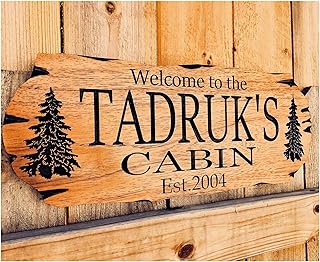

Shipping a long wooden sign requires careful planning and preparation to ensure it arrives safely and undamaged. The first step is to measure the sign’s dimensions and select an appropriately sized shipping container, such as a custom-made wooden crate or a sturdy cardboard tube, depending on the sign’s length and thickness. Wrap the sign in protective materials like bubble wrap or foam padding to cushion it from impacts, and secure it with packing tape to prevent shifting during transit. For added protection, line the shipping container with additional padding or use corner protectors to safeguard vulnerable edges. Clearly label the package as fragile and handle with care to alert carriers to its delicate nature. Finally, choose a reliable shipping service that offers tracking and insurance, especially for longer distances, to provide peace of mind and financial protection in case of damage or loss.

| Characteristics | Values |

|---|---|

| Packaging Material | Use sturdy cardboard, plywood, or foam boards to protect the sign. |

| Cushioning | Wrap the sign in bubble wrap, foam sheets, or packing paper. |

| Custom Crate | Build a wooden crate tailored to the sign's dimensions for maximum protection. |

| Corner Protection | Add corner protectors or foam padding to prevent damage. |

| Sealing | Use strong packing tape to seal all edges and corners securely. |

| Labeling | Mark the package as "Fragile" and "Handle with Care." |

| Shipping Carrier | Choose carriers like FedEx, UPS, or USPS with tracking and insurance. |

| Shipping Method | Opt for ground shipping for cost-effectiveness or expedited for urgency. |

| Insurance | Purchase shipping insurance to cover potential damage or loss. |

| Dimensions Limit | Ensure the package does not exceed carrier size limits (e.g., 108" length for most). |

| Weight Limit | Keep the package under carrier weight limits (e.g., 70 lbs for USPS). |

| Cost | Varies based on size, weight, and carrier; expect $50-$200+ for long items. |

| International Shipping | Check customs regulations and use reinforced packaging for longer transit. |

| Delivery Time | 2-7 business days domestically; longer for international shipments. |

| Tracking | Use carrier-provided tracking to monitor shipment progress. |

| Eco-Friendly Options | Use recyclable materials and minimal packaging to reduce environmental impact. |

Explore related products

What You'll Learn

- Packaging Materials: Choose sturdy cardboard, bubble wrap, and foam to protect the sign during transit

- Securing the Sign: Use straps or tape to prevent shifting and ensure stability inside the box

- Box Selection: Opt for a custom crate or long box that fits the sign’s dimensions snugly

- Shipping Labels: Clearly mark Fragile and Handle with Care to alert carriers to its delicacy

- Carrier Options: Compare services like USPS, FedEx, or freight for cost-effective and safe delivery

Packaging Materials: Choose sturdy cardboard, bubble wrap, and foam to protect the sign during transit

Sturdy cardboard forms the backbone of your packaging, but not all cardboard is created equal. For a long wooden sign, opt for double-walled corrugated cardboard, which offers superior strength and durability compared to single-walled options. Measure your sign’s dimensions and choose a box that allows for at least 2 inches of buffer space on all sides. This extra room ensures the sign doesn’t shift during transit, reducing the risk of damage. Reinforce the box’s seams with high-quality packing tape, applying it in a "H" pattern across the top and bottom for added security.

Bubble wrap serves as the first line of defense against shocks and vibrations. Wrap the wooden sign in at least two layers of large-bubble (1-inch diameter) wrap, ensuring complete coverage. Pay special attention to corners and edges, which are most vulnerable to impact. For added protection, secure the bubble wrap with tape, but avoid adhering it directly to the wood to prevent residue. If the sign has intricate carvings or raised designs, consider using foam sheets or foam peanuts to fill gaps between the wrap and the wood, creating a snug, cushioned fit.

