Wood carving enthusiasts and artisans in Long Beach Blvd often seek effective methods to preserve and enhance their creations, and cloaking wood carvings is a technique that combines protection with aesthetic appeal. Cloaking involves applying a thin layer of protective material, such as varnish, resin, or oil, to seal the wood and shield it from environmental damage, moisture, and UV rays. This process not only extends the lifespan of the carving but also enhances its natural grain and color, making it a popular choice for both indoor and outdoor pieces. For those in Long Beach Blvd looking to master this skill, understanding the right materials, application techniques, and maintenance tips is essential to ensure their wood carvings remain vibrant and durable for years to come.

Explore related products

What You'll Learn

Choosing the Right Wood Type

The wood you choose for your Long Beach Blvd-inspired carvings isn't just about aesthetics; it's about durability, workability, and the story you want to tell. Hardwoods like oak or walnut offer strength and a rich grain, ideal for intricate details and pieces meant to withstand the coastal climate. Softer woods like pine or cedar are easier to carve but may require more maintenance in humid environments.

Consider the carving style you're aiming for. Relief carvings, popular for their depth and texture, benefit from woods with consistent grain patterns, such as basswood or butternut. For 3D sculptures, stability is key—hardwoods like mahogany or maple resist warping and cracking over time. If you're incorporating paint or stain, choose a wood with minimal natural color variation, like poplar or birch, to ensure even coverage.

Don’t overlook sustainability. Opt for locally sourced or reclaimed wood to reduce environmental impact. Long Beach’s coastal vibe pairs well with driftwood or salvaged teak, adding a unique, weathered charm. However, ensure reclaimed wood is free of rot or pests before beginning your project.

Finally, think about finish and maintenance. Oils like tung or linseed enhance the natural beauty of hardwoods, while polyurethanes provide a protective barrier for outdoor pieces. Softwoods may require more frequent sealing to combat moisture. Choose a finish that aligns with your carving’s intended location—whether it’s a beachside display or an indoor centerpiece.

By carefully selecting your wood type, you’ll not only bring your Long Beach Blvd-inspired carvings to life but also ensure they stand the test of time, both artistically and structurally.

Seasoning Gumball Wood: Understanding the Timeframe for Optimal Results

You may want to see also

Explore related products

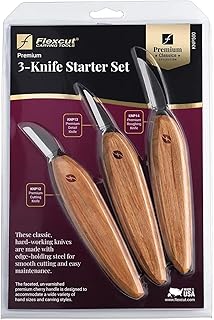

Essential Tools for Carving

Wood carving is a craft that demands precision, patience, and the right tools. Among the essentials, the chisel stands out as the cornerstone of any carver’s toolkit. Available in various shapes and sizes—straight, V-shaped, or gouges—chisels allow for both rough removal of material and fine detailing. For beginners, a set of 6 to 8 chisels with different blade profiles (e.g., 1/4-inch straight, 3/8-inch gouge) is ideal. Always sharpen chisels before use; a dull blade not only ruins the wood but also increases the risk of injury. Pro tip: Invest in a honing guide to maintain consistent bevel angles.

While chisels do the heavy lifting, mallets provide the controlled force needed to drive them. Choose a mallet made of hardwood or plastic, weighing between 8 to 12 ounces for most carving tasks. Heavier mallets are suitable for larger projects, but they can fatigue your hand quickly. For delicate work, consider a lighter mallet or even a wooden hammer. Avoid metal mallets, as they can damage your chisel handles. Pairing the right mallet with your chisel ensures clean, controlled cuts without splintering the wood.

No carving project is complete without proper safety gear. A cut-resistant glove on your non-dominant hand is non-negotiable, as it protects against slips while guiding the chisel. Safety glasses shield your eyes from flying wood chips, especially when working with power tools. For dust management, a dust mask or respirator is essential, particularly when sanding or working with exotic woods that may release harmful particles. Remember: Safety tools aren’t optional—they’re as vital as your chisels.

