When it comes to cutting hard wood, the longevity of a chainsaw chain's sharpness is a critical factor for efficiency and safety. Different chainsaw chains are designed with varying materials, cutting angles, and tooth configurations, which significantly impact their performance and durability. Chains with carbide-tipped cutters, for example, tend to stay sharper longer on hard wood due to their hardness and resistance to wear, though they are more expensive. Alternatively, full chisel chains offer faster cutting speeds but may dull quicker, while semi-chisel chains provide a balance between speed and longevity. Additionally, factors like chain maintenance, proper filing, and using the right bar and chain oil play a vital role in preserving sharpness. Understanding these nuances helps users select the best chain for their specific needs, ensuring smoother cuts and reduced downtime.

| Characteristics | Values |

|---|---|

| Chain Type | Full chisel chains (e.g., Oregon PowerCut, Stihl Rapid Duro) |

| Material | Carbide-tipped or chrome-plated steel for enhanced hardness |

| Tooth Design | Square-corner chisel teeth for aggressive cutting and longer sharpness |

| Gauge (Thickness) | Thicker gauges (e.g., .050", .058") for durability on hardwood |

| Pitch | Common pitches: 3/8" or .404" depending on bar size |

| Lubrication Requirement | High-quality bar and chain oil to reduce friction and heat |

| Heat Resistance | Superior heat resistance to prevent dulling from friction |

| Hardwood Performance | Specifically designed for dense woods like oak, maple, and hickory |

| Sharpening Frequency | Less frequent sharpening compared to standard chains |

| Brand Examples | Oregon, Stihl, Husqvarna, Carlton |

| Maintenance | Regular cleaning and proper filing technique to extend sharpness |

| Cost | Higher initial cost due to advanced materials and design |

| Durability | Longer lifespan in demanding hardwood cutting conditions |

| Vibration Reduction | Some models feature vibration-reducing designs for smoother operation |

| Compatibility | Check bar length and pitch compatibility with your chainsaw model |

Explore related products

What You'll Learn

Carbide-tipped chainsaw chains

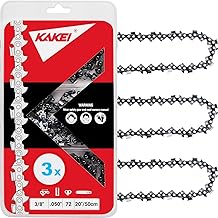

When selecting a carbide-tipped chain, consider the pitch and gauge to ensure compatibility with your chainsaw. Most carbide chains are available in standard pitches (e.g., 3/8-inch or .325-inch) and gauges (e.g., .050-inch or .058-inch). Installation is straightforward, but proper tensioning is critical to prevent premature wear. Use a chain tension gauge to maintain optimal slack, typically around 0.1 to 0.2 inches at the center of the guide bar. Regularly inspect the chain for signs of damage, such as cracked carbide tips, and replace it if necessary to avoid safety risks.

One of the most compelling advantages of carbide-tipped chains is their ability to retain sharpness 10 to 20 times longer than conventional chains when cutting hardwood. This makes them ideal for high-volume cutting tasks or environments with abrasive conditions, such as sandy soil or dirty wood. However, carbide chains are not invincible. They are more brittle than steel cutters and can chip if they encounter rocks or metal. Always clear the cutting area of debris and use a chainsaw with a chain brake for added safety.

While carbide-tipped chains are more expensive upfront, their extended lifespan often justifies the investment. For instance, a carbide chain priced at $100 may last as long as three to five standard chains, each costing $30 to $40. To maximize their value, store the chain in a dry place and use a protective cover when not in use. Additionally, avoid using carbide chains for pruning or limbing, as these tasks involve frequent contact with dirt and small debris, which can accelerate wear.

In conclusion, carbide-tipped chainsaw chains are a game-changer for cutting hardwood, offering unparalleled sharpness retention and durability. By understanding their strengths, limitations, and maintenance requirements, users can harness their full potential. Whether you’re a professional logger or a weekend warrior, investing in a carbide chain can transform your woodcutting experience, saving time, effort, and money in the long run.

Enhance and Preserve: Secrets to Long-Lasting Wood Furniture Shine

You may want to see also

Explore related products

Semi-chisel vs. full chisel cutters

The choice between semi-chisel and full chisel cutters significantly impacts a chainsaw chain's performance and longevity when cutting hardwood. Semi-chisel chains, with their rounded corners, are more forgiving and stay sharper longer in dirty or abrasive conditions. They’re ideal for occasional users or those working in mixed wood types, as they resist dulling from sand, dirt, or accidental contact with the ground. However, they cut slower than full chisel chains, making them less efficient for professional or high-volume hardwood cutting.

