The question of whether old wooden ships leaked is a fascinating one that delves into the maritime history and craftsmanship of bygone eras. Constructed primarily from timber, these vessels were held together with wooden pegs, iron nails, and sealed with various materials like pitch or tar to prevent water ingress. Despite these measures, wooden ships were not entirely watertight; they naturally absorbed moisture, and their planks could swell or shrink with changes in humidity, leading to small gaps. However, this did not necessarily mean they were constantly leaking. Skilled shipwrights and regular maintenance ensured that leaks were minimal and manageable, allowing these ships to traverse vast oceans and endure long voyages. Thus, while old wooden ships did experience some leakage, it was often an expected and manageable aspect of their design rather than a critical flaw.

| Characteristics | Values |

|---|---|

| Leakage Occurrence | Yes, old wooden ships did leak due to the natural properties of wood and the limitations of construction techniques. |

| Causes of Leaks | - Wood expansion and contraction due to moisture changes. - Seam separation between wooden planks. - Wear and tear from wave action and marine organisms. - Insufficient caulking or deterioration of sealing materials. |

| Leak Management | - Regular caulking and sealing with materials like oakum and pitch. - Use of pumps to remove water. - Frequent inspections and repairs during voyages. |

| Impact on Voyages | Leaks were common and expected; ships often carried extra supplies and crew to manage them. |

| Modern Understanding | Archaeological studies and historical records confirm that leakage was a normal part of wooden ship operation. |

| Construction Techniques | Early ships relied on overlapping planks (clinker-built) or carvel construction, both prone to leaks over time. |

| Historical Context | Leakage was accepted as a trade-off for the flexibility and repairability of wooden ships. |

Explore related products

What You'll Learn

Causes of leaks in wooden ships

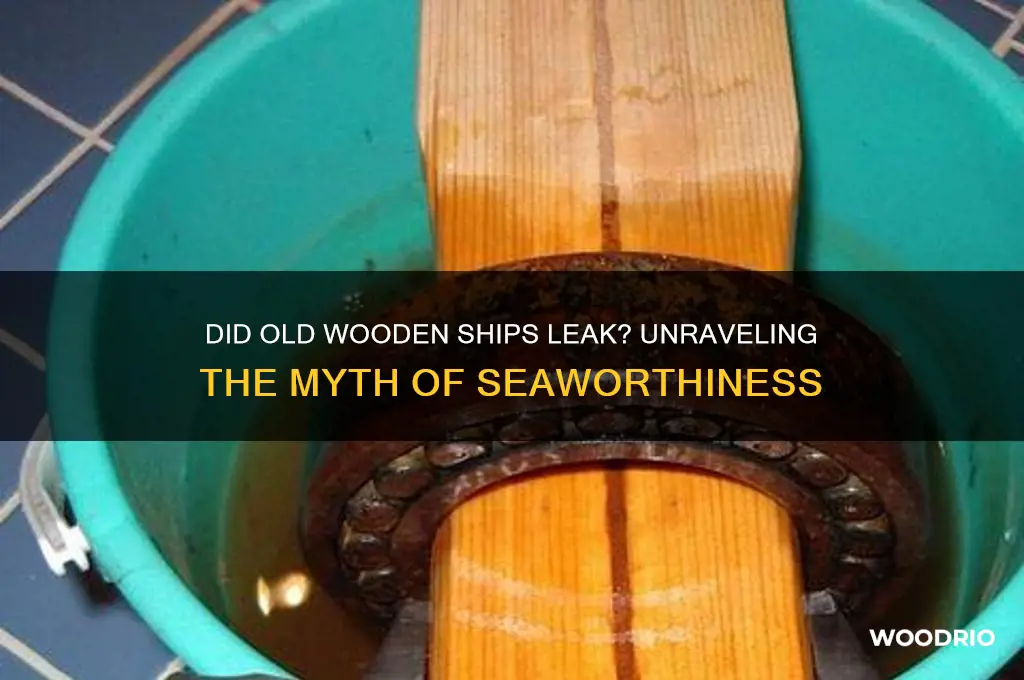

Wooden ships, despite their majestic appearance and historical significance, were inherently prone to leaks due to the natural properties of wood and the challenges of early shipbuilding techniques. Unlike modern materials, wood expands and contracts with changes in temperature and humidity, creating gaps between planks over time. This movement, combined with the constant stress of waves and cargo weight, led to the gradual separation of seams, allowing water to seep in. Even with meticulous caulking—a process of sealing gaps with fibrous materials like oakum and pitch—these ships were never entirely watertight. The very nature of wood ensured that leaks were a persistent issue, requiring constant maintenance and vigilance from crews.

