Mitering a long piece of wood on a table saw requires careful planning and precise execution to ensure accuracy and safety. Unlike shorter pieces, longer boards can be unwieldy and pose unique challenges, such as maintaining control and preventing binding or kickback. To achieve a clean, accurate miter cut, you’ll need to set up your table saw with a miter gauge or sliding table, secure the workpiece properly, and use appropriate techniques to manage the length of the wood. This process involves measuring and marking the cut line, adjusting the blade angle, and feeding the wood through the saw in a controlled manner. By following these steps and prioritizing safety, you can successfully miter long pieces of wood with professional results.

| Characteristics | Values |

|---|---|

| Tool Required | Table saw with miter gauge or sliding table saw |

| Wood Length | Typically longer than the table saw's standard cutting capacity (e.g., 8 feet or more) |

| Miter Angle | Commonly 45°, but adjustable based on project needs |

| Safety Equipment | Push sticks, featherboards, safety glasses, ear protection, dust mask |

| Cutting Technique | Use a miter gauge for shorter lengths; for longer pieces, use a sliding table or outfeed support |

| Support Method | Outfeed table, roller stand, or helper to support the wood's overhang |

| Blade Type | Fine-tooth crosscut blade for clean cuts |

| Measuring Tools | Tape measure, square, marking tools (pencil, marker) |

| Clamping | Use clamps to secure the wood to the table saw or support structure |

| Cut Direction | Always push the wood through the blade away from the body, never pull it back |

| Material Thickness | Suitable for various thicknesses, but ensure the blade height is adjusted accordingly |

| Precision | Requires careful alignment of the miter gauge or sliding table for accurate angles |

| Dust Collection | Use a dust collection system or shop vacuum to manage sawdust |

| Practice | Test cuts on scrap wood to ensure accuracy and technique |

| Common Applications | Framing, trim work, furniture making, and other woodworking projects requiring angled cuts |

| Challenges | Managing the weight and length of the wood, maintaining control during the cut |

| Alternative Methods | Miter saw with extensions or circular saw with a guide for longer pieces |

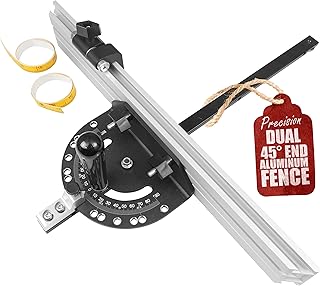

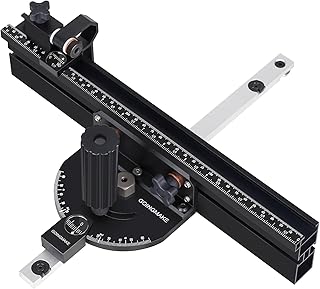

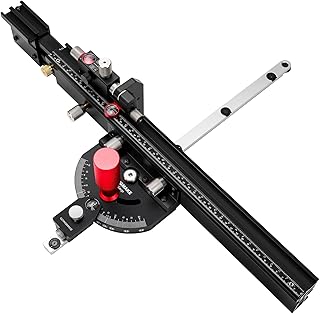

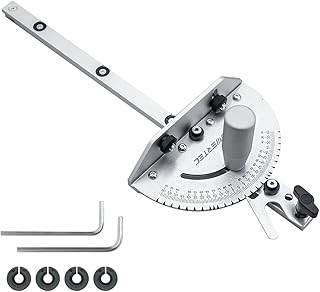

Explore related products

What You'll Learn

- Safety Gear and Setup: Wear protective gear, ensure saw stability, and check blade alignment before starting

- Measuring and Marking: Accurately measure and mark cut lines using a square for precision

- Featherboard Use: Secure wood with featherboards to prevent kickback and maintain control during cutting

- Cutting Technique: Push wood steadily, keeping hands clear of the blade, and use a push stick

- Post-Cut Finishing: Sand edges, check for splinters, and ensure smooth, accurate mitered ends

Safety Gear and Setup: Wear protective gear, ensure saw stability, and check blade alignment before starting

Before you even think about firing up your table saw, prioritize safety. This isn't just about avoiding accidents; it's about ensuring you can continue woodworking for years to come. Start by suiting up. Safety glasses are non-negotiable, shielding your eyes from flying debris. Ear protection is crucial, as table saws are notoriously loud. Consider a dust mask, especially for longer cuts, to protect your lungs from fine wood particles. Gloves, while tempting, can actually be dangerous, as they can get caught in the blade.

Opt for a push stick or push block to maintain a safe distance from the blade.

A wobbly table saw is a recipe for disaster. Ensure your saw is on a sturdy, level surface. Check for any loose bolts or screws, tightening them securely. If your saw has adjustable feet, level it meticulously. An uneven saw can lead to binding, kickback, and inaccurate cuts. Remember, stability isn't just about the saw itself; it's about your entire workspace. Clear the area of clutter and ensure good footing.

