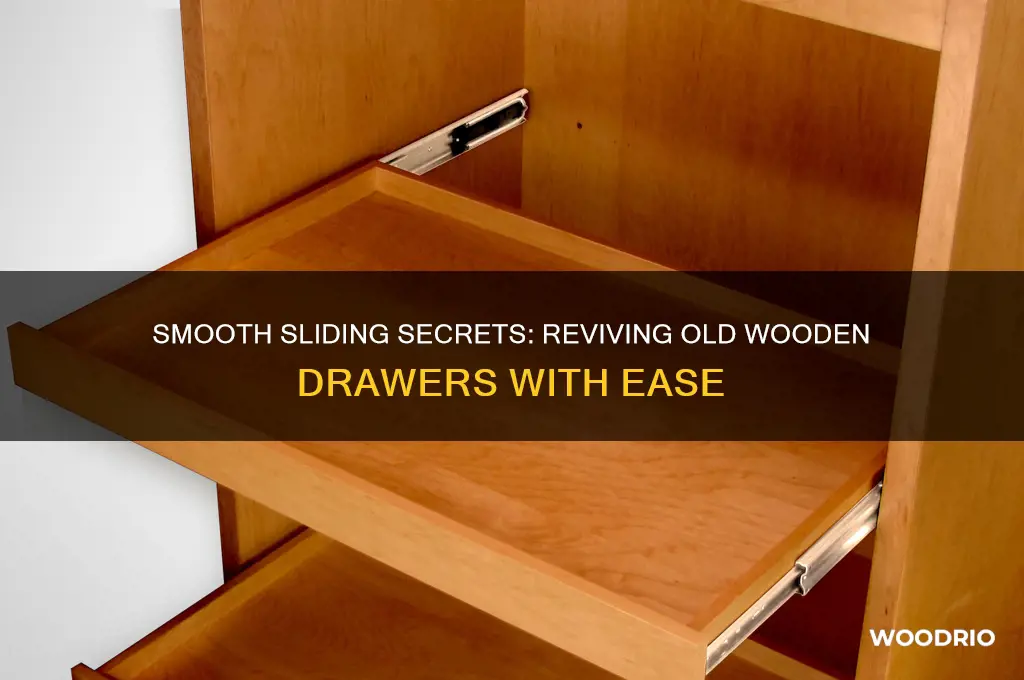

Old wooden drawers often become stiff and difficult to slide due to factors like friction, warping, or accumulated dirt. Fortunately, there are several simple and effective ways to restore smooth operation. By cleaning the tracks, applying lubricants like wax or soap, sanding rough edges, or installing drawer slides, you can significantly improve their functionality. These methods not only enhance ease of use but also extend the life of your furniture, making it a worthwhile DIY project for any homeowner.

| Characteristics | Values |

|---|---|

| Lubrication | Apply wax (e.g., beeswax, paraffin wax, or candle wax), soap, or silicone-based lubricant to the drawer runners and grooves. |

| Cleaning | Remove dirt, dust, and debris from the drawer runners and grooves using a soft brush, vacuum, or cloth. |

| Sanding | Lightly sand the drawer runners and grooves with fine-grit sandpaper (e.g., 220-grit) to smooth out rough spots and splinters. |

| Wood Swelling | Reduce humidity levels or apply a dehumidifier to prevent wood swelling, which can cause drawers to stick. |

| Drawer Adjustment | Adjust the drawer's position by loosening the screws, realigning the drawer, and retightening the screws. |

| Runner Replacement | Replace damaged or worn-out wooden runners with new ones made of hardwood or install metal drawer slides for smoother operation. |

| Drawer Glide Installation | Install drawer glides or slides (e.g., ball-bearing slides or roller slides) to reduce friction and improve drawer movement. |

| Wood Conditioning | Apply wood conditioner or oil (e.g., linseed oil, mineral oil, or Danish oil) to nourish the wood and reduce friction. |

| Drawer Weight Reduction | Remove heavy items or redistribute the weight inside the drawer to reduce strain on the runners. |

| Regular Maintenance | Periodically clean, lubricate, and inspect the drawers to ensure smooth operation and prevent future issues. |

Explore related products

What You'll Learn

Clean and sand drawer tracks for smoother movement

Over time, wooden drawer tracks accumulate dust, debris, and even small wood splinters, all of which can hinder smooth movement. This buildup creates friction, causing drawers to stick or move unevenly. Cleaning and sanding these tracks is a straightforward yet effective solution to restore ease of use. Start by removing the drawer entirely to gain full access to the tracks. Use a soft brush or a vacuum with a narrow nozzle to clear out loose particles. For stubborn grime, a slightly damp cloth can be employed, but ensure the wood is not saturated to prevent warping.

Once the tracks are clean, sanding becomes the next critical step. Begin with a medium-grit sandpaper, such as 120-grit, to smooth out rough spots and remove any remaining splinters. Follow this with a finer grit, like 220-grit, to create a smoother surface that reduces friction. Sand in the direction of the wood grain to avoid scratches or damage. For hard-to-reach areas, consider using a sanding sponge or a small piece of sandpaper wrapped around a flat tool. This process not only improves drawer movement but also extends the life of the wooden components by preventing further wear.

