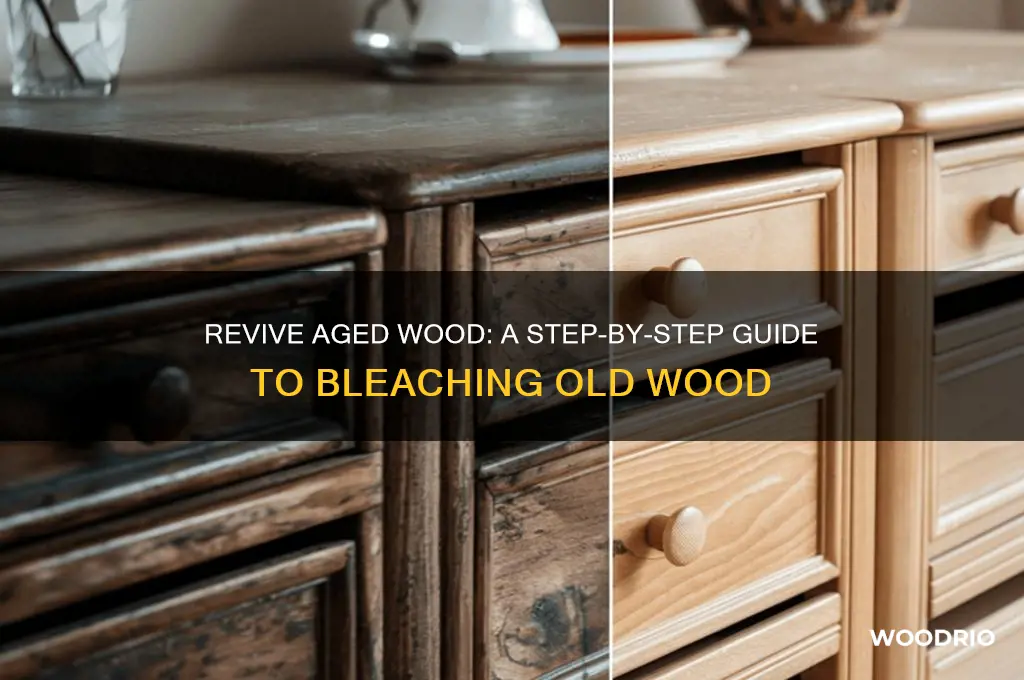

Bleaching old wood is a transformative process that can restore its original color, remove stains, and brighten its appearance, making it ideal for reviving aged or discolored wooden furniture, floors, or decor. This method involves using wood bleach, typically a two-part solution containing oxalic acid or a peroxide-based formula, to break down and neutralize dark stains caused by water, mold, or aging. Before starting, it’s essential to prepare the wood by sanding it lightly to remove any surface finishes and ensure the bleach can penetrate effectively. Safety precautions, such as wearing gloves and working in a well-ventilated area, are crucial due to the chemicals involved. After bleaching, the wood should be neutralized, rinsed thoroughly, and allowed to dry before applying a protective finish to preserve its renewed look. This technique is particularly useful for preserving the natural beauty of wood while giving it a fresh, updated appearance.

Explore related products

What You'll Learn

- Preparing the wood surface: Clean, sand, and remove old finish for even bleach absorption

- Choosing the right bleach: Select oxalic, chlorine, or two-part bleach based on wood type

- Applying bleach safely: Use gloves, ventilate, and follow instructions to avoid damage or injury

- Neutralizing and rinsing: Stop bleaching process by neutralizing and rinsing thoroughly after desired shade

- Sealing and finishing: Apply sealant or stain to protect wood and enhance its appearance

Preparing the wood surface: Clean, sand, and remove old finish for even bleach absorption

Before bleaching old wood, the surface must be free of dirt, grime, and old finishes that could hinder even absorption. Start by cleaning the wood thoroughly. Use a mild detergent mixed with warm water and a soft-bristled brush to scrub away surface contaminants. For stubborn stains, a trisodium phosphate (TSP) solution (1/2 cup TSP per gallon of water) is effective, but wear gloves and rinse the wood afterward to remove residue. This step ensures the bleach penetrates uniformly, preventing patchy results.

