When working with wood veneer, understanding the proper waiting time for glue to set and the clamping process is crucial for achieving a strong and durable bond. The duration required for glue to cure can vary significantly depending on the type of adhesive used, such as PVA (white glue), epoxy, or contact cement, as well as environmental factors like temperature and humidity. Generally, PVA glue may take anywhere from 30 minutes to 24 hours to fully set, while epoxy can require several hours to a day. Clamping time is equally important, as it ensures even pressure and proper adhesion; for most veneer projects, clamping should be maintained for at least 30 minutes to an hour, but thicker or larger pieces may necessitate longer clamping periods. Always refer to the manufacturer’s instructions for specific guidelines to ensure optimal results.

| Characteristics | Values |

|---|---|

| Glue Type | PVA (White Glue), Epoxy, Contact Cement, Hide Glue, Polyurethane Glue |

| Clamping Time (General) | 30 minutes to 24 hours (varies by glue type and manufacturer) |

| PVA Glue | 30 minutes to 1 hour for initial set, 24 hours for full cure |

| Epoxy Glue | 5-30 minutes for initial set, 24 hours for full cure |

| Contact Cement | 15-30 minutes for initial tack, 24 hours for full bond |

| Hide Glue | 15-30 minutes for initial set, 24 hours for full cure |

| Polyurethane Glue | 30 minutes to 1 hour for initial set, 24 hours for full cure |

| Veneer Thickness | Thicker veneers may require longer clamping times |

| Humidity & Temperature | Higher humidity and temperature can accelerate curing time |

| Pressure Applied | Even pressure ensures proper bonding; use clamps or weights |

| Manufacturer Recommendations | Always follow specific instructions on the glue packaging |

| Initial Handling Time | 1-2 hours after clamping (check glue type for specifics) |

| Full Cure Time | 24-48 hours for most glues, depending on environmental conditions |

| Testing Bond Strength | Wait at least 24 hours before testing the bond strength |

| Safety Precautions | Wear gloves and work in a well-ventilated area |

Explore related products

What You'll Learn

Optimal Glue Drying Time

The optimal drying time for glue when working with wood veneer is a delicate balance between patience and precision. Too little time, and the bond may fail; too much, and you risk over-clamping or wasting valuable workshop hours. For most wood glues, including PVA (polyvinyl acetate) and epoxy, the initial clamping period should last 30 minutes to 2 hours, depending on humidity and temperature. However, this is merely the first phase. Full curing, where the glue reaches maximum strength, can take 24 to 48 hours. Rushing this process can lead to weak joints or veneer delamination, especially in high-stress applications like furniture or cabinetry.

Consider the environmental factors at play. In a dry, warm workshop (70–80°F or 21–27°C), glue dries faster, but in humid or cold conditions, curing slows significantly. For instance, a thin layer of PVA glue might set in 30 minutes under ideal conditions but could take up to 4 hours in a damp basement. To mitigate this, use a space heater or dehumidifier to create a controlled environment. Additionally, apply glue sparingly—a thin, even coat ensures faster drying and avoids squeeze-out, which can weaken the bond or mar the veneer surface.

The type of glue also dictates drying time. Cyanoacrylate (super glue) sets in seconds to minutes but lacks the strength for structural veneer work. Epoxy, on the other hand, offers superior bonding but requires 4 to 6 hours of clamping and up to 24 hours for full cure. For veneers, PVA remains the go-to choice due to its balance of strength, flexibility, and working time. Always follow manufacturer guidelines, as some specialty glues may have unique curing profiles or require specific clamping pressures.

Practical tips can streamline the process. Use wax paper or parchment between the veneer and clamps to prevent glue stains. For large veneer panels, apply even pressure with cauls or use vacuum bagging to ensure consistent contact. Test the glue’s set by gently tapping the joint after the initial clamping period—if it feels firm, it’s ready for release. Avoid handling the piece until the full curing time has elapsed, especially in areas where the veneer is thin or delicate.

In conclusion, optimal glue drying time for wood veneer is a blend of science and craftsmanship. By understanding glue types, environmental factors, and practical techniques, you can achieve strong, durable bonds without unnecessary delays. Patience isn’t just a virtue here—it’s the key to professional results.

Spider Wood Durability: Lifespan in Aquascaping Explained

You may want to see also

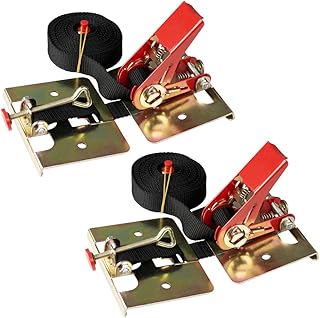

Explore related products

Clamping Pressure for Veneer

Applying the right clamping pressure is critical when working with wood veneer, as it ensures a strong bond without damaging the delicate material. Too little pressure can result in gaps or weak adhesion, while excessive force may crush the veneer or squeeze out glue unevenly. The ideal pressure typically ranges between 50 and 100 psi (pounds per square inch), depending on the veneer thickness and the type of glue used. For thin veneers (0.6mm or less), aim for the lower end of this range to avoid distortion. Thicker veneers (1mm or more) can withstand higher pressure but still require careful monitoring to prevent over-clamping.