While sanding, it’s essential to strike a balance between thoroughness and preservation. Over-sanding can weaken the tracks, especially in older furniture where the wood may be more fragile. Work gently and inspect the tracks frequently to ensure you’re achieving the desired smoothness without compromising structural integrity. After sanding, wipe the tracks with a dry cloth to remove any dust residue, as leftover particles can negate your efforts. This attention to detail ensures the drawers glide effortlessly without reintroducing friction.

A practical tip to enhance the longevity of your efforts is to apply a dry lubricant, such as wax or soap, to the freshly sanded tracks. Beeswax or a specialized drawer wax can be rubbed onto the surfaces to create a low-friction barrier. Alternatively, a bar of soap run along the tracks can achieve similar results. These methods not only improve movement but also protect the wood from future buildup. By combining cleaning, sanding, and lubrication, you can transform stubborn drawers into smoothly operating components, breathing new life into old wooden furniture.

Elijah Wood's Age in 'Fellowship of the Ring' Revealed

You may want to see also

Explore related products

Apply wax or soap to reduce friction

One of the simplest and most effective ways to make old wooden drawers slide more smoothly is by applying wax or soap to the contact points. These natural lubricants reduce friction between the drawer and its runners, allowing for effortless movement. Unlike synthetic options, wax and soap are gentle on wood, preserving its integrity while providing a long-lasting solution. This method is particularly ideal for antique furniture or pieces where you want to maintain an authentic, chemical-free approach.

To apply wax, start by cleaning the drawer and runner surfaces with a damp cloth to remove dirt and debris. Use a hard wax, such as beeswax or paraffin wax, and rub it directly onto the edges of the drawer and the runner channels. Work the wax in with a cloth or your fingers, ensuring an even coat. For soap, opt for a bar of pure glycerin or saddle soap. Rub the soap along the same contact points, then buff the surface lightly to remove any residue. Both methods create a slick barrier that minimizes resistance, though wax tends to last longer and is better suited for high-use drawers.

While this technique is straightforward, there are a few cautions to keep in mind. Overapplication can lead to a greasy buildup, attracting dust and potentially staining the wood. Apply sparingly, focusing on areas where the drawer makes direct contact with the frame. Additionally, avoid using scented or colored soaps, as these may contain additives that could damage the wood over time. For best results, reapply wax every 6–12 months or soap every 3–4 months, depending on usage.

Comparing wax and soap reveals distinct advantages for each. Wax provides a harder, more durable finish, making it superior for heavy drawers or those used frequently. Soap, on the other hand, is easier to apply and remove, offering a quick fix for lighter drawers or temporary solutions. Both are cost-effective and readily available, making them accessible options for DIY enthusiasts. Ultimately, the choice depends on the drawer’s weight, usage frequency, and your preference for maintenance.

In practice, this method not only improves functionality but also enhances the longevity of your wooden drawers. By reducing friction, you minimize wear and tear on the wood, preventing splintering or warping over time. It’s a small investment of effort that yields significant returns in usability and preservation. Whether you’re restoring a family heirloom or upgrading everyday furniture, applying wax or soap is a tried-and-true solution that combines simplicity with effectiveness.

Melissa Wood Tepperberg's Age: Unveiling the Fitness Guru's Timeline

You may want to see also

Explore related products

Install ball-bearing slides for effortless glide

Ball-bearing slides are a game-changer for old wooden drawers that stick or drag. These mechanisms replace the traditional wooden runners, introducing a system of rolling steel balls that reduce friction to nearly zero. The result? Drawers that glide open and shut with minimal effort, even when fully loaded. This upgrade is particularly beneficial for heavy or frequently used drawers, such as those in kitchens or workshops, where smooth operation is essential for efficiency and convenience.

Installing ball-bearing slides requires precision but is achievable with basic tools and patience. Begin by removing the drawer and measuring its width to select the appropriate slide length—typically, slides should be three-quarters the length of the drawer for optimal support. Next, attach the cabinet member of the slide to the inside of the cabinet using screws, ensuring it’s level and aligned with the drawer’s path. Then, mount the drawer member to the underside of the drawer, double-checking alignment before securing it. Finally, reconnect the drawer to the slides, test the glide, and adjust as needed. Pro tip: use a clamp to hold components in place while screwing for accuracy.

While ball-bearing slides offer superior performance, they aren’t without considerations. The installation process may require modifying the drawer or cabinet to accommodate the slides, particularly in older furniture with irregular dimensions. Additionally, the cost of high-quality slides can add up, especially for multiple drawers. However, the long-term benefits—durability, smoothness, and ease of use—often outweigh the initial investment. For those hesitant to alter vintage pieces, consider this: the slides can be removed or replaced without causing permanent damage, preserving the furniture’s integrity.