Once cleaned, sanding becomes critical to expose fresh wood fibers and create a receptive surface for bleach. Begin with 80-grit sandpaper to remove the old finish and smooth out rough areas, then progress to 120-grit for a finer finish. Always sand in the direction of the grain to avoid scratches. For intricate or carved pieces, use a sanding sponge or block to reach tight spaces. Dust removal post-sanding is essential; wipe the surface with a tack cloth or vacuum with a brush attachment to eliminate particles that could interfere with bleaching.

Removing old finishes, such as varnish or paint, is a non-negotiable step for successful bleaching. Chemical strippers (e.g., citristrip or paint stripper) can be applied with a brush, left to soften the finish (15–30 minutes), and then scraped off with a plastic putty knife. For thicker finishes, multiple applications may be needed. Alternatively, a heat gun can be used cautiously to avoid scorching the wood. After stripping, neutralize the surface with a solvent like mineral spirits and allow it to dry completely before proceeding.

The interplay between cleaning, sanding, and finish removal is key to achieving even bleach absorption. Skipping any step risks uneven results, as contaminants or residual finishes can create barriers. For example, oil-based stains left behind after inadequate cleaning will repel bleach, leading to blotchy discoloration. Similarly, unsanded surfaces may absorb bleach inconsistently due to varying wood densities. By meticulously preparing the wood, you create a uniform foundation that ensures the bleach works as intended, revitalizing the wood’s natural tone without surprises.

Elijah Wood's Age in 'Fellowship of the Ring' Revealed

You may want to see also

Explore related products

Choosing the right bleach: Select oxalic, chlorine, or two-part bleach based on wood type

Bleaching old wood isn't a one-size-fits-all process. The type of bleach you choose depends heavily on the wood species and the desired outcome. Oxalic acid, chlorine bleach, and two-part bleaches each have distinct properties, making them suitable for different scenarios. Understanding these differences is crucial to achieving the desired result without damaging the wood.

Oxalic Acid: The Gentle Restorer

For delicate, aged woods like oak or pine, oxalic acid is often the preferred choice. This mild bleach effectively removes dark stains caused by water damage, rust, or aging without significantly altering the wood's natural color. It's particularly useful for restoring antique furniture or flooring where preserving the original patina is essential. To use, dissolve 4 ounces of oxalic acid crystals in 1 gallon of warm water, apply with a brush, and allow it to sit for 10-15 minutes before rinsing thoroughly. Always wear gloves and work in a well-ventilated area, as oxalic acid can irritate skin and eyes.

Chlorine Bleach: The Stain Fighter

Chlorine bleach is a powerful option for tackling deep-set stains on durable woods like teak or mahogany. However, its strength comes with a caveat: it can lighten the wood significantly, sometimes resulting in an uneven or overly bleached appearance. This makes it less ideal for projects where color consistency is critical. To minimize damage, dilute chlorine bleach with water at a ratio of 1:3, apply it sparingly, and neutralize the wood with a solution of vinegar and water (1:1) after rinsing. Avoid using chlorine bleach on softwoods or woods with a high tannin content, as it can cause discoloration.

Two-Part Bleach: The Precision Tool

Two-part bleach systems, typically consisting of sodium hydroxide and hydrogen peroxide, offer a more controlled bleaching process. They are particularly effective for achieving a uniform color on hardwoods like walnut or cherry. The two components are mixed just before application, creating a chemical reaction that breaks down stains and lightens the wood. Follow the manufacturer’s instructions carefully, as improper mixing can lead to uneven results or damage. This method is ideal for professional refinishers or DIYers tackling complex projects, but it requires precision and caution due to the chemicals involved.

