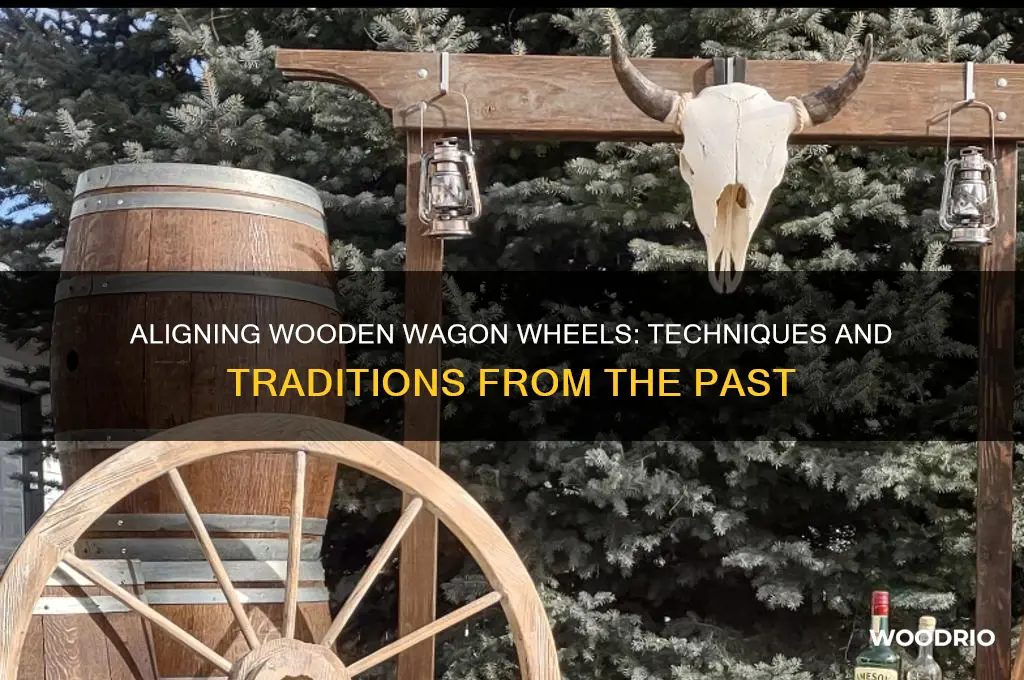

The alignment of wooden wagon wheels was a critical aspect of their functionality and durability, particularly in historical contexts where these wheels were essential for transportation. Crafted from wood, these wheels required precise alignment to ensure smooth movement and to minimize wear and tear. The process involved careful consideration of the wheel’s components, such as the hub, spokes, and rim, which were often made from different types of wood to balance strength and flexibility. Aligning the wheels correctly was crucial to prevent wobbling, uneven wear, and potential breakage, especially under heavy loads or on rough terrain. Techniques varied by region and era, but often included methods like truing, where the wheel was adjusted to run straight, and the use of metal bands or tires to enhance stability. Understanding how these wooden wagon wheels were aligned provides insight into the ingenuity and craftsmanship of early transportation technology.

Explore related products

What You'll Learn

- Traditional Wheel Alignment Methods: Hand tools and visual inspection techniques used by wheelwrights for precise alignment

- Axle and Hub Integration: Ensuring proper fit between the axle and hub for smooth rotation

- Spoke Tensioning Techniques: Balancing spoke tightness to maintain wheel stability and prevent wobbling

- Rim Truing Process: Adjusting the wooden rim to eliminate warping and ensure even rolling

- Alignment Tools and Jigs: Specialized devices used to measure and correct wheel alignment accurately

Traditional Wheel Alignment Methods: Hand tools and visual inspection techniques used by wheelwrights for precise alignment

Long before laser alignment systems and digital precision tools, wheelwrights relied on keen observation, tactile feedback, and simple hand tools to ensure wooden wagon wheels ran true. Central to their craft was the spoke rule, a specialized tool resembling a caliper with adjustable arms. By measuring the distance from the hub to the rim at various points, wheelwrights could detect deviations in radial alignment, ensuring each spoke contributed evenly to the wheel’s integrity. This method, though rudimentary by modern standards, demanded a practiced hand and an eye for symmetry.

