When considering whether it’s better to have longer runs of wood, several factors come into play, including structural integrity, aesthetics, and cost-effectiveness. Longer runs of wood can minimize the number of joints, reducing potential weak points and creating a smoother, more seamless appearance, which is particularly desirable in flooring, paneling, or furniture. However, longer pieces may be more prone to warping or bowing due to natural wood movement, especially in environments with fluctuating humidity or temperature. Additionally, longer runs can be more challenging to transport, handle, and install, potentially increasing labor costs. Ultimately, the decision depends on the specific application, the type of wood, and the desired balance between durability, visual appeal, and practicality.

| Characteristics | Values |

|---|---|

| Structural Integrity | Longer runs of wood generally provide better structural integrity due to fewer joints, reducing weak points. |

| Aesthetic Appeal | Continuous wood runs create a seamless, visually appealing look without visible seams or breaks. |

| Material Efficiency | Longer pieces reduce waste from cutting and fitting multiple shorter pieces. |

| Installation Time | Fewer pieces mean faster installation, saving labor costs and time. |

| Cost | Longer runs can be more expensive due to higher demand for larger, defect-free wood pieces. |

| Stability | Longer wood runs are less prone to warping or movement compared to multiple shorter pieces. |

| Maintenance | Fewer joints mean less maintenance and lower risk of joint failure over time. |

| Customization | Longer runs may limit design flexibility in certain applications. |

| Availability | Longer, high-quality wood pieces are less common and may be harder to source. |

| Environmental Impact | Using longer runs can reduce waste, contributing to more sustainable practices. |

Explore related products

What You'll Learn

- Durability vs. Length: Longer wood runs reduce joints, increasing structural integrity but may limit flexibility in design

- Cost Efficiency: Fewer cuts and joints can lower labor costs, but longer pieces may be pricier

- Aesthetic Appeal: Continuous wood runs create seamless, elegant looks but can overpower small spaces

- Installation Complexity: Longer pieces are harder to handle and install, requiring more skill and tools

- Material Waste: Longer runs minimize offcuts, reducing waste, but mistakes are costlier to fix

Durability vs. Length: Longer wood runs reduce joints, increasing structural integrity but may limit flexibility in design

Longer runs of wood inherently minimize the number of joints in a structure, which directly translates to fewer weak points. Each joint, whether a splice or corner connection, introduces potential for movement, splitting, or failure over time. For example, a 20-foot span of continuous wood decking will have significantly greater resistance to warping and sagging compared to the same span achieved with four 5-foot boards joined together. This principle is particularly critical in load-bearing applications like beams, flooring, or framing, where joint integrity is paramount.

However, the trade-off for this increased durability lies in design constraints. Longer wood runs demand meticulous planning to accommodate material dimensions and site conditions. A 16-foot ceiling, for instance, requires either a single 16-foot beam or a complex joint system to maintain structural continuity. While the former offers superior strength, sourcing such lengths may be cost-prohibitive or logistically challenging, especially in residential construction. Designers must weigh the structural benefits against practical limitations like material availability, transportation, and installation feasibility.

From a practical standpoint, achieving the benefits of longer runs often involves strategic material selection and joint optimization. For example, using 12-foot studs in wall framing reduces joints by 33% compared to 8-foot studs, enhancing wall rigidity. However, this approach necessitates careful layout to minimize waste and ensure alignment with standard building module sizes. In applications like cabinetry or furniture, longer runs can simplify assembly but may restrict customization—a 10-foot countertop with no seams is more durable but offers less adaptability than modular sections.

Ultimately, the decision to prioritize longer wood runs hinges on project-specific priorities. In high-stress environments like bridges or heavy timber framing, the durability gains far outweigh design inflexibility. Conversely, in projects where aesthetics or modularity are key, shorter runs with well-engineered joints may be preferable. For instance, a live-edge dining table constructed from a single 12-foot slab will outlast a jointed version but may cost 2-3 times more. Balancing these factors requires a nuanced understanding of both structural principles and design objectives.

Durability of Pine Wood Furniture: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Cost Efficiency: Fewer cuts and joints can lower labor costs, but longer pieces may be pricier

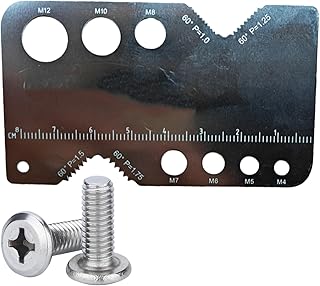

Longer runs of wood inherently reduce the number of cuts and joints required in a project, which can significantly lower labor costs. Each cut demands time, precision, and skill, whether performed by hand or machine. For instance, a 16-foot span covered by two 8-foot boards requires one joint, whereas four 4-foot boards would need three joints, tripling the assembly time. In commercial construction or high-volume furniture production, this difference scales dramatically: reducing joints from 100 to 50 per project could save hours of labor per unit. For DIY enthusiasts, this translates to faster completion times and less frustration with alignment and clamping.

However, the material cost of longer wood pieces often offsets labor savings, creating a cost-efficiency paradox. Lumber pricing typically increases exponentially with length due to higher demand for longer, defect-free boards and limited availability. For example, a 12-foot 2x4 might cost 50% more than two 6-foot boards, even though it eliminates one joint. In structural applications like flooring or framing, where longer spans are common, this premium can add hundreds to material budgets. To mitigate this, calculate the total project cost by comparing the labor savings from fewer joints against the price difference in longer boards, ensuring the trade-off aligns with your budget.

Despite higher material costs, longer runs of wood can yield long-term savings by minimizing waste and improving structural integrity. Shorter boards often generate offcuts too small for practical use, contributing to 10-15% waste in typical projects. Longer pieces reduce this waste, especially in repetitive patterns like decking or paneling. Additionally, fewer joints mean fewer weak points prone to shifting, warping, or failure over time, reducing maintenance costs. For outdoor projects exposed to moisture or temperature fluctuations, this durability advantage can outweigh the initial material expense.

To optimize cost efficiency, strategically balance board length with project requirements. For load-bearing structures, prioritize longer runs to enhance stability, even if pricier. In non-critical areas like decorative trim or temporary fixtures, shorter, more affordable boards suffice. Use digital tools or manual calculations to map out cuts and joints before purchasing, identifying opportunities to use longer pieces where they deliver the most value. For example, in a 12x16-foot deck, allocate 16-foot boards for joists and shorter boards for perimeter edging, combining strength where needed with cost savings elsewhere.

Ultimately, the decision to use longer runs of wood hinges on a project’s scale, purpose, and budget. Small-scale projects may not justify the material premium, while large-scale or high-stakes applications often do. Always factor in hidden costs like transportation (longer boards may require specialized delivery) and storage (they take up more space). By weighing these variables, you can harness the labor-saving benefits of longer wood without overspending, ensuring both efficiency and practicality in every cut.

Wood Pellets vs. Propane: Comparing Fuel Longevity for Grilling

You may want to see also

Explore related products

$11.59 $18

Aesthetic Appeal: Continuous wood runs create seamless, elegant looks but can overpower small spaces

Longer, continuous runs of wood flooring or paneling can transform a space, offering a sleek and sophisticated aesthetic that few other materials can match. The uninterrupted flow of grain patterns creates a visual harmony that draws the eye, making rooms appear more cohesive and intentional. This effect is particularly striking in open-concept layouts or large areas where the wood’s natural beauty can fully unfold. However, this elegance comes with a caveat: in smaller spaces, the same seamless look can feel overwhelming, dominating the room rather than enhancing it.

