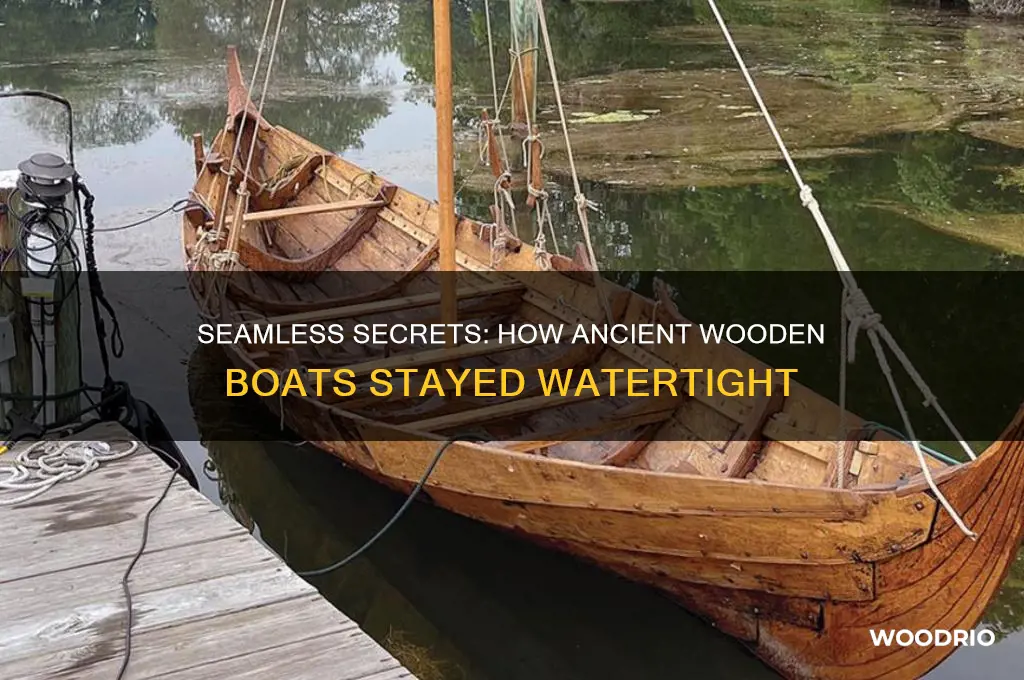

Old wooden boats were ingeniously designed to remain watertight despite being constructed from materials that naturally absorb moisture. Shipbuilders employed several techniques to prevent leaks, including the use of overlapping wooden planks, a method known as clinker or lapstrake construction, which allowed water to run off the hull. Additionally, they utilized waterproof caulking materials, such as oakum (hemp fiber soaked in pine tar), to seal the gaps between planks. The wood itself, often chosen for its natural resistance to decay, was carefully selected and shaped to ensure a tight fit. Over time, the wood would swell when exposed to water, further tightening the joints and reducing the likelihood of leaks. These combined methods, honed over centuries of maritime craftsmanship, ensured that wooden boats remained seaworthy and durable even in challenging conditions.

| Characteristics | Values |

|---|---|

| Hull Construction | Built using overlapping wooden planks (carvel or clinker methods) to create a watertight seal. |

| Caulking Material | Natural fibers like oakum (hemp or flax fibers) were forced into seams between planks. |

| Sealing Compounds | Pitch, tar, or resin applied over caulking to waterproof seams and prevent leaks. |

| Wood Selection | Naturally water-resistant woods like oak, cedar, or teak were used for their durability. |

| Plank Expansion | Wood swells when wet, tightening the seams and reducing leakage over time. |

| Regular Maintenance | Frequent re-caulking and re-sealing were necessary to maintain watertight integrity. |

| Design Features | Curved hull shapes and proper weight distribution reduced stress on seams. |

| Copper Sheathing | Later boats used copper sheets below the waterline to prevent shipworm damage and reduce leaks. |

| Breathability | Wood allowed moisture to pass through, preventing rot and maintaining structural integrity. |

| Skilled Craftsmanship | Expert boatbuilders ensured precise fitting of planks and proper sealing techniques. |