Visual inspection played an equally critical role, often beginning with the sighting technique. A wheelwright would stand back from the wheel, aligning one eye with the hub and rim, checking for any wobble or deviation from a straight line. For finer adjustments, they’d use a straightedge, laying it across the wheel’s circumference to identify high or low spots. This process was iterative, with small adjustments made to spokes or felloes until the wheel appeared perfectly round when rotated. Patience and precision were paramount, as even a minor misalignment could lead to uneven wear or instability under load.

Another traditional method involved the use of plumb lines and levels. By suspending a weighted string from the axle or hub, wheelwrights could verify vertical alignment, ensuring the wheel sat squarely on the ground. Horizontal alignment was checked with a spirit level placed atop the wheel’s rim, confirming it was perpendicular to the axle. These tools, though simple, provided empirical data that complemented visual and tactile assessments, creating a multi-faceted approach to alignment.

Practical tips from the wheelwright’s bench include marking reference points on the wheel with chalk or charcoal to track adjustments and testing under simulated load. By placing weights on the wheel or rolling it across a flat surface, craftsmen could observe real-world performance, making final tweaks to eliminate any residual imbalance. While these methods may seem archaic, they underscore the ingenuity of traditional craftsmanship, where skill and observation compensated for the absence of modern technology.

In contrast to today’s automated systems, these hand-tool techniques fostered a deep understanding of the wheel’s mechanics, turning alignment into an art as much as a science. For enthusiasts or historians recreating period-accurate wheels, mastering these methods offers not just functional knowledge but a connection to centuries of wheelwright tradition. The takeaway? Precision alignment isn’t solely about tools—it’s about cultivating an eye for detail and a feel for the material, principles as relevant today as they were in the age of wooden wagons.

Elijah Wood's Age in Deep Impact: Surprising Facts Revealed

You may want to see also

Explore related products

Axle and Hub Integration: Ensuring proper fit between the axle and hub for smooth rotation

The alignment of wooden wagon wheels depended heavily on the precision of axle and hub integration. A poorly fitted axle would cause friction, wear, and eventual failure, rendering the wheel—and thus the wagon—useless. Historical craftsmen understood this, employing techniques like seasoning wood to reduce shrinkage and using lubricants such as animal fat to minimize resistance. Modern enthusiasts recreating these wheels often overlook the critical interplay between axle and hub, leading to wobbling or premature breakage. This section dissects the mechanics of this relationship, offering actionable insights for both historical accuracy and functional durability.

To ensure a proper fit, start by selecting hardwoods like oak or maple for both the hub and axle, as their density resists deformation under load. The axle should be slightly tapered, with a diameter no more than 0.5 inches less than the hub’s bore at its widest point. This taper allows for a snug fit when driven into the hub, but avoid forcing it—use a mallet and wooden block to prevent splitting. For added stability, soak the hub in water for 24 hours before assembly; the swollen wood will shrink tightly around the axle as it dries. Always test the rotation by hand before attaching the wheel to the wagon, ensuring it spins freely without binding.

A common mistake is neglecting the role of moisture in wooden wheel construction. Wood expands when wet and contracts when dry, so assemble components in a controlled environment with 40–60% humidity. If the axle is too tight, sand it down incrementally (no more than 1/16 inch at a time) until it slides in with moderate pressure. Conversely, if the fit is loose, wrap the axle with linen or hemp fibers soaked in glue before insertion. This technique, borrowed from ancient wheelwrights, creates a durable bond without compromising rotation. Lubricate the contact points with beeswax or tallow post-assembly to reduce friction and protect against moisture.

