Extending the length of wood stair spindles can be a practical solution when updating or renovating a staircase to match new design heights or to replace damaged sections. This process typically involves carefully measuring the required additional length, selecting a matching wood species, and crafting or sourcing extensions that seamlessly blend with the existing spindles. Techniques such as splicing, where a new piece is joined to the original spindle, or using a longer replacement with a custom-fitted base, are common approaches. Proper sanding, staining, and finishing ensure the extensions match the original spindles in color and texture, maintaining the staircase’s aesthetic integrity while achieving the desired height.

Explore related products

What You'll Learn

- Extending with Wood Blocks: Attach solid wood blocks to the bottom of existing spindles for added length

- Using Metal Extensions: Insert metal rods or tubes to seamlessly lengthen spindles without replacing them

- Tapered Wood Joints: Join additional wood pieces with tapered cuts for a smooth, integrated look

- Hollow Core Fillers: Fill hollow spindles with wooden dowels or rods to increase height

- Custom Turned Pieces: Order or craft custom-turned wood extensions to match existing spindle designs

Extending with Wood Blocks: Attach solid wood blocks to the bottom of existing spindles for added length

Extending wood stair spindles with solid wood blocks is a practical solution for homeowners seeking to increase spindle length without replacing the entire structure. This method involves attaching a block of wood to the bottom of each existing spindle, effectively elongating it to meet height requirements or aesthetic preferences. The process is straightforward, cost-effective, and allows for customization in terms of wood type and finish to match the existing staircase.

Steps to Extend Spindles with Wood Blocks:

- Measure and Cut Blocks: Determine the desired additional length and cut solid wood blocks to match. Ensure the blocks are slightly larger than the spindle diameter for a secure fit.

- Sand and Prepare: Sand the blocks and the bottom of the spindles to create a smooth surface for adhesion. Wipe away dust to ensure a clean bond.

- Attach Blocks: Use a high-strength wood adhesive or epoxy to secure the blocks to the spindles. Reinforce the joint with screws or dowels for added stability, especially in high-traffic areas.

- Finish and Blend: Sand any rough edges and apply stain or paint to match the existing woodwork. Allow the finish to dry completely before reinstallation.

Cautions and Considerations:

While this method is effective, it’s crucial to ensure the blocks are securely attached to prevent wobbling or detachment. Avoid using lightweight or low-quality wood, as it may compromise durability. Additionally, check local building codes to ensure the modified spindles meet safety standards, particularly regarding height and spacing.

Comparative Advantage:

Compared to replacing entire spindles or using extensions, the wood block method is less invasive and more budget-friendly. It preserves the original character of the staircase while addressing functional or stylistic needs. For older homes with unique spindle designs, this approach allows for preservation without sacrificing modernity.

Practical Tips:

For a seamless look, select wood blocks from the same species as the existing spindles. Pre-drilling holes for screws minimizes the risk of splitting the wood. If the spindles are painted, consider priming the blocks before attachment to ensure uniform coverage. This technique is particularly useful for homeowners tackling DIY projects, as it requires minimal tools and expertise.

How Long Will a 15kg Wood Pellet Bag Last You?

You may want to see also

Explore related products

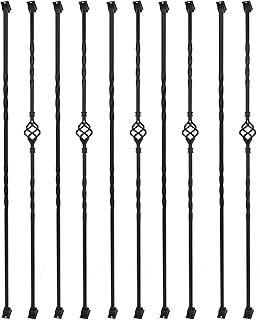

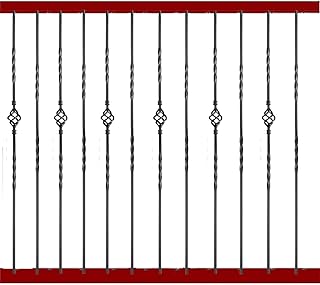

Using Metal Extensions: Insert metal rods or tubes to seamlessly lengthen spindles without replacing them

Metal extensions offer a sleek, modern solution for lengthening wood stair spindles without the hassle of replacement. By inserting metal rods or tubes into the existing spindles, you can achieve a seamless, integrated look that blends traditional wood craftsmanship with contemporary industrial design. This method is particularly effective when you need to extend spindles to meet building code requirements or simply to update the aesthetic of your staircase. The key lies in selecting metal components that complement the wood’s tone and texture, ensuring the extension feels intentional rather than improvised.