One of the primary causes of leaks in wooden ships was the aging and deterioration of the hull. Wood, being organic, is susceptible to rot, particularly in areas exposed to constant moisture. Shipworms, a type of marine borer, further exacerbated this problem by tunneling through the wood, weakening the structure and creating pathways for water infiltration. Additionally, the repeated impact of waves and grounding on shallow waters caused physical damage to the hull, cracking planks and dislodging caulking. Ships that spent extended periods at sea or in tropical climates were especially vulnerable, as these conditions accelerated wood decay and increased the likelihood of leaks.

Another significant factor was the limitations of early shipbuilding technology. Before the advent of precision tools and standardized designs, shipbuilders relied on hand-cut planks and eyeballed measurements, leading to inconsistencies in hull construction. Even with skilled craftsmanship, the lack of uniformity meant that some seams were tighter than others, leaving potential weak points for leaks. Furthermore, the use of iron fasteners, such as nails and bolts, introduced another vulnerability. Over time, these fasteners corroded, causing the wood around them to weaken and allowing water to penetrate the hull. This corrosion was particularly problematic in saltwater environments, where the rate of degradation was significantly higher.

To mitigate leaks, shipbuilders employed various techniques, but each had its limitations. Caulking, while effective in the short term, required regular reapplication as the materials degraded. Copper sheathing, introduced in the 18th century to protect against shipworms, reduced but did not eliminate leaks, as it could become dislodged or damaged. Crews also relied on pumps to remove water that did enter the ship, but this was a reactive measure rather than a preventive one. The reality was that leaks were an accepted part of sailing in wooden ships, and managing them was as much a part of seamanship as navigation.

In conclusion, the causes of leaks in wooden ships were multifaceted, stemming from the inherent properties of wood, environmental factors, and technological limitations of the time. While shipbuilders and crews developed strategies to minimize water infiltration, the very nature of these vessels ensured that leaks were an ongoing challenge. Understanding these causes not only sheds light on the ingenuity of early maritime engineering but also highlights the resilience of those who sailed and maintained these ships. For enthusiasts and historians alike, this knowledge deepens appreciation for the craftsmanship and hardships of wooden shipbuilding.

Revitalize Aged Wood: Simple Techniques to Restore Its Natural Beauty

You may want to see also

Explore related products

$115.75 $125

Methods for sealing wooden hulls

Wooden ships, despite their romantic allure, were inherently prone to leakage due to the natural properties of wood. To combat this, shipbuilders developed ingenious methods for sealing hulls, ensuring seaworthiness and longevity. One of the earliest and most widespread techniques involved caulking, a labor-intensive process that required skilled craftsmen. Caulking involved driving fibrous materials, such as oakum (tarred hemp or flax fibers), into the seams between wooden planks. These fibers were then sealed with a mixture of pine tar and pitch, creating a flexible yet watertight barrier. The effectiveness of caulking depended on the quality of materials and the precision of application, as improperly sealed seams could still allow water to seep through.

Another method, often used in conjunction with caulking, was the application of tarred felt or canvas to the exterior of the hull. This technique, known as sheathing, provided an additional layer of protection against water intrusion. The felt or canvas was saturated with hot tar and carefully applied to the hull, smoothing out any wrinkles or air pockets. While this method was less common than caulking, it was particularly effective in reducing leakage caused by worm infestations, as the tar acted as a deterrent to marine borers. However, sheathing required regular maintenance, as the tar could crack or wear away over time, exposing the hull to potential damage.

For ships operating in colder climates, icing posed a unique challenge to hull integrity. To address this, shipbuilders sometimes employed a technique called double planking, where an inner layer of thinner planks was fitted beneath the outer hull. This created an insulating air gap that reduced the risk of ice forming directly on the outer planks, which could cause splitting or warping. The inner layer was often sealed with pitch or resin, further enhancing its water resistance. While double planking added weight and complexity to construction, it proved invaluable for vessels navigating icy waters, where leakage could be catastrophic.

