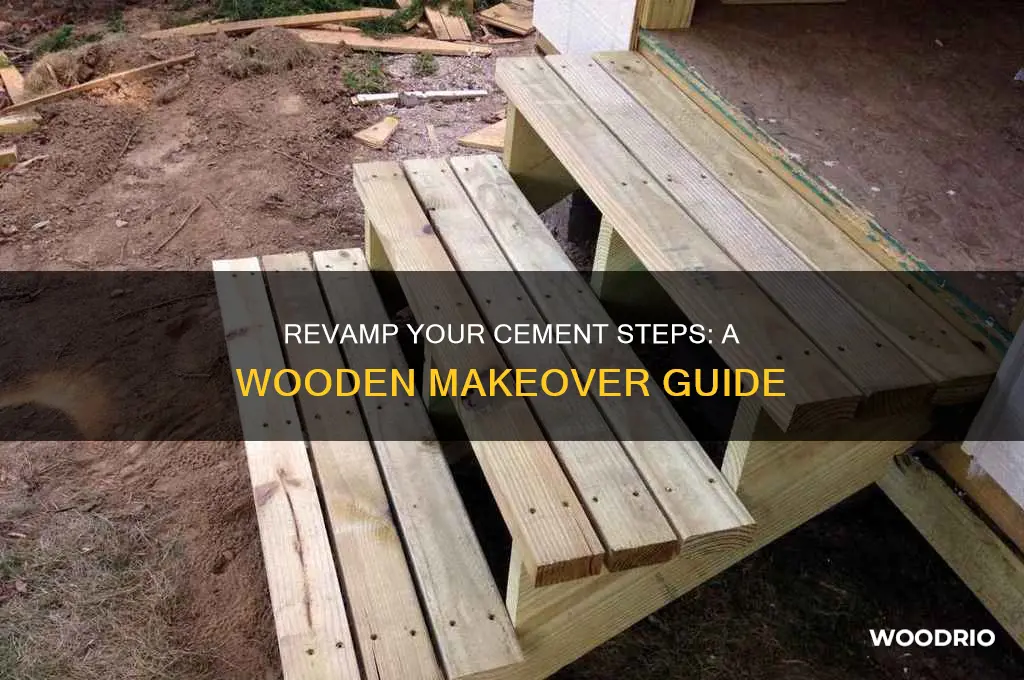

Revitalizing old cement steps with a wooden overlay is a practical and aesthetically pleasing way to enhance your home's entrance or outdoor space. This project not only improves the appearance of worn or cracked steps but also adds warmth and texture, blending seamlessly with natural surroundings. By covering the existing cement with wood, you can achieve a more inviting look while potentially extending the lifespan of the steps. The process involves careful planning, including measuring the steps, selecting durable wood materials, and ensuring proper waterproofing to prevent rot and decay. With the right tools and techniques, this DIY-friendly upgrade can transform your steps into a functional and stylish feature.

| Characteristics | Values |

|---|---|

| Purpose | To improve aesthetics, safety, and durability of old cement steps. |

| Materials Needed | Wood planks (pressure-treated or composite), screws, adhesive, sealant. |

| Tools Required | Drill, saw, screwdriver, measuring tape, level, hammer, safety gear. |

| Preparation Steps | Clean cement steps, repair cracks, ensure surface is level and dry. |

| Installation Method | Attach wood planks directly to cement using adhesive and screws. |

| Weather Resistance | Use pressure-treated or composite wood for better durability. |

| Maintenance | Regular sealing, cleaning, and inspection for wear and tear. |

| Cost | Moderate to high, depending on wood type and labor. |

| DIY Feasibility | Possible with intermediate DIY skills; professional help recommended. |

| Aesthetic Options | Stain, paint, or leave wood natural for various looks. |

| Safety Considerations | Ensure non-slip surface, secure installation, and proper drainage. |

| Time Required | 1-2 days, depending on the number of steps and preparation needed. |

| Environmental Impact | Sustainable if using reclaimed or composite wood. |

| Longevity | 10-20 years with proper maintenance. |

| Additional Features | Can add railings or lighting for enhanced safety and aesthetics. |

Explore related products

What You'll Learn

- Prepare the Steps: Clean, repair cracks, and ensure the cement surface is level and dry

- Measure and Cut Wood: Accurately measure steps, cut wood planks to fit each tread and riser

- Attach Wood to Steps: Use adhesive and screws to secure wood planks firmly to the cement

- Sand and Finish Wood: Smooth edges, apply stain or sealant for durability and aesthetic appeal

- Add Safety Features: Install non-slip strips or outdoor rugs to prevent accidents on wooden steps

Prepare the Steps: Clean, repair cracks, and ensure the cement surface is level and dry

Before you transform your old cement steps with a warm wooden overlay, ensure the foundation is sound. A clean, level, and dry surface is critical for adhesion, longevity, and safety. Neglecting this step risks uneven surfaces, wood rot, and premature failure.