Explore related products

What You'll Learn

- Caulking techniques using fibers and tar to seal plank gaps effectively

- Wood swelling in water naturally closes seams and reduces leaks

- Pegged joints with wooden dowels prevent planks from shifting apart

- Pitch and resin coatings create waterproof barriers on hull surfaces

- Careful craftsmanship ensures tight fits and minimal gaps in construction

Caulking techniques using fibers and tar to seal plank gaps effectively

The art of caulking wooden boats with fibers and tar is a centuries-old practice that ensured seaworthiness long before modern sealants. This traditional method relied on a combination of natural materials and meticulous craftsmanship to create a watertight hull. By packing fibrous materials into the seams between planks and sealing them with hot tar, shipwrights achieved a flexible, durable barrier against leaks.

Materials and Preparation:

Effective caulking begins with selecting the right fibers. Oakum, a loosely twisted hemp or jute fiber, was the standard choice due to its ability to expand when wet, tightening the seal. Modern alternatives include cotton or synthetic fibers, though traditionalists prefer oakum for its historical accuracy. The planks must be dry and clean, with seams slightly opened using a caulking iron to ensure the fibers penetrate deeply. Heat the tar to a workable consistency—typically between 250°F and 300°F—to allow it to flow into the seams without burning the wood or fibers.

Step-by-Step Caulking Process:

- Packing the Seam: Use a marlinespike or similar tool to force oakum into the seam, starting at the bottom of the plank and working upward. The fibers should be compacted tightly but not so much that they distort the plank’s shape.

- Applying Tar: Pour hot tar over the packed seam, ensuring it saturates the fibers completely. A caulking mallet can be used to gently tap the seam, helping the tar penetrate and bond with the fibers.

- Finishing the Seal: Once cooled, the tar forms a hard yet flexible seal. Inspect the seam for gaps or uneven coverage, reheating and reapplying tar as needed. A second layer of fibers and tar may be added for critical areas like the keel or gunwales.

Challenges and Cautions:

Caulking with fibers and tar is labor-intensive and requires precision. Overheating tar can release toxic fumes, so proper ventilation is essential. Applying tar too hot can scorch the wood, while too cool tar won’t flow properly. Fibers must be packed evenly; uneven packing can lead to weak spots that leak under pressure. Regular maintenance is crucial, as tar can crack or wear over time, especially in harsh marine environments.

Historical Context and Modern Relevance:

This technique was the backbone of shipbuilding for millennia, from Viking longships to 19th-century clippers. Its effectiveness lies in the synergy between the swelling fibers and the adhesive properties of tar, creating a seal that moves with the wood as it expands and contracts. Today, while synthetic sealants dominate, traditional caulking remains a valuable skill for restoring historic vessels and preserving maritime heritage. For enthusiasts, mastering this craft offers a tangible connection to the ingenuity of past shipwrights.

Are Vintage Wooden Ironing Boards Valuable Collectibles or Just Clutter?

You may want to see also

Explore related products

Wood swelling in water naturally closes seams and reduces leaks

Wood exposed to water undergoes a fascinating transformation: it swells. This natural process, often seen as a nuisance in furniture or flooring, becomes a critical ally in the construction of old wooden boats. When dry, wooden planks used in boatbuilding have slight gaps between them, necessary for expansion and contraction with moisture changes. However, once immersed in water, the wood fibers absorb moisture and expand, effectively closing these seams. This swelling acts as a self-sealing mechanism, significantly reducing the likelihood of leaks and ensuring the vessel's integrity.

The effectiveness of this natural sealing depends on the type of wood and its grain orientation. Woods with a tight, straight grain, such as oak or cedar, are particularly effective because they swell uniformly, creating a consistent seal. Conversely, woods with irregular grain patterns may swell unevenly, leaving potential weak spots. Builders of old wooden boats carefully selected wood not only for its strength but also for its swelling properties, ensuring that the natural expansion would work in their favor.

To maximize this effect, boatbuilders employed specific techniques. Planks were often soaked in water before assembly to pre-swell the wood, ensuring a tighter fit from the outset. Additionally, the use of caulking materials, such as oakum (hemp fiber) or cotton, in the seams provided an extra layer of protection. When the wood swelled, it compressed these materials, further sealing the gaps. This combination of natural swelling and strategic caulking created a remarkably watertight hull, even without modern adhesives or synthetic sealants.

