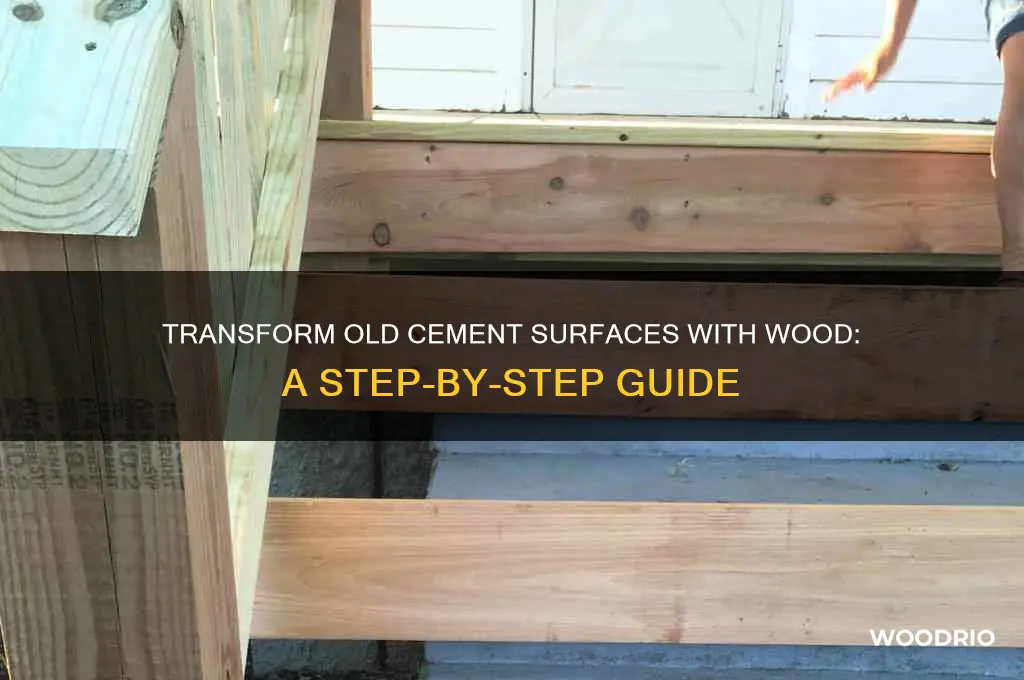

Covering old cement with wood is a practical and aesthetically pleasing way to refresh outdoor or indoor spaces, blending durability with natural warmth. This process involves careful planning, starting with assessing the condition of the existing cement to ensure it’s stable and level. Next, a moisture barrier, such as a plastic sheet or specialized sealant, is applied to prevent water damage to the wood. A subframe or sleeper system is then installed directly onto the cement, providing a sturdy foundation for the wood planks or tiles. Finally, the wood is laid and secured, creating a seamless and inviting surface that transforms the area while protecting the underlying cement. This method not only enhances visual appeal but also extends the lifespan of the original surface.

| Characteristics | Values |

|---|---|

| Surface Preparation | Clean cement thoroughly, repair cracks, ensure surface is dry and level. |

| Materials Needed | Wood planks/tiles, adhesive (construction glue or epoxy), screws/nails. |

| Wood Type | Pressure-treated wood, cedar, or composite wood for durability. |

| Installation Method | Direct adhesion, floating floor system, or framing with supports. |

| Moisture Protection | Use moisture barrier (e.g., plastic sheeting) between cement and wood. |

| Cost | Moderate to high, depending on wood type and installation method. |

| Durability | High, especially with proper sealing and maintenance. |

| Aesthetic Appeal | Enhances space with natural wood look, customizable with stains/finishes. |

| Maintenance | Regular sealing, cleaning, and inspection for moisture or damage. |

| DIY Feasibility | Moderate; requires basic carpentry skills and tools. |

| Environmental Impact | Varies; sustainable if using reclaimed or FSC-certified wood. |

| Time Required | 1-3 days, depending on area size and preparation needs. |

| Indoor/Outdoor Use | Suitable for both, but outdoor use requires weather-resistant materials. |

| Weight Consideration | Ensure cement structure can support added weight of wood and adhesives. |

| Alternatives | Concrete staining, epoxy coating, or tile overlay. |

Explore related products

What You'll Learn

- Prepare Surface: Clean, repair cracks, and ensure cement is level for wood installation

