Tapering a long piece of wood is a fundamental woodworking skill that involves gradually reducing the thickness or width of the wood along its length, creating a smooth, angled transition. This technique is commonly used in furniture making, cabinetry, and crafting to achieve aesthetic appeal or functional design, such as for table legs, chair spindles, or handles. The process requires careful planning, precise measurements, and the right tools, such as a table saw, band saw, hand plane, or spokeshave, depending on the desired taper and the woodworker's preference. Proper technique ensures a clean, even taper while minimizing waste and maintaining the structural integrity of the wood. Whether using power tools or hand tools, understanding the principles of tapering is essential for achieving professional results in woodworking projects.

| Characteristics | Values |

|---|---|

| Tools Required | Table saw, band saw, hand plane, spokeshave, belt sander, disc sander, chisels, marking gauge, measuring tape, pencil |

| Wood Preparation | Choose straight-grained, dry wood; ensure it's free from defects like knots or cracks |

| Marking the Taper | Measure and mark the desired taper length and angles on both ends of the wood |

| Taper Angles | Common angles range from 1:10 (shallow) to 1:4 (steep), depending on the project |

| Cutting Methods | Table saw taper jig, band saw freehand or with a fence, hand planing for fine adjustments |

| Sanding Techniques | Belt sander for initial shaping, disc sander for smoothing, hand sanding for final finish |

| Safety Precautions | Wear safety glasses, ear protection, and dust mask; secure wood firmly before cutting |

| Precision Tips | Use a marking gauge for consistent lines, check taper frequently with a straightedge |

| Finishing | Sand to desired grit, apply finish (stain, varnish, oil) to protect the wood |

| Common Applications | Table legs, chair spindles, tool handles, decorative elements |

| Troubleshooting | Uneven taper: re-measure and adjust cuts; tear-out: use sharper blades or reduce feed rate |

Explore related products

What You'll Learn

- Marking the Taper: Measure and mark the start and end points of the taper for accuracy

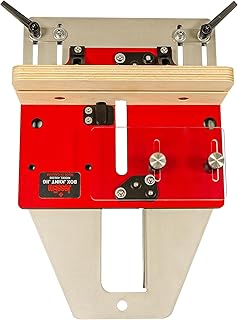

- Using a Jig: Create or use a tapering jig to guide the wood during cutting

- Hand Planing: Employ a hand plane to gradually remove material for a smooth taper

- Power Tools: Utilize a table saw or bandsaw with a taper guide for precision

- Sanding Techniques: Finish the taper with sandpaper to ensure a seamless, polished edge

Marking the Taper: Measure and mark the start and end points of the taper for accuracy

Precision in marking is the cornerstone of a successful taper, ensuring the wood transitions smoothly from thick to thin without errors. Begin by identifying the start and end points of the taper along the length of the wood. Use a tape measure to determine the exact dimensions at both ends, noting the difference in width or thickness. For example, if you’re tapering a 4-inch-wide board to 2 inches over a 4-foot length, mark these measurements clearly at the beginning and end of the workpiece. This initial step eliminates guesswork and provides a visual guide for the shaping process.

Once measurements are taken, transfer them to the wood with a pencil and a straightedge. Draw a line at the start point to indicate the full width and another at the end point to show the reduced dimension. For added accuracy, use a combination square or ruler to ensure the lines are straight and perpendicular to the wood’s edge. If the taper is complex or angled, consider marking intermediate points along the length to create a stepped guide. This method breaks the taper into manageable sections, making it easier to maintain consistency during shaping.

A practical tip for ensuring precision is to double-check your marks before proceeding. Align the start and end points with the intended orientation of the wood in your project. For instance, if the tapered piece will be part of a leg or rail, ensure the marks align with the structural requirements. Mistakes at this stage can lead to uneven results, so take the time to verify measurements and adjust as needed. Using a sharp pencil and light pressure will allow for easy corrections without damaging the wood surface.

Comparing traditional and modern marking techniques can offer additional insights. While a simple ruler and pencil suffice for most projects, digital tools like laser guides or marking apps can enhance accuracy for intricate tapers. However, these tools are often overkill for basic woodworking tasks and may introduce unnecessary complexity. The key is to choose a method that aligns with the project’s demands and your skill level. Regardless of the approach, the goal remains the same: clear, accurate marks that serve as a reliable roadmap for shaping the wood.