Matching Bleach to Wood Type: Practical Tips

When selecting a bleach, consider the wood’s hardness, age, and existing finish. Softwoods like pine or cedar are more susceptible to damage from harsh chemicals, making oxalic acid the safer choice. Hardwoods can generally withstand stronger bleaches, but always test a small, inconspicuous area first. For very old or fragile wood, opt for gentler methods to avoid weakening the structure. Additionally, factor in the desired final look—whether you aim to restore the original color or achieve a lighter tone—to guide your bleach selection. With the right choice, you can breathe new life into old wood while preserving its integrity.

James Woods Skier Age: Unveiling the Olympic Freestyle Star's Birth Year

You may want to see also

Explore related products

Applying bleach safely: Use gloves, ventilate, and follow instructions to avoid damage or injury

Bleach is a powerful tool for transforming old wood, but its strength demands respect. Before you begin, understand that bleach is a corrosive substance that can cause skin irritation, respiratory issues, and damage to your wood if not handled correctly. This isn't a project for bare hands and a stuffy room.

Safety goggles, gloves, and a well-ventilated workspace are your first line of defense. Opt for nitrile gloves, which offer better chemical resistance than latex. Ensure your workspace has open windows and, ideally, a fan to circulate fresh air. If working indoors, consider a respirator mask to protect your lungs from fumes.

The type of bleach matters. Chlorine bleach, a common household variety, is effective but harsh. For a gentler approach, consider oxygen-based bleaches, which are less likely to damage the wood's fibers. Regardless of type, always dilute bleach according to the manufacturer's instructions. A typical dilution ratio for chlorine bleach is 1 part bleach to 3 parts water, but this can vary, so read the label carefully. Applying undiluted bleach can lead to uneven bleaching, wood discoloration, and even structural damage.

Test your bleach solution on a small, inconspicuous area of the wood before proceeding. This allows you to gauge the bleaching effect and ensure the wood tolerates the solution. If the wood shows signs of distress, such as raised grain or discoloration, adjust the bleach concentration or consider an alternative method.

Application technique is key. Use a brush or spray bottle to apply the bleach solution evenly, working in the direction of the wood grain. Avoid over-saturation, which can lead to blotching. Allow the bleach to sit for the recommended time, usually 10-15 minutes, then neutralize it with a solution of vinegar and water (1 part vinegar to 4 parts water). This stops the bleaching process and prevents further lightening. Finally, rinse the wood thoroughly with clean water and allow it to dry completely before sanding or refinishing.

Revive Your Vintage Wooden Office Chair: Simple Adjustment Tips and Tricks

You may want to see also

Explore related products

Neutralizing and rinsing: Stop bleaching process by neutralizing and rinsing thoroughly after desired shade

Once the wood reaches your desired shade, it’s crucial to halt the bleaching process immediately to prevent over-lightening or damage. Neutralizing the bleach is the first step in this process, acting as a chemical stop sign that deactivates the bleaching agent. For wood bleached with oxalic acid or chlorine-based solutions, a neutralizing agent like baking soda or vinegar is commonly used. Mix 1 cup of baking soda with 1 gallon of water for a mild, effective neutralizer, or dilute 1 cup of white vinegar in 1 gallon of water for acidic bleach solutions. Apply this neutralizer generously to the wood using a sponge or spray bottle, ensuring every bleached surface is covered.

The application of the neutralizer should be followed by a thorough rinse to remove all traces of bleach and neutralizing agents. Use clean, cool water and rinse the wood multiple times, especially in crevices or textured areas where residue might linger. For larger projects, a garden hose with a gentle spray setting works well, while smaller pieces can be rinsed in a sink or with a bucket of water. The goal is to eliminate any chemical remnants that could affect the wood’s final appearance or its ability to absorb stain or sealant.

