Bracing two long pieces of wood together is a fundamental skill in woodworking and construction, ensuring stability, strength, and alignment for projects like framing, shelving, or furniture. The process involves selecting appropriate joining methods, such as using wooden braces, metal brackets, or structural connectors, and securing them with screws, nails, or adhesives. Proper alignment and clamping are critical to prevent warping or shifting during assembly, while reinforcing the joint with additional supports or cross-bracing enhances rigidity. Whether for temporary or permanent structures, understanding the principles of bracing ensures a durable and reliable connection between the wood pieces.

Explore related products

What You'll Learn

- Using Metal Brackets: Secure with L-shaped or flat brackets, screws, and pre-drilled holes for stability

- Wood Joinery Techniques: Employ lap, butt, or spline joints for seamless wooden connections

- Angle Bracing Methods: Add diagonal braces to prevent racking and enhance structural integrity

- Epoxy and Glue Bonding: Use strong adhesives like epoxy for invisible, durable bonding

- Reinforcing with Splines: Insert wooden splines into grooves for added strength and alignment

Using Metal Brackets: Secure with L-shaped or flat brackets, screws, and pre-drilled holes for stability

Metal brackets offer a robust solution for bracing two long pieces of wood together, combining strength, durability, and versatility. L-shaped brackets, in particular, excel at creating a right-angled joint, distributing weight evenly, and resisting torsion. Flat brackets, while simpler, provide ample support for lighter loads or applications where space is limited. Both types rely on screws and pre-drilled holes to ensure a secure, long-lasting connection that minimizes wood splitting and maximizes stability.

To implement this method, begin by aligning the wood pieces in the desired configuration, ensuring the joint is square. Position the metal bracket so it spans both pieces, with one leg flush against each surface. Mark the screw hole locations through the bracket onto the wood, then pre-drill holes slightly smaller than your screw diameter. This step is critical: pre-drilling prevents the wood from splitting, especially in hardwoods or near the ends of boards. Use galvanized or stainless steel screws to avoid rust, particularly in outdoor applications. Drive the screws firmly, but avoid over-tightening, which can strip the wood or deform the bracket.

A key advantage of metal brackets lies in their adaptability. L-shaped brackets can be paired with additional brackets for heavier loads, such as in shelving or framing. Flat brackets work well for reinforcing corners or edges, often used in furniture or cabinetry. For added strength, consider using brackets with larger surface areas or thicker gauge metal. When bracing long spans, space brackets every 12 to 16 inches along the joint to maintain rigidity and prevent sagging.

Despite their effectiveness, metal brackets require careful planning. Ensure the bracket size matches the wood dimensions—a bracket too small may not provide adequate support, while one too large can be cumbersome. Always use a level and square to verify alignment before securing the brackets. For outdoor projects, apply a protective coating to the wood and bracket edges to prevent moisture infiltration, which can lead to rot or corrosion.

In conclusion, metal brackets, whether L-shaped or flat, provide a reliable and customizable method for bracing wood joints. By following precise installation steps and considering load requirements, you can achieve a stable, professional result. This approach is particularly well-suited for applications demanding strength and longevity, from DIY projects to structural builds. With the right materials and techniques, metal brackets transform a simple joint into a robust connection capable of withstanding significant stress.

Mastering Wood Carving: Optimal Drying Time for Perfect Results

You may want to see also

Explore related products

Wood Joinery Techniques: Employ lap, butt, or spline joints for seamless wooden connections

Wood joinery is an art that transforms simple wooden pieces into robust, seamless structures. Among the myriad techniques, lap, butt, and spline joints stand out for their versatility and strength. Each method serves a unique purpose, depending on the project’s demands and the desired aesthetic. Understanding these joints not only enhances structural integrity but also elevates craftsmanship, ensuring your wooden connections are both functional and visually appealing.

