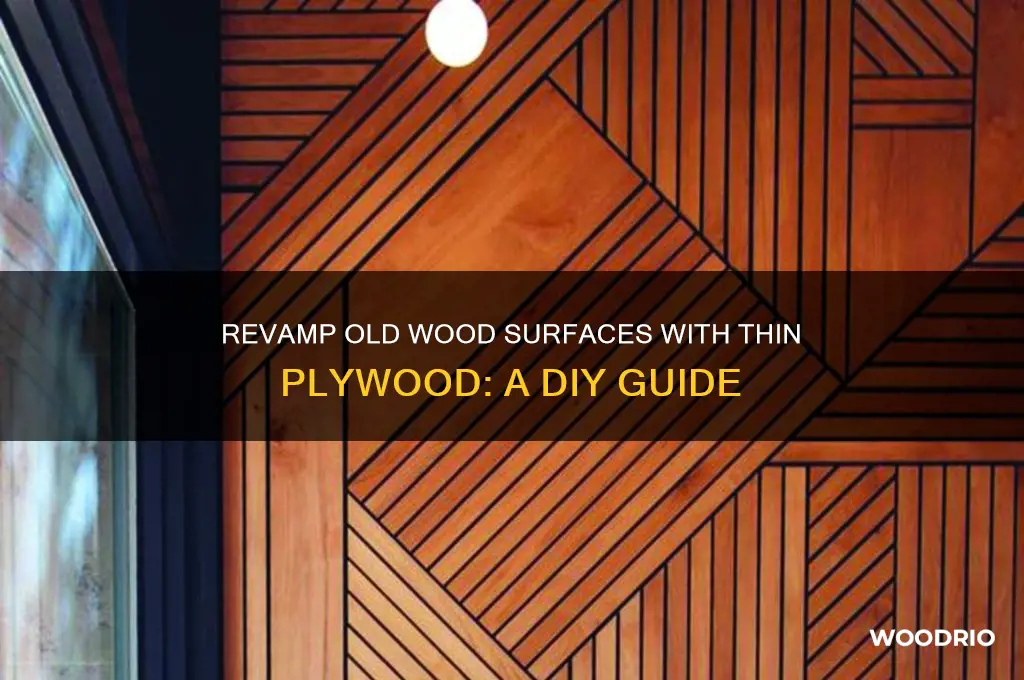

Covering old wood with thin plywood is a practical and cost-effective way to refresh and enhance the appearance of worn or damaged surfaces while adding durability. This method is ideal for projects like furniture restoration, wall paneling, or flooring updates, as it allows you to preserve the structural integrity of the existing wood while achieving a smooth, modern finish. By carefully preparing the old wood surface—sanding, cleaning, and ensuring it is level—you can create a solid foundation for the plywood. Thin plywood, typically 1/8 to 1/4 inch thick, is lightweight and easy to work with, making it suitable for both DIY enthusiasts and professionals. Proper adhesion techniques, such as using construction adhesive or screws, ensure a secure bond, while finishing touches like paint, stain, or sealant can customize the final look to match your aesthetic goals.

| Characteristics | Values |

|---|---|

| Surface Preparation | Sand the old wood to remove rough spots, dirt, and old finish. Ensure the surface is smooth and clean. |

| Plywood Thickness | Typically 1/4 inch or 3/16 inch for lightweight coverage. |

| Adhesive | Use construction adhesive or wood glue for strong bonding. Apply evenly to both surfaces. |

| Fasteners | Use finishing nails or screws for added stability. Space them 6-8 inches apart along the edges and field. |

| Seams | Stagger plywood seams over multiple supports to avoid weak spots. Use filler or caulk to seal gaps. |

| Finishing | Sand edges and seams after installation. Apply paint, stain, or sealant to match the desired look. |

| Tools Required | Circular saw, jigsaw, drill, nail gun, sandpaper, measuring tape, and clamps. |

| Cost | Varies based on plywood quality and quantity. Generally affordable compared to replacing wood. |

| Durability | Provides a smooth, renewed surface. Plywood adds structural strength if properly installed. |

| Application | Suitable for floors, walls, ceilings, and furniture restoration. |

| Time Required | Depends on project size. Typically a few hours to a day for small to medium projects. |