In conclusion, marking the taper is a deceptively simple yet critical step in woodworking. It demands attention to detail, careful measurement, and thoughtful execution. By taking the time to mark start and end points accurately, you lay the foundation for a seamless taper that enhances both the functionality and aesthetics of your project. Whether you’re crafting furniture, tools, or decorative pieces, this step ensures your workpiece transitions gracefully, reflecting your skill and precision.

Understanding Wood Stud Lengths: A Comprehensive Guide for Builders

You may want to see also

Explore related products

Using a Jig: Create or use a tapering jig to guide the wood during cutting

A tapering jig is a woodworker's secret weapon for achieving precise, consistent tapers on long pieces of wood. By creating or purchasing a jig tailored to your project, you eliminate the guesswork and potential errors associated with freehand cutting. This method is particularly valuable for projects requiring multiple identical tapers, such as table legs or chair rails, where uniformity is key.

A well-designed jig acts as a guide, ensuring your saw blade follows the exact angle and path needed for the desired taper.

Designing Your Jig:

Imagine a simple yet effective jig: a sturdy base with an adjustable fence. The fence, positioned at the desired taper angle, guides the wood against the saw blade. Consider using a miter gauge slot on your table saw for added stability. For a more complex taper, incorporate a sliding mechanism allowing for micro-adjustments. Remember, the jig's design should prioritize safety, accuracy, and ease of use.

Utilize materials like plywood or MDF for the base and hardwood for the fence, ensuring durability and minimal deflection during cutting.

Using the Jig: Secure your jig to the table saw or band saw, ensuring it's flush with the blade. Mark the taper line on your wood, aligning it with the jig's fence. Feed the wood through the jig, maintaining steady pressure and allowing the fence to guide the cut. For longer pieces, consider using a push stick for added control and safety.

Benefits and Considerations: The jig method offers unparalleled precision and repeatability, making it ideal for batch work or intricate projects. However, it requires initial setup time and investment in materials or purchasing a pre-made jig. For occasional tapering needs, simpler methods might suffice. Ultimately, the jig's value lies in its ability to transform a potentially challenging task into a streamlined, accurate process.

Discovering the Lifespan of Wood Ducks: How Long Do They Live?

You may want to see also

Explore related products

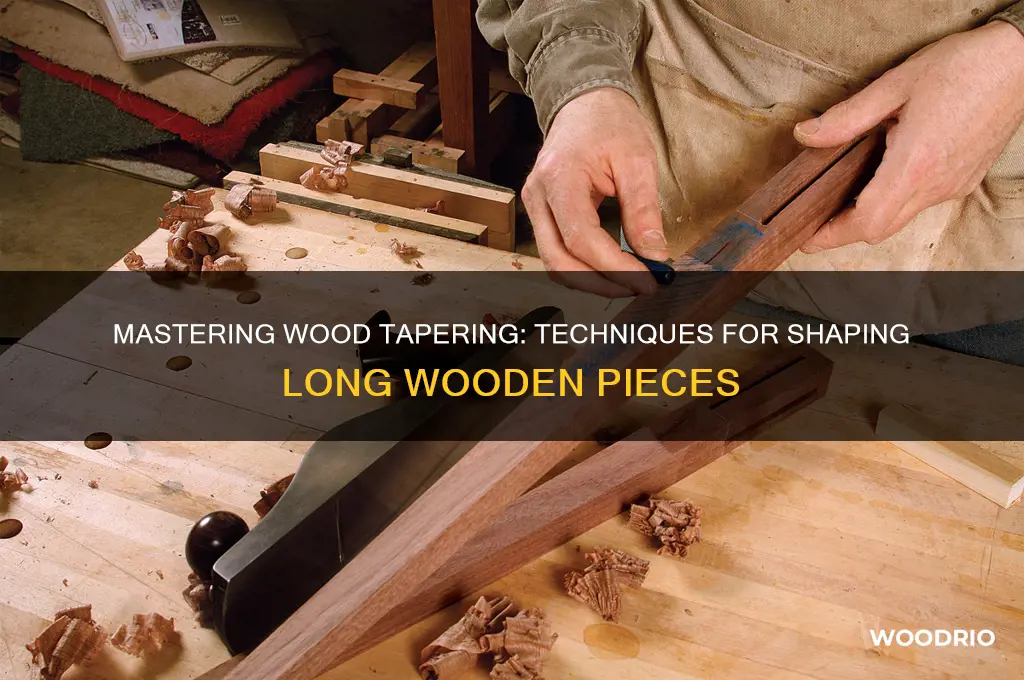

Hand Planing: Employ a hand plane to gradually remove material for a smooth taper