Full chisel chains, on the other hand, are designed for speed and precision in clean, hardwood environments. Their square-cornered cutters bite aggressively into the wood, delivering faster cutting times. Yet, this sharpness comes at a cost: full chisel chains dull quickly when exposed to dirt or grit, and they require frequent sharpening to maintain performance. Professionals often choose these chains for dedicated hardwood tasks, but only when working in controlled conditions where debris is minimal.

To maximize sharpness longevity in hardwood, consider the environment and frequency of use. For weekend warriors or those cutting in less-than-ideal conditions, semi-chisel chains offer a balance of durability and performance. Professionals working exclusively in clean hardwood settings may prefer full chisel chains, paired with meticulous maintenance practices. Sharpening intervals for full chisel chains should be more frequent—every 1-2 hours of cutting—while semi-chisel chains can often go 3-4 hours before needing attention.

A practical tip for extending chain life is to pre-clean the cutting area, removing dirt and debris whenever possible. For full chisel chains, investing in a high-quality file and guide ensures precise sharpening, preserving the square corners essential for their performance. Semi-chisel chains are more forgiving during sharpening, making them a better choice for those less experienced with chain maintenance. Ultimately, the decision hinges on balancing cutting speed with maintenance demands and environmental factors.

When Will Wood Prices Drop? A Lumber Market Forecast

You may want to see also

Explore related products

$29.99 $39.99

Chain material and hardness levels

The material and hardness of a chainsaw chain are critical factors in determining how long it stays sharp when cutting hardwood. Chains are typically made from carbon steel or a blend of steel alloys, with carbide-tipped chains being a premium option. Carbon steel chains, while affordable, tend to dull faster under the stress of hardwood. Alloy steel chains, often containing chromium and nickel, offer improved hardness and wear resistance, making them a better choice for demanding tasks. Carbide-tipped chains, though more expensive, are the most durable, as the carbide tips retain their edge significantly longer than steel, even when cutting dense woods like oak or hickory.

Hardness levels in chainsaw chains are measured using the Rockwell scale, typically ranging from 50 to 62 HRC (Hardness Rockwell C). A higher HRC value indicates a harder chain, which is more resistant to wear but also more brittle. For hardwood cutting, a chain with a hardness of 58-60 HRC strikes a balance between durability and flexibility, reducing the risk of chipping or breaking under pressure. Chains with lower hardness levels (50-55 HRC) are better suited for softer woods, as they are more forgiving but wear out faster on hardwood.

Selecting the right chain material and hardness level requires considering the type of wood you’ll cut most frequently. For occasional hardwood use, a mid-range alloy steel chain (58 HRC) is practical and cost-effective. Professional loggers or those cutting hardwood daily should invest in carbide-tipped chains, despite their higher cost, as they minimize downtime for sharpening. Always match the chain’s hardness to the wood’s density to maximize both performance and longevity.

Proper maintenance can extend the life of any chain, regardless of material or hardness. Regularly sharpen the chain with a file or electric sharpener, ensuring the correct filing angle and depth gauge setting. Clean debris from the chain after each use to prevent premature wear. For carbide-tipped chains, professional sharpening is recommended, as the carbide material requires specialized tools. By combining the right chain material, hardness level, and maintenance practices, you can significantly reduce the frequency of replacements and maintain optimal cutting efficiency.

Understanding Woodworm Lifespan: How Long Do These Pests Survive?

You may want to see also

Explore related products

Optimal chain gauge and pitch

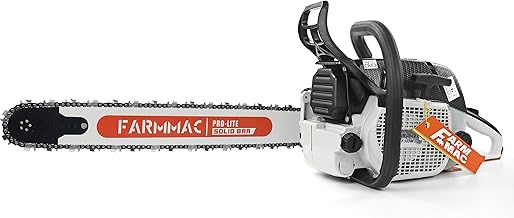

The gauge and pitch of a chainsaw chain are critical determinants of its longevity and performance when cutting hardwood. Gauge refers to the thickness of the drive links, which fit into the guide bar groove. A thinner gauge reduces friction, allowing the chain to cut more efficiently and stay sharper longer. For hardwood, a gauge between 0.050" and 0.058" is ideal, striking a balance between durability and reduced drag. Pitch, the distance between any three rivets divided by two, dictates the size of the chain’s teeth and how aggressively it cuts. A smaller pitch, such as 3/8" low-profile, is recommended for hardwood because it minimizes the effort required to sever dense fibers, reducing wear on the cutting edges.

