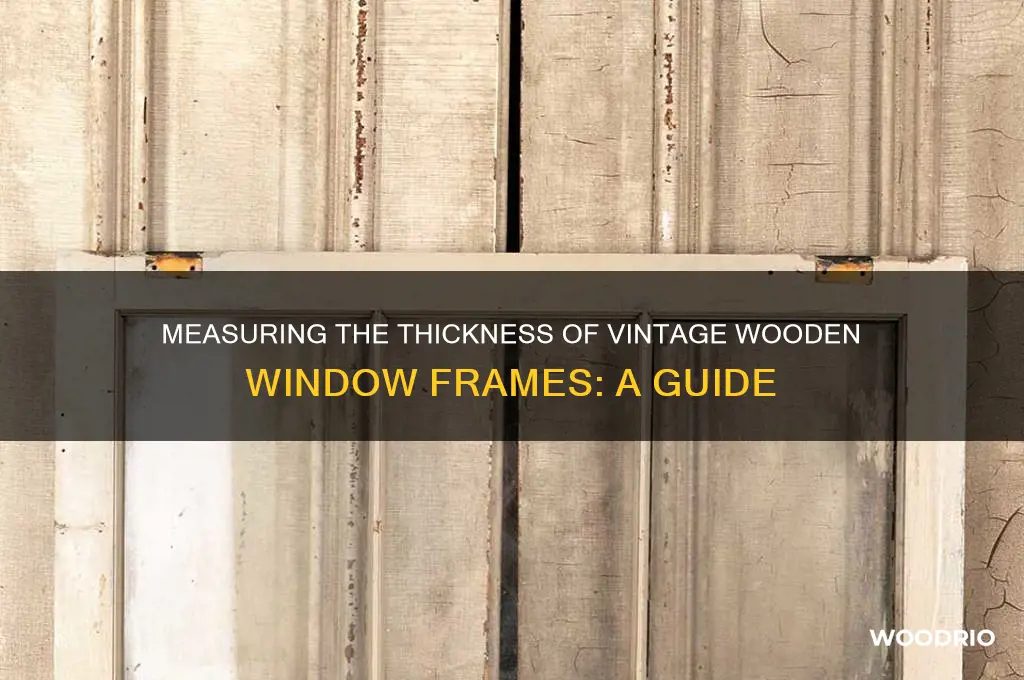

Old wooden window frames vary significantly in thickness depending on their age, architectural style, and regional craftsmanship. Typically, frames from the 19th and early 20th centuries range between 1.5 to 2.5 inches in thickness, with sash components often measuring around 0.75 to 1.25 inches. This thickness was designed to provide structural integrity, accommodate glazing putty, and ensure proper insulation for the era. However, variations exist due to factors like wood type, preservation, and customization, making precise measurements dependent on individual frame examination.

Explore related products

What You'll Learn

Measuring Techniques for Accurate Thickness Assessment

Accurate thickness measurement of old wooden window frames is crucial for restoration, replacement, or customization projects. The first step involves selecting the right tool for the job. Calipers, both digital and manual, offer precision down to 0.01 millimeters, making them ideal for detailed work. For broader areas, a tape measure or ruler can provide a quick estimate, though these lack the finesse of calipers. Always ensure the measuring tool is clean and free of debris to avoid inaccurate readings.

When measuring, consider the frame’s condition. Warped or uneven surfaces can skew results. To address this, take multiple measurements at different points along the frame’s width and height. For example, measure the top, middle, and bottom of the frame, then average the values for a more reliable thickness assessment. This method accounts for natural wear and tear, such as warping or shrinkage, common in aged wood.

Environmental factors play a significant role in measurement accuracy. Wood expands and contracts with changes in humidity and temperature. For the most precise results, measure the frame under controlled conditions—ideally, at room temperature (20–22°C) and 40–50% humidity. If measuring outdoors, choose a dry, mild day and work quickly to minimize the impact of environmental fluctuations.

Advanced techniques can further enhance accuracy. Using a laser thickness gauge provides non-contact measurements, reducing the risk of damaging delicate surfaces. Alternatively, ultrasonic thickness gauges are effective for deeper structural assessments, though they are less common for window frames. Pairing these tools with traditional methods ensures a comprehensive understanding of the frame’s dimensions.

Finally, document your findings meticulously. Record each measurement, its location, and the tool used. This data becomes invaluable for planning repairs, sourcing replacement materials, or crafting custom fittings. By combining the right tools, mindful techniques, and attention to detail, you can achieve precise thickness assessments that honor the integrity of old wooden window frames.

Unveiling Archie Wood's Age: A Surprising Discovery in His Legacy

You may want to see also

Explore related products

Common Thickness Ranges in Vintage Wooden Frames

The thickness of vintage wooden window frames varies significantly based on era, region, and architectural style. Generally, these frames range from 1.5 to 3 inches in thickness, with most falling between 1.75 and 2.25 inches. This range reflects the balance between structural integrity and material efficiency, as older craftsmanship prioritized durability without unnecessary bulk. For example, Victorian-era windows often feature thicker frames (around 2.5 inches) to accommodate ornate detailing and multi-pane designs, while mid-century frames tend to be slightly slimmer (1.75–2 inches) due to simpler aesthetics and advancements in joinery techniques.

