Restoring old wood is a rewarding process that breathes new life into aged, weathered, or damaged wooden pieces, preserving their character and historical value. Whether it’s antique furniture, vintage flooring, or weathered outdoor structures, the key steps involve assessing the wood’s condition, cleaning it thoroughly to remove dirt, grime, and old finishes, and repairing any cracks, splits, or missing pieces. Sanding is crucial to smooth the surface and prepare it for refinishing, while staining or sealing can enhance its natural beauty and protect it from future wear. With patience, the right tools, and attention to detail, restoring old wood not only revitalizes its appearance but also ensures its longevity for generations to come.

| Characteristics | Values |

|---|---|

| Cleaning | Remove dirt, grime, and old finishes using a mild detergent or wood cleaner. For stubborn stains, use a mixture of vinegar and water or a commercial wood stripper. |

| Sanding | Start with coarse-grit sandpaper (80-120 grit) to remove old finishes and smooth the surface. Progress to finer grits (150-220 grit) for a smoother finish. Use a power sander for large areas and hand sand for details. |

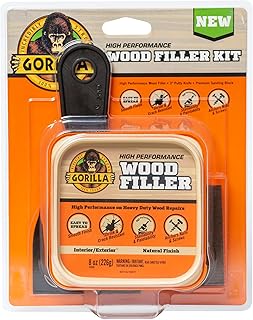

| Repairing Damage | Fill cracks, holes, and gaps with wood filler or epoxy resin. Replace severely damaged sections with matching wood pieces. Use wood glue for reattaching loose parts. |

| Staining (Optional) | Apply a wood stain to enhance or change the color of the wood. Test the stain on a small area first. Use a brush, cloth, or sponge for application. Wipe off excess stain for an even finish. |

| Sealing | Apply a protective finish such as polyurethane, varnish, or wax. Choose between matte, satin, or gloss finishes based on preference. Apply multiple thin coats, sanding lightly between coats for a smooth finish. |

| Polishing | Use a soft cloth to apply wood polish or wax for added shine and protection. Buff the surface to achieve the desired luster. |

| Preserving Natural Patina | If retaining the aged look is desired, avoid heavy sanding and use minimal staining. Apply a clear sealant to protect the wood without altering its appearance. |

| Tools Needed | Sandpaper, power sander, wood filler, stain, sealant, brushes, cloths, gloves, safety goggles, and a dust mask. |

| Safety Precautions | Work in a well-ventilated area. Wear protective gear (gloves, goggles, mask). Follow manufacturer instructions for chemicals and finishes. |

| Environmental Considerations | Use eco-friendly products when possible. Dispose of chemicals and waste properly. Avoid over-sanding to preserve the wood's integrity. |

| Maintenance | Regularly dust and clean the restored wood. Reapply sealant or polish as needed to maintain protection and appearance. |

Explore related products

What You'll Learn

- Cleaning Techniques: Remove dirt, grime, and old finishes gently without damaging the wood surface

- Repairing Damage: Fix cracks, holes, and splits using wood filler or epoxy resin

- Sanding Methods: Smooth surfaces with progressive grits to restore original texture and appearance

- Staining & Finishing: Apply stains and sealants to enhance color and protect the wood

- Preserving Patina: Retain aged character while stabilizing and protecting the wood’s natural wear

Cleaning Techniques: Remove dirt, grime, and old finishes gently without damaging the wood surface

The first step in restoring old wood is to assess the surface for damage and determine the appropriate cleaning method. Wood, especially aged or antique pieces, can be delicate, and using harsh chemicals or aggressive techniques may cause irreversible harm. A gentle approach is key to preserving the wood's integrity. Start by inspecting the wood for any signs of wear, cracks, or previous repairs, as these areas will require extra care.