Hand planing is an art that transforms rough wood into a refined, tapered masterpiece. Unlike power tools, a hand plane offers precision and control, allowing you to gradually remove material in thin, consistent shavings. This method is ideal for long pieces of wood where uniformity and smoothness are paramount. The key lies in the rhythmic motion of the plane, guided by your hands and keen eye, ensuring the taper progresses seamlessly from thick to thin.

To begin, mark the taper on your wood, clearly defining the starting and ending points. Secure the piece firmly in a vise or on a workbench to prevent movement. Start planing at the thicker end, holding the plane at a slight angle to follow the taper line. Apply even pressure, letting the blade do the work as you push the plane along the grain. Each pass should remove a thin layer, no more than 1/16 inch, to maintain control and avoid tear-out. Gradually adjust the angle of the plane as you move toward the thinner end, ensuring a smooth transition.

One common mistake is rushing the process, which can lead to uneven results or gouges. Patience is your greatest ally here. If you encounter tear-out, switch to a finer-toothed blade or adjust the plane’s depth setting. For long tapers, periodically check your progress with a straightedge or ruler to ensure consistency. Remember, hand planing is as much about feel as it is about sight—listen to the sound of the blade cutting through the wood, and adjust your technique as needed.

Compared to sanding or routing, hand planing offers a tactile connection to the material, allowing you to shape the wood with intention. While it demands more time and skill, the result is a taper that feels alive, bearing the mark of craftsmanship. This method is particularly suited for fine woodworking projects like table legs, chair arms, or tool handles, where precision and aesthetics are critical.

In conclusion, hand planing is a rewarding technique for creating a smooth, elegant taper. It requires practice, but the control and satisfaction it provides are unmatched. With sharp tools, careful marking, and a steady hand, you can achieve professional results that elevate your woodworking to the next level. Master this skill, and you’ll find yourself reaching for the hand plane whenever a taper is called for.

Wood in Cement: Durability, Lifespan, and Longevity Explained

You may want to see also

Explore related products

Power Tools: Utilize a table saw or bandsaw with a taper guide for precision

Tapered wood pieces add elegance and functionality to furniture, architectural elements, and even tool handles. Achieving a precise taper by hand can be time-consuming and prone to error, especially for longer pieces. This is where power tools like a table saw or bandsaw, paired with a taper guide, become invaluable. These tools transform a complex task into a repeatable, accurate process, ensuring your taper is consistent along the entire length of the wood.

For a table saw, a taper guide is typically a long, straight edge clamped to the saw’s fence at the desired angle. The wood is fed through the saw, riding against the guide to create the taper. Bandsaws use a similar principle, with the guide attached to the table or fence, allowing the blade to follow the angled path. Both methods require careful setup: measure twice, mark the taper lines clearly, and ensure the guide is securely fastened. Start with a shallow cut, gradually increasing depth to avoid binding or kickback. Always prioritize safety by using push sticks and keeping hands clear of the blade.

The choice between a table saw and bandsaw depends on the project’s specifics. Table saws excel at long, straight tapers, particularly for thicker stock, as their wide tables provide stability. Bandsaws, with their thinner blades and greater maneuverability, are ideal for curved or irregular tapers, though they may require more finesse to maintain precision. A key advantage of both tools is their ability to handle longer pieces of wood, which can be challenging with handheld tools or smaller machinery. For example, tapering a 6-foot table leg on a bandsaw with a taper guide ensures the angle remains consistent from top to bottom, a feat nearly impossible without such a setup.