Analyzing these thicknesses reveals a correlation between frame depth and window functionality. Thicker frames typically housed heavier glass and provided better insulation, which was crucial in pre-modern buildings lacking advanced weatherproofing. A 2.25-inch frame, for instance, could support double-glazed sashes or storm windows, while a 1.5-inch frame was more common in milder climates or interior partitions. This variation underscores the importance of considering both historical context and intended use when restoring or replicating vintage windows.

For those restoring old windows, measuring frame thickness is a critical step in sourcing replacement parts or replicating original designs. Use a caliper for precision, as even a 1/8-inch discrepancy can affect fit and performance. If the original frame measures 2 inches thick but replacement wood is only available in 1.75-inch stock, consider adding a reinforcing strip along the interior edge to maintain structural stability. Alternatively, custom milling may be necessary for historically accurate restorations, especially in landmarked buildings.

Comparatively, modern window frames are often thinner (1–1.5 inches) due to advancements in materials like vinyl and aluminum, which offer strength without bulk. However, vintage wooden frames remain prized for their aesthetic appeal and thermal properties when properly maintained. A 2-inch wooden frame, for example, can outperform thinner modern alternatives in terms of sound insulation and energy efficiency when paired with weatherstripping and storm windows. This highlights the enduring value of traditional craftsmanship in sustainable building practices.

In practical terms, understanding frame thickness helps homeowners and craftsmen make informed decisions about repairs or replacements. For instance, a 1.75-inch frame may be suitable for a single-glazed window in a temperate climate, but a 2.5-inch frame is better suited for harsher conditions or double-glazed units. Always consider the load-bearing capacity of the surrounding structure when altering frame thickness, as significant changes can compromise the integrity of the wall or sash. By respecting historical standards while adapting to modern needs, vintage wooden windows can continue to function beautifully for generations.

Unveiling Charloe Woods' Age: A Comprehensive Look at Her Life

You may want to see also

Explore related products

$40.24

$37.66

Factors Affecting Frame Thickness Over Time

The thickness of old wooden window frames is not a fixed measurement but a variable influenced by historical context, craftsmanship, and environmental factors. Early 20th-century residential windows, for instance, often featured frames ranging from 1.5 to 2.5 inches in thickness, reflecting the availability of old-growth timber and the need for durability in drafty homes. In contrast, 18th-century European windows might exceed 3 inches, showcasing both the era’s architectural grandeur and the structural demands of larger glass panes. These variations highlight how frame thickness served both functional and aesthetic purposes across different periods.

Environmental conditions play a pivotal role in altering frame thickness over time. Prolonged exposure to moisture, for example, causes wood to swell, increasing thickness temporarily before leading to rot and deterioration. Conversely, dry climates can shrink wood, reducing thickness and compromising structural integrity. A study on Victorian-era windows in coastal regions revealed that frames exposed to saltwater air were, on average, 10–15% thicker initially but degraded faster than inland counterparts. Homeowners in humid areas can mitigate swelling by applying water-repellent sealants annually, while those in arid regions should use wood conditioners to prevent shrinkage.

Technological advancements in woodworking also shaped frame thickness trends. Before the 19th century, hand-hewn frames were thicker due to the limitations of manual tools and the need for structural robustness. The introduction of mechanized sawmills in the mid-1800s allowed for more precise cuts, reducing average thickness by up to 20%. However, this shift sometimes compromised longevity, as thinner frames were more susceptible to warping. Modern restorers often reinforce these thinner sections with splines or epoxy to balance historical accuracy with durability, ensuring frames last another century.

Cultural and regional preferences further dictated frame thickness. In Scandinavian architecture, thick window frames (often 3–4 inches) were essential for insulation against harsh winters, while Mediterranean designs favored thinner frames (1–2 inches) to maximize light and airflow. These regional differences persist in restoration projects, where authenticity requires adhering to original thickness specifications. For DIY enthusiasts, measuring the sash and mullion thickness of existing frames provides a baseline for replication, ensuring historical accuracy in renovations.

Finally, the type of wood used significantly impacts frame thickness and longevity. Hardwoods like oak and mahogany, prized for their density, allowed for thinner yet stronger frames compared to softer woods like pine. However, hardwood scarcity in the 20th century led to thinner, less durable frames as builders turned to softer alternatives. When restoring old windows, assess the wood type and adjust thickness accordingly; for instance, replacing rotted pine with oak may require reducing the frame thickness to avoid visual disproportion. This blend of material science and historical insight ensures both authenticity and functionality.

Should You Oil Old Wooden Spoons? A Complete Care Guide

You may want to see also

Explore related products

Tools for Inspecting Old Window Frame Dimensions

Accurate measurement of old wooden window frames begins with the right tools. A digital caliper offers precision down to 0.01 millimeters, ideal for capturing the thickness of weathered or uneven surfaces. Pair this with a flexible ruler to measure curved or irregular profiles, ensuring no detail is overlooked. For deeper inspections, a moisture meter identifies hidden rot, which can distort frame dimensions over time. These tools collectively provide a comprehensive understanding of the frame’s condition and thickness.