Blade alignment is critical for both safety and precision. A misaligned blade can cause the wood to bind, leading to kickback. Use a combination square to check that the blade is perfectly perpendicular to the table. Adjust the blade height so it protrudes no more than 1/4 inch above the wood. This minimizes the risk of the wood pinching the blade and reduces tear-out on the cut edge.

Regularly inspect your blade for dullness or damage. A sharp, clean blade cuts more efficiently and safely.

Think of safety gear and setup as the foundation of your miter cut. Skipping these steps is like building a house on sand. By prioritizing safety, you're not just protecting yourself; you're setting yourself up for a successful and enjoyable woodworking experience. Remember, a little extra time spent on preparation can save you from a world of hurt later.

Perfecting Wood Staining: Rit Dye Application Time for Optimal Results

You may want to see also

Explore related products

Measuring and Marking: Accurately measure and mark cut lines using a square for precision

Precision in measuring and marking is the cornerstone of a successful miter cut on a long piece of wood. Even the slightest inaccuracy can lead to misaligned joints or uneven edges, undermining the integrity of your project. A square—whether a speed square, combination square, or try square—is your most reliable tool for ensuring that your cut lines are perfectly perpendicular or at the desired angle. Without it, you’re left to guesswork, and in woodworking, guesswork rarely yields professional results.

Begin by placing the square firmly against the edge of the wood, ensuring it sits flush with the surface. For a 90-degree miter cut, align the blade of the square with the edge you intend to cut. If you’re working with a different angle, adjust the square accordingly, using its markings as a guide. Hold the square steady and draw a crisp, continuous line along its edge with a sharp pencil. A wobbly or faint line will only complicate the cutting process, so take your time to ensure clarity and accuracy.

Consider the length of the wood when measuring. Long pieces can be unwieldy, and it’s easy to lose alignment as you move along the board. One practical tip is to measure from both ends toward the center, ensuring the marks meet in the middle. This minimizes the risk of errors caused by warping or uneven surfaces. If you’re working with particularly long or heavy stock, enlist a helper to hold the wood steady while you measure and mark.

Double-checking your measurements is non-negotiable. Use the square to verify that your lines are indeed at the correct angle. A common mistake is assuming the wood’s factory edge is straight; always measure from the actual reference point you’re using, not from an assumed edge. If you’re cutting multiple pieces, mark them all before making any cuts to maintain consistency and avoid confusion.

Finally, remember that the goal is not just accuracy but also efficiency. A well-marked piece of wood ensures smoother cuts and reduces the need for adjustments later. By mastering this step, you’ll save time, material, and frustration, setting the stage for a seamless miter cut that enhances the overall quality of your project.

How Long Does COVID-19 Survive on Wooden Surfaces?

You may want to see also

Explore related products

Featherboard Use: Secure wood with featherboards to prevent kickback and maintain control during cutting

Featherboards are essential tools for table saw safety, particularly when mitering long pieces of wood. Their primary function is to apply consistent pressure against the workpiece, keeping it firmly against the fence and table. This prevents the wood from shifting or lifting, which can lead to kickback—a dangerous situation where the wood is violently thrown back toward the operator. By using featherboards, you not only enhance safety but also improve the accuracy of your cuts, ensuring the wood remains aligned with the blade throughout the entire operation.

To effectively use featherboards, start by positioning one ahead of the blade to hold the wood down and against the fence as it feeds into the cut. Place a second featherboard behind the blade to maintain control of the piece as it’s severed. Adjust the featherboards so they apply firm pressure without binding the wood, allowing it to move smoothly through the cut. For long pieces, consider adding an additional featherboard along the table to support the overhanging wood, reducing the risk of tipping or wobbling. Proper placement is key—ensure the featherboards are tight enough to secure the wood but not so tight that they impede its movement.

A common mistake is neglecting to use featherboards because the wood "feels stable" during setup. However, the real danger arises when the blade begins cutting, creating an imbalance in the workpiece. For example, a 10-foot board being mitered will have a significant portion unsupported once the cut progresses, making it prone to shifting or lifting. Featherboards counteract this by providing continuous downward and lateral pressure, effectively acting as a third hand to guide the wood. This is especially critical when working with heavy or unwieldy pieces that are difficult to control manually.

While featherboards are indispensable, they are not a substitute for proper technique. Always push the wood through the blade with a push stick or push pad once it nears the end of the cut, ensuring your hands remain clear of the blade. Combine featherboards with other safety measures, such as a riving knife or splitter, to minimize the risk of kickback further. Regularly inspect your featherboards for wear or damage, as worn components can reduce their effectiveness. With consistent use and proper setup, featherboards transform a potentially hazardous task into a controlled, precise operation.

Optimal Wood Drying Time: Ensuring Quality and Durability for Projects

You may want to see also

Explore related products

Cutting Technique: Push wood steadily, keeping hands clear of the blade, and use a push stick

Mitering long pieces of wood on a table saw demands precision and safety. The cutting technique—pushing the wood steadily, keeping hands clear of the blade, and using a push stick—is foundational to achieving clean cuts while minimizing risk. This method ensures control over the material’s movement, reduces the chance of kickback, and protects your hands from the blade’s path. Without it, even experienced woodworkers risk uneven cuts or injury, especially when handling unwieldy lengths.

