The question of whether old Volkswagen engines had wooden parts is a fascinating one that delves into the early history of automotive engineering. During the 1930s and 1940s, when Volkswagen was developing its iconic Beetle, materials like steel and aluminum were in short supply, particularly in war-torn Germany. As a result, engineers had to get creative with alternative materials. While it is a common myth that Volkswagen engines contained wooden parts, the reality is that wooden components were not used in the engine itself. However, wooden parts were indeed utilized in other areas of the vehicle, such as the dashboard, steering wheel, and even some structural elements, due to their availability and lightweight nature. This ingenuity highlights the resourcefulness of early automotive designers in overcoming material shortages.

| Characteristics | Values |

|---|---|

| Wooden Parts in Old Volkswagen Engines | Early Volkswagen engines, particularly the Type 1 (Beetle) engines produced in the 1930s and 1940s, did indeed incorporate wooden parts. |

| Specific Components | The most notable wooden part was the distributor rotor, which was made of a phenolic resin-impregnated wood (often referred to as "Bakelite" or a similar material). This material was chosen for its electrical insulating properties and durability. |

| Purpose of Wooden Parts | The wooden distributor rotor helped prevent electrical arcing and ensured reliable ignition timing. It was also used in some valve spring retainers and insulators in early models. |

| Material Transition | By the 1950s and 1960s, Volkswagen transitioned to more modern materials like plastic and metal for these components due to advancements in manufacturing and material science. |

| Historical Context | The use of wood was common in early automotive engineering due to its availability, cost-effectiveness, and suitability for certain applications. |

| Modern Relevance | Today, wooden parts are no longer used in Volkswagen engines or any modern vehicles, as synthetic materials offer superior performance and longevity. |

| Collector's Interest | Original wooden parts from early Volkswagen engines are highly sought after by collectors and restorers of vintage Volkswagens. |

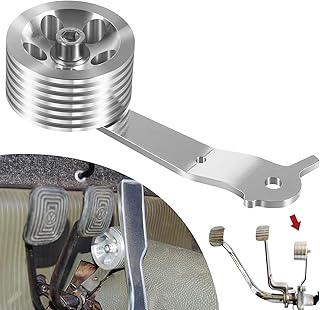

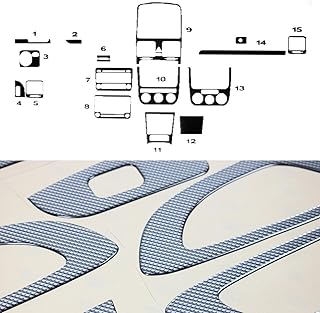

Explore related products

What You'll Learn

Wooden Distributor Blocks in Early VW Engines

Early Volkswagen engines, particularly those from the 1930s to the 1950s, incorporated wooden distributor blocks as a practical solution to the material constraints of the era. These blocks, typically made from phenolic-impregnated wood, were used to insulate the distributor’s electrical components from the metal housing. The wood’s natural insulating properties prevented electrical shorts and ensured reliable spark distribution to the engine’s cylinders. This design choice was both innovative and cost-effective, reflecting the resourcefulness of Volkswagen’s engineers during a time when advanced synthetic materials were scarce or expensive.

The manufacturing process for these wooden distributor blocks was precise and deliberate. Phenolic resin, a thermosetting plastic, was infused into hardwoods like beech or birch to create a composite material that combined the wood’s insulating properties with the resin’s durability. This treated wood was then machined to exact specifications, ensuring a snug fit within the distributor assembly. Mechanics and enthusiasts today often marvel at the longevity of these components, as many original wooden blocks remain functional in restored vehicles, a testament to their robust design.

Despite their effectiveness, wooden distributor blocks were not without limitations. Exposure to heat, moisture, and engine vibrations could cause the wood to crack or warp over time, leading to misfires or electrical failures. Modern restorations often involve replacing these blocks with synthetic alternatives, such as Bakelite or modern plastics, which offer superior durability and resistance to environmental factors. However, purists argue that retaining the original wooden components preserves the authenticity and historical accuracy of the vehicle.