While high-tech tools are valuable, simplicity often reigns supreme. A steel tape measure remains indispensable for quick, reliable measurements of overall frame width and height. However, its rigidity limits accuracy on intricate details. Here, a feel gauge—a set of thin, flat blades of varying thicknesses—can be slid into gaps or against surfaces to estimate thickness where calipers cannot reach. This low-tech approach bridges the gap between precision and practicality.

Inspecting old window frames requires more than just tools—it demands technique. Start by cleaning the frame’s surface to remove dirt or paint buildup that could skew measurements. Measure at multiple points, as age-related warping often results in inconsistent thickness. For example, a frame’s bottom rail may be thicker than its stiles due to water damage. Document these variations to inform restoration decisions, such as whether to replicate the original profile or standardize dimensions for new components.

Choosing the right tool depends on the frame’s age and condition. For 19th-century windows, where craftsmanship varied widely, a combination of calipers and feel gauges is essential to capture both precision and nuance. In contrast, mid-20th-century frames often feature more uniform profiles, making a tape measure and moisture meter sufficient. Always cross-reference measurements with historical records or similar period windows to ensure accuracy, especially when replicating or replacing parts.

Beyond measurement, these tools serve a diagnostic purpose. A frame measuring 1.5 to 2 inches thick at the sash but showing signs of rot detected by a moisture meter may require partial replacement rather than full restoration. Conversely, a frame with consistent thickness but cracked glazing beads might only need localized repairs. By integrating tools with observational skills, inspectors can balance preservation goals with practical solutions, ensuring old windows endure without compromising their character.

Unveiling Avery Woods' Age: A Comprehensive Look at Her Timeline

You may want to see also

Explore related products

Restoration Tips for Preserving Original Frame Thickness

Old wooden window frames, often ranging from 1.5 to 2.5 inches in thickness, are more than just structural elements—they are historical artifacts. Preserving their original thickness during restoration is crucial for maintaining both aesthetic integrity and structural stability. Thinner modern replacements can compromise the window’s ability to support surrounding masonry, while altering the frame’s profile disrupts the building’s character. Before beginning any restoration, measure the frame’s thickness at multiple points to establish a baseline and identify areas of wear or damage.

One of the most effective methods for preserving thickness is selective repair rather than full replacement. For rotted sections, use epoxy wood fillers specifically designed for historical restoration. These fillers, such as Abatron WoodEpox, can be applied in layers to match the original thickness precisely. Sand each layer lightly before adding the next to ensure a seamless integration. For larger voids, splice in new wood pieces of matching thickness, using traditional joinery techniques like scarfing or dutchman repairs. Avoid the temptation to plane down the entire frame to achieve uniformity—this sacrifices historical material and weakens the structure.

Moisture management is critical to preventing future thickness loss. Apply a breathable wood preservative, such as borate-based solutions, to protect against rot without trapping moisture. Follow this with a high-quality exterior primer and paint, ensuring all end grains are sealed. Install discreet drip caps above the frame to divert water and consider adding a bead of silicone caulk at the junction between the frame and masonry. Regularly inspect for cracks or peeling paint, addressing issues promptly to avoid water infiltration that could lead to swelling or shrinkage.

When reassembling the frame, prioritize original hardware and techniques. Use traditional linseed oil-based putty for glazing rather than modern synthetic alternatives, as it moves with the wood and prevents cracking. Reinstall original sash cords or chains, ensuring the weight distribution remains consistent with the frame’s original design. If the frame has warped slightly, use gentle heat and clamps to coax it back into shape rather than forcing it, which could split the wood. Always work in controlled temperature and humidity conditions to minimize stress on the material.

Finally, document every step of the restoration process. Take detailed photographs and notes on the frame’s condition, materials used, and techniques applied. This not only aids future restorers but also ensures compliance with historical preservation guidelines. By combining meticulous craftsmanship with respect for original materials, you can preserve the frame’s thickness—and its story—for generations to come.

Unveiling Stephanie Woods' Age: A Comprehensive Look at Her Life

You may want to see also

Frequently asked questions

A typical old wooden window frame ranges from 1.5 to 2.5 inches (38 to 64 mm) in thickness, depending on the age, style, and purpose of the window.

Yes, the thickness can vary by architectural period. Older windows from the 18th and 19th centuries tend to be thicker (2 to 2.5 inches) due to craftsmanship and materials, while later Victorian or Edwardian windows may be slightly thinner (1.5 to 2 inches).

Old wooden window frames are generally thicker than modern frames, which often range from 1 to 1.5 inches. Modern frames use engineered materials and thinner profiles for efficiency and aesthetics.

Yes, thicker frames can provide better insulation due to the increased wood mass, but their effectiveness also depends on the condition of the wood, glazing, and any gaps or drafts present.