Begin with a thorough cleaning. Remove dirt, debris, and organic growth like moss or mildew. Pressure washing is effective, but use a fan tip nozzle (15–25 degrees) to avoid etching the concrete. For stubborn stains, apply a concrete cleaner mixed at a ratio of 1:4 (concentrate to water) and scrub with a stiff-bristle brush. Rinse thoroughly and allow 24–48 hours for drying, depending on humidity.

Address cracks and damage next. Hairline cracks (less than 1/8 inch) can be filled with a concrete crack sealant, applied with a putty knife. Wider cracks or spalled areas require a vinyl concrete patcher, troweled smooth and allowed to cure for 4–6 hours. For structural damage, consult a professional—wood cannot compensate for compromised integrity.

Leveling is non-negotiable. Minor unevenness (up to 1/4 inch) can be shimmed later, but larger discrepancies must be ground down or built up. Use a concrete grinder for high spots, wearing a respirator and eye protection. For low spots, apply a self-leveling concrete mix, following the manufacturer’s water-to-powder ratio (typically 5–6 quarts per 50-pound bag). Allow 24 hours for curing before proceeding.

Moisture management is key. Test for moisture by taping an 18-inch plastic sheet to the surface for 24 hours. If condensation forms underneath, apply a concrete sealer or moisture barrier. In humid climates, consider a vapor-permeable wood adhesive to prevent delamination. Always work on a surface with a moisture content below 5% for optimal wood adhesion.

By meticulously preparing the cement steps, you create a stable base that ensures the wooden overlay not only looks seamless but also withstands foot traffic and weather. Skipping these steps may save time initially but will cost you in repairs later. Precision here pays dividends in durability.

Unveiling Victor Wood's Age: A Surprising Journey Through Time

You may want to see also

Explore related products

Measure and Cut Wood: Accurately measure steps, cut wood planks to fit each tread and riser

Precision is paramount when measuring and cutting wood to cover old cement steps. Begin by meticulously measuring each tread and riser, accounting for any irregularities in the existing structure. Use a tape measure to record the length, width, and height of each step, ensuring accuracy to within 1/16 of an inch. Note any variations in size between steps, as cement steps often settle unevenly over time. These measurements will dictate the dimensions of your wood planks, so double-check your numbers before proceeding.

Once measurements are finalized, select wood planks that complement your desired aesthetic and withstand outdoor conditions. Pressure-treated lumber or naturally rot-resistant species like cedar or redwood are ideal choices. Transfer your measurements to the wood, marking each plank with a pencil and straightedge. For treads, cut the planks to match the width and depth of the step, ensuring a snug fit. Risers require vertical planks cut to the height of the step and the width of the stair stringer. Use a circular saw or table saw for straight, clean cuts, and always prioritize safety by wearing protective gear and following proper cutting techniques.

Cutting wood for stair coverings involves more than just straight lines. Tread planks often require notching to fit around the nose of the step, creating a seamless transition. Measure the overhang of the existing cement tread and mark the notch on the wood plank accordingly. Use a jigsaw to carefully cut out the notched area, ensuring a precise fit. For risers, consider whether you’ll attach them directly to the cement or to a wooden frame. If attaching to cement, pre-drill holes to prevent splitting and use masonry screws for a secure hold.

A critical aspect of this process is accounting for expansion and contraction of the wood due to weather changes. Leave a small gap (approximately 1/8 inch) between planks to allow for movement, preventing warping or buckling over time. Additionally, sand all cut edges to remove splinters and ensure a smooth finish. Applying a coat of exterior wood sealant or stain before installation can enhance durability and appearance, though this step can also be done after the wood is in place.