A common mistake is rushing the rinsing process, which can leave behind a white, powdery residue or cause uneven absorption of subsequent treatments. To ensure completeness, test the wood’s pH with a strip after rinsing; it should read close to neutral (pH 7). If the wood still feels slippery or looks cloudy, continue rinsing until the surface is clean and smooth to the touch. This step is particularly important for indoor projects, where residual chemicals can off-gas or cause irritation.

Finally, allow the wood to dry completely before proceeding with staining, sealing, or finishing. Proper neutralization and rinsing not only preserve the wood’s integrity but also ensure that future treatments adhere correctly and last longer. Think of this step as the bridge between bleaching and beautifying—skipping it risks undermining all your hard work. By taking the time to neutralize and rinse thoroughly, you safeguard the wood’s natural character while achieving the lightened look you desire.

Unveiling Tony Woods' Age: A Comprehensive Look at His Life

You may want to see also

Explore related products

Sealing and finishing: Apply sealant or stain to protect wood and enhance its appearance

After bleaching old wood, sealing and finishing are crucial steps to protect the wood from moisture, UV damage, and wear while enhancing its natural beauty. The choice of sealant or stain depends on the desired aesthetic and the wood’s intended use. For instance, a matte polyurethane sealant provides a natural, unaltered look, while a tinted stain can deepen the wood’s color or add warmth. Always test the product on a small, inconspicuous area to ensure compatibility with the bleached wood.

Instructively, begin by sanding the bleached wood with 220-grit sandpaper to create a smooth surface for application. Remove all dust with a tack cloth or damp rag. Apply the sealant or stain in thin, even coats using a foam brush or sprayer, following the manufacturer’s drying times between layers. Typically, two to three coats are sufficient for optimal protection. For outdoor wood, choose a marine-grade sealant or UV-resistant stain to combat weather exposure. Avoid over-applying, as this can lead to a sticky or uneven finish.

Persuasively, investing in a high-quality sealant or stain is a small price to pay for long-term durability and aesthetic appeal. Cheaper products may yellow over time or fail to adhere properly, undermining your bleaching efforts. For example, a premium water-based polyurethane offers low VOCs, quick drying, and a clear finish that won’t alter the wood’s tone. If sustainability is a priority, opt for natural oils like tung or linseed, which penetrate deeply but require more frequent reapplication.

Comparatively, stains and sealants serve different purposes. Stains, such as those from Minwax or Varathane, add color and can mask imperfections, making them ideal for unevenly bleached surfaces. Sealants, like epoxy or polycrylic, prioritize protection and are better suited for high-traffic areas or furniture. Combining both—applying a stain first, followed by a sealant—offers the best of both worlds, though this approach requires careful product compatibility checks to avoid adhesion issues.

Descriptively, the final finish transforms the bleached wood into a tactile and visual masterpiece. A satin sealant imparts a soft, velvety sheen, while a gloss finish reflects light, accentuating the wood’s grain. For a rustic, matte look, consider a wax-based sealant, which provides a smooth, natural feel. Whichever option you choose, the end result should not only protect the wood but also elevate its character, turning a once-faded piece into a timeless treasure.

Unveiling Greenlee Wood's Age: A Surprising Discovery Awaits

You may want to see also

Frequently asked questions

Oxygen-based bleaches (like wood bleach or powdered bleach) are generally the best choice for old wood, as they are less harsh than chlorine-based bleaches and reduce the risk of damage.

Sand the wood lightly to remove any old finishes, dirt, or grime. Clean the surface with a damp cloth and let it dry completely before applying the bleach.

Yes, but you may need to strip the existing finish first. Use a paint stripper or sandpaper to remove stains or paint before applying the bleach for best results.

Follow the manufacturer’s instructions, but typically, bleach should be left on the wood for 15–30 minutes. Monitor the process to avoid over-bleaching or damage.

Yes, after rinsing off the bleach, neutralize the wood with a solution of vinegar and water (1:1 ratio) or a commercial neutralizer to stop the bleaching process and prevent discoloration.