To maximize the aesthetic appeal of continuous wood runs, consider the scale of the space. In larger rooms, such as living areas or hallways, longer planks or panels can create a sense of grandeur and fluidity. For example, using 7- to 8-foot planks in a spacious living room can emphasize the room’s dimensions while maintaining a balanced visual rhythm. Conversely, in smaller rooms like bathrooms or cozy bedrooms, opt for shorter planks or introduce breaks in the wood run to prevent the space from feeling cramped. A practical tip is to use area rugs or furniture placement to visually segment the wood, softening its dominance without compromising its elegance.

The direction of the wood run also plays a critical role in its aesthetic impact. Running planks parallel to the longest wall can elongate a room, making it feel more expansive, while perpendicular runs can add width and coziness. For instance, in a narrow hallway, laying planks lengthwise can create an illusion of depth, whereas in a square bedroom, a perpendicular layout can make the space appear more open. This strategic use of direction allows you to tailor the wood’s effect to the room’s unique proportions.

While continuous wood runs offer undeniable visual appeal, their success hinges on thoughtful execution. Overuse in small spaces can lead to a claustrophobic effect, as the wood’s richness and texture become too dominant. To avoid this, balance the wood with lighter elements, such as white walls or minimalist decor, to create contrast and breathing room. Additionally, incorporating natural light through windows or mirrors can reflect the wood’s warmth without intensifying its presence. By carefully considering the space’s size, layout, and complementary elements, you can harness the elegance of continuous wood runs without letting them overpower the room.

How Long Does Wood Take to Submerge in Fresh Water?

You may want to see also

Explore related products

Installation Complexity: Longer pieces are harder to handle and install, requiring more skill and tools

Longer runs of wood, while aesthetically pleasing and structurally sound, introduce significant installation challenges. The sheer size and weight of these pieces demand careful planning and execution. Handling them requires at least two skilled workers to prevent damage or injury, and specialized tools like panel carriers or vacuum lifters become essential for safe maneuvering. Precise measurements and cutting are critical, as errors in longer pieces are more noticeable and costly to correct. This complexity underscores the need for experienced installers who can manage the logistical and technical demands of working with extended lengths.

Consider the installation process step-by-step to fully grasp the difficulty. First, transportation to the site becomes a hurdle, as longer pieces may not fit in standard vehicles and require specialized delivery. On-site, positioning these planks or panels often involves navigating tight spaces, such as doorways or staircases, where their length becomes a liability. Securing them in place demands additional clamps, braces, or adhesives to ensure stability during installation. Each step highlights the increased labor intensity and potential for errors, making it clear why longer runs are not for the novice installer.

From a persuasive standpoint, the added complexity of installing longer wood runs should give pause to anyone prioritizing ease of installation. While the seamless look of extended planks may be tempting, the practical challenges cannot be overlooked. For DIY enthusiasts, the learning curve is steep, and the risk of costly mistakes is high. Even professionals may charge a premium for handling these materials, as the job requires more time, manpower, and specialized equipment. Weighing the visual benefits against the logistical hurdles is crucial before committing to longer runs.

A comparative analysis reveals that shorter wood pieces, though less striking in appearance, offer significant installation advantages. They are lighter, easier to transport, and more forgiving in terms of measurement errors. For instance, a 12-foot plank requires twice the effort to handle and position compared to a 6-foot piece, yet both achieve similar structural integrity when installed correctly. Shorter runs also allow for more flexibility in design adjustments mid-project, reducing stress and potential rework. This trade-off between aesthetics and practicality is a key consideration for any wood installation project.

In conclusion, the installation complexity of longer wood runs is a critical factor that cannot be ignored. While the end result may be visually stunning, the process demands a higher level of skill, more specialized tools, and careful planning. For those willing to invest the time and resources, longer runs can be a worthwhile choice. However, for projects where efficiency and simplicity are priorities, shorter pieces offer a more manageable alternative without sacrificing quality. Understanding these challenges ensures a more informed decision and a smoother installation experience.