To achieve consistent pressure, use a combination of clamps and caul plates. Caul plates distribute pressure evenly across the surface, reducing the risk of indentations or high spots. Place the plates directly on either side of the veneer and apply clamps perpendicular to the grain. For larger projects, consider using vacuum pressing, which applies uniform pressure across the entire surface without the need for multiple clamps. If vacuum pressing isn’t an option, space clamps every 6 to 8 inches along the workpiece to ensure even distribution.

Monitoring clamping pressure is equally important as applying it. Use a pressure gauge if available, especially for critical projects. If a gauge isn’t accessible, rely on tactile feedback: the veneer should feel firmly seated without visible gaps or excessive glue squeeze-out. Periodically check the clamping setup during the initial stages of curing, as wood movement or glue expansion can alter pressure over time. Adjust clamps as needed to maintain consistent force.

The duration of clamping depends on both the glue type and the clamping pressure. For PVA (white or yellow) glues, maintain pressure for at least 30 minutes to an hour, depending on humidity and temperature. Epoxy or polyurethane glues may require longer clamping times, often 2 to 4 hours, to ensure a full cure. Always refer to the glue manufacturer’s recommendations for specific curing times. Once the glue has set, release the clamps gradually to avoid stressing the bond.

Finally, consider the wood species and moisture content when clamping veneer. Veneers with high moisture content or from softer woods (like pine) are more prone to compression under pressure. Allow these materials to acclimate to the workshop environment before gluing and clamping. For added protection, apply a thin layer of wax or release agent to the caul plates to prevent glue from bonding them to the veneer. With careful attention to pressure, materials, and technique, clamping veneer becomes a precise and reliable process.

Mastering Wood Plank Fish: Perfect Cooking Times for Juicy Results

You may want to see also

Explore related products

Environmental Factors Affecting Cure

Temperature plays a critical role in the curing process of glue when bonding wood veneer. Most wood glues, particularly polyvinyl acetate (PVA) and epoxy types, have optimal curing temperatures ranging between 65°F and 80°F (18°C to 27°C). Below 50°F (10°C), curing slows dramatically, and some glues may not fully harden. Above 90°F (32°C), the glue can cure too quickly, leading to weak bonds or surface imperfections. For example, if working in a cold garage during winter, consider using a space heater to maintain the ideal temperature range. Conversely, in hot climates, ensure the workspace is shaded or air-conditioned to prevent overheating. Always check the manufacturer’s guidelines for specific temperature recommendations, as some specialty glues may have narrower tolerances.

Humidity levels directly impact the moisture content of both the glue and the wood veneer, affecting adhesion and curing time. High humidity (above 70%) can cause PVA glues to cure more slowly and may lead to a weaker bond due to excessive moisture absorption. In contrast, low humidity (below 30%) can cause the glue to dry too quickly, resulting in a brittle bond. For optimal results, aim to work in an environment with 40–60% humidity. If humidity is uncontrollable, consider using a dehumidifier or humidifier to regulate the workspace. Additionally, store glue and veneer in a controlled environment to prevent moisture-related issues before application.

Airflow is often overlooked but can significantly influence curing time and bond quality. Adequate ventilation ensures that solvent-based glues release fumes properly, preventing the formation of a weak, gummy layer. However, excessive airflow can cause the glue to dry too quickly, especially in thin veneer applications. To strike a balance, use a fan on low settings to maintain gentle airflow without accelerating drying. For clamping, ensure the veneer is shielded from drafts that could unevenly affect the glue’s curing process. Always prioritize safety by wearing a mask when working with solvent-based adhesives in enclosed spaces.

Direct sunlight can degrade both the glue and the wood veneer, particularly when using UV-sensitive adhesives or light-colored veneers. Prolonged exposure to sunlight can cause the glue to cure unevenly or yellow the veneer surface. If working outdoors or near windows, cover the project with a light cloth or move it to a shaded area during curing. For indoor projects, use artificial lighting instead of natural light to avoid UV interference. This precaution is especially important for epoxy glues, which can become brittle when exposed to UV rays over time. Always plan your workspace to minimize sunlight exposure for consistent and reliable results.

Altitude affects atmospheric pressure, which in turn influences the curing behavior of certain glues, particularly two-part epoxies. At higher elevations (above 5,000 feet or 1,500 meters), lower air pressure can cause some glues to off-gas more rapidly, leading to air bubbles in the bond. To mitigate this, mix epoxy glues slowly and thoroughly, allowing time for bubbles to escape. Additionally, consider using pressure-sensitive clamps to ensure even contact between the veneer and substrate. If working at high altitudes, test the glue on a scrap piece of veneer to confirm curing behavior before proceeding with the final project. Adjustments to clamping pressure or curing time may be necessary to achieve a strong bond.