Comparing traditional methods to modern practices reveals a trade-off between craftsmanship and efficiency. Contemporary metal axles offer precision and longevity but lack the shock absorption of wood, making them less suitable for rough terrain. Wooden axles, while more labor-intensive, provide a smoother ride and are repairable with basic tools. For hobbyists, combining a wooden hub with a metal-tipped axle strikes a balance, preserving historical aesthetics while enhancing durability. Regardless of the approach, the goal remains the same: achieving a seamless union between axle and hub that withstands the test of time and terrain.

In conclusion, mastering axle and hub integration requires patience, attention to detail, and respect for the material’s natural properties. By understanding the mechanics of fit, the role of moisture, and the merits of traditional versus modern techniques, craftsmen can recreate wheels that not only align historically but also function reliably. Whether for restoration or recreation, this focused approach ensures that the wheel—the cornerstone of transportation for millennia—continues to roll smoothly into the future.

Robert Redford's Age in 'A Walk in the Woods' Revealed

You may want to see also

Explore related products

Spoke Tensioning Techniques: Balancing spoke tightness to maintain wheel stability and prevent wobbling

Achieving uniform spoke tension is critical for wooden wagon wheel stability, as uneven tightness causes wobbling and premature wear. Historically, wheelwrights used tactile methods—plucking spokes like guitar strings to gauge tension by ear—a technique still relevant today. Modern tools like tension meters offer precision, but the principle remains: consistency ensures the wheel’s structural integrity under load. Without balanced tension, the wheel’s rim may distort, spokes can loosen over time, and the entire assembly risks failure.

To tension spokes effectively, start by tightening them in a cross-pattern, similar to lug nuts on a car wheel. Use a spoke wrench to apply force incrementally, rotating around the wheel in stages. For wooden wheels, aim for a tension that allows the spoke to flex slightly under thumb pressure but not bend excessively. Over-tightening risks splitting the wood, while under-tightening leaves the wheel prone to lateral movement. Periodically spin the wheel to check for trueness, adjusting tension as needed to eliminate wobble.

Comparing wooden wagon wheels to their metal counterparts highlights the importance of material-specific techniques. Metal spokes tolerate higher tension and benefit from torque specifications, whereas wooden spokes require a gentler approach. Wheelwrights often soaked wooden spokes in water to soften them before assembly, ensuring they seated properly without cracking. This historical method underscores the need to work with the material’s natural properties, not against them, to achieve durability.

A practical tip for maintaining spoke tension is to inspect wheels regularly, especially after heavy use or exposure to moisture. Wooden spokes expand and contract with humidity, potentially altering tension over time. Re-tensioning every six months or after significant environmental changes can prevent issues. For restoration projects, consult historical manuals or experienced wheelwrights to replicate traditional tensioning methods, preserving both function and authenticity. Balanced tension isn’t just about stability—it’s about honoring the craftsmanship of the past while ensuring longevity for the future.

Cathie Wood's Age: Unveiling the Financial Guru's Timeline

You may want to see also

Explore related products

Rim Truing Process: Adjusting the wooden rim to eliminate warping and ensure even rolling

Wooden wagon wheels, with their intricate construction, were prone to warping due to environmental factors like moisture and temperature fluctuations. The rim truing process was a critical maintenance task to ensure these wheels rolled smoothly and evenly, prolonging their lifespan and improving safety. This process involved meticulous adjustments to correct misalignments caused by natural wear or external stresses.

Steps in Rim Truing:

- Inspection: Begin by placing the wheel on a flat surface and spinning it slowly. Observe any wobble or deviation from a true circle. Mark the high points of the rim, which indicate areas of warping.

- Moistening: Lightly dampen the compressed side of the warp (the inner curve) with water. This softens the wood, making it more pliable for adjustment. Avoid over-saturating, as excessive moisture can weaken the structure.