Finally, test-fit each piece before permanently securing it. Dry-fit the treads and risers to ensure they align perfectly with the cement steps and adjacent planks. Adjust any pieces as needed, sanding or trimming for a flawless fit. Once satisfied, secure the wood using galvanized screws or nails to prevent rust. This meticulous approach to measuring and cutting ensures a professional-looking result that not only revitalizes old cement steps but also adds warmth and character to your outdoor space.

Can Roses Propagate from Old Wood? A Comprehensive Guide

You may want to see also

Explore related products

Attach Wood to Steps: Use adhesive and screws to secure wood planks firmly to the cement

Attaching wood to old cement steps requires a dual approach: adhesive for initial bonding and screws for long-term stability. Construction adhesives, such as polyurethane-based formulas, create a strong chemical bond between wood and concrete. Apply a ¼-inch bead along the edges and center of each plank, ensuring even distribution. This method alone, however, risks wood warping or shifting under foot traffic. Screws, driven through pre-drilled holes, provide mechanical reinforcement, anchoring the wood firmly to the substrate. Together, adhesive and screws create a durable, weather-resistant surface capable of withstanding daily use.

The process begins with surface preparation. Clean the cement steps thoroughly, removing dirt, grease, and loose debris with a wire brush and pressure washer. Etch the surface with a masonry acid solution (following manufacturer instructions) to improve adhesive grip. Allow the steps to dry completely before proceeding. For wood planks, select pressure-treated lumber to resist moisture and decay. Cut planks to fit each step, leaving a ¼-inch gap between boards for expansion. Sand rough edges to prevent splinters and ensure a uniform finish.

Adhesive application demands precision. Use a caulking gun to lay beads of adhesive in a zigzag pattern across the cement surface. Position the wood plank immediately, pressing firmly to activate the bond. Weigh down the plank with heavy objects or use clamps for 24 hours to ensure proper adhesion. While adhesive sets, pre-drill pilot holes through the wood into the cement using a masonry bit. Space screws 12–16 inches apart along the plank’s perimeter and center for maximum hold. Countersink screws slightly to prevent tripping hazards and maintain a clean aesthetic.

Caution: Over-tightening screws can crack the wood or strip threads in the cement. Use a torque-limiting drill setting or hand-tighten the final turns. For added protection, seal the wood with a weatherproof stain or paint after installation. This not only enhances appearance but also extends the lifespan by repelling water and UV damage. Regularly inspect screws for looseness and re-tighten as needed, particularly after seasonal temperature shifts.

This method transforms worn cement steps into a warm, natural wood surface without the cost of complete replacement. By combining adhesive bonding and mechanical fastening, the result is a secure, long-lasting upgrade suitable for high-traffic areas. While labor-intensive, the process requires minimal specialized tools and yields professional-grade results accessible to DIY enthusiasts. Properly executed, wood-covered steps offer both functional durability and aesthetic appeal, bridging the gap between old and new materials seamlessly.

Jacqueline Woods' Children Ages: A Look at Her Family Life

You may want to see also

Explore related products

Sand and Finish Wood: Smooth edges, apply stain or sealant for durability and aesthetic appeal

Sanding wood is a transformative step in the process of covering old cement steps, turning raw, rough surfaces into smooth, inviting textures. Begin with medium-grit sandpaper (120-150 grit) to remove imperfections and splinters, then progress to fine-grit (220 grit) for a polished finish. Focus on edges and corners, where wear and tear are most noticeable, ensuring a uniform surface that feels safe and comfortable underfoot. Hand sanding is ideal for precision, but an orbital sander can expedite larger areas, saving time without sacrificing quality.

Once the wood is smooth, the application of stain or sealant becomes both a protective measure and a design choice. Stains enhance the wood’s natural grain while adding color, ranging from rich mahoganies to soft grays. For durability, opt for a penetrating oil-based stain, which resists moisture and UV damage—crucial for outdoor steps exposed to the elements. Apply in thin, even coats with a brush or rag, allowing each layer to dry fully before adding another. For high-traffic areas, consider a semi-transparent stain, which balances appearance with resilience.

Sealants, on the other hand, prioritize protection over color alteration. Polyurethane is a popular choice, offering a clear, durable barrier against water, stains, and scratches. For outdoor steps, use an exterior-grade sealant with UV inhibitors to prevent fading. Apply with a foam brush or roller in smooth, overlapping strokes, ensuring full coverage. Two to three coats are typically sufficient, with drying times of 2–4 hours between applications. Avoid walking on the steps for at least 24 hours to allow the sealant to cure completely.