Foam is your secret weapon for absorbing heavy impacts. Closed-cell foam, such as polyethylene or EVA foam, is ideal due to its moisture resistance and shock-absorbing properties. Cut foam sheets to line the interior of the cardboard box, creating a custom cradle for the sign. Alternatively, use foam edge protectors along the sign’s length to shield against corner drops. For signs longer than 4 feet, insert foam blocks at regular intervals (every 12–18 inches) to distribute pressure evenly and prevent bending or warping during transit.

Combining these materials strategically maximizes protection without adding excessive weight. Start by placing a layer of foam at the box’s bottom, followed by the bubble-wrapped sign, and finish with another foam layer on top. Fill any remaining voids with crumpled kraft paper or air pillows to prevent shifting. Seal the box securely, labeling it with "Fragile" and "This Side Up" stickers for handler awareness. This layered approach ensures the sign arrives intact, even when shipped over long distances or handled roughly.

While cost is a consideration, skimping on packaging materials can lead to costly damages. A $10 investment in high-quality cardboard, bubble wrap, and foam pales in comparison to replacing a broken sign or refunding a customer. For signs valued over $200, consider adding insurance to your shipment. Always test the package’s durability by dropping it from a 3-foot height before sealing it—if the sign remains undamaged, your packaging is ready for transit.

Wood Tick Season Duration: Understanding Its Length and Timing

You may want to see also

Explore related products

Securing the Sign: Use straps or tape to prevent shifting and ensure stability inside the box

Straps and tape are your allies in the battle against shifting during transit. Imagine your wooden sign as a passenger in a car—without a seatbelt, it’s at risk of sliding, tipping, or colliding with the sides during sudden stops or turns. Similarly, securing the sign inside the box prevents damage by minimizing movement. Use polyester or nylon straps for their strength and flexibility, wrapping them diagonally or horizontally across the sign’s surface. For smaller signs, heavy-duty packing tape can be applied in an "H" or "X" pattern to hold it firmly against the box’s interior padding. The goal is to create a snug fit, like a custom cradle, ensuring the sign remains stationary even if the box is jostled.

Consider the physics of motion when choosing your securing method. During shipping, packages experience three types of movement: linear (back-and-forth), angular (tilting), and rotational (spinning). Straps are ideal for countering linear and rotational forces, as they distribute pressure evenly across the sign’s surface. Tape, on the other hand, excels at preventing angular shifts when applied directly to the box’s interior walls. For maximum stability, combine both: use straps to anchor the sign to the box’s base, then reinforce with tape along the sides. This dual approach mimics the stability of a three-point seatbelt, securing the sign from multiple axes of movement.

Not all straps and tapes are created equal. Avoid using duct tape or twine, as they can leave residue or damage the wood’s finish. Instead, opt for packing straps with quick-release buckles for easy removal and polyethylene tape for its high tensile strength. For signs with intricate carvings or fragile edges, apply foam padding under the straps to prevent indentation. Measure the sign’s dimensions and calculate the strap length needed, allowing an extra 12–18 inches for tightening and securing. A common mistake is over-tightening, which can warp the wood—aim for a snug fit, not a vise-like grip.

A real-world example illustrates the importance of proper securing. A 6-foot wooden sign shipped without adequate strapping arrived with a cracked corner due to repeated shifting during transit. Upon inspection, the box showed signs of internal abrasion, indicating the sign had moved despite the padding. In contrast, a similarly sized sign secured with crisscrossed straps and reinforced tape arrived unscathed, even after traveling 2,000 miles. The difference? The second shipper accounted for the sign’s center of gravity, placing straps at the midpoint and ends to counteract pivoting. This case highlights the need for strategic placement, not just the use of materials.

Finally, test your securing method before sealing the box. Gently tilt and shake the package to simulate transit conditions. If the sign shifts or rattles, adjust the straps or add additional tape. Think of this as a final safety check, akin to ensuring a car’s cargo is secure before driving. For long signs, consider adding a third strap midway along the length to prevent bending or bowing. By treating securing as a precise science rather than a cursory step, you ensure the sign arrives as it was sent—pristine and ready to display.