Modern boat enthusiasts can replicate this ancient wisdom by understanding the swelling properties of different woods and applying traditional techniques. For instance, when restoring a wooden boat, it’s advisable to test the wood’s swelling behavior by submerging a sample in water for 24–48 hours. If the wood swells uniformly, it’s a good candidate for use in the hull. Always ensure the wood is properly seasoned and free of cracks before installation. By harnessing the natural tendency of wood to swell in water, builders—both past and present—can create vessels that are not only functional but also a testament to the ingenuity of traditional craftsmanship.

Are Old Wooden Boxes Valuable? Unlocking Their Hidden Worth

You may want to see also

Explore related products

Pegged joints with wooden dowels prevent planks from shifting apart

Wooden boats of old didn't leak because their builders understood the importance of securing planks against movement. One ingenious method was the use of pegged joints with wooden dowels. This technique, simple yet effective, involved drilling holes through the overlapping edges of planks and inserting wooden dowels, often made from hardwoods like oak or locust, to create a mechanical bond. These dowels, typically ½ to ¾ inch in diameter and slightly longer than the thickness of the planks, were driven through the holes, swelling as they absorbed water and creating a tight, watertight seal.

Imagine a shipwright carefully selecting straight-grained wood for the dowels, ensuring they were free of knots or defects that could compromise their strength. The dowels were then tapered slightly at one end to ease insertion and driven through the pre-drilled holes with a mallet, ensuring a snug fit. This process, repeated along the entire length of the hull, created a network of interlocking joints that resisted the constant stresses of waves and wind, preventing the planks from shifting apart and allowing water to seep in.

The beauty of pegged joints lies in their simplicity and durability. Unlike metal fasteners, which can corrode and weaken over time, wooden dowels, when properly chosen and installed, can last for centuries. The natural swelling of the wood as it absorbs water further tightens the joint, creating a self-sealing mechanism that improves with age. This method was particularly effective in clinker-built boats, where the overlapping planks relied heavily on the strength of these joints to maintain their integrity.

However, the success of pegged joints depends on precise craftsmanship. The holes must be drilled at the correct angle and depth to ensure the dowels align perfectly with the grain of the planks. Improperly installed dowels can split the wood or fail to create a watertight seal. Additionally, the choice of wood for both the planks and the dowels is crucial; hardwoods with high natural oils, like teak or cedar, are less prone to rot and provide better long-term performance.

In practice, maintaining pegged joints requires periodic inspection, especially after prolonged exposure to saltwater. If a dowel becomes loose or damaged, it can be replaced by carefully drilling out the old one and inserting a new, slightly larger dowel. This process, known as "treenailing," ensures the joint remains secure and watertight. By understanding and applying this traditional technique, modern boatbuilders can recreate the durability and elegance of old wooden boats, ensuring they remain seaworthy for generations to come.

Are Vintage Playskool Wooden Puzzles from the 1970s Lead-Safe?

You may want to see also

Explore related products

$18.99 $26.04

Pitch and resin coatings create waterproof barriers on hull surfaces

Wooden boats have sailed the seas for millennia, yet their longevity and seaworthiness often puzzle modern observers. One of the key secrets lies in the application of pitch and resin coatings, which form a protective, waterproof barrier on hull surfaces. These natural substances, derived from pine trees and other conifers, were meticulously applied to seal the wood, preventing water ingress and ensuring the vessel’s integrity. The process was labor-intensive but essential, as it transformed porous wood into a durable, watertight structure capable of withstanding the rigors of maritime travel.

The application of pitch and resin was both an art and a science. Sailors and shipwrights would heat the pitch until it became malleable, then carefully spread it across the hull in thin, even layers. Resin, often harvested from pine sap, was mixed in to enhance flexibility and adhesion. This combination created a barrier that not only repelled water but also resisted cracking under the stress of waves and shifting temperatures. For optimal results, the coating was applied in multiple layers, with each allowed to dry before the next was added. This method ensured a seamless, impenetrable shield that could last for years with proper maintenