Seasoning a wood block for printing is a crucial step in the traditional woodblock printing process, ensuring durability and optimal ink transfer. The duration required to season a wood block can vary significantly depending on factors such as the type of wood, humidity levels, and the desired level of hardness. Typically, hardwoods like cherry, pear, or boxwood are preferred for their density and grain structure, and they may require anywhere from several months to a year or more to fully season. During this time, the wood must be stored in a controlled environment, allowing it to gradually dry and stabilize to prevent warping or cracking. Proper seasoning not only enhances the wood’s longevity but also improves the precision and clarity of the printed designs, making it an essential investment for artisans and printmakers.

| Characteristics | Values |

|---|---|

| Ideal Seasoning Time | 6 months to 2 years, depending on wood type and environmental conditions |

| Wood Type Influence | Harder woods (e.g., cherry, maple) require longer seasoning (1-2 years) |

| Softwood Seasoning Time | Softer woods (e.g., pine, basswood) may season in 6-12 months |

| Moisture Content Goal | Aim for 8-12% moisture content for optimal printing results |

| Environmental Factors | Seasoning time increases in humid climates; decreases in dry climates |

| Storage Conditions | Store wood in a dry, well-ventilated area, away from direct sunlight |

| Thickness Impact | Thicker blocks require longer seasoning than thinner ones |

| Checking for Readiness | Wood should feel dry, lightweight, and show no signs of warping |

| Accelerated Seasoning Methods | Kiln drying can reduce seasoning time to weeks, but may affect quality |

| Traditional vs. Modern Methods | Traditional air drying takes longer but is preferred for fine printing |

Explore related products

What You'll Learn

Ideal Wood Types for Seasoning

The choice of wood significantly influences the seasoning duration and the final print quality. Hardwoods like maple, cherry, and birch are ideal due to their dense grain structure, which minimizes warping and ensures consistent ink absorption. These woods typically require 6 to 12 months of seasoning, depending on thickness and humidity levels. Softwoods, such as pine or cedar, are less recommended because their porous nature can lead to uneven drying and potential cracking, though they may season faster (3–6 months) if properly managed.

For optimal results, select wood with a moisture content below 12%. Use a moisture meter to verify this before beginning the seasoning process. Air-dry the wood in a well-ventilated, shaded area, stacking boards with spacers to allow airflow. Rotate the stack monthly to ensure even drying. If time is a constraint, kiln-drying can reduce seasoning time to 2–4 weeks, but this method risks over-drying or internal stresses, which may affect print stability.

Consider the wood’s natural oils when choosing a species. Oily woods like teak or walnut resist moisture but can repel ink, requiring longer seasoning (up to 18 months) to balance oil distribution. Non-oily hardwoods like beech or poplar are more forgiving, seasoning in 6–9 months and providing a smoother surface for detailed prints. Always test a small block before committing to a large project to assess how the wood responds to ink and pressure.

Finally, factor in environmental conditions. High humidity prolongs seasoning, while dry climates accelerate it. In humid regions, use a dehumidifier or seal the wood with a breathable wrap to control moisture exposure. Conversely, in arid areas, mist the wood occasionally to prevent excessive drying. Pairing the right wood type with mindful seasoning practices ensures a durable, high-quality printing block that delivers consistent results.

Seasoning Wood for Furniture: Optimal Drying Time Explained

You may want to see also

Explore related products

Optimal Seasoning Duration Explained

The optimal seasoning duration for a wood block used in printing hinges on balancing moisture content and structural stability. Wood naturally contains moisture, and improper drying can lead to warping, cracking, or uneven printing surfaces. Seasoning—the process of controlled drying—reduces moisture levels to around 8-12%, depending on the wood type and environmental conditions. This range ensures the wood remains dimensionally stable, crucial for precise, consistent prints. Rushing this process risks compromising the block’s integrity, while over-seasoning can make the wood brittle.

Analyzing wood types reveals varying seasoning needs. Hardwoods like maple or cherry, denser and more moisture-resistant, typically require 3-6 months of seasoning. Softer woods like pine or basswood, more prone to warping, may need 6-12 months. Climate plays a critical role: humid environments demand longer seasoning periods, while dry climates accelerate drying. A practical tip is to monitor the wood’s weight; when it stops losing weight, it’s reached equilibrium moisture content (EMC), signaling readiness for use.

For those seeking a structured approach, follow these steps: 1) Cut the wood block to size, ensuring clean edges. 2) Store it in a well-ventilated, shaded area, stacking blocks with spacers to allow airflow. 3) Rotate the blocks weekly to promote even drying. 4) Use a moisture meter to check progress; aim for 8-12% moisture content. Caution: Avoid direct sunlight or heat sources, as these can cause uneven drying and cracks.