To execute this technique, begin by measuring the required extension length and sourcing metal rods or tubes of matching diameter. Stainless steel or wrought iron are durable choices that resist corrosion and wear, while brass or copper can add a warm, decorative touch. Cut the metal to size, ensuring a precise fit, and sand the edges to prevent sharp points. Next, hollow out the bottom portion of the wooden spindle using a drill or router, creating a cavity deep enough to accommodate the metal extension. Secure the metal piece with epoxy adhesive or screws, depending on the desired permanence and structural integrity. For a polished finish, fill any gaps with wood filler and stain or paint the metal to match the surrounding elements.

One of the standout advantages of metal extensions is their versatility. Unlike wood, metal can be easily customized in terms of shape, thickness, and finish, allowing for creative design possibilities. For instance, a tapered metal rod can add a subtle elegance, while a fluted tube introduces texture and visual interest. Additionally, metal’s strength ensures the extended spindle remains sturdy and safe, even under heavy use. This method is especially cost-effective for homeowners looking to update their staircase without investing in entirely new spindles.

However, there are considerations to keep in mind. Metal and wood expand and contract at different rates due to temperature and humidity changes, which can lead to gaps or instability over time. To mitigate this, use flexible adhesives and leave a small allowance for movement during installation. Regular maintenance, such as tightening screws and reapplying sealant, will also prolong the life of the extension. While this approach requires precision and attention to detail, the result is a staircase that feels both timeless and innovative.

In conclusion, using metal extensions to lengthen wood stair spindles is a practical, stylish solution that marries form and function. With careful planning and execution, you can achieve a seamless integration that enhances the overall design of your staircase. Whether you’re aiming for compliance, aesthetics, or both, this method offers a unique way to breathe new life into your home’s architectural details.

Timmy Woods' Purse Legacy: A Journey Through Decades of Craftsmanship

You may want to see also

Explore related products

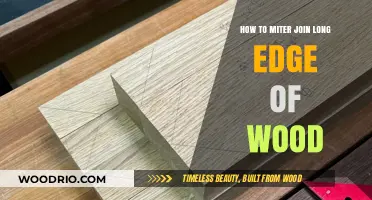

Tapered Wood Joints: Join additional wood pieces with tapered cuts for a smooth, integrated look

Tapered wood joints offer a seamless solution for extending stair spindles, blending additional pieces into the original structure with precision and elegance. By angling the cuts, you create a joint that minimizes visible seams and distributes stress evenly, ensuring both strength and aesthetic continuity. This technique is particularly effective when the spindle’s length needs to be increased without compromising its slender profile or structural integrity.

To execute a tapered joint, begin by measuring the required extension length and selecting a complementary wood species. Mark the taper angle on both the original spindle and the extension piece, ensuring the cuts align perfectly. A common angle for tapered joints is 1:8 (1 inch of taper for every 8 inches of length), but adjust this based on the spindle’s diameter and desired fit. Use a bandsaw or handsaw to make the angled cuts, followed by careful sanding to achieve a smooth, snug fit. Test the joint dry before gluing to ensure alignment and stability.

One of the key advantages of tapered joints is their ability to mimic the natural profile of turned spindles. Unlike butt joints or splices, which can appear bulky or abrupt, tapered joints maintain the spindle’s graceful taper, making the extension nearly imperceptible. This is especially valuable in historic or high-end staircases where preserving the original design is paramount. For added strength, consider reinforcing the joint with a dowel or spline, though this may require additional planning to maintain the seamless appearance.

When working with tapered joints, precision is critical. Even a slight misalignment can result in gaps or uneven stress distribution, compromising both aesthetics and durability. Use a jig or clamping system to hold the pieces securely during gluing, and allow ample drying time before sanding and finishing. For best results, practice the taper cut on scrap wood first to refine your technique. With careful execution, tapered wood joints can transform a simple extension into an integrated, professional-grade solution for longer stair spindles.

Wood Casket Durability: Lifespan in the Ground Explained

You may want to see also

Explore related products

Hollow Core Fillers: Fill hollow spindles with wooden dowels or rods to increase height

Hollow stair spindles often present a unique challenge when extending their height, but filling them with wooden dowels or rods offers a straightforward, cost-effective solution. This method leverages the existing structure, avoiding the need for complete replacements or complex modifications. By inserting a solid wooden core into the hollow spindle, you create a seamless extension that blends with the original design while adding structural integrity.