Mayo on Wood: Optimal Time for Effective Treatment and Results

You may want to see also

Explore related products

Material Waste: Longer runs minimize offcuts, reducing waste, but mistakes are costlier to fix

Longer runs of wood inherently reduce material waste by minimizing the number of cuts required. Each cut generates offcuts, and in projects with shorter runs, these remnants often become too small for practical reuse. For instance, in cabinetry, a single 8-foot board used in two 4-foot runs produces two usable pieces but leaves no significant waste. Contrast this with four 2-foot runs, which create three offcuts, two of which are likely too short for future projects. This inefficiency compounds with scale: a 100-board project with 4-foot runs might yield 50% usable offcuts, while 2-foot runs could reduce that to 25%. The math is clear: longer runs optimize material utilization by reducing the frequency of cuts and maximizing the size of offcuts.

However, the trade-off lies in the cost of mistakes. A single error in a longer run can render a larger portion of the material unusable. For example, a miscalculation on a 16-foot run of hardwood could waste $50–$100 worth of material, whereas a mistake on a 4-foot run might only cost $15–$25. This risk escalates with precision-dependent projects, such as joinery or intricate furniture, where a misaligned cut can cascade into multiple unusable sections. To mitigate this, professionals often implement double-checking protocols: measure twice, mark clearly, and use sacrificial test cuts on scrap wood before committing to the final material.

Despite the risk, longer runs align with sustainability goals by reducing overall waste. A study in the *Journal of Wood Science* found that projects using runs longer than 6 feet reduced waste by 30–40% compared to those with runs under 3 feet. This efficiency extends beyond raw material savings to include reduced labor and energy for processing smaller pieces. For DIYers or small shops, this translates to lower project costs and less storage space needed for unusable scraps. A practical tip: plan projects to use full sheet sizes (e.g., 4x8 plywood) in as few cuts as possible, prioritizing designs that allow for continuous runs.

Yet, the decision isn’t one-size-fits-all. Shorter runs may be preferable when precision is paramount and the cost of error outweighs waste savings. For example, in high-end millwork, where tolerances are tight and materials expensive, breaking a long run into shorter segments allows for more control and easier correction of mistakes. Conversely, in structural framing or large-scale paneling, where tolerances are looser and material costs dominate, longer runs are almost always the better choice. The key is to balance waste reduction with the project’s specific demands and the skill level of the craftsman.

Ultimately, the choice between longer and shorter runs requires a pragmatic assessment of priorities. For those focused on sustainability and cost-efficiency, longer runs offer a clear advantage in minimizing waste. However, this strategy demands meticulous planning and execution to avoid costly errors. A hybrid approach—using longer runs for straight, repetitive elements and shorter runs for complex, high-risk sections—can often strike the best balance. Tools like digital cutting diagrams or software (e.g., CutList Plus) can aid in optimizing layouts to maximize material use while minimizing risk. In the end, the goal is not just to reduce waste but to do so without compromising the integrity or budget of the project.

Mastering Wood Bending: Optimal Steaming Times for Perfect Curves

You may want to see also

Frequently asked questions

Longer runs of wood can create a more seamless and visually appealing look, reducing the number of end joints and enhancing the flow of the space. However, it depends on the room size and layout.

Longer runs of wood can provide better structural stability in some cases, as there are fewer end joints that could weaken over time. However, proper installation and acclimation are equally important.

Longer runs of wood can be more expensive due to the higher cost of longer planks and potential waste during installation. However, they may save on labor costs by reducing the number of cuts and joints.

Longer runs of wood are ideal for larger, open spaces but may not be practical in smaller rooms or areas with many obstacles. Always measure and plan carefully to ensure compatibility with your space.

![Rest & Recover Sleep Tea by Long Run Co. – Caffeine‑Free Herbal Tea with Melatonin (25 Tea Bags) – All Natural, Better Sleep & Recovery, Wake Up Refreshed [6mg Melatonin, Peach Cobbler]](https://m.media-amazon.com/images/I/71IprUUOmAL._AC_UY218_.jpg)