Selecting the right combination of gauge and pitch involves understanding the wood’s density and your chainsaw’s power. Hardwoods like oak or hickory demand a chain that can maintain sharpness under high stress. A 3/8" low-profile chain with a 0.050" gauge is a popular choice for professional loggers, as it delivers precision without overloading the saw. Conversely, a larger pitch or thicker gauge may cause the chain to dull quickly due to excessive friction and heat buildup. Always consult your chainsaw’s manual to ensure compatibility, as mismatched gauge or pitch can damage the guide bar or reduce cutting efficiency.

To maximize sharpness retention, consider the chain’s design alongside gauge and pitch. Full chisel chains, with square-cornered teeth, cut faster but dull quicker on hardwood. Semi-chisel chains, with rounded teeth, offer better durability but slightly slower cutting speeds. For hardwood, a semi-chisel chain with a 3/8" low-profile pitch and 0.050" gauge provides the best compromise, staying sharper longer while maintaining acceptable cutting performance. Regularly inspect the chain for signs of wear, such as rounded cutters or burrs, and sharpen it promptly to preserve edge integrity.

Practical maintenance tips can further extend chain life. Use a file gauge to ensure consistent sharpening angles, typically 30 degrees for most chains. Clean the guide bar and chain after each use to prevent debris buildup, which accelerates wear. Lubricate the chain adequately to reduce friction and heat, especially when cutting hardwood. Finally, avoid forcing the saw through cuts, as excessive pressure increases the risk of dulling the chain prematurely. By optimizing gauge, pitch, and maintenance practices, you can significantly enhance the longevity of your chainsaw chain on hardwood.

Composite Wood Off-Gassing Timeline: What to Expect and How Long It Lasts

You may want to see also

Explore related products

Impact of lubrication on sharpness retention

Proper lubrication is critical for maximizing the sharpness retention of a chainsaw chain, especially when cutting hard wood. Friction, the arch-nemesis of sharpness, skyrockets when oil isn't effectively delivered to the cutting edges. Every stroke without adequate lubrication accelerates wear, dulling the chain faster than a novice woodworker's enthusiasm.

Think of it like this: imagine sanding a piece of metal without any lubricant. The heat generated would quickly degrade the abrasive surface. The same principle applies to your chainsaw chain.

The type of oil used matters. Bar and chain oil, specifically formulated for chainsaws, is your best bet. Its viscosity and additives are designed to cling to the chain even under the high-speed, high-pressure conditions of cutting. Motor oil, while tempting due to its availability, lacks these crucial properties and will lead to premature dulling. Aim for a flow rate of 2-3 ounces per hour for optimal lubrication. This may seem excessive, but remember, you're battling the relentless friction of hard wood.

Adjusting the oil pump settings on your chainsaw is crucial. Too little oil and your chain suffers, too much and you risk a messy, inefficient cut. Most chainsaws have adjustable oil pumps, allowing you to fine-tune the flow based on the wood hardness and cutting conditions.

Don't underestimate the importance of a clean oil system. Sawdust and debris can clog the oil passages, starving your chain of its lifeblood. Regularly clean the oil tank, bar grooves, and oil holes to ensure uninterrupted flow. A simple cleaning routine can significantly extend the life of your chain and save you from frequent sharpening sessions.

Finally, consider the environmental impact. While oil is essential, overuse can harm the environment. Opt for biodegradable bar and chain oil whenever possible. This small change can make a big difference, especially for those working in ecologically sensitive areas. Remember, responsible lubrication practices benefit both your chainsaw and the world around you.

Perfect Wood Staining: Optimal Keda Dye Application Time Revealed

You may want to see also

Frequently asked questions

A chainsaw chain with carbide-tipped cutters stays sharper longer on hard wood due to the extreme hardness and wear resistance of carbide.

Yes, a thicker gauge chain (e.g., .063") is more durable and resists wear better on hard wood compared to thinner gauge chains, which can dull faster.

Full chisel chains cut faster but dull quicker on hard wood. Semi-chisel or low-profile chains are better for maintaining sharpness longer in such conditions.

Chains made from high-quality steel, such as those with chrome or nickel alloys, retain their sharpness longer on hard wood compared to standard carbon steel chains.