Explore related products

What You'll Learn

- Preparing the Wood Surface: Clean, sand, and repair old wood for smooth plywood adhesion

- Measuring and Cutting Plywood: Accurately measure and cut thin plywood to fit the wood surface

- Applying Adhesive: Use wood glue or adhesive evenly for secure plywood bonding

- Securing Plywood: Nail or screw plywood in place, ensuring it’s firmly attached to the wood

- Finishing Touches: Sand edges, fill gaps, and apply paint or sealant for a polished look

Preparing the Wood Surface: Clean, sand, and repair old wood for smooth plywood adhesion

Old wood, weathered and worn, often bears the marks of time—cracks, splinters, and a surface that’s anything but smooth. Before you can seamlessly cover it with thin plywood, preparation is key. A poorly prepped surface will lead to adhesion failure, gaps, or an uneven finish. Think of it as laying the foundation for a house: if it’s unstable, everything built on top will suffer.

Cleaning the Surface: Removing Barriers to Adhesion

Dirt, grease, and old finishes act like invisible saboteurs, preventing glue or adhesive from bonding effectively. Start by wiping the wood with a damp cloth to remove surface dust. For stubborn grime, use a mild detergent mixed with water, scrubbing gently with a soft-bristled brush. Avoid harsh chemicals that can weaken the wood fibers. For oily surfaces, a solvent like mineral spirits works best—apply sparingly, let it sit for 5–10 minutes, then wipe clean. Always allow the wood to dry completely before proceeding.

Sanding: Smoothing the Path for Plywood

Sanding isn’t just about aesthetics; it’s about creating a texture that adhesives can grip. Begin with 80-grit sandpaper to remove old paint, rough patches, or splinters. Follow with 120-grit to smooth the surface further, ensuring uniformity. For intricate areas or tight corners, use a sanding block or folded sandpaper to maintain control. Dust is your enemy here—it can interfere with adhesion. Vacuum the surface thoroughly, then wipe it down with a tack cloth to capture any lingering particles.

Repairing Damage: Filling Gaps and Cracks

Cracks, holes, or loose joints compromise both the structural integrity and the final appearance. Small gaps can be filled with wood filler or epoxy, applied with a putty knife and smoothed flush with the surface. For larger voids, consider cutting out the damaged section and patching it with a matching wood piece, secured with wood glue and clamps. Allow repairs to dry fully—typically 24 hours—before sanding them smooth. This step ensures the plywood adheres evenly, without dips or bumps.

Final Inspection: The Litmus Test for Readiness

Before applying adhesive or plywood, scrutinize the surface under bright light. Run your hand over it to detect any missed imperfections. If the wood feels smooth, looks clean, and has no visible damage, it’s ready. Skipping this step risks adhesion failure or a visibly flawed finish. Remember, the goal isn’t just to cover old wood—it’s to create a surface so well-prepared that the plywood becomes an extension of it, seamless and enduring.

Amanda Woods' Age: Unveiling the Mystery Behind Her Birth Year

You may want to see also

Explore related products

Measuring and Cutting Plywood: Accurately measure and cut thin plywood to fit the wood surface

Accurate measurement is the cornerstone of a seamless plywood overlay. Begin by cleaning the old wood surface to ensure precise readings, as dirt or debris can skew dimensions. Use a rigid tape measure or a straight edge to capture the length and width, noting any irregularities like curves or corners. For complex shapes, consider creating a template from cardboard or paper, tracing directly onto the plywood for a perfect fit. Always measure twice to avoid costly mistakes.

Cutting thin plywood requires the right tools and technique. A sharp utility knife or fine-toothed jigsaw works best for straight cuts, while a scroll saw handles intricate details. Secure the plywood firmly to prevent splintering—clamps or a sacrificial board beneath the cut line can help. When using power tools, maintain a steady hand and follow the marked lines closely. For curved cuts, adjust the saw’s speed and angle gradually, ensuring smooth transitions.