Modern enthusiasts and restorers of wooden ships often turn to epoxy resins as a contemporary solution for sealing hulls. Unlike traditional methods, epoxy forms a rigid, durable bond that can fill even the smallest gaps and cracks. To apply epoxy, the hull must first be thoroughly cleaned and dried. A thin layer of epoxy is then brushed or rolled onto the surface, followed by a layer of fiberglass cloth for added strength. After curing, a second coat of epoxy is applied to create a smooth, watertight finish. While epoxy is highly effective, it requires careful preparation and application to avoid air bubbles or uneven coverage, which can compromise its sealing properties.

In conclusion, sealing wooden hulls has evolved from ancient techniques like caulking and sheathing to modern innovations like epoxy resins. Each method has its strengths and limitations, but all share the common goal of preventing leakage and ensuring the ship’s survival at sea. Whether restoring a historic vessel or building a new one, understanding these methods allows craftsmen to choose the most appropriate approach for their needs, blending tradition with technology to preserve the legacy of wooden shipbuilding.

Revive Aged Wood: Expert Tips to Restore Old Wood's Beauty

You may want to see also

Explore related products

Impact of wood aging on leaks

Wooden ships, particularly those constructed before the 19th century, were inherently prone to leaks due to the natural properties of wood. As wood ages, it undergoes physical and chemical changes that affect its structural integrity. One of the primary factors is the gradual loss of moisture, which causes the wood to shrink and crack. These cracks, often microscopic at first, create pathways for water infiltration. For instance, oak, a common shipbuilding material, can shrink by up to 10% in thickness as it dries, leading to gaps between planks. This process is exacerbated in older ships, where decades of exposure to varying humidity and temperature conditions accelerate wood degradation.

To mitigate leaks caused by aging wood, shipwrights historically employed caulking—a process of sealing gaps between planks with fibrous materials like oakum, coated with tar or pitch. However, as wood ages, it becomes less pliable, making it harder for caulking to adhere effectively. Over time, the caulking material itself degrades, losing its water-resistant properties. For example, a study on 18th-century shipwrecks revealed that caulking in older vessels was often brittle and fragmented, offering little resistance to leaks. Modern restoration efforts often involve re-caulking with synthetic materials, but this is a temporary solution, as the underlying aged wood continues to warp and split.

The impact of wood aging on leaks is not uniform across all wooden ships. Factors such as the type of wood, construction techniques, and environmental exposure play significant roles. For instance, ships built with denser woods like teak or cedar tend to age more gracefully, as these woods are naturally more resistant to rot and shrinkage. In contrast, softer woods like pine are more susceptible to rapid degradation, leading to frequent leaks. Additionally, ships that spent most of their lives in saltwater environments experience faster deterioration due to the corrosive effects of salt, which accelerates wood decay and weakens joints.

Practical tips for managing leaks in aging wooden ships include regular inspection and maintenance. Shipowners should monitor for signs of wood shrinkage, such as widening seams or visible cracks, and address them promptly. Applying modern sealants like epoxy resins can provide temporary relief, but it’s crucial to assess the overall condition of the wood first. For older vessels, consider partial plank replacement using new wood, ensuring it matches the original in density and grain. Finally, storing wooden ships in controlled environments, such as dry docks or covered slips, can slow the aging process and reduce the frequency of leaks.

In conclusion, the aging of wood in old ships is a complex process that significantly contributes to leaks. While historical methods like caulking were effective in their time, they are less reliable as wood loses its structural integrity. By understanding the specific vulnerabilities of aged wood and implementing targeted maintenance strategies, it is possible to preserve these maritime treasures and keep them seaworthy for future generations.

Ron Wood's Age: Unveiling the Rolling Stones Guitarist's Timeless Journey

You may want to see also

Explore related products

Role of ship maintenance in leak prevention

Wooden ships, particularly those from centuries past, were marvels of engineering but inherently prone to leaks due to the natural expansion and contraction of wood, the relentless assault of seawater, and the structural stresses of sailing. Regular maintenance was not just a routine task but a critical practice that determined a vessel's seaworthiness and the safety of its crew. Without diligent care, even the most robust wooden hulls would succumb to the elements, turning a sturdy ship into a sieve.

Preventive Measures: The Backbone of Leak Prevention

Effective ship maintenance began with preventive measures designed to mitigate the primary causes of leaks. Caulking, the process of sealing seams between wooden planks with fibrous materials like oakum soaked in tar, was a cornerstone of this practice. Sailors and shipwrights would inspect and re-caulk hulls regularly, often before and after long voyages. For instance, historical records show that ships like the *Mary Rose* required extensive caulking to maintain buoyancy. Additionally, painting the hull with a mixture of tar, pitch, and oil created a protective barrier against water infiltration and marine borers, which could weaken the wood over time.