Lap Joints: Strength in Overlap

Lap joints involve overlapping two pieces of wood and securing them with screws, nails, or adhesive. This technique is ideal for bracing long pieces together, as it distributes weight evenly and provides a large surface area for bonding. For example, a half-lap joint, where each piece is notched to half its thickness, creates a flush connection that’s both strong and discreet. To execute this, measure and mark the overlap area, then use a circular saw or hand saw to remove the excess material. Sand the edges for a smooth fit, and reinforce with wood glue before fastening. Lap joints are particularly effective for horizontal braces, such as in shelving or framing, where stability is paramount.

Butt Joints: Simplicity Meets Reinforcement

Butt joints are the most straightforward method, involving the end-to-end alignment of two pieces. While inherently weaker than lap or spline joints, they can be reinforced with mechanical fasteners or biscuits for added strength. For bracing long pieces, consider a reinforced butt joint with a backing board or metal bracket. This approach is best for vertical connections, like in door frames or tall structures, where the joint is less likely to shear under pressure. Pro tip: Pre-drill holes to prevent splitting, and use waterproof glue for outdoor applications to ensure longevity.

Spline Joints: Precision and Elegance

Spline joints introduce a third element—a spline—to bridge the gap between two pieces. This technique is perfect for aligning long boards edge-to-edge or end-to-end, creating a seamless connection. To create a spline joint, cut matching grooves along the edges of the wood using a router or table saw. Insert a spline (a thin strip of wood or metal) into the grooves and secure it with glue. This method not only strengthens the joint but also adds a decorative touch, making it ideal for visible connections like tabletops or paneling. For maximum durability, choose a spline material that complements the wood’s hardness and grain.

Choosing the Right Joint for Your Project

The choice between lap, butt, and spline joints depends on the project’s requirements. Lap joints excel in load-bearing applications, butt joints offer simplicity with reinforcement options, and spline joints combine strength with aesthetic appeal. Consider factors like visibility, stress points, and material thickness when deciding. For instance, a spline joint might be overkill for a hidden brace but perfect for a visible edge. Always test your joint on scrap wood before committing, and invest in quality tools to ensure precision. With the right technique, your wooden connections will be as enduring as they are elegant.

Wood Coffee Boulevard Hours: Open Until When?