The Power of Mild Solutions: For initial cleaning, a simple mixture of mild dish soap and warm water is often effective. This solution is gentle enough for most wood types and can cut through grease and grime without stripping the wood's natural oils. Dip a soft-bristled brush or a clean cloth into the soapy water, ensuring it's not too wet to avoid excess moisture seeping into the wood. Gently scrub the surface, following the wood grain to prevent scratching. This method is particularly useful for removing surface-level dirt and light stains.

Tackling Tougher Grime: In cases of stubborn dirt or old wax build-up, a slightly more robust approach is necessary. Create a paste by mixing baking soda with a small amount of water to form a thick consistency. Apply this paste to the wood and let it sit for a few minutes, allowing it to penetrate the grime. Then, using a soft-bristled toothbrush, gently scrub the area in circular motions. This technique is ideal for detailed areas and carvings where a larger brush might be too cumbersome. Rinse the area with a damp cloth and dry it immediately to prevent water damage.

Chemical Strippers: A Last Resort: For old finishes or paint that need removal, chemical strippers can be used, but with caution. These products are powerful and should be handled with care, especially on older wood. Always test a small, inconspicuous area first to ensure the wood can withstand the treatment. Apply the stripper according to the manufacturer's instructions, typically involving a waiting period for the chemicals to break down the finish. Use a plastic scraper to remove the softened finish, being mindful not to gouge the wood. This process may require multiple applications for complete removal.

Caution and Aftercare: Regardless of the cleaning method, always work in a well-ventilated area, especially when using chemical products. Wear protective gloves and consider eye protection to safeguard against splashes. After cleaning, ensure the wood is thoroughly dried. You can use a hairdryer on a low setting to speed up the process, keeping the dryer in constant motion to avoid overheating the wood. Proper drying is crucial to prevent moisture-related issues like warping or mold.

By employing these techniques, you can effectively clean and prepare old wood for restoration, ensuring the surface is ready for the next steps, such as repairing damage or applying new finishes, all while preserving the wood's natural beauty and character. This careful cleaning process is a vital foundation for any successful wood restoration project.

Unveiling Avery Woods' Age: A Comprehensive Look at Her Timeline

You may want to see also

Explore related products

$27.3 $32.15

$123.95 $143.98

Repairing Damage: Fix cracks, holes, and splits using wood filler or epoxy resin

Cracks, holes, and splits mar the beauty of old wood, but they don’t have to be permanent. Wood filler and epoxy resin are your allies in restoring structural integrity and aesthetic appeal. Each material has its strengths: wood filler is ideal for shallow imperfections and surface-level repairs, while epoxy resin excels at bonding deep cracks and stabilizing structural damage. Choosing the right one depends on the severity of the damage and the desired finish.

To begin, assess the damage. Small cracks and surface holes can be filled with wood filler, which comes in various colors to match wood tones. For deeper splits or structural issues, epoxy resin is the better choice due to its superior bonding strength. Clean the damaged area thoroughly, removing dust and debris with a brush or compressed air. For epoxy, roughen the surface slightly with sandpaper to ensure better adhesion. Follow the manufacturer’s instructions for mixing ratios—typically, epoxy requires precise measurements to cure properly. Overfilling or under-mixing can compromise the repair.

Application techniques differ between the two materials. Wood filler is straightforward: press it into the crack or hole with a putty knife, ensuring it’s slightly overfilled to account for shrinkage as it dries. Epoxy, however, demands precision. Apply it in thin layers, allowing each to cure partially before adding more. This prevents air bubbles and ensures a strong bond. For large splits, use clamps or tape to hold the wood together while the epoxy sets. Both materials require sanding once cured to achieve a smooth, seamless finish.

While wood filler is forgiving and beginner-friendly, epoxy resin requires patience and attention to detail. Its clarity makes it ideal for preserving the wood’s natural grain, especially in visible areas like tabletops or furniture legs. However, it’s more expensive and time-consuming to work with. Wood filler, on the other hand, is cost-effective and dries quickly, making it suitable for larger projects or less critical repairs. Pairing the right material with the right technique ensures not just a repair, but a restoration that honors the wood’s age and character.