- Choose Wood Type: Select durable, weather-resistant wood suitable for your project needs

- Install Subframe: Build a sturdy wooden or metal subframe for support and stability

- Lay Wood Planks: Secure planks evenly over the cement using screws or adhesive

- Seal and Finish: Apply sealant and stain to protect wood from moisture and wear

Prepare Surface: Clean, repair cracks, and ensure cement is level for wood installation

Before laying wood over old cement, the surface must be pristine and structurally sound. Begin by clearing debris—sweep away dust, dirt, and loose particles. For stubborn grime, a pressure washer or a stiff-bristled brush with a degreaser solution works effectively. Oil stains, common in garages or patios, require a specialized cleaner; apply a trisodium phosphate (TSP) mixture (½ cup TSP per gallon of water), scrub, and rinse thoroughly. Allow the surface to dry completely, as moisture can compromise adhesive bonding.

Cracks in the cement are more than eyesores—they’re structural weaknesses that can telegraph through wood flooring. Hairline cracks (under ⅛ inch) can be filled with a concrete crack sealant or epoxy injection. Wider cracks demand a more robust approach: chisel out the damaged area to create a V-shaped groove, then fill with a polymer-modified cement patching compound. For deep repairs, follow the manufacturer’s instructions for mixing ratios (typically 1 part water to 5 parts compound) and curing times, which range from 4 to 24 hours depending on product and humidity.

Leveling the cement surface is non-negotiable for wood installation. Minor imperfections (under ¼ inch) can be smoothed with a self-leveling compound, applied with a trowel in thin layers. For more pronounced unevenness, grinding down high spots with a diamond cup wheel attached to a grinder is effective, though it generates dust—wear a respirator and eye protection. Alternatively, build up low areas with a floor leveling compound, mixed to a pourable consistency and spread evenly with a gauge rake. Allow 24–48 hours for curing before proceeding.

A critical yet often overlooked step is testing the cement’s moisture content. Excess moisture can cause wood to warp or adhesives to fail. Use a calcium chloride test kit: seal a 2-foot square area with plastic tape, place a dish of calcium chloride under the plastic, and weigh the dish before and after 72 hours. If moisture loss exceeds 3 pounds per 1,000 square feet per 24 hours, apply a moisture barrier primer or consider a vapor barrier system. This step ensures long-term adhesion and prevents costly future repairs.

Finally, inspect the surface for any remaining issues. Run a straightedge or level across the floor to identify dips or peaks. Sand high spots with a pole sander fitted with 60-grit paper, and spot-treat low areas with additional leveling compound. Vacuum thoroughly to remove all dust, as residual particles can interfere with adhesive contact. With a clean, crack-free, and level surface, you’ve laid the foundation for a wood installation that’s not only aesthetically pleasing but also durable and stable.

Pears on New or Old Wood: Understanding Tree Growth for Fruit Production

You may want to see also

Explore related products

Choose Wood Type: Select durable, weather-resistant wood suitable for your project needs

Selecting the right wood type is the cornerstone of any project aiming to cover old cement, as it determines longevity, aesthetics, and maintenance demands. Tropical hardwoods like Ipe or Teak are prime choices due to their natural resistance to rot, insects, and UV degradation. These woods contain high levels of natural oils and tannins, which act as built-in preservatives, making them ideal for outdoor applications. While their upfront cost is higher—often $5 to $20 per square foot—their lifespan of 40+ years with minimal upkeep justifies the investment. For budget-conscious projects, consider Cedar or Redwood, which offer moderate durability at $2 to $5 per square foot but may require sealant reapplication every 2–3 years.

Analyzing the project’s exposure to moisture is critical when choosing wood. In areas with high humidity or direct ground contact, pressure-treated lumber becomes a practical option. Treated with chemicals like ACQ (alkaline copper quaternary) or CA-B (copper azole), this wood resists fungal decay and termite damage, costing around $1.50 to $3 per linear foot. However, its greenish tint and tendency to warp over time may limit its appeal for visible surfaces. For a balance of durability and aesthetics, Accoya—a modified pine treated with acetic anhydride—offers dimensional stability and a 50-year warranty, though at a premium price of $8 to $12 per square foot.

Persuasive arguments for sustainability often steer homeowners toward composite wood, a blend of recycled plastic and wood fibers. Brands like Trex or TimberTech mimic the look of natural wood while offering superior resistance to fading, staining, and splintering. Priced at $4 to $12 per square foot, composites eliminate the need for staining or sealing, making them low-maintenance but less eco-friendly due to their plastic content. For purists seeking authenticity, thermo-treated wood—such as Kebony—undergoes heat and steam treatment to enhance durability without chemicals, costing $7 to $15 per square foot.

Comparing wood types reveals trade-offs between cost, appearance, and performance. Exotic hardwoods like Massaranduba provide unmatched durability but may contribute to deforestation if not sourced responsibly. Bamboo, often marketed as eco-friendly, is technically a grass but offers hardness comparable to oak, though its susceptibility to moisture requires meticulous sealing. Pine, the most affordable option at $1 to $2 per square foot, is best reserved for interior or covered areas due to its vulnerability to rot and warping. Each choice reflects a compromise between initial expense and long-term value, making project-specific needs the ultimate arbiter.

Descriptive details of wood grain, color, and texture can elevate the aesthetic appeal of your cement cover-up. Mahogany, with its rich reddish-brown hue and straight grain, adds elegance but requires annual oiling to prevent graying. Cypress, known for its pecky knots and honeyed tones, develops a silver patina over time, blending seamlessly with rustic landscapes. For modern designs, charred wood (Shou Sugi Ban) offers a sleek, blackened finish that repels water and insects, though its labor-intensive process adds to costs. Ultimately, the wood’s visual character should harmonize with the surrounding environment while meeting functional demands.

Black Currants: Fruiting on Old Wood or New Growth?

You may want to see also

Explore related products

Install Subframe: Build a sturdy wooden or metal subframe for support and stability

A subframe is the unsung hero of any wood-over-concrete project, providing the critical foundation that ensures longevity and stability. Without it, your wooden surface risks warping, shifting, or even collapsing under pressure. Think of it as the skeleton that bears the load, distributes weight, and protects the wood from moisture seeping up from the concrete. Whether you choose wood or metal depends on your budget, climate, and desired lifespan, but either way, precision in construction is non-negotiable.

Steps to Build a Wooden Subframe:

- Measure and Plan: Outline the area to be covered, ensuring the subframe fits snugly without gaps. Use pressure-treated lumber (e.g., 2x4s or 2x6s) to resist rot and insect damage.

- Lay the Joists: Start by placing joists parallel to each other, spaced 12–16 inches apart for adequate support. Secure them to perimeter boards using galvanized screws or brackets to prevent rust.

- Add Crossbeams: Install crossbeams perpendicular to the joists every 4–6 feet to enhance rigidity. This grid-like structure mimics the strength of a floor system in traditional construction.

- Level and Secure: Use shims or adjustable feet to ensure the subframe is level, especially if the concrete surface is uneven. Anchor the frame to the concrete using concrete screws or masonry anchors for stability.

Metal Subframe Alternative:

For a more durable but pricier option, aluminum or galvanized steel framing offers superior resistance to moisture and corrosion. Pre-fabricated metal subframe systems are available, often with interlocking components that simplify assembly. While metal is lighter and easier to cut, it requires specialized tools like metal saws and self-tapping screws. Ensure all connections are watertight to prevent rust over time.

Cautions and Considerations:

- Moisture Barrier: Always install a vapor barrier (e.g., 6-mil polyethylene sheeting) between the concrete and subframe to prevent moisture migration.

- Expansion Gaps: Leave a ¼-inch gap around the perimeter of the subframe to allow for wood expansion and contraction.

- Weight Limits: Ensure the subframe can support the intended load, whether it’s foot traffic, furniture, or vehicles. Overloading can lead to structural failure.

A well-built subframe is the difference between a temporary fix and a lasting solution. It not only elevates the wood surface but also safeguards it from the inherent challenges of concrete substrates. By investing time and precision in this step, you create a robust base that ensures your wooden covering remains stable, level, and beautiful for years to come.

Kultida Woods Age: Unveiling the Mystery Behind Her Timeless Presence

You may want to see also

Explore related products

$59.99 $129.99

Lay Wood Planks: Secure planks evenly over the cement using screws or adhesive

Wood planks offer a warm, natural aesthetic that can transform dull, aging cement into a visually appealing surface. This method is particularly effective for patios, walkways, or indoor floors where a rustic or modern wood look is desired. The key to success lies in the precision of laying and securing the planks, ensuring both durability and a seamless finish.