You may want to see also

Explore related products

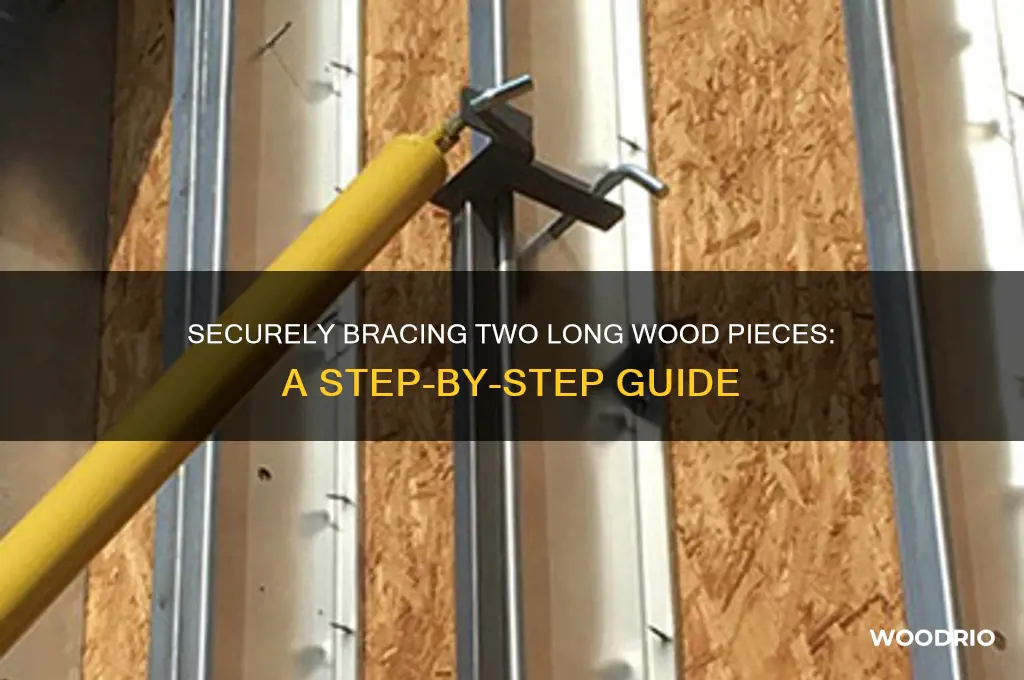

Angle Bracing Methods: Add diagonal braces to prevent racking and enhance structural integrity

Diagonal braces act as the unsung heroes of structural stability, counteracting the natural tendency of long, parallel wooden members to twist or rack under lateral pressure. This racking force, often caused by wind, seismic activity, or even uneven weight distribution, can compromise the integrity of a structure. Angle bracing, by introducing a diagonal element, creates a rigid triangle—a shape renowned for its inherent strength and resistance to deformation.

Imagine a simple rectangular frame: without bracing, it's susceptible to collapsing inward or outward. Adding a diagonal brace across one corner transforms it into two triangles, effectively distributing the load and preventing racking.

Implementing angle bracing involves careful consideration of angle and placement. The ideal angle for maximum strength is 45 degrees, creating an isosceles triangle. However, practical considerations like available space and aesthetic preferences might dictate a steeper or shallower angle. Braces should be securely fastened at both ends, using appropriate hardware like galvanized nails, screws, or metal brackets. For heavier loads or critical applications, consider using metal bracing or laminated veneer lumber (LVL) for added strength.

Remember, the effectiveness of angle bracing relies on proper installation. Ensure joints are tight and hardware is driven straight to maximize load transfer.

While angle bracing is a powerful technique, it's not a one-size-fits-all solution. For structures subjected to significant lateral forces, combining angle bracing with other methods like cross-bracing or shear panels might be necessary. Additionally, consider the direction of anticipated forces. Bracing should be strategically placed to counteract the primary racking forces acting on the structure.

Angle bracing, when executed correctly, provides a simple yet highly effective means of enhancing the structural integrity of wooden assemblies. By understanding the principles behind this method and applying it thoughtfully, you can ensure your wooden structures stand strong against the test of time and external forces.

Gesso Drying Time on Wood: Tips for Perfect Application

You may want to see also

Explore related products

$18.99 $19.99

Epoxy and Glue Bonding: Use strong adhesives like epoxy for invisible, durable bonding

Epoxy resins stand out as a premier choice for bonding two long pieces of wood together, offering both strength and discretion. Unlike mechanical fasteners, which can leave visible holes or weaken the wood over time, epoxy creates an invisible bond that distributes stress evenly across the joint. This makes it ideal for applications where aesthetics and structural integrity are paramount, such as furniture making or structural framing. The key lies in its chemical composition: epoxy cures into a rigid, gap-filling material that adheres tenaciously to wood fibers, forming a bond often stronger than the wood itself.

To achieve a successful epoxy bond, preparation is critical. Begin by ensuring both wood surfaces are clean, dry, and free of dust or debris. Sand the mating surfaces lightly to create a rough texture, enhancing the adhesive’s grip. Mix the epoxy according to the manufacturer’s instructions, typically combining resin and hardener in a precise ratio (e.g., 1:1 or 2:1 by volume). Apply a generous, even coat to both surfaces using a spatula or brush, then clamp the pieces together firmly. Clamping pressure should be sufficient to squeeze out excess epoxy, which indicates a proper bond. Allow the epoxy to cure fully, which can take anywhere from 24 hours to several days, depending on the product and environmental conditions.