Understanding 1x1 Wood Dimensions: Length, Uses, and Practical Applications

You may want to see also

Explore related products

Box Selection: Opt for a custom crate or long box that fits the sign’s dimensions snugly

Shipping a long wooden sign requires precision in packaging to ensure it arrives undamaged. A custom crate or long box tailored to the sign’s dimensions is not just a preference—it’s a necessity. Standard boxes often leave excessive space, allowing the sign to shift during transit, which increases the risk of cracks, splinters, or breaks. A snug fit minimizes movement, acting as a protective shell that absorbs shocks and vibrations. Think of it as a tailored suit for your sign: it fits perfectly, looks professional, and provides maximum protection.

When selecting a custom crate, consider the material. Plywood or solid wood crates offer superior durability compared to cardboard, especially for longer items. Reinforce corners and edges with metal brackets or additional wood strips to prevent splitting under pressure. For added security, line the crate’s interior with foam padding or bubble wrap, ensuring the sign doesn’t touch the crate’s walls directly. This dual-layer approach—a rigid exterior and a cushioned interior—distributes impact evenly and safeguards against damage.

Long boxes, another viable option, are ideal for signs with uniform thickness. These boxes are designed to accommodate length without unnecessary bulk, making them cost-effective and space-efficient. When using a long box, secure the sign with packing paper or air pillows to fill any gaps. Avoid overstuffing, as this can create pressure points that weaken the sign’s structure. A well-fitted long box should allow the sign to slide in effortlessly but leave no room for movement once sealed.

The decision between a custom crate and a long box hinges on the sign’s fragility and your budget. For high-value or intricately designed signs, a custom crate is the safer bet, offering robust protection and peace of mind. Long boxes, while more affordable, are better suited for simpler, sturdier signs shipped over shorter distances. Regardless of choice, ensure the box is sealed with heavy-duty packing tape and labeled with “Fragile” and “Handle with Care” warnings to alert handlers.

In conclusion, the right box selection is a critical step in shipping a long wooden sign. A custom crate or long box that fits snugly eliminates the guesswork, reducing the risk of damage and ensuring your sign arrives in pristine condition. Invest time in measuring accurately and choosing the appropriate material—it’s a small effort that pays off in big ways. After all, the goal isn’t just to ship a sign; it’s to deliver a piece of craftsmanship intact.

Composting Wood Chips: Understanding the Timeframe for Natural Breakdown

You may want to see also

Explore related products

Shipping Labels: Clearly mark Fragile and Handle with Care to alert carriers to its delicacy

Shipping a long wooden sign requires more than just a sturdy box—it demands clear communication with carriers about its fragility. One of the most effective ways to do this is by using shipping labels that boldly state "Fragile" and "Handle with Care." These labels serve as a visual cue, instantly alerting everyone in the shipping process to treat the package with extra caution. Without them, your carefully crafted sign risks being mishandled, leading to cracks, splinters, or worse.

Consider the journey your package will take: from your hands to the delivery truck, through sorting facilities, and finally to its destination. Each step involves multiple handlers who may not know what’s inside. A "Fragile" label acts as a universal language, transcending barriers and ensuring your sign is prioritized for gentle treatment. For added impact, pair these labels with arrows pointing to the sign’s orientation, such as "This Side Up," to prevent it from being placed in a damaging position during transit.

While it might seem like a small detail, the placement of these labels matters. Position them prominently on all sides of the package, especially the top and sides, to ensure they’re visible no matter how the box is oriented. Use high-contrast colors—bold red or black on white—to make the text stand out. If you’re shipping internationally, consider adding translations of "Fragile" and "Handle with Care" in the destination country’s language to eliminate any ambiguity.