To begin, prepare the cement surface by cleaning it thoroughly to remove dirt, debris, and any loose material. A pressure washer or stiff brush with a degreaser can be used for this purpose. Once clean, inspect the surface for cracks or unevenness. Minor imperfections can be filled with a cement patch compound, while larger issues may require professional repair. Allow the surface to dry completely before proceeding.

Next, select the appropriate wood planks for your project. Hardwoods like teak or ipe are ideal for outdoor applications due to their natural resistance to moisture and decay. For indoor use, softer woods such as pine or oak can be chosen based on aesthetic preference and budget. Ensure the planks are treated or sealed to enhance their longevity, especially in high-moisture areas. Pre-cut planks to the desired length, allowing for a 1/4-inch expansion gap between each plank to accommodate natural wood movement.

The method of securing the planks depends on the specific application and personal preference. Using screws provides a more permanent and stable installation. Drill pilot holes through the planks into the cement, ensuring the screws are countersunk to maintain a smooth surface. Construction adhesive offers a less invasive option, particularly suitable for indoor projects. Apply a generous bead of adhesive along the cement surface, following the manufacturer’s recommended coverage rate (typically 1/8-inch thick). Press the planks firmly into place, using spacers to maintain even gaps.

Regardless of the securing method, ensure the planks are laid in a staggered pattern to distribute weight evenly and enhance visual appeal. Use a rubber mallet to adjust planks as needed, ensuring they are level and tightly fitted. After installation, apply a final coat of sealant to protect the wood from wear and environmental factors. This step is crucial for outdoor applications to prevent warping, splitting, or discoloration over time. With proper installation and maintenance, wood planks can provide a durable and attractive cover for old cement surfaces, blending functionality with natural beauty.

Discovering the Lifespan of Wood Ducks in the Wild

You may want to see also

Explore related products

Seal and Finish: Apply sealant and stain to protect wood from moisture and wear

Wood, while aesthetically pleasing, is inherently vulnerable to the elements. Moisture, UV rays, and foot traffic can quickly degrade its beauty and structural integrity. This is where sealant and stain become indispensable allies in your quest to cover old cement with wood. Think of them as a protective shield, safeguarding your investment and ensuring its longevity.

Sealants act as a barrier, repelling water and preventing it from seeping into the wood grain. This is crucial, as moisture can lead to warping, cracking, and even rot. Choose a sealant specifically formulated for exterior wood, considering factors like UV protection and flexibility to accommodate wood movement. Apply it generously, following the manufacturer's instructions for drying times and recommended coats.

Stain, beyond its decorative role, adds another layer of protection. It penetrates the wood, enhancing its natural beauty while providing a barrier against UV damage and mildew. Opt for a stain with a semi-transparent or solid finish, depending on your desired level of wood grain visibility. Remember, darker stains generally offer better UV protection. Apply stain after the sealant has fully cured, using a brush or sprayer for even coverage.

Allow ample drying time between coats, and avoid applying stain in direct sunlight or on hot surfaces.

The frequency of reapplication depends on various factors, including climate, sun exposure, and foot traffic. As a general rule, plan to reseal and restain your wood surface every 2-3 years. Regularly inspect the wood for signs of wear and tear, addressing any issues promptly to prevent further damage.

By diligently sealing and staining your wood, you're not just enhancing its appearance; you're investing in its durability. This proactive approach ensures your wood-covered cement surface remains beautiful and functional for years to come, defying the elements and standing the test of time.

John Gillespie's Age: Unveiling the Wisconsin Waterman's Legacy

You may want to see also

Frequently asked questions

First, clean the cement surface thoroughly. Next, install a moisture barrier if needed. Then, lay a subfloor (e.g., plywood or sleeper system) over the cement. Finally, install the wood flooring of your choice on top.

Yes, the cement surface should be clean, dry, and level. Repair any cracks or uneven areas to ensure a smooth base for the wood installation.

It’s not recommended to install wood directly on cement due to moisture issues. Use a subfloor or sleeper system to create a barrier and allow for proper ventilation.

Engineered wood flooring is ideal for cement surfaces because it’s more resistant to moisture and temperature changes compared to solid hardwood.

Use a moisture barrier or underlayment between the cement and subfloor. Ensure proper ventilation and consider using a dehumidifier in damp areas.