Changing the belt on an old 1940s wood lathe requires careful attention to detail and respect for the machine's vintage design. Begin by disconnecting the power source to ensure safety. Inspect the existing belt for wear and note its position on the pulleys, as these lathes often feature flat or round belts that drive the spindle. Loosen the motor or idler pulley adjustment mechanism, typically secured by bolts or set screws, to release tension and remove the old belt. Install the new belt, ensuring it sits properly in the grooves of the pulleys, and gradually retighten the adjustment mechanism to achieve the correct tension. Double-check alignment and rotation before reconnecting the power to test the lathe's operation, preserving its functionality while maintaining its historical integrity.

| Characteristics | Values |

|---|---|

| Tools Required | Wrenches, screwdrivers, belt tension gauge (optional), safety gloves, safety goggles. |

| Safety Precautions | Disconnect power, ensure lathe is stable, wear protective gear. |

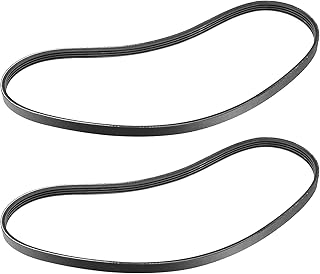

| Belt Type | Flat or V-belt, depending on lathe model (check manufacturer's manual or markings). |

| Belt Size | Measure old belt or consult lathe manual for length and width specifications. |

| Steps to Change Belt | 1. Disconnect power. 2. Loosen motor mounting bolts. 3. Adjust motor position to release tension. 4. Remove old belt. 5. Install new belt. 6. Re-tension motor. 7. Tighten mounting bolts. 8. Reconnect power and test. |

| Tension Adjustment | Ensure belt has proper tension (not too loose or tight) to avoid slippage or damage. |

| Motor Alignment | Align motor pulley with drive pulley to ensure belt runs straight. |

| Common Issues | Belt slipping, incorrect tension, misaligned pulleys, worn pulleys. |

| Maintenance Tips | Regularly inspect belt for wear, clean pulleys, and lubricate moving parts as needed. |

| Parts to Check | Pulleys, motor mounts, belt guards, and drive shaft for wear or damage. |

| Replacement Frequency | Replace belt every 1-2 years or when signs of wear (cracks, fraying) appear. |

| Historical Context | 1940s lathes often used flat or V-belts, with simpler mechanisms compared to modern lathes. |

Explore related products

What You'll Learn

- Safety Precautions: Wear protective gear, disconnect power, secure the lathe to prevent movement during belt replacement

- Identify Belt Type: Measure old belt size, check for flat or V-belt compatibility with the lathe's pulleys

- Remove Old Belt: Loosen motor mount, slide belt off pulleys, inspect for wear or damage

- Install New Belt: Align pulleys, stretch belt into place, ensure proper tension for smooth operation

- Test and Adjust: Reconnect power, run lathe at low speed, adjust tension if slipping occurs

Safety Precautions: Wear protective gear, disconnect power, secure the lathe to prevent movement during belt replacement

Before attempting to change the belt on your 1940s wood lathe, prioritize safety to prevent accidents and injuries. Start by wearing appropriate protective gear, including safety goggles to shield your eyes from debris, ear protection to guard against the noise of the machinery, and gloves to protect your hands from sharp edges and moving parts. Ensure your clothing is fitted and free of loose ends that could get caught in the lathe. This gear is your first line of defense against potential hazards.

Next, disconnect the power source to eliminate the risk of accidental activation. Unplug the lathe from the electrical outlet or switch off the circuit breaker if it’s hardwired. For added safety, use a voltage tester to confirm that no power is flowing to the machine. Never assume the lathe is off simply because it’s not running—always verify. This step is critical, as even a momentary activation during belt replacement can lead to severe injury.

Securing the lathe to prevent movement is another essential precaution. Old lathes, especially those from the 1940s, may have worn or unstable bases. Use clamps or heavy-duty straps to anchor the lathe to a sturdy workbench or the floor. If the lathe has adjustable feet, ensure they are tightened and locked in place. Movement during belt replacement can cause the machine to tip or shift, creating a dangerous situation. Stability is key to maintaining control throughout the process.

Consider the environment in which you’re working. Ensure the area is well-lit to avoid missteps and clearly see the lathe’s components. Keep the workspace clean and free of clutter to minimize tripping hazards. If working in a shared space, alert others to stay clear of the area. By taking these precautions, you create a safer environment for yourself and those around you. Safety isn’t just about protecting yourself—it’s about preventing accidents that could affect others.

Finally, take a moment to assess your preparedness before beginning. Double-check that all safety measures are in place: gear is worn, power is disconnected, and the lathe is securely anchored. If you’re unsure about any step, consult the lathe’s manual or seek guidance from an experienced user. Rushing through safety precautions can lead to oversight, so approach each step methodically. By prioritizing safety, you ensure that the belt replacement process is not only successful but also free from harm.