Finally, sharpening and maintenance tools are the unsung heroes of wood carving. A whetstone (grits 400 and 1000 are versatile for most needs) keeps your chisels razor-sharp. A strop with compounded leather ensures a polished edge for fine detailing. Regularly clean your tools with a wire brush and apply a light coat of oil to prevent rust. Neglecting maintenance shortens the lifespan of your tools and compromises the quality of your carvings. Think of it as grooming your tools—they’ll reward you with smoother, more precise work.

Sealing Wood Post-Pressure Wash: Optimal Waiting Time Explained

You may want to see also

Explore related products

$14.99 $15.95

Sealing Techniques for Longevity

Wood carvings exposed to the elements along Long Beach Blvd face relentless sun, salt air, and temperature swings. Without proper sealing, these factors accelerate cracking, warping, and discoloration. The key to longevity lies in choosing the right sealant and applying it meticulously.

Marine-grade spar varnish, with its high oil content and UV inhibitors, offers superior protection against moisture penetration and sun damage. Apply thin coats with a natural-bristle brush, allowing ample drying time between layers. For intricate carvings, consider using a spray gun to ensure even coverage in crevices.

While traditional oil-based sealants provide deep penetration, water-based alternatives are gaining popularity for their low VOC emissions and easier cleanup. Polyurethane sealers, available in satin or gloss finishes, offer excellent durability and scratch resistance. However, they may yellow over time, particularly on light-colored woods. For a more natural look, consider a penetrating epoxy sealer, which hardens the wood fibers from within while maintaining its original appearance.

Regular maintenance is crucial for maximizing the lifespan of your sealed wood carvings. Inspect them annually for signs of wear, such as flaking or dullness. Reapply sealant as needed, focusing on areas exposed to direct sunlight or moisture. For heavily weathered pieces, light sanding before resealing can restore their original beauty.

Remember, the longevity of your wood carvings along Long Beach Blvd depends on the quality of the sealant, the precision of application, and consistent maintenance. By investing time and effort in proper sealing techniques, you can ensure these artistic creations withstand the test of time and continue to enhance the vibrant streetscape.

Treated Wood Deck Drying Time: Essential Tips for a Perfect Finish

You may want to see also

Explore related products

Protecting Against Weather Damage

Wood carvings exposed to the elements along Long Beach Blvd face relentless assault from sun, rain, wind, and temperature extremes. UV radiation fades colors and dries wood, while moisture seeps into cracks, causing warping, splitting, and rot. Windborne debris scratches surfaces, and temperature fluctuations accelerate deterioration. Without proactive measures, even the most intricate carvings will succumb to weather damage within months.

Pre-Treatment: The Foundation of Protection

Begin by selecting weather-resistant wood species like teak, cedar, or cypress. For existing carvings, thoroughly clean surfaces with a mild detergent solution and stiff brush to remove dirt, mildew, and old finishes. Sand rough areas with 120-grit sandpaper, progressing to 220-grit for a smooth finish. Apply a wood preservative containing fungicides and insecticides to prevent biological decay. Allow the preservative to penetrate for 24-48 hours before proceeding.

Sealing the Deal: Choosing the Right Finish

Select a finish based on desired appearance and protection level. For a natural look, use penetrating oil finishes like linseed or tung oil, reapplied every 6-12 months. For enhanced durability, choose marine-grade varnishes or polyurethanes, applied in 2-3 thin coats with 24-hour drying time between applications. Water-based finishes offer low VOCs and easy cleanup, while oil-based options provide superior moisture resistance. Avoid thick, glossy finishes that can crack and peel under temperature stress.

Maintenance: The Key to Longevity

Inspect carvings quarterly for signs of damage, such as cracking, peeling, or discoloration. Reapply finishes as needed, focusing on areas with high exposure. Keep carvings free of debris and mildew by rinsing with water and mild soap. For added protection, consider installing awnings or overhangs to shield carvings from direct rain and sunlight. In regions with extreme weather, store carvings indoors during harsh seasons or use removable covers.