For those maintaining or restoring early VW engines, inspecting the wooden distributor block is a critical step. Look for signs of cracking, discoloration, or brittleness, which indicate deterioration. If replacement is necessary, sourcing a phenolic-impregnated block from a reputable supplier ensures compatibility and performance. Alternatively, 3D-printed or CNC-machined replicas made from modern insulating materials can provide a balance between authenticity and reliability. Regular maintenance, such as cleaning contacts and ensuring proper lubrication, can extend the life of the distributor assembly, whether original or upgraded.

In conclusion, the wooden distributor blocks in early VW engines are a fascinating example of engineering ingenuity under material constraints. While they may require careful maintenance or replacement in modern restorations, their historical significance and functional design continue to captivate enthusiasts. Understanding their role and limitations allows owners to make informed decisions, preserving the legacy of these iconic vehicles while ensuring their reliability on the road.

Natalie Wood's Age in Miracle on 34th Street: A Surprising Fact

You may want to see also

Explore related products

Plywood Fan Blades in Air-Cooled Models

Early Volkswagen air-cooled engines, particularly those in the iconic Beetle and Type 2 models, featured plywood fan blades as a standard component. These blades, typically constructed from multiple layers of thin wood veneers bonded together, were designed to draw air through the engine’s cooling system efficiently. The choice of plywood was no accident; its lightweight nature reduced rotational inertia, allowing the fan to spin freely without overloading the crankshaft. This design decision aligned with Volkswagen’s engineering philosophy of simplicity, durability, and cost-effectiveness, ensuring the engine remained cool under prolonged operation.

The manufacturing process for these plywood fan blades was precise. Layers of wood were glued and pressed under high pressure to create a rigid, balanced component. The blades were then cut to exact specifications, ensuring they fit seamlessly into the fan housing. This attention to detail was critical, as even minor imbalances could lead to vibrations that might damage the engine. Volkswagen’s use of plywood also leveraged the material’s natural ability to absorb minor impacts, reducing the risk of cracking or shattering under stress—a common issue with metal blades.

Despite their effectiveness, plywood fan blades required regular maintenance. Over time, exposure to heat, oil, and moisture could cause the wood to warp or delaminate. Owners were advised to inspect the blades periodically, particularly after 50,000 miles or if unusual engine noises occurred. Replacement was straightforward, with aftermarket options available in both plywood and modern materials like fiberglass or plastic. However, purists often opted for original plywood designs to maintain authenticity and preserve the engine’s vintage character.

Comparatively, modern air-cooled engines rarely use wooden components, favoring synthetic materials for their consistency and longevity. Yet, the plywood fan blades in Volkswagen’s air-cooled models remain a testament to innovative engineering. They demonstrate how natural materials can be effectively integrated into mechanical systems when chosen and treated thoughtfully. For enthusiasts restoring classic Volkswagens, understanding the role and care of these blades is essential to preserving both performance and historical accuracy.

In practice, replacing a plywood fan blade involves removing the fan housing, extracting the old blade, and installing the new one while ensuring proper alignment. Balancing the fan assembly is crucial; even a slight misalignment can cause excessive wear on engine bearings. For those sourcing replacement blades, verifying compatibility with the specific engine model is vital, as designs varied slightly across years and models. While plywood blades may seem anachronistic today, their use in Volkswagen’s air-cooled engines highlights a unique intersection of material science and automotive history.