Comparing traditional and modern methods highlights efficiency trade-offs. Traditional air-drying is cost-effective but time-consuming, while kiln-drying reduces seasoning time to weeks but requires specialized equipment. For hobbyists, air-drying suffices, but professionals may opt for kiln-drying to meet tight deadlines. The takeaway: prioritize consistency over speed to ensure the wood block’s longevity and performance in printing.

Finally, consider the wood’s end use. Blocks for fine art printing demand stricter seasoning standards than those for casual projects. For example, a block intended for detailed line work requires meticulous drying to prevent surface imperfections. Conversely, a block for bold, abstract prints may tolerate slight variations. Tailor the seasoning duration to the project’s precision needs, ensuring the wood block becomes a reliable tool rather than a source of frustration.

Efficient Wood Tile Installation: Timeframe and Tips for a Seamless Finish

You may want to see also

Explore related products

$18

Environmental Factors Affecting Seasoning

The time required to season a wood block for printing is not a one-size-fits-all scenario. Environmental factors play a critical role in determining how long the wood needs to dry and stabilize. Humidity, temperature, and airflow are the primary variables that can either accelerate or hinder the seasoning process. For instance, wood blocks seasoned in a dry, warm environment with consistent airflow can take as little as 3–6 months, whereas those in high-humidity regions may require 12–18 months or more. Understanding these factors allows artisans to plan effectively and ensure the wood is ready for precise, high-quality printing.

Humidity: The Silent Saboteur

High humidity levels are the arch-nemesis of wood seasoning. Wood naturally absorbs moisture from the air, and in humid climates, this process slows down significantly. For optimal seasoning, aim for a relative humidity of 50–60%. If you’re in a region with humidity above 70%, consider using a dehumidifier in the storage area. Alternatively, placing the wood blocks in a well-ventilated, shaded outdoor space during dry seasons can help mitigate moisture absorption. Pro tip: Use a hygrometer to monitor humidity levels and adjust conditions accordingly.

Temperature: The Accelerator or Delayer

Temperature directly impacts the rate of moisture evaporation from the wood. Warmer temperatures (68–86°F or 20–30°C) speed up the seasoning process by encouraging moisture to escape more rapidly. However, extreme heat can cause uneven drying, leading to cracks or warping. Conversely, cold temperatures slow down seasoning and may prolong the process by months. If you’re seasoning wood in a cooler climate, ensure the wood is stored in a temperature-controlled environment, such as a heated workshop or a space with consistent warmth.

Airflow: The Unseen Catalyst

Proper airflow is essential for even seasoning. Stagnant air traps moisture around the wood, prolonging the drying process. Stack wood blocks with spacers or stickers between them to allow air to circulate freely. If seasoning indoors, use fans to promote airflow, but avoid directing them directly at the wood to prevent surface drying faster than the interior. For outdoor seasoning, choose a covered but open area to protect the wood from rain while allowing natural air movement.

Practical Tips for Optimal Seasoning

To minimize the impact of environmental factors, start by selecting the right wood species. Hardwoods like maple or cherry season more predictably than softwoods. Seal the ends of the wood blocks with a non-toxic sealant to prevent rapid moisture loss from these areas, which can cause splitting. Regularly inspect the wood for signs of mold or uneven drying, especially in humid conditions. Finally, document the seasoning process by recording environmental conditions weekly—this data will help refine your approach for future projects. By mastering these environmental factors, you can ensure your wood blocks are perfectly seasoned for crisp, professional prints.

Understanding 2x4 Wood Dimensions: Length, Uses, and Practical Tips

You may want to see also

Explore related products

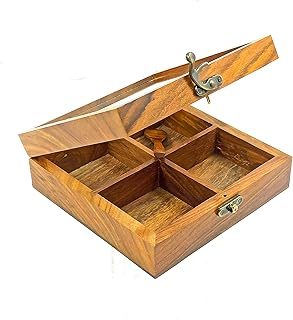

Signs of Properly Seasoned Wood

Wood that has been properly seasoned for block printing exhibits a distinct lack of moisture-related defects, such as warping, cracking, or splitting. These issues arise when wood is cut, carved, or used before it has reached an equilibrium moisture content (EMC) with its environment. For printing blocks, the ideal EMC ranges between 8-12%, depending on the humidity of the region where the wood is stored. To assess this, use a moisture meter—readings above 15% indicate insufficient seasoning and will compromise the block’s stability during carving and printing.