The interplay between sanding and finishing is where functionality meets aesthetics. A well-sanded surface ensures the stain or sealant adheres evenly, preventing blotches or peeling. Meanwhile, the choice of finish dictates the steps’ long-term appearance and maintenance needs. For instance, a matte sealant offers a subtle, natural look, while a gloss finish adds a sleek, modern touch but may show scuffs more easily. Consider the surrounding environment and personal style when making this decision.

Finally, maintenance is key to preserving the wood’s beauty and integrity. Reapply sealant every 1–2 years, depending on exposure to weather and foot traffic. Inspect for signs of wear, such as cracking or discoloration, and address issues promptly. Keep the steps clean by sweeping regularly and washing with mild soap and water as needed. With proper care, your wood-covered cement steps will not only enhance curb appeal but also withstand the test of time, blending durability with timeless charm.

Unveiling Frank Woods' Age: A Deep Dive into His Timeline

You may want to see also

Explore related products

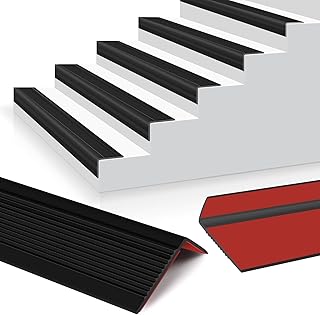

Add Safety Features: Install non-slip strips or outdoor rugs to prevent accidents on wooden steps

Wood, while aesthetically pleasing, can become treacherous when wet or worn. Rain, snow, and even morning dew create slippery surfaces that increase the risk of falls. This is especially concerning for steps, where a misstep can lead to serious injury. Non-slip strips and outdoor rugs offer a simple yet effective solution, transforming your wooden steps from hazard zones into safe passageways.

Imagine a rainy afternoon, the wooden steps leading to your porch gleaming with moisture. Without proper traction, each step becomes a gamble. Now picture those same steps adorned with subtle black non-slip strips, providing a secure grip even in the wettest conditions. This small addition significantly reduces the risk of accidents, giving you peace of mind and ensuring the safety of your family and guests.

Choosing the Right Safety Feature:

Non-slip strips, typically made from durable materials like rubber or vinyl, come in various widths and colors to complement your wood's tone. They're easy to install, often requiring only adhesive backing or screws. For a more decorative touch, consider outdoor rugs specifically designed for steps. These rugs are weather-resistant, featuring non-slip backings and patterns that add visual interest while enhancing safety.

When selecting non-slip strips, opt for a width that covers at least two-thirds of the step's depth. This ensures maximum coverage and traction. Outdoor rugs should be sized to fit each step snugly, preventing tripping hazards.

Installation Tips for Maximum Effectiveness:

Clean the wooden steps thoroughly before installation, removing any dirt, debris, or old coatings that could hinder adhesion. For non-slip strips, follow the manufacturer's instructions for adhesive application or screw placement. Ensure the strips are level and securely attached. When installing outdoor rugs, use rug pads underneath for added cushioning and to prevent slipping.

Maintenance for Long-Lasting Safety:

Regularly inspect your non-slip strips and outdoor rugs for signs of wear and tear. Replace them as needed to maintain optimal traction. Clean them periodically with mild soap and water to remove dirt and debris, ensuring their effectiveness. By incorporating these simple safety features, you can transform your wooden steps from potential hazards into safe and stylish entryways, enjoying the beauty of wood without compromising on safety.

Jordie Woods' Age: Unveiling the Mystery Behind Her Birth Year

You may want to see also

Frequently asked questions

You will need pressure-treated lumber for the treads and risers, galvanized or stainless steel screws, wood glue, a saw, drill, sander, and a level. Optionally, consider a waterproof sealant to protect the wood.

Clean the cement steps thoroughly to remove dirt, debris, and any loose material. Ensure the surface is level and repair any cracks or damage. If the steps are uneven, use a self-leveling compound to create a smooth base.

Yes, you can install wood directly on top of the cement steps. Use a layer of rubber or foam padding between the wood and cement to prevent moisture absorption and provide a cushion. Secure the wood with screws drilled into the cement using concrete anchors.

Regularly inspect the wood for signs of wear, rot, or damage. Clean the steps periodically with mild soap and water, and reapply a waterproof sealant every 1-2 years. Ensure proper drainage around the steps to prevent water accumulation.