One of the advantages of epoxy is its versatility in joint types. Whether you’re creating a butt joint, edge joint, or miter joint, epoxy can adapt to the geometry of the connection. For long pieces of wood, consider using a combination of epoxy and mechanical reinforcement, such as screws or dowels, to provide immediate stability while the adhesive cures. This hybrid approach ensures the joint remains aligned during curing and adds long-term durability. However, be cautious not to over-rely on fasteners, as they can compromise the epoxy’s ability to distribute stress uniformly.

While epoxy is highly effective, it’s not without limitations. It performs best in indoor applications, as prolonged exposure to UV light and moisture can degrade the bond over time. For outdoor projects, choose a marine-grade epoxy or apply a protective finish to shield the joint. Additionally, epoxy’s curing time requires patience; rushing the process can lead to weak bonds. Always work in a well-ventilated area, as epoxy fumes can be irritating, and wear gloves to protect your skin from direct contact with the adhesive.

In conclusion, epoxy bonding offers a superior method for bracing two long pieces of wood together, combining strength, invisibility, and adaptability. By following proper preparation and application techniques, you can create joints that rival the wood’s natural durability. Whether for a DIY project or professional craftsmanship, epoxy stands as a testament to the power of modern adhesives in woodworking.

Wood vs. Siding Sheds: Which Material Offers Greater Durability?

You may want to see also

Explore related products

Reinforcing with Splines: Insert wooden splines into grooves for added strength and alignment

Wood joints often fail due to shear forces, which can cause glued surfaces to separate over time. Splines—thin strips of wood inserted into matching grooves—address this weakness by increasing the glued surface area and providing mechanical reinforcement. Unlike simple butt joints, splined connections distribute stress more evenly, making them ideal for bracing long pieces of wood that bear lateral or vertical loads. This method is particularly effective in applications like tabletops, shelving, or framing where alignment and strength are critical.

To implement spline reinforcement, begin by marking and cutting identical grooves along the edges of the wood pieces to be joined. Use a router with a straight bit or a table saw with a dado stack to create channels that are slightly narrower than the spline thickness. For optimal strength, position grooves at regular intervals—typically every 6 to 12 inches—depending on the wood length and expected load. Ensure grooves are aligned vertically and horizontally to maintain a flush joint.

Selecting the right spline material is key. Hardwoods like maple or oak are preferred for their density and durability, though softer woods can be used if the joint will not bear heavy stress. Splines should be cut to fit snugly within the grooves, with a thickness that matches the groove depth. Apply a thin, even coat of wood glue to both the spline and groove surfaces before assembly. Clamp the joint firmly, ensuring splines are fully seated, and allow the glue to cure according to manufacturer instructions—typically 24 hours for most wood glues.

While splines enhance joint strength, they are not a substitute for proper design. Overloading the joint or using insufficient spline spacing can still lead to failure. For structural applications, test the joint under expected loads before final installation. Additionally, consider pre-finishing the spline edges to prevent moisture absorption, which can cause warping or swelling over time. When executed correctly, spline reinforcement combines precision craftsmanship with practical engineering, resulting in a joint that is both robust and visually appealing.

Measuring History: Understanding Cordwood Lengths in Traditional Times

You may want to see also

Frequently asked questions

Use a combination of metal bracing brackets, screws, and wood glue. Attach the brackets at multiple points along the joint, ensuring they are perpendicular to the wood for added strength.

Yes, you can use wooden cleats or splices cut from the same type of wood. Secure them with screws or nails and reinforce the joint with wood glue for a strong bond.

Use clamps to hold the pieces in place while attaching the braces. Measure and mark the alignment points beforehand, and double-check for squareness using a carpenter’s square.

![Right Angle Clamp, Housolution [4 PACK] Single Handle 90° Aluminum Alloy Corner Clamp, Clamps for Woodworking Adjustable Swing Jaw, Woodworking Tools Photo Frame Vise Holder, Gifts for Men Dad](https://m.media-amazon.com/images/I/71xNSiBOZ+L._AC_UL320_.jpg)