Precision in cutting is as critical as measurement. Account for a 1/16-inch allowance when marking cut lines to accommodate slight variations in the old wood’s surface. Sand the edges post-cut to eliminate roughness and ensure a snug fit. If gaps remain, fill them with wood putty or caulk for a polished finish. Remember, thin plywood is forgiving but unforgiving of imprecision—small errors become glaring flaws.

Comparing manual and power tools reveals trade-offs. Hand tools offer control and quiet operation, ideal for small projects or noise-sensitive environments. Power tools, however, expedite the process and excel at handling repetitive cuts or thick plywood layers. Choose based on project scale, skill level, and desired finish. Whichever method you select, prioritize safety: wear gloves, eye protection, and a dust mask to mitigate risks.

In conclusion, measuring and cutting thin plywood demands attention to detail and the right tools. By combining accurate measurements, appropriate cutting techniques, and post-cut refinements, you can achieve a professional finish that revitalizes old wood surfaces. Practice patience, as rushing often leads to errors that compromise the final result. With care, your plywood overlay will not only cover but enhance the underlying wood.

Eric Wood's Age: A Look at the Buffalo Bills Veteran

You may want to see also

Explore related products

Applying Adhesive: Use wood glue or adhesive evenly for secure plywood bonding

A strong bond between old wood and new plywood hinges on even adhesive application. Uneven glue distribution leads to weak spots, warping, and an unattractive finish. Imagine a mosaic where some tiles cling tightly while others hang precariously – that's the risk of inconsistent adhesive.

The Science Behind Even Application: Wood glue, typically a polyvinyl acetate (PVA) formula, creates a bond by penetrating the wood fibers and hardening. When applied thinly and uniformly, it maximizes surface contact, allowing for optimal fiber interlocking. Thick globs, conversely, prevent proper penetration and can trap air pockets, weakening the bond.

Think of it like spreading butter on toast – a thin, even layer ensures every bite is flavorful, while clumps leave dry patches.

Practical Tips for Precision: Use a notched trowel specifically designed for adhesive application. The notches create a ribbed pattern, ensuring consistent glue thickness. Aim for a coverage rate of approximately 100-150 grams of glue per square meter, depending on the plywood thickness and wood porosity. For smaller areas, a paintbrush can be used, but be meticulous to avoid streaks.

Work in sections, applying glue to both the old wood and the plywood backside. This double application guarantees complete coverage and minimizes the risk of gaps.

Cautions and Considerations: Avoid over-application. Excess glue will squeeze out when clamping, creating a messy cleanup and potentially weakening the bond if it dries on the surface. Allow adequate drying time, typically 24 hours, before removing clamps and applying pressure to the bonded surfaces. Rushing this step can compromise the bond's strength.

Remember, patience and precision are key. A little extra time spent on even adhesive application will reward you with a durable and aesthetically pleasing plywood covering.

Sealing Old Barn Wood: A Step-by-Step Preservation Guide

You may want to see also

Explore related products

Securing Plywood: Nail or screw plywood in place, ensuring it’s firmly attached to the wood

Securing thin plywood over old wood is a delicate balance of strength and precision. Nails offer speed and simplicity, but screws provide superior holding power, especially in high-stress areas like floors or countertops. For most applications, 1½-inch screws spaced every 6 to 8 inches along the edges and every 12 inches in the field will ensure a firm bond without compromising the plywood’s integrity. Use a drill with a clutch setting to avoid overdriving screws, which can weaken the wood or split the plywood.

Consider the wood’s condition before choosing fasteners. If the old wood is brittle or warped, screws are the safer option, as nails may cause further cracking. For softer woods or thin plywood (¼-inch or less), use finer gauge screws (such as #6) to prevent splitting. Pre-drilling pilot holes is essential in these cases, even with screws. Nails, while faster, are best reserved for low-stress areas or temporary fixes, as they lack the pull-out resistance of screws.