Charlie Woods Age: Tiger's Son Grows Up in Spotlight

You may want to see also

Explore related products

Identify Belt Type: Measure old belt size, check for flat or V-belt compatibility with the lathe's pulleys

Before attempting to replace the belt on your 1940s wood lathe, it’s crucial to identify the correct belt type. Start by measuring the old belt’s length and width, even if it’s worn or damaged. Use a flexible tape measure to get an accurate reading, noting the overall length and the cross-sectional dimensions. This step is essential because older lathes often used non-standard belt sizes, and modern replacements may not align perfectly without precise measurements. Record these numbers for reference when sourcing a new belt.

Next, examine the lathe’s pulleys to determine compatibility with flat or V-belts. Flat belts were common in early 20th-century machinery, characterized by their rectangular cross-section and smooth surface. V-belts, with their trapezoidal shape, became more prevalent later but may have been retrofitted to older lathes. Inspect the pulley grooves: flat pulleys have a flat, wide surface, while V-belt pulleys feature angled grooves designed to match the belt’s shape. Mismatched belts and pulleys can cause slippage, reduced efficiency, or damage to the lathe.

If the old belt is missing or unrecognizable, analyze the pulleys alone. Measure the groove width and angle (if applicable) to deduce the belt type. For V-belts, the groove angle typically matches the belt’s cross-section, often 40 degrees for standard V-belts. Flat pulleys require a belt with a width that fits snugly without overhang. Cross-reference these measurements with belt sizing charts available from suppliers or online resources to ensure accuracy.

A practical tip: if the lathe has been modified over the years, consult any documentation or markings on the machine. Some lathes have manufacturer plates or manuals that specify the original belt type and size. If no records exist, consider reaching out to vintage machinery forums or experts who specialize in restoring old tools. They can provide insights based on similar models or known modifications.

In conclusion, identifying the correct belt type is a blend of measurement, observation, and research. Accurate sizing and compatibility checks ensure the new belt functions efficiently and prolongs the life of your 1940s wood lathe. Taking the time to get this step right will save you from frustration and potential damage down the line.

Oak Leaf Hydrangeas: Blooming on Old or New Wood?

You may want to see also

Explore related products

Remove Old Belt: Loosen motor mount, slide belt off pulleys, inspect for wear or damage

The first step in replacing the belt on your 1940s wood lathe is to remove the old one, a process that requires careful attention to the machine's mechanics. Begin by locating the motor mount, typically secured with bolts or screws. Loosen these fasteners, but don't remove them entirely; you want to create enough slack to maneuver the belt. This step is crucial, as it allows you to access the belt without straining the motor or its mounting system.

With the motor mount loosened, you can now focus on the belt itself. Slide the belt off the pulleys, taking note of its path and the tension it was under. This is a delicate operation, as you don't want to force the belt, which could lead to damage or, worse, injury. A gentle, steady hand is key here. As you remove the belt, inspect it for wear and tear. Look for cracks, fraying, or any signs of deterioration, especially in the areas that were under the most tension. This inspection is vital, as it provides insights into the lathe's maintenance history and can guide future belt choices.

The removal process is not just about taking off the old belt but also about understanding the lathe's mechanics. As you work, observe how the motor mount is designed and how it interacts with the pulleys. This knowledge will be invaluable when installing the new belt, ensuring it is aligned correctly and under the right tension. It's a blend of practical action and analytical observation, a unique aspect of working with vintage machinery.

In the context of a 1940s wood lathe, this process might reveal the machine's age and the need for careful handling. These lathes were built to last, but their components require respect and precision. For instance, the motor mount might be made of cast iron, a material that can be brittle, so gentle loosening is essential. Similarly, the belt, possibly made of leather or an early synthetic material, could be more delicate than modern alternatives, making the inspection step even more critical.

This procedure is a blend of art and science, requiring both physical skill and an understanding of the machine's history. It's a testament to the craftsmanship of the past and a reminder that working with vintage tools demands a unique approach, combining practical steps with a deep respect for the machinery's heritage. By carefully removing the old belt, you're not just preparing for a replacement; you're engaging in a dialogue with the lathe's past, ensuring its continued operation for years to come.

Master the Art of Aging Wood: Techniques for a Timeless, Vintage Look

You may want to see also

Explore related products

Install New Belt: Align pulleys, stretch belt into place, ensure proper tension for smooth operation

The pulleys on your 1940s wood lathe are the heart of its power transmission system, and their alignment is critical for efficient operation. Misaligned pulleys can cause the belt to slip, wear unevenly, or even break, leading to frustration and potential damage. Before installing a new belt, inspect the pulleys for any signs of wear, such as grooves or cracks. Use a straightedge or a laser alignment tool to ensure both pulleys are parallel and at the same height. Adjust the motor or headstock position if necessary, tightening the mounting bolts securely once alignment is achieved.