Advanced Strategies: Going the Extra Mile

For high-value or intricate carvings, consider professional treatments like pressure-treating or epoxy consolidation. Pressure-treating infuses wood with preservatives under high pressure, providing decades of protection. Epoxy consolidation fills cracks and stabilizes deteriorating wood, though it alters the carving’s texture. Consult a conservator for guidance on these specialized techniques. By combining proper material selection, meticulous finishing, and regular maintenance, wood carvings along Long Beach Blvd can withstand the elements and retain their beauty for generations.

Perfectly Cooked Wood Duck: Timing Tips for Tender, Juicy Results

You may want to see also

Explore related products

Display and Maintenance Tips

Displaying wood carvings effectively enhances their aesthetic appeal and protects them from environmental damage. Opt for wall-mounted shelves or freestanding display cases with UV-protected glass to shield carvings from sunlight, which can fade colors and dry out the wood. Position carvings away from direct heat sources like radiators or fireplaces to prevent warping or cracking. For larger pieces, consider a dedicated pedestal or platform that complements the carving’s style, ensuring it remains a focal point without overwhelming the space. Group smaller carvings by theme or material to create visual cohesion, but leave enough space between them to avoid clutter and allow for proper air circulation.

Regular maintenance is key to preserving the longevity and beauty of wood carvings. Dust carvings weekly using a soft, dry microfiber cloth or a brush with fine bristles to avoid scratching the surface. For deeper cleaning, lightly dampen the cloth with distilled water and a mild, wood-safe cleaner, wiping gently along the grain. Avoid harsh chemicals or excessive moisture, as they can strip finishes or cause swelling. Apply a thin coat of wood polish or wax every 6–12 months to maintain luster and protect against dryness, but test on a small area first to ensure compatibility with the finish.

Environmental control plays a critical role in wood carving preservation. Maintain indoor humidity levels between 40–50% to prevent the wood from expanding, contracting, or developing cracks. Use a dehumidifier in damp climates or a humidifier in dry environments to stabilize conditions. If displaying carvings outdoors or in semi-exposed areas, choose weather-resistant woods like teak or cedar and apply a marine-grade sealant annually. Inspect carvings seasonally for signs of pest infestation, such as small holes or sawdust, and address issues promptly with professional pest control.

Creative lighting can dramatically enhance the visual impact of wood carvings. Use directional spotlights or LED strip lights to highlight intricate details and textures, ensuring the light source is cool to avoid heat damage. For a warmer ambiance, opt for adjustable floor lamps with dimmer switches, allowing you to control intensity. Avoid fluorescent lighting, as it can cast unflattering shadows and distort colors. Experiment with backlighting for wall-mounted carvings to create a silhouette effect, adding depth and drama to the display.

Rotation and storage are often overlooked but essential aspects of wood carving care. Periodically rotate displayed pieces to minimize prolonged exposure to light and dust, giving each carving a chance to rest in a controlled storage environment. Store unused carvings in a cool, dry, and dark space, preferably in acid-free boxes or wrapped in breathable fabric to prevent dust accumulation. Label storage containers with details like material, origin, and maintenance history for easy reference. By incorporating these practices, you ensure your wood carvings remain vibrant and structurally sound for generations.

Seasoning Miller Wood: Understanding the Time It Takes to Dry Properly

You may want to see also

Frequently asked questions

Use a soft, dry microfiber cloth to gently dust the surface. For deeper cleaning, lightly dampen the cloth with a mixture of mild soap and water, ensuring no excess moisture seeps into the wood.

Apply a protective finish, such as wax or oil, every 6 to 12 months, depending on exposure to sunlight, humidity, and wear. Always test a small area first.

Avoid harsh chemicals as they can damage the wood. Instead, use a gentle wood cleaner or a mixture of vinegar and water for stubborn stains, followed by a protective finish.

Keep carvings out of direct sunlight or use UV-protective coatings. If displayed outdoors, consider placing them in shaded areas or using weather-resistant finishes.