Visually and tactilely, properly seasoned wood feels lighter in weight compared to its green (freshly cut) state, as moisture loss reduces density. The surface should appear matte rather than glossy, with no signs of mold, mildew, or discoloration caused by fungal growth. Run your hand along the grain—smoothness without raised fibers suggests the wood has dried evenly. If the block sounds dull when tapped (rather than a sharp, resonant sound), it may still retain moisture, requiring further seasoning.

A critical test for seasoned wood is its response to carving. When using sharp tools, the wood should yield cleanly without tearing or splintering, which indicates proper fiber relaxation. Green or partially seasoned wood tends to compress under pressure, distorting fine details in the print. For best results, carve a small test area first; if the wood chips cleanly and holds its shape, it’s ready. If not, allow additional seasoning time—typically 6-12 months for hardwoods like maple or cherry, and up to 2 years for denser species like oak.

For printers working with softwoods like pine, seasoning time can be shorter (3-6 months), but these woods are more prone to denting and wear. To expedite seasoning, store wood in a well-ventilated, temperature-controlled space with consistent humidity (40-50% is ideal). Stack blocks with stickers (spacers) between layers to promote airflow, and rotate the stack monthly to ensure even drying. Avoid kiln-drying for printing blocks, as rapid drying can introduce internal stresses that affect carving and longevity.

Finally, seasoned wood accepts ink and resists absorption better than green wood, ensuring sharper prints with minimal bleeding. Test readiness by applying a small amount of ink—properly seasoned wood will repel excess moisture, leaving a crisp impression. If the ink spreads or the wood darkens significantly, it’s not yet ready. Patience in seasoning is non-negotiable; rushing this step undermines the precision and durability of the final print, turning a potentially timeless piece into a temporary experiment.

Baking Wood to Charcoal: Optimal Time and Techniques Revealed

You may want to see also

Explore related products

Accelerating the Seasoning Process

Wood seasoning, a critical step in preparing blocks for printing, traditionally demands patience, often spanning months. However, modern techniques and innovative approaches can significantly reduce this timeline, allowing artists and craftsmen to expedite their projects without compromising quality. The key lies in understanding the science behind wood drying and applying targeted methods to accelerate moisture evaporation while maintaining the wood's integrity.

The Science of Accelerated Drying

The primary goal is to remove moisture from the wood fibers efficiently. Conventional air drying relies on natural evaporation, a slow process influenced by humidity and temperature. To speed this up, consider the following: kiln drying, a controlled environment method, can reduce seasoning time to weeks. Kilns use heat and airflow to extract moisture, with temperatures typically ranging from 120°F to 180°F (49°C to 82°C). For smaller blocks, a solar kiln offers an eco-friendly alternative, harnessing sunlight to create a greenhouse effect. This method is particularly effective in regions with ample sunshine, reducing drying time by 50-70%.

Practical Techniques for Home Workshops

For those without access to kilns, microwave vacuum drying presents a viable option. This technique involves placing the wood in a vacuum chamber and applying microwave energy, which heats the water molecules directly, causing rapid evaporation. However, caution is necessary to avoid overheating, which can lead to cracks or warping. A more accessible method is air circulation enhancement. Positioning the wood blocks in a well-ventilated area with fans directed at them can significantly improve drying rates. Ensure the wood is stacked with spacers to allow air to flow between pieces, and rotate the blocks periodically for even drying.

Chemical Treatments: A Double-Edged Sword

While less conventional, chemical treatments can expedite seasoning. Oven-dry wood preservatives, such as polyethylene glycol (PEG), can be applied to accelerate moisture removal. PEG, typically used in concentrations of 50-100% solution, penetrates the wood, reducing its moisture content. However, this method requires precise application and may alter the wood's properties, affecting print quality. Caution: Always test chemicals on a small sample to ensure compatibility with your printing process.

Balancing Speed and Quality

Incorporating these accelerated techniques requires careful consideration of the wood type, desired print quality, and available resources. By combining scientific principles with practical methods, artisans can significantly reduce seasoning time, enabling faster production cycles while preserving the wood's suitability for intricate printing projects. This approach not only saves time but also opens up new possibilities for experimentation and creativity in woodblock printing.

Drying Pallet Wood: Essential Timeframe for Safe and Effective Use

You may want to see also

Frequently asked questions

Seasoning a wood block for printing usually takes 3 to 6 months, depending on the type of wood, humidity, and climate conditions.

While seasoning time cannot be significantly reduced, storing the wood block in a dry, well-ventilated area with consistent temperature can help ensure even drying.

A fully seasoned wood block will feel dry to the touch, have no visible moisture, and show no signs of warping or cracking. It should also have a stable weight, indicating the moisture content has stabilized.