- Applying Pressure: Use a truing stand or clamps to apply gentle, even pressure to the swollen side of the warp (the outer curve). Gradually increase pressure until the rim begins to straighten. Hold this position for 12–24 hours, allowing the wood to set in its corrected shape.

- Final Adjustment: After releasing the pressure, inspect the wheel again. If minor imperfections remain, repeat the moistening and pressing process until the rim is uniformly round.

Cautions: Over-tightening clamps or applying heat can crack the wood, rendering the wheel unusable. Always work with the grain of the wood, and avoid truing wheels with structural damage, such as split spokes or a broken felloe.

Practical Tips: For stubborn warps, wrap the dampened area in a wet cloth and secure it with plastic to retain moisture. In colder climates, perform truing indoors to prevent the wood from drying too quickly. Regularly inspect wheels after heavy use or exposure to harsh weather to catch warping early.

Eco-Friendly Disposal: Smart Ways to Dump Old Wood Responsibly

You may want to see also

Explore related products

Alignment Tools and Jigs: Specialized devices used to measure and correct wheel alignment accurately

Wooden wagon wheels, with their intricate construction, required precise alignment to ensure smooth and efficient movement. Achieving this accuracy was no small feat, especially considering the tools available in the past. Enter alignment tools and jigs—specialized devices designed to measure and correct wheel alignment with remarkable precision. These tools were the backbone of wheelwright craftsmanship, transforming a potentially cumbersome task into a systematic process.

One of the earliest and most ingenious alignment tools was the wheel alignment jig, a wooden or metal frame that held the wheel in place while measurements were taken. This jig often featured adjustable arms and calibrated markings, allowing the wheelwright to check the trueness of the wheel’s circumference and the alignment of the spokes. By securing the wheel within the jig, craftsmen could identify deviations from perfect alignment and make necessary adjustments. For example, if a spoke was misaligned, the jig would highlight the discrepancy, enabling the wheelwright to correct it by reshaping or repositioning the spoke.

Another critical tool was the spoke tension gauge, which measured the tension in each spoke to ensure uniformity. Uneven tension could cause the wheel to wobble or deform under load. This gauge, often a simple yet effective device, consisted of a lever and a scale that indicated the force applied to each spoke. Wheelwrights would systematically check each spoke, adjusting its tension until all readings matched. This process was particularly important for heavy-duty wagons, where consistent spoke tension was essential for durability.

For more advanced alignment, wheelwrights employed truing stands, which allowed the wheel to rotate freely while being inspected. These stands often included a pointer or indicator that would trace the wheel’s circumference, revealing any high or low spots. By observing the movement of the pointer, craftsmen could identify areas requiring adjustment. Truing stands were especially useful for fine-tuning the alignment of large wheels, such as those used on stagecoaches or agricultural wagons.

While these tools were effective, their use required skill and experience. Wheelwrights had to understand the interplay between spoke tension, rim shape, and hub alignment to achieve optimal results. Modern alignment tools, such as laser-guided systems, have since replaced these traditional devices, but the principles remain the same: precision and attention to detail. For enthusiasts or historians recreating wooden wagon wheels today, investing in replicas of these alignment tools can provide both authenticity and functionality, ensuring that the wheels perform as they did centuries ago.

Unveiling Jerry Wood's Age in The Outsiders: A Character Analysis

You may want to see also

Frequently asked questions

Wooden wagon wheels were aligned using a combination of careful craftsmanship and simple tools. Wheelwrights would ensure the spokes were evenly spaced and the wheel was true by sight and measurement, often using a straightedge or a rim gauge.

Wheelwrights used tools like a spoke shave, drawknife, and a straightedge to shape and align wooden wagon wheels. A rim gauge was also employed to ensure the wheel was round and true.

Wheelwrights would check the alignment by rolling the wheel on a flat surface or using a balancing tool. They would adjust the spokes and rim as needed to correct any wobble or misalignment, ensuring the wheel ran smoothly.