can dull sandpaper faster. Conversely, softwoods may require frequent sandpaper changes due to rapid clogging from their resinous nature.

In conclusion, understanding the relationship between wood type and sanding speed is crucial for efficiency and quality. Softwoods offer a quick, forgiving sanding experience, while hardwoods demand patience, the right tools, and a strategic approach. By tailoring your technique to the wood’s characteristics, you can achieve consistent results without unnecessary delays or damage.

1992 Pressurized Wood Durability: Lifespan and Longevity Explained

You may want to see also

Explore related products

Techniques to Save Time

Sanding 0.1 inches of wood is a task that demands precision and patience, but with the right techniques, you can significantly reduce the time spent. One of the most effective methods is using a coarse-grit sandpaper as your starting point. Begin with an 80-grit sandpaper to quickly remove the bulk of the material. This aggressive grit cuts through wood faster, allowing you to achieve the desired depth more efficiently. Once you’re close to 0.1 inches, switch to a finer grit, such as 120 or 150, to smooth the surface without over-sanding. This two-step approach minimizes time wasted on unnecessary passes.

Another time-saving technique is leveraging power tools like a belt sander or an orbital sander. These tools are designed to cover large areas quickly and maintain consistent pressure, reducing the physical effort and time required. For example, a belt sander can remove 0.1 inches of wood in a fraction of the time it takes to do it by hand, especially on softer woods like pine. However, exercise caution with power tools—they can remove material faster than expected, so monitor your progress frequently to avoid overshooting your target depth.

A less obvious but highly effective strategy is planning your sanding path. Instead of randomly moving the sandpaper or tool, work in systematic, overlapping strokes in the direction of the wood grain. This ensures even material removal and prevents uneven spots that require additional sanding. For example, divide the wood surface into sections and tackle one section at a time, checking the depth with a caliper after each pass. This methodical approach saves time by eliminating the need to backtrack and correct mistakes.

Finally, consider pre-treating the wood to make sanding easier. If the wood surface is rough or has stubborn imperfections, lightly scoring it with a utility knife or scraper can help. This pre-treatment breaks up the surface layer, allowing the sandpaper to work more efficiently. Additionally, keeping the wood well-hydrated with a damp cloth can raise the grain slightly, making it easier to sand down to the desired depth. These preparatory steps may add a few minutes upfront but can save significantly more time during the sanding process.

By combining these techniques—starting with coarse grits, using power tools judiciously, planning your sanding path, and pre-treating the wood—you can streamline the process of sanding 0.1 inches of wood. Each method addresses a specific inefficiency, ensuring that your time is spent productively and the task is completed with precision.

Pressure Washing Wood: How Long Does It Stay Looking Great?

You may want to see also

Explore related products

Avoiding Common Sanding Mistakes

Sanding 0.1 inches of wood is a task that demands precision, patience, and the right technique. One common mistake is using excessive force, which can lead to uneven surfaces or even damage the wood. Applying too much pressure not only wears out sandpaper faster but also increases the risk of sanding through the wood’s surface layer, especially in softer woods like pine or cedar. Instead, let the weight of the sander or sanding block do the work, maintaining a consistent, light touch to achieve a smooth finish without over-sanding.

Another frequent error is skipping grit progression, a critical step in achieving a professional-grade finish. Starting with a coarse grit (e.g., 80-grit) to remove the bulk of the material is essential, but failing to transition to finer grits (e.g., 120, 180, 220) leaves the wood with visible scratches. Each grit should be used progressively to refine the surface, ensuring the final result is smooth to the touch. Ignoring this step can double the time spent sanding, as coarser scratches require more effort to remove.

Overlooking the direction of sanding is a subtle but significant mistake. Sanding against the grain raises wood fibers and creates a rough, uneven surface. Always sand in the direction of the wood grain, especially when using finer grits. For curved or contoured pieces, use a flexible sanding sponge or folded sandpaper to follow the shape without scratching the surface. This attention to detail ensures the wood’s natural beauty is preserved.

Finally, neglecting to clean the surface between grit changes undermines the entire sanding process. Dust and debris left on the wood can clog sandpaper and create imperfections. Use a tack cloth or a damp rag to wipe the surface thoroughly after each grit change. This simple step ensures that the next grit works effectively and prevents contaminants from scratching the wood. By avoiding these common mistakes, sanding 0.1 inches of wood becomes a manageable task with consistent, high-quality results.

Chemical Retention in Treated Wood: Duration and Environmental Impact Explained

You may want to see also

Frequently asked questions

Sanding 1 inch of wood by hand depends on the wood type, grit used, and effort applied. It can take several hours to a full day for coarse grits (e.g., 40-80 grit), while finer grits (e.g., 120-220 grit) may take less time but require more precision.

Using a power sander (e.g., belt sander or orbital sander) can significantly reduce time. Sanding 1 inch of wood may take 15–30 minutes for coarse grits, depending on the sander's power and wood hardness. Finer grits will take less time but require careful control.

Key factors include the wood type (hardwoods take longer), grit size (coarser grits remove material faster but take more time), tool used (power sanders are faster than hand sanding), and the wood's condition (rough or uneven surfaces require more effort).