Are Old Wooden Utensils Sanitary? Debunking Myths and Best Practices

You may want to see also

Explore related products

$20

Wooden Carburetor Components in Beetle Engines

The Volkswagen Beetle, an icon of automotive history, is renowned for its simplicity and durability. Among its many unique features, one stands out: the use of wooden components in its carburetor. This seemingly unconventional choice was not a design oversight but a deliberate engineering decision rooted in practicality and resourcefulness. Wooden parts, specifically in the carburetor’s float, were used to regulate fuel levels efficiently. The wood’s natural buoyancy and resistance to fuel absorption made it an ideal material, ensuring precise fuel metering without the risk of swelling or degradation over time.

To understand the wooden carburetor components, consider the historical context of the Beetle’s production. During the mid-20th century, materials like plastic were not yet widely available or reliable for automotive applications. Wood, however, was abundant, inexpensive, and easily machinable. Volkswagen engineers selected specific types of wood, such as beech or maple, for their density and stability. These woods were carefully treated to withstand exposure to gasoline, ensuring longevity and functionality. For enthusiasts restoring a classic Beetle, sourcing or recreating these wooden parts requires attention to detail—modern replacements often use synthetic materials, but purists insist on authenticity.

From a practical standpoint, maintaining or replacing wooden carburetor components in a Beetle engine involves specific steps. First, inspect the float for cracks, warping, or fuel saturation. If damaged, replace it with a correctly sized wooden or synthetic alternative. Second, ensure the carburetor is clean and free of debris, as contaminants can disrupt fuel flow. Third, calibrate the float level according to the manufacturer’s specifications, typically around 27–29 mm from the top of the carburetor body. Improper calibration can lead to flooding or lean running, so precision is key.

Comparatively, wooden carburetor components highlight the ingenuity of early automotive engineering. While modern carburetors rely on plastics and metals, the Beetle’s wooden parts demonstrate how resource constraints can drive innovative solutions. This approach not only reduced costs but also leveraged natural materials in ways that synthetic alternatives struggled to match at the time. Today, these wooden components serve as a reminder of the Beetle’s enduring legacy—a car designed to be simple, reliable, and accessible, even in its smallest details.

For those restoring or maintaining a Beetle, preserving its wooden carburetor components is both a technical challenge and a nod to its heritage. While synthetic replacements offer convenience, they lack the historical authenticity of wood. Enthusiasts often turn to specialized suppliers or craft their own parts using period-correct materials and techniques. By doing so, they not only ensure the engine’s functionality but also honor the Beetle’s unique design philosophy. In a world of increasingly complex vehicles, the wooden carburetor components of the Beetle remain a testament to the power of simplicity and ingenuity.

Are Old Wood Pallets Safe for Reuse? A Comprehensive Guide

You may want to see also

Explore related products

Phenolic Resin Parts vs. Actual Wood

A common misconception about early Volkswagen engines is that they incorporated actual wooden parts. In reality, what many mistake for wood is phenolic resin, a composite material that mimics wood’s appearance but offers superior durability and heat resistance. Phenolic resin parts, such as valve spring seats and distributor caps, were engineered to withstand the harsh conditions within an engine bay, combining the lightweight properties of wood with the resilience of synthetic materials. This innovation allowed Volkswagen to achieve optimal performance without relying on organic materials prone to degradation.

Phenolic resin parts are created through a process that involves impregnating layers of paper or fabric with phenolic resin, then curing them under heat and pressure. This results in a hard, dense material that resists warping, cracking, and thermal expansion—critical traits for components operating in high-temperature environments. Actual wood, by contrast, would expand, contract, and eventually fail under such conditions, making it unsuitable for engine applications. Volkswagen’s choice of phenolic resin over wood was a pragmatic decision rooted in material science, not a nostalgic nod to traditional craftsmanship.

To distinguish between phenolic resin and wood, examine the part’s surface: phenolic resin often has a laminated, layered appearance, while wood shows distinct grain patterns. Additionally, phenolic resin is non-porous and does not absorb moisture, unlike wood, which can swell or rot when exposed to fluids. For restoration projects, it’s crucial to replace phenolic resin parts with like materials rather than wood substitutes, as the latter will compromise performance and longevity. Authentic phenolic resin components can often be sourced from specialty suppliers catering to vintage Volkswagen enthusiasts.