Unveiling Monica Woods' Age: A Comprehensive Look at Her Life

You may want to see also

Explore related products

$36.32 $49

Sanding Methods: Smooth surfaces with progressive grits to restore original texture and appearance

Sanding is a critical step in restoring old wood, but it’s not just about removing imperfections—it’s about revealing the wood’s original character. The key lies in using progressive grits, a methodical approach that balances efficiency with preservation. Start with a coarse grit, such as 60 or 80, to tackle deep scratches, stains, or old finishes. This initial pass removes the bulk of the damage without overworking the wood. Gradually move to finer grits—120, 180, and finally 220—to smooth the surface and prepare it for finishing. Each grit refines the previous one’s work, ensuring a seamless transition to the wood’s natural texture.

The choice of grit progression depends on the wood’s condition and your goals. For heavily weathered or painted surfaces, a more aggressive starting grit like 40 might be necessary, but exercise caution to avoid gouging softer wood species like pine. Harder woods, such as oak or maple, can withstand coarser grits but still require careful handling to preserve their grain. Always sand in the direction of the grain to avoid scratches that can mar the final appearance. Hand sanding is ideal for intricate details or delicate areas, while power sanders save time on larger, flat surfaces.

One common mistake is rushing the process or skipping grits, which can leave the wood uneven or overly smooth, stripping away its natural patina. Think of sanding as a layered conversation with the wood—each grit asks a question, and the wood responds with its texture. Skipping steps can lead to a loss of character, especially in antique pieces where the wear tells a story. For example, a 100-year-old oak table might retain subtle distressing that adds to its charm; over-sanding could erase this history.

Practical tips can make this process more efficient. Use a sanding block for flat surfaces to ensure even pressure and avoid rounding edges. For curved or detailed areas, wrap sandpaper around a dowel or use specialized sanding tools. Vacuum or wipe the surface between grits to monitor progress and prevent clogging. If using a power sander, keep it moving to avoid heat buildup, which can scorch the wood. Finally, test the final grit on a small, inconspicuous area to ensure it achieves the desired smoothness without altering the wood’s natural feel.

The takeaway is that sanding with progressive grits is both an art and a science. It requires patience, attention to detail, and respect for the wood’s unique qualities. Done correctly, this method not only restores the wood’s original texture and appearance but also sets the stage for a finish that enhances, rather than masks, its inherent beauty. Whether you’re reviving a family heirloom or refinishing a vintage find, mastering this technique ensures the wood’s story continues for generations.

Distressing Wood with Vinegar: Easy DIY Aging Technique for Rustic Charm

You may want to see also

Explore related products

Staining & Finishing: Apply stains and sealants to enhance color and protect the wood

Staining and finishing old wood isn’t just about aesthetics—it’s about preservation. Wood, especially aged pieces, is susceptible to moisture, UV damage, and wear. A well-applied stain penetrates the surface, enhancing the natural grain while adding a layer of protection. Sealants, on the other hand, act as a barrier, locking out water and preventing cracks or warping. Together, they breathe new life into weathered wood, ensuring it remains both beautiful and durable for years to come.

Before diving into staining, preparation is key. Start by sanding the wood to remove old finishes, dirt, and rough patches. Use progressively finer grits (80 to 220) to achieve a smooth surface. Clean the wood thoroughly with a damp cloth to remove dust, and let it dry completely. If the wood is particularly dry or cracked, consider applying a wood conditioner first. This pre-stain treatment ensures even absorption, preventing blotchy results. Always test the stain on a small, inconspicuous area to confirm the color matches your vision.

When applying stain, work in the direction of the grain using a brush, rag, or foam applicator. Apply thin, even coats, allowing each layer to dry fully before adding another. For deeper color, add multiple coats rather than overloading the wood with a single heavy application. Once the desired shade is achieved, let the stain cure for at least 24 hours. Follow up with a sealant—polyurethane, varnish, or wax—applying it with a clean brush or cloth. Two to three coats are typically sufficient, with drying time between each. Sand lightly with 400-grit paper between sealant coats for a smoother finish.