How Long Does Vinegar Smell Linger on Wood Surfaces?

You may want to see also

Explore related products

$17.99 $19.99

Types of Wood Glue Used

Wood glue selection is critical when working with wood veneer, as the adhesive must bond thin layers securely without causing warping or discoloration. Polyvinyl acetate (PVA) glue is a popular choice due to its ease of use and strong bond. It dries clear, making it ideal for visible joints, and typically sets within 30 minutes to an hour. However, full curing can take up to 24 hours, depending on humidity and temperature. For best results, apply a thin, even layer to both surfaces, clamp firmly, and wipe away excess glue immediately to prevent seepage.

Epoxy resins offer a more robust alternative, particularly for veneers subjected to moisture or stress. Unlike PVA, epoxy requires mixing a resin and hardener, which initiates a chemical reaction. This process can take 5 to 15 minutes, depending on the product, and clamping should begin immediately. Epoxy bonds are stronger and more water-resistant than PVA but require precision in mixing ratios. Over-clamping can lead to squeeze-out, which hardens and becomes difficult to remove. Use epoxy for high-demand applications, but be mindful of its longer working time and potential for discoloration if not applied correctly.

Hide glue, a traditional option, is prized for its reversibility and historical authenticity. It comes in granule or liquid form and must be heated to activate. Application requires a brush or roller, and clamping should begin within 1–2 minutes of cooling. Hide glue sets quickly but remains reversible with heat, making it ideal for repairs or restorations. However, it is less water-resistant than modern adhesives and may not suit all veneer projects. Always test on scrap material to ensure compatibility with your wood type.

Urea formaldehyde glue is another option, though less common in hobbyist settings due to its toxicity and specialized application. It requires heat and pressure to cure, typically in a vacuum press, and is often used in industrial veneer applications. While it forms an exceptionally strong bond, its complexity and health risks make it impractical for most DIY projects. If using, ensure proper ventilation and follow safety guidelines meticulously.

Choosing the right glue depends on your project’s demands. For quick, visible joints, PVA is reliable. For moisture resistance, epoxy excels. Hide glue offers flexibility for repairs, while urea formaldehyde is best reserved for professional use. Always consider curing times, clamping pressure, and environmental factors to ensure a durable bond. Test adhesives on scrap veneer to avoid surprises and achieve a seamless finish.

Durability of Wooden Garden Furniture: Lifespan and Maintenance Tips

You may want to see also

Explore related products

$28.79 $31.99

Veneer Thickness & Clamping Duration

Veneer thickness directly influences clamping duration, a relationship often overlooked in woodworking projects. Thinner veneers, typically ranging from 0.5mm to 1.5mm, require less time under pressure because the glue penetrates and bonds more quickly. For instance, a 0.6mm veneer might only need 30–45 minutes of clamping, whereas a 1.5mm veneer could demand up to 2 hours. This is because thicker veneers have more material for the adhesive to saturate, necessitating extended clamping to ensure a strong, even bond. Understanding this correlation ensures efficient workflow and optimal adhesion.

When working with veneers thicker than 2mm, the clamping strategy must shift to accommodate the material’s density and glue absorption rate. For example, a 3mm veneer may require 4–6 hours of clamping, especially when using slower-drying glues like urea formaldehyde. To expedite the process, consider applying heat (e.g., a heating blanket) to accelerate curing, but avoid excessive temperatures that could warp the wood. Always refer to the glue manufacturer’s guidelines for recommended curing times based on veneer thickness.

A comparative analysis reveals that the type of glue also interacts with veneer thickness to determine clamping duration. Fast-drying glues like cyanoacrylate (super glue) can bond a 1mm veneer in as little as 15 minutes, while slower-drying options like PVA (white glue) may require 1–2 hours for the same thickness. For thicker veneers, epoxy adhesives offer superior strength but often need 8–12 hours to fully cure. Pairing the right glue with the appropriate clamping time ensures a durable bond without compromising the veneer’s integrity.

Practical tips can streamline the clamping process for various veneer thicknesses. For thin veneers, use a caul or sacrificial layer to distribute pressure evenly, preventing indentations. When clamping thicker veneers, apply pressure incrementally, starting with light force and gradually increasing to avoid glue squeeze-out or veneer distortion. Always test a small sample piece to confirm clamping times and adjust as needed. By tailoring your approach to the veneer’s thickness, you’ll achieve professional results with minimal trial and error.

How Long Does Pressure Treated Wood Stay Green?

You may want to see also

Frequently asked questions

Most wood glues require 30 minutes to 1 hour for initial curing, but it’s best to clamp the veneer for at least 2–4 hours to ensure a strong bond. Full curing typically takes 24 hours.

No, it’s crucial to keep the veneer clamped until the glue reaches its initial cure (2–4 hours) to prevent shifting or warping. Premature removal may weaken the bond.

High humidity or low temperatures can slow down drying time, potentially doubling it. In such conditions, allow extra time for curing and ensure proper clamping pressure.