While the resemblance to wood may spark curiosity, phenolic resin parts are a testament to early automotive engineering’s ingenuity. They bridged the gap between natural and synthetic materials, offering a lightweight, cost-effective solution for critical engine components. Today, these parts remain a fascinating example of how material science shaped the reliability of iconic vehicles like the Volkswagen Beetle. Understanding their composition not only dispels myths but also ensures accurate preservation of these automotive classics.

Unveiling Leonard Wood's Age: A Historical Figure's Lifespan Explored

You may want to see also

Explore related products

Historical Use of Wood in VW Engine Design

Wooden parts in early Volkswagen engines are not a myth but a fascinating chapter in automotive history. During World War II, metal shortages forced engineers to innovate with alternative materials. Volkswagen, under the direction of Ferdinand Porsche, turned to wood for certain engine components. Piston rings, for instance, were crafted from a dense, heat-resistant wood composite. This adaptation was a practical solution to resource constraints, showcasing the ingenuity of wartime engineering. While these wooden parts were functional, they were not without limitations, such as reduced durability compared to metal counterparts.

The use of wood in VW engines extended beyond pistons to other critical components. Fan blades in the cooling system, for example, were often made from lightweight, durable wood like beech or birch. These materials were chosen for their ability to withstand high temperatures and rotational forces. However, maintaining wooden parts required meticulous care. Owners had to regularly inspect for cracks or warping and apply protective coatings to prevent moisture absorption. Despite these challenges, wooden components played a vital role in keeping vehicles operational during a time of severe material scarcity.

Comparing wooden parts to their modern metal equivalents highlights the evolution of automotive technology. While wood offered a temporary solution, it lacked the longevity and precision of metal alloys. Modern engines rely on materials like aluminum and steel, which provide superior strength and heat resistance. However, the historical use of wood in VW engines serves as a reminder of the resourcefulness required in times of crisis. It also underscores the importance of material science in engineering, as advancements in metallurgy and composites have since eliminated the need for such improvisations.

For enthusiasts restoring vintage Volkswagens, understanding the role of wooden parts is crucial. Replacing these components with modern materials is often recommended for safety and reliability. However, preserving original wooden parts can add historical authenticity to a restoration project. When working with wooden engine components, use marine-grade varnish to protect against moisture and heat. Additionally, consult specialized manuals or forums for guidance on sourcing period-correct materials. While wooden parts may no longer be practical for daily driving, they remain a testament to the ingenuity of early automotive design.

Restoring Old Wood Window Frames: A Step-by-Step Repair Guide

You may want to see also

Frequently asked questions

Yes, early Volkswagen engines, particularly the Type 1 (Beetle) engines, used wooden parts in the form of phenolic resin impregnated fiber boards for the cylinder head gaskets and thrust washers.

Volkswagen used wooden parts due to material shortages during World War II and the post-war period. Phenolic resin-impregnated wood was durable, heat-resistant, and an effective substitute for metal in certain applications.

Many of the original wooden parts, such as the cylinder head gaskets, have been replaced with modern materials like metal or composite gaskets. However, some restored engines may still use wooden parts for historical accuracy.

While the wooden parts were designed to be durable, they can degrade over time due to heat, oil, and age. This can lead to leaks, reduced engine performance, or even failure if not properly maintained or replaced.

No, modern Volkswagen engines do not use wooden parts. Advances in materials and manufacturing have led to the use of more reliable and efficient components like metal, rubber, and synthetic materials.

![Matchbox Volkswagen GTI, [Black] 79/100](https://m.media-amazon.com/images/I/81IISf5LLeL._AC_UL320_.jpg)

![Matchbox 2019 Volkswagens Beetle Convertible, [White] 27/100](https://m.media-amazon.com/images/I/71-78RAJXNL._AC_UL320_.jpg)