Routine Inspections: Detecting Issues Before They Escalate

Regular inspections were another vital aspect of maintenance. Sailors would "sound the hull," tapping the wooden planks to detect hollow spots that indicated rot or damage. This method, combined with visual inspections, allowed crews to identify weak points early. For example, the *HMS Victory*, Nelson’s flagship, underwent meticulous inspections to ensure its longevity. Addressing small issues promptly—such as replacing damaged planks or reinforcing stressed areas—prevented minor leaks from becoming catastrophic failures.

The Human Factor: Skill and Discipline in Maintenance

The effectiveness of ship maintenance relied heavily on the skill and discipline of the crew. Shipwrights and sailors needed to understand the unique properties of wood, such as its tendency to swell when wet and shrink when dry. This knowledge informed practices like keeping the hull consistently wet during repairs to avoid warping. Moreover, maintaining a disciplined schedule for upkeep, even during long voyages, was essential. Neglecting maintenance for just a few months could lead to irreversible damage, as evidenced by the sinking of numerous ships during the Age of Exploration due to poor upkeep.

Modern Lessons: Applying Historical Practices Today

While modern ships are constructed from materials like steel and fiberglass, the principles of maintenance derived from wooden shipbuilding remain relevant. Regular inspections, preventive treatments, and addressing issues promptly are universal practices that ensure vessel integrity. For enthusiasts restoring historic wooden ships, adhering to traditional methods—such as using natural fibers for caulking and avoiding modern adhesives that can trap moisture—is crucial. By studying and applying these historical maintenance techniques, we not only preserve maritime heritage but also gain insights into effective leak prevention in any era.

Unveiling the Age of Wood: Techniques and Secrets Behind Its Timelessness

You may want to see also

Explore related products

Historical tools for detecting and repairing leaks

Leak detection and repair were critical skills for sailors aboard old wooden ships, where the constant battle against water intrusion could mean the difference between a successful voyage and disaster. Early mariners relied on simple yet effective tools to identify leaks, often using their senses as the first line of defense. A keen ear could detect the telltale sound of water dripping or gurgling through the hull, while a trained eye might spot the faint line of moisture creeping along wooden seams. One common method involved swinging a lantern or candle near the hull; the flickering flame would react to drafts caused by water seeping through cracks, revealing hidden leaks. This rudimentary approach, though basic, saved countless ships from sinking.

Once a leak was detected, repairing it required ingenuity and resourcefulness. Caulking, a process of sealing seams with a mixture of fibers and tar, was a staple of ship maintenance. Sailors used caulking irons—heated metal tools—to soften and press the material into place, creating a watertight barrier. For larger breaches, wooden plugs or patches were hammered into the hull, often reinforced with canvas or metal. In emergencies, sailors might stuff the hole with oakum (hemp fibers soaked in tar) or even their own clothing to slow the inflow of water. These repairs were temporary fixes, but they bought precious time until the ship could reach port for proper restoration.

The bilge pump, a hand-operated device, was another indispensable tool for managing leaks. Positioned in the lowest part of the ship, it allowed sailors to manually remove water that accumulated in the bilge. Pumping was grueling work, often performed in shifts to keep the ship afloat. The efficiency of the bilge pump was a matter of life and death, and its design evolved over centuries to maximize water displacement. Despite its simplicity, the bilge pump remains one of the most enduring symbols of maritime resilience.

Comparing these historical methods to modern leak detection and repair highlights the ingenuity of early sailors. Today, sonar, thermal imaging, and advanced sealants make the process faster and more precise. Yet, the principles remain the same: detect, contain, and repair. Historical tools like the lantern test and caulking iron demonstrate how sailors adapted to their environment with limited resources, turning everyday items into life-saving instruments. Their legacy reminds us that innovation often thrives under constraint, and that the simplest solutions can be the most effective.

Wooden Wonders: Uncovering the Truth About Vintage Volkswagen Engines

You may want to see also

Frequently asked questions

Yes, old wooden ships naturally leaked to some extent due to the materials and construction methods used.

Sailors used techniques like caulking (sealing seams with oakum and pitch), regular inspections, and manual pumping to manage leaks.

Yes, leaks were a constant concern, as they could lead to water accumulation, instability, and even sinking if not addressed promptly.

Yes, wooden ships became more prone to leaks over time due to wear, rot, and the drying of wooden planks, which caused seams to open.