While power tools streamline the process, success hinges on attention to detail. Begin by calculating the taper’s angle and length, then transfer these measurements to the wood. Secure the taper guide firmly, double-checking its alignment before making the first cut. For bandsaws, use a blade with the appropriate tooth count for the wood species—fewer teeth for softer woods, more for hardwoods. On a table saw, ensure the blade height is set just above the wood thickness to minimize tear-out. Practice on scrap wood to fine-tune your technique and confirm the guide’s accuracy.

Despite their efficiency, power tools demand respect. Always wear safety gear, including eye protection and hearing protection when using loud machinery. Keep the workspace clear of debris and ensure proper lighting to avoid mistakes. For longer pieces, enlist a helper to support the wood’s far end, preventing it from sagging or binding. Finally, maintain your tools regularly—sharp blades and clean guides are essential for clean, precise cuts. With practice and care, a table saw or bandsaw equipped with a taper guide becomes a go-to method for achieving professional-quality tapers on long pieces of wood.

Aquarium Wood Color Fading: Timeline and Tips for a Clear Tank

You may want to see also

Explore related products

Sanding Techniques: Finish the taper with sandpaper to ensure a seamless, polished edge

Sanding is the final, transformative step in tapering a long piece of wood, turning a rough, uneven surface into a smooth, polished edge. After shaping the taper with tools like a plane, chisel, or router, the wood’s surface often retains minor imperfections—scratches, tool marks, or uneven grain. Sandpaper, with its abrasive grit, systematically removes these flaws, blending the taper into a cohesive, seamless transition. The key lies in progression: start with a coarse grit (80–120) to level major inconsistencies, then graduate to finer grits (220–400) for a glass-like finish. Each grit pass refines the surface, ensuring the taper not only looks professional but feels flawless to the touch.

The technique matters as much as the tool. Always sand in the direction of the wood grain to avoid cross-grain scratches, which can mar the final appearance. For long tapers, use a sanding block or wrap the sandpaper around a flat, rigid surface to maintain even pressure and prevent rounding over the edges. Circular motions or back-and-forth strokes can create uneven wear, so stick to consistent, linear passes. For curved or intricate tapers, consider flexible sanding sponges or folded sandpaper to conform to the shape. Patience is paramount—rushing through grits or applying excessive pressure can leave visible scratches or burnish the wood, defeating the purpose of sanding.

A common mistake is skipping grits or jumping directly to fine sandpaper. Coarse grits remove material aggressively but leave deep scratches; finer grits refine the surface but cannot correct major flaws. Each grit step must fully eliminate the scratches left by the previous one. Test the surface with your hand or under bright light to identify remaining imperfections. For oily woods like teak or walnut, clean the surface between grits with a tack cloth to remove residue that can clog the sandpaper. Similarly, for hardwoods like oak or maple, which have open grain, consider sealing the wood with a grain filler before final sanding to achieve a smoother finish.

The final grit determines the taper’s sheen and texture. A 220-grit finish is suitable for most projects, providing a smooth, matte surface ready for stain or finish. For a high-gloss polish, progress to 400-grit or higher, but note that finer grits require more effort and time. If the piece will be painted, 150-grit is often sufficient, as paint can fill minor imperfections. Always finish sanding before applying any finish, as oils or stains can make the wood harder to sand and may accentuate scratches. The goal is to create a surface so refined that it enhances the wood’s natural beauty, not detracts from it.

In conclusion, sanding a tapered piece of wood is both art and science, demanding precision, patience, and attention to detail. By methodically progressing through grits, maintaining proper technique, and addressing the wood’s unique characteristics, you can achieve a taper that is not just functional but visually stunning. The final sanded edge should feel as smooth as glass, with no visible transitions or tool marks, ensuring the piece stands the test of time and craftsmanship. Master this step, and your tapered wood will be a testament to skill and dedication.

How Long Does It Take to Make Wood Sink?

You may want to see also

Frequently asked questions

Essential tools include a table saw, band saw, hand plane, or a router with a straight bit. A marking gauge, tape measure, and pencil are also necessary for layout and precision.

Measure and mark the desired width at both ends of the wood. Use a straightedge or chalk line to connect the marks, creating a tapered line. Double-check measurements for accuracy before cutting.

Yes, tapering by hand is possible using a hand plane or spokeshave. Mark the taper, then carefully remove material along the marked line, working progressively from one end to the other until the taper is achieved.