Comparing ball-bearing slides to other solutions, such as wax or nylon runners, highlights their unique advantages. Wax and nylon are quick fixes but wear out over time, especially under heavy use. Ball-bearing slides, on the other hand, are built to last, with some rated to support loads of 100 pounds or more. They also eliminate the need for frequent maintenance, making them a more reliable choice for drawers that see daily use. For anyone seeking a permanent, high-performance solution, ball-bearing slides are the clear winner.

Unveiling Gage Wood's Age: A Comprehensive Look at His Life

You may want to see also

Explore related products

Adjust drawer alignment to fix sticking issues

Misaligned drawers are a common culprit behind sticking and resistance. Over time, wooden drawers can warp or shift, causing them to bind against the frame. Even a fraction of an inch can make a significant difference in how smoothly a drawer glides. Addressing this issue requires a keen eye and some basic tools, but the results can be transformative.

Begin by fully removing the drawer from the cabinet or furniture piece. Inspect the runners or grooves along which the drawer slides. Look for signs of wear, splintering, or uneven contact points. Use a straightedge or level to check if the drawer itself is square and if the runners are parallel. If misalignment is evident, mark the problem areas with a pencil for reference.

To correct alignment, start by sanding down any high spots or rough patches on the drawer or runners. A medium-grit sandpaper (120-150 grit) works well for this purpose. For more severe cases, you may need to plane or chisel away excess material. Ensure all surfaces are smooth and even before reassembling. If the drawer still binds, consider adjusting the position of the runners. Loosen the screws holding them in place, shift them slightly to create a more uniform gap, and retighten.

A lesser-known but effective technique involves using wax or soap as a temporary guide. Rub a bar of soap or paraffin wax along the edges of the drawer and runners. Attempt to slide the drawer in and out, noting where the wax wears away. These marks indicate the points of highest friction. Focus your adjustments on these areas, sanding or shifting as needed. Repeat the process until the drawer glides smoothly without resistance.

While adjusting alignment is often sufficient, it’s crucial to address underlying issues like humidity-induced warping or structural damage. For older wooden furniture, consider using a dehumidifier or placing silica gel packets nearby to stabilize moisture levels. If the drawer box itself is warped, you may need to reinforce it with corner brackets or replace it entirely. By combining precise alignment adjustments with preventative measures, you can restore both function and longevity to your wooden drawers.

Accurate Measurement Guide for Replacing Old Wood Windows

You may want to see also

Explore related products

Use wood glue to repair loose joints

Loose joints in wooden drawers can cause friction and resistance, making them difficult to slide smoothly. Over time, the constant opening and closing can weaken the connections between the drawer components, leading to wobbling or sticking. Wood glue offers a straightforward solution to reinforce these joints, restoring stability and ease of movement. By addressing this issue, you not only improve functionality but also extend the life of the furniture.

To begin, disassemble the drawer carefully, identifying the loose joints that need attention. Clean out any old glue or debris using a chisel or sandpaper to ensure a fresh surface for adhesion. Apply a thin, even coat of high-quality wood glue to both mating surfaces, using a small brush for precision. Clamping the joint firmly for at least 30 minutes allows the glue to set properly. For larger joints or added strength, consider using wooden dowels or biscuits in conjunction with the glue. This combination provides mechanical reinforcement, ensuring the joint remains tight even under repeated stress.

While wood glue is effective, it’s crucial to choose the right type for the job. Polyvinyl acetate (PVA) glue is a popular choice for its strong bond and ease of use, but epoxy or polyurethane adhesives offer superior strength for heavily used drawers. Avoid over-applying glue, as excess can seep out and create a messy finish. If the drawer is painted or finished, test the glue on a hidden area first to ensure it doesn’t affect the surface. Patience is key—allow the glue to cure fully, typically 24 hours, before reassembling the drawer.

Comparing this method to alternatives like metal brackets or screws, wood glue is less invasive and preserves the drawer’s original aesthetic. It’s also cost-effective and requires minimal tools, making it accessible for DIY enthusiasts. However, it may not be suitable for severely damaged joints or drawers exposed to high humidity, where more robust solutions are necessary. By carefully assessing the condition of the drawer and applying wood glue correctly, you can achieve a seamless repair that enhances sliding performance.

In practice, this technique is particularly useful for antique or heirloom pieces where maintaining authenticity is important. For example, a vintage dresser with dovetail joints can be restored to its original functionality without compromising its craftsmanship. Pairing this repair with other maintenance steps, such as waxing the drawer slides or adjusting the fit, ensures a comprehensive solution. With proper care, a wood-glued joint can last for years, allowing the drawer to glide effortlessly once again.

Distressing Wood with Vinegar: Easy DIY Aging Technique for Rustic Charm

You may want to see also

Frequently asked questions

You can use paraffin wax, beeswax, or a silicone-based lubricant to reduce friction and help wooden drawers slide smoothly.

Use a soft brush or vacuum to remove dust and debris, then wipe the tracks with a damp cloth and let them dry completely before lubricating.

Yes, rubbing a bar of soap or candle wax along the drawer tracks can act as a temporary lubricant to improve sliding.

Check for swelling or warping in the wood, and lightly sand the edges of the drawer or tracks to ensure a smooth fit before reapplying lubricant.