The angle and depth of fastening matter more than you might think. Drive screws at a 90-degree angle for maximum grip, but if the plywood meets a wall or edge, tilt the screw slightly inward to avoid protruding into adjacent surfaces. For nails, use a nail set to countersink the heads below the surface, then fill with wood putty for a seamless finish. Both methods require attention to alignment—misaligned fasteners weaken the bond and mar the appearance.

A practical tip for large surfaces: use construction adhesive in conjunction with screws for added stability. Apply a bead of adhesive along the edges and every 12 inches in the field before securing the plywood. This not only strengthens the bond but also reduces squeaks and movement over time. However, avoid overusing adhesive, as it can create a messy cleanup and hinder future repairs.

Finally, inspect your work under different lighting conditions to ensure the plywood lies flat and the fasteners are flush. Uneven surfaces or protruding screws can ruin the aesthetic and structural integrity of the project. If gaps appear between the plywood and old wood, remove the fasteners, shim the area, and reattach—rushing this step will lead to long-term issues. With careful planning and execution, securing plywood becomes a straightforward task that transforms old wood into a renewed, durable surface.

Tiger Woods' Age: Unveiling the Golf Legend's Birth Year

You may want to see also

Explore related products

Finishing Touches: Sand edges, fill gaps, and apply paint or sealant for a polished look

Sanding the edges of your plywood overlay is the first critical step in achieving a seamless, professional finish. Use 120-grit sandpaper to smooth rough edges where the plywood meets the old wood, followed by 220-grit for a finer finish. Focus on blending the transition between surfaces to avoid visible ridges. Hand-sanding is ideal for control, but a power sander with a light touch can save time on larger areas. Always sand in the direction of the wood grain to prevent splintering.

Gaps between the plywood and the old wood are inevitable, but they don’t have to ruin your project. Fill small gaps (less than 1/8 inch) with wood filler or spackling compound, applying it with a putty knife and smoothing it flush with the surface. For larger gaps, consider using thin strips of wood or caulk to create a stable base before filling. Allow the filler to dry completely—typically 2–4 hours, depending on the product—then sand the area again to ensure a level surface. This step is essential for both aesthetics and structural integrity.

Painting or sealing is where your project transforms from functional to finished. If painting, prime the surface first, especially if the plywood or old wood has knots or stains. Use a high-quality primer and allow it to dry for at least 2 hours. Apply two coats of paint, letting each layer dry fully before adding the next. For a natural wood look, choose a clear sealant like polyurethane, applying it with a foam brush in thin, even coats. Sand lightly with 320-grit sandpaper between sealant coats for a smoother finish.

The choice between paint and sealant depends on your desired outcome. Paint offers endless color options and hides imperfections, making it ideal for high-traffic areas or when you want a bold statement. Sealant, on the other hand, enhances the wood’s natural beauty and is perfect for spaces where texture and grain are part of the design. Whichever you choose, ensure proper ventilation during application and allow ample drying time—typically 24–48 hours for full curing.

Finally, inspect your work under different lighting conditions to catch any missed spots or imperfections. Run your hand over the surface to feel for rough patches or gaps that need further attention. This final touch not only ensures a polished look but also extends the life of your project by preventing moisture or debris from penetrating seams. With these finishing touches, your plywood-covered wood will look intentional, cohesive, and professionally crafted.

Elijah Wood's Age in The Fellowship of the Ring Revealed

You may want to see also

Frequently asked questions

It’s best to prepare the surface first by sanding it smooth, cleaning off any dirt or debris, and ensuring it’s dry. This helps the plywood adhere properly and creates a more even finish.

Use a strong wood glue or construction adhesive suitable for plywood. For added stability, especially in larger areas, combine adhesive with screws or brad nails spaced evenly across the surface.

Yes, sealing or finishing the plywood is recommended to protect it from moisture, wear, and tear. Use a suitable wood sealer, paint, or varnish depending on the desired look and usage.

Fill gaps or uneven areas with wood filler or shims before attaching the plywood. Sand the surface smooth after filling to ensure a seamless finish once the plywood is applied.