Choosing the right products can make or break your project. Water-based stains dry quickly and are low-odor, but they may raise the grain slightly. Oil-based stains penetrate deeper and provide richer color but take longer to dry. For sealants, polyurethane offers excellent durability but can yellow over time, while wax provides a natural look but requires more frequent reapplication. Consider the wood’s intended use—high-traffic areas like floors or tabletops benefit from harder finishes, while decorative pieces may prioritize appearance.

Finally, maintenance is crucial to prolonging the life of your restored wood. Avoid harsh chemicals and use mild soap and water for cleaning. Reapply sealant every few years, or as needed, to maintain protection. For outdoor wood, inspect annually for signs of wear or water damage. With proper care, stained and sealed wood retains its beauty and structural integrity, transforming a relic of the past into a timeless piece for the future.

Lexi Wood's Age: Unveiling the Mystery of Summer House Star

You may want to see also

Explore related products

$57.3 $61.79

Preserving Patina: Retain aged character while stabilizing and protecting the wood’s natural wear

The allure of aged wood lies in its patina—a unique blend of wear, color, and texture that tells a story. Yet, preserving this character while ensuring structural integrity requires a delicate balance. Unlike aggressive restoration, which strips away history, patina preservation focuses on stabilization and protection. This approach honors the wood’s journey, allowing its natural wear to remain a focal point while safeguarding it for future generations.

To begin, assess the wood’s condition. Surface cracks, loose joints, and flaking finishes are common issues in aged pieces. Avoid over-sanding or using harsh chemicals, as these can erase the patina. Instead, clean the surface gently with a mixture of mild soap and water, using a soft-bristle brush to remove dirt without disturbing the aged texture. For stubborn grime, a paste of baking soda and water applied sparingly can lift stains without damage. Always test a small, inconspicuous area first to ensure compatibility.

Stabilization is the next critical step. For structural weaknesses, such as loose joints or splintered edges, use wood glue specifically designed for aged materials. Apply it sparingly, clamping the pieces together until fully dried. For surface cracks, a thin application of boiled linseed oil mixed with a few drops of turpentine can penetrate deeply, restoring flexibility without altering the patina. Reapply this treatment annually in dry climates to maintain moisture balance.

Protection is key to long-term preservation. Traditional waxes, like beeswax or carnauba, offer a breathable barrier that enhances the wood’s natural luster without creating a glossy finish. For added durability, consider a matte, water-based polyurethane designed for aged wood. Apply thin coats with a natural-bristle brush, allowing each layer to dry completely before adding another. This ensures the wood can continue to breathe, preventing moisture buildup that could lead to rot or warping.

Finally, embrace the imperfections. Knots, nail holes, and uneven coloring are part of the wood’s charm. Rather than filling or disguising them, highlight these features with strategic lighting or placement. For example, a table with a weathered top can become a conversation piece when paired with modern, minimalist decor. By preserving patina, you’re not just restoring wood—you’re honoring its history and ensuring its story continues.

Are Vintage Wooden Ironing Boards Valuable Collectibles or Just Clutter?

You may want to see also

Frequently asked questions

Begin by assessing the condition of the wood, removing any dirt or debris with a soft brush or cloth. Next, inspect for damage like cracks, splinters, or rot, and address these issues before proceeding with restoration.

Use a chemical stripper or a heat gun to safely remove old finishes. Follow the product instructions carefully, and always work in a well-ventilated area. After stripping, sand the wood to smooth the surface.

Fill cracks or holes with wood filler or epoxy resin, matching the color and grain as closely as possible. Allow the filler to dry completely, then sand it smooth to blend with the surrounding wood.

Sand the wood progressively with finer grits to achieve a smooth surface. Apply a stain (if desired) to enhance the color, followed by a protective finish like polyurethane or wax to seal and protect the wood.