Consider the mechanics of this technique. Pushing the wood steadily maintains consistent pressure against the fence, which is critical for accurate miter cuts. Jerky or uneven movements can cause the wood to bind or shift, leading to blade deflection or a ruined piece. Meanwhile, keeping hands clear of the blade is non-negotiable. The table saw’s blade spins at thousands of revolutions per minute, and even a momentary lapse in focus can result in severe injury. A push stick bridges the gap, allowing you to guide the wood through the final inches of the cut without risking your fingers.

Practical implementation requires attention to detail. Position your hands firmly on the wood, using your body weight to guide it along the fence. As the piece nears the blade, introduce the push stick to maintain control. For longer pieces, consider using a featherboard to hold the wood against the fence, freeing your hands to focus on the push stick. Always ensure the push stick is made of a durable material like hardwood or plastic, with a comfortable grip to prevent slipping. Avoid makeshift tools, as they may fail under pressure.

Comparing this technique to alternatives highlights its efficiency. Some woodworkers attempt to freehand long cuts, relying on sheer strength to control the wood. However, this approach lacks precision and increases the risk of kickback. Others use a miter gauge alone, which can wobble under the weight of longer pieces. The push stick technique, when paired with a fence, provides stability and control unmatched by other methods. It’s a small investment in time and effort that yields professional results.

In conclusion, mastering the push technique is essential for safe and accurate miter cuts on long pieces of wood. It combines steady pressure, hand safety, and the strategic use of tools to deliver consistent outcomes. By integrating this method into your workflow, you not only protect yourself but also elevate the quality of your craftsmanship. Remember: precision starts with control, and control begins with the right technique.

March of the Wooden Soldiers: Unveiling the Duration of the Classic Toy Parade

You may want to see also

Explore related products

Post-Cut Finishing: Sand edges, check for splinters, and ensure smooth, accurate mitered ends

After the table saw has done its job, the raw mitered ends of your wood piece will likely have rough edges, minor tear-outs, or splinters that detract from the precision of your cut. Post-cut finishing is where the true craftsmanship comes into play, transforming a good miter into a great one. Begin by sanding the edges with progressively finer grits of sandpaper—start with 120-grit to remove imperfections, then move to 180-grit for smoothing, and finish with 220-grit for a polished feel. Use a sanding block or a power sander for consistency, especially on long pieces where hand sanding can lead to uneven results.

Splinters are the silent saboteurs of a perfect miter joint. Run your fingers gently along the cut edges to detect any raised fibers or rough spots, but be cautious to avoid injury. A quick once-over with a sharp chisel can carefully remove stubborn splinters, but take care not to alter the angle of the miter. For delicate or intricate pieces, a fine-toothed rasp or a cabinet scraper can be more effective than sandpaper in achieving a smooth finish without rounding over the edges.

Accuracy is the hallmark of a well-executed miter, and post-cut finishing is your last chance to ensure the ends align flawlessly. Hold the mitered pieces together and inspect the joint under bright light to highlight gaps or misalignments. If discrepancies are found, lightly sand or plane the high spots, testing the fit frequently. Remember, it’s easier to remove a little material at a time than to correct over-sanding. A dry fit before final assembly is crucial—if the joint doesn’t close perfectly now, it won’t improve with glue.

For a professional touch, consider applying a coat of sealant or finish to the mitered ends before assembly. This not only enhances the wood’s appearance but also protects the end grain from moisture absorption, which can cause swelling or warping. Use a small brush or cloth to apply the finish, ensuring it penetrates the end grain evenly. Allow ample drying time before joining the pieces to avoid contamination of the glue line. With careful sanding, splinter removal, and accuracy checks, your mitered ends will not only look smooth but also function seamlessly in the final project.

Seasoning Mulberry Wood: Understanding the Timeframe for Optimal Results

You may want to see also

Frequently asked questions

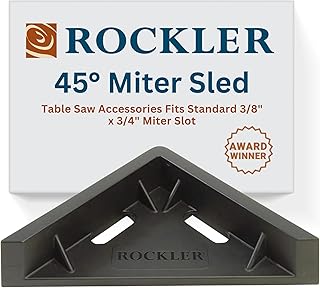

Use a sliding miter gauge or a miter sled to ensure stability and accuracy. Secure the workpiece with clamps or a push stick to keep your hands away from the blade.

Ensure the blade is sharp and properly aligned. Reduce the blade height to just above the thickness of the wood, and feed the material slowly and smoothly through the saw.

Yes, but it’s riskier. Use a standard miter gauge with a long fence extension or a helper to support the far end of the wood. Always prioritize safety and control.

Double-check the miter gauge’s calibration and use a square to verify the angle before cutting. Measure and mark the cut line carefully, and use a featherboard to keep the wood aligned.

Use a roller stand or a helper to support the overhanging end of the wood. This reduces strain on the saw and ensures better control during the cut.