Stretching the new belt into place requires patience and precision. Start by looping the belt around the larger drive pulley, then carefully guide it onto the smaller pulley, ensuring it sits correctly in the grooves. Avoid forcing the belt, as excessive tension at this stage can damage the belt or pulleys. If the belt is too tight to install easily, consider using a belt installation tool or a pry bar to gently stretch it into position. Remember, the goal is to achieve a snug fit, not to over-tighten.

Proper tension is the key to smooth and efficient lathe operation. A belt that’s too loose will slip under load, while one that’s too tight can cause premature wear on bearings and pulleys. To adjust tension, locate the motor adjustment screws or sliding base, if your lathe has one. Gradually move the motor until the belt deflects approximately 1/4 to 1/2 inch when moderate pressure is applied. This range ensures enough flexibility to absorb shock without compromising power transfer. Test the tension by running the lathe at low speed, listening for any squealing or slippage, and making final adjustments as needed.

For added longevity, consider applying a small amount of belt dressing or conditioner to the new belt after installation. This reduces friction and helps the belt seat properly into the pulley grooves. However, use these products sparingly, as excessive dressing can attract dust and debris, accelerating wear. Regularly inspect the belt for signs of wear or misalignment, especially during the first few hours of operation, as this is when most issues become apparent. With proper alignment, installation, and tension, your 1940s wood lathe will run smoothly, preserving its vintage charm while delivering reliable performance.

Reviving Vintage Charm: Are Old Wooden Fruit Crates Worth Selling?

You may want to see also

Explore related products

Test and Adjust: Reconnect power, run lathe at low speed, adjust tension if slipping occurs

Once the new belt is in place, the real test begins. Reconnect the power supply to the lathe, ensuring all safety precautions are observed. Start the machine at its lowest speed setting—this gradual approach allows you to observe the belt’s behavior without risking immediate damage. Watch closely for any signs of slipping, which could indicate improper tension. A properly tensioned belt should flex slightly (about ¼ to ½ inch) when moderate pressure is applied. If slipping occurs, turn off the lathe and adjust the tension by moving the motor or idler pulley, depending on your lathe’s design. Use a wrench or adjusting screw, typically found near the motor mount, to make incremental changes. Avoid over-tightening, as excessive tension can strain the motor and reduce belt life.

The process of testing and adjusting is iterative, requiring patience and precision. After each adjustment, run the lathe again at low speed to evaluate the belt’s performance. Listen for unusual noises, such as squealing or grinding, which may signal misalignment or improper tension. Observe the belt’s movement on the pulleys—it should track straight without wandering or rubbing against the sides. If issues persist, double-check the belt’s alignment and ensure the pulleys are clean and free of debris. This step is critical for older lathes, as decades of wear can introduce subtle irregularities that affect belt operation.

From a practical standpoint, consider marking the motor’s position before making adjustments to track changes. This allows you to revert to a previous setting if an adjustment worsens the issue. For lathes with flat belts, ensure the belt sits evenly in the pulley grooves, as these older designs are less forgiving of misalignment. If your lathe uses a V-belt, verify that the belt’s angle matches the pulley’s groove to maximize contact and efficiency. Remember, the goal is not just to stop slipping but to achieve optimal tension for smooth, consistent operation.

Finally, treat this phase as a learning opportunity. Older lathes often require a delicate balance between tension and alignment, and understanding your machine’s quirks can save time in future maintenance. Keep a notebook or log of adjustments made, noting how each change affects performance. This documentation becomes invaluable over time, especially if multiple people operate the lathe. By systematically testing and adjusting, you ensure the belt functions reliably, preserving both the machine’s performance and its historical integrity.

Unveiling Grant Wood's Age: A Look at the Artist's Life

You may want to see also

Frequently asked questions

You’ll typically need a wrench or socket set to remove guards or pulleys, a screwdriver for any screws holding the belt cover, and possibly a pry bar or belt tensioning tool. Always refer to your lathe’s manual for specific requirements.

Measure the original belt’s length and width, or check the lathe’s manual for specifications. If the original belt is missing, measure the distance between the pulleys and choose a belt that matches the size and type (e.g., flat or V-belt).

First, ensure the lathe is unplugged. Loosen any tensioning mechanisms or pulleys, then carefully slide the belt off the pulleys. Avoid forcing it to prevent damage to the pulleys or lathe components.

Adjust the tensioning mechanism (if available) or move the motor or pulley to achieve the correct tension. The belt should have slight give when pressed but not be too loose or tight. Refer to the manual for specific tension guidelines.

Check that the belt is properly seated on the pulleys and that the tension is correct. Clean the pulleys if they are dirty or worn, as debris can cause slippage. If the issue persists, ensure the belt is the correct size and type for your lathe.