To execute this technique, begin by measuring the required additional height and selecting a dowel or rod with a diameter slightly smaller than the spindle’s inner width. Sand the dowel to ensure a snug fit, and consider staining or painting it to match the spindle’s finish. Insert the dowel into the spindle, using wood glue for adhesion, and secure it with a clamp until the glue dries. For taller extensions, join multiple dowels end-to-end, ensuring a tight connection with a small amount of glue or a wooden spline for added stability.

One advantage of this method is its adaptability to various spindle designs and materials. Whether your spindles are painted, stained, or varnished, the filler can be customized to match seamlessly. Additionally, wooden dowels are readily available at hardware stores and can be cut to precise lengths, making this a DIY-friendly approach. However, ensure the spindle’s hollow core is clean and free of debris before insertion to guarantee a strong bond.

While this technique is effective, it’s essential to consider the spindle’s overall strength and aesthetics. Overfilling or using a dowel that’s too thick can cause splitting or an uneven appearance. Test the fit with a dry run before applying glue, and use a mallet to gently tap the dowel into place if needed. For spindles with intricate designs or visible ends, trim the dowel flush and sand it smooth to maintain a polished look.

In conclusion, filling hollow spindles with wooden dowels or rods is a practical, budget-friendly way to extend their height while preserving the original style. With careful measurement, proper material selection, and attention to detail, this method yields professional results that enhance both safety and aesthetics. Whether tackling a single spindle or an entire staircase, this approach offers a durable solution that stands the test of time.

Drying Pine Wood: Optimal Timeframe for Perfectly Seasoned Lumber

You may want to see also

Explore related products

Custom Turned Pieces: Order or craft custom-turned wood extensions to match existing spindle designs

Custom turned pieces offer a seamless solution for extending wood stair spindles while preserving the original design aesthetic. By crafting or ordering extensions that match the existing spindle profile, you ensure continuity in both style and material. This approach is particularly valuable for historic homes or renovations where maintaining architectural integrity is paramount. Unlike generic extensions, custom-turned pieces are tailored to fit the exact diameter, taper, and decorative details of your spindles, eliminating the need for visible joints or awkward transitions.

To begin, measure the diameter and length of your existing spindles, noting any unique features such as flutes, beads, or turned accents. If you’re crafting the extensions yourself, select wood that matches the species and grain pattern of the original spindles. For example, oak spindles require oak extensions to ensure consistent color and texture. Use a lathe to replicate the design, starting with rough shaping and progressing to finer details. Sand meticulously to achieve a smooth finish, and apply a matching stain or finish to blend the new piece with the old.

If you lack woodworking expertise or tools, ordering custom-turned extensions is a practical alternative. Provide detailed measurements, photographs, and material specifications to a skilled turner or millwork shop. Many artisans specialize in replicating historical designs and can work from sketches or samples. Request a prototype for approval before proceeding with the full order to ensure accuracy. Costs vary based on complexity, but investing in custom pieces often yields a more polished result than improvising with off-the-shelf options.

One caution: ensure the extensions are structurally sound. Stair spindles bear weight and must comply with safety standards. Reinforce the joint between the original spindle and extension with a dowel or adhesive, such as epoxy, to prevent shifting or separation. Test the connection by applying pressure before installation. For added durability, consider using a harder wood species for the extension, even if it requires staining to match.

In conclusion, custom-turned wood extensions provide an elegant and precise solution for lengthening stair spindles. Whether crafted in-house or commissioned from a professional, these pieces maintain the visual harmony of your staircase while addressing functional needs. With careful planning and attention to detail, the result is virtually indistinguishable from the original spindles, ensuring a cohesive and enduring design.

Perfect Timing: When to Clean Up Wood Glue for Best Results

You may want to see also

Frequently asked questions

Yes, you can extend wood stair spindles by adding a wooden extension piece at the bottom or top, ensuring it matches the spindle’s diameter and style for a seamless look.

You’ll need matching wood for the extension, wood glue, a saw, sandpaper, and possibly a drill or dowels for a secure joint. Stain or paint may also be required to match the existing finish.

Use a strong wood adhesive and consider reinforcing the joint with dowels or screws. Sand the extension smoothly and ensure it fits securely into the stair structure for stability.

Yes, but it’s easier to remove the spindle first. Cut it to the desired length, add the extension, and then reinstall it. If removal isn’t possible, carefully measure and attach the extension in place.

Sand the extension to match the spindle’s texture, then apply stain or paint to blend it with the existing finish. Test the color on a scrap piece of wood first to ensure a perfect match.