Don’t underestimate the power of redundancy. In addition to labels, include a note inside the package reiterating its fragility. This two-pronged approach ensures that even if the external labels are overlooked, the internal message will reinforce the need for careful handling. Think of it as a safety net for your sign, doubling the chances it arrives intact.

Finally, remember that labels are just one part of a comprehensive shipping strategy. Pair them with proper packaging—bubble wrap, foam padding, and a custom-sized box—to create a protective cocoon for your sign. Together, these measures transform a fragile wooden item into a resilient package ready to withstand the rigors of shipping. By clearly marking "Fragile" and "Handle with Care," you’re not just protecting your sign—you’re investing in its safe arrival.

Durability of Wood Posts: Lifespan and Maintenance Tips Revealed

You may want to see also

Explore related products

Carrier Options: Compare services like USPS, FedEx, or freight for cost-effective and safe delivery

Shipping a long wooden sign requires careful consideration of carrier options to balance cost and safety. USPS, FedEx, and freight services each offer distinct advantages and limitations. USPS is often the most cost-effective for lighter, smaller items, but its size restrictions (maximum length of 108 inches combined length and girth) may not accommodate longer signs. FedEx, with its FedEx Ground and FedEx Express services, provides more flexibility for oversized items, though costs can escalate quickly. Freight services, while pricier, are ideal for bulky or heavy signs, offering specialized handling and secure delivery.

When evaluating USPS, consider its Parcel Select Ground service for cost savings, but note that delivery times are longer (2–8 days). For expedited shipping, Priority Mail is an option, but its dimensional weight pricing can make it expensive for oversized items. USPS also lacks specialized handling for fragile or awkwardly shaped items, increasing the risk of damage. To mitigate this, use robust packaging—double-walled corrugated cardboard, foam padding, and corner protectors—and clearly label the package as "Fragile" and "Handle with Care."

FedEx stands out for its ability to handle oversized packages, with FedEx Ground accepting items up to 108 inches in length and 165 inches in combined length and girth. Its Express services offer faster delivery but at a premium. FedEx’s packaging guidelines are strict; ensure your sign is securely wrapped in bubble wrap or foam and placed in a custom crate or reinforced box. For added protection, consider FedEx’s Declared Value for Carriage service, which provides insurance beyond the standard $100 liability coverage.

Freight shipping is the go-to option for signs exceeding carrier size or weight limits. Less-than-Truckload (LTL) freight is cost-effective for smaller shipments, while Full Truckload (FTL) is suitable for bulk orders. Freight carriers specialize in handling oversized items, often using pallets and shrink-wrap for added security. However, freight shipping involves more steps—scheduling pickups, preparing bills of lading, and coordinating delivery appointments. Costs vary based on weight, dimensions, and distance, so obtain quotes from multiple providers to find the best deal.

In conclusion, the choice of carrier depends on your sign’s dimensions, budget, and delivery timeline. For smaller, lighter signs, USPS may suffice with careful packaging. FedEx offers a middle ground for oversized items, balancing cost and speed. Freight services are the safest bet for large, heavy signs, despite higher costs. Always measure your sign accurately, compare carrier restrictions, and invest in quality packaging to ensure safe delivery.

Understanding Cord Measurements: How Long is the Wood in Feet?

You may want to see also

Frequently asked questions

Use a sturdy cardboard box or custom wooden crate that fits the sign snugly. Wrap the sign in bubble wrap or foam padding to protect it from scratches and impacts. Secure it inside the box with packing paper or airbags to prevent shifting during transit.

Clearly mark the package with "Fragile" and "Handle with Care" labels. Indicate the correct orientation (e.g., "This Side Up") to ensure proper handling. Include the recipient’s address and your return address prominently.

Choose a carrier that offers package tracking and insurance, such as FedEx, UPS, or USPS. For oversized signs, consider freight shipping services, which specialize in handling larger and heavier items.

Use high-quality packing materials, secure the sign tightly to prevent movement, and consider adding corner protectors. Insure the package for its full value and select a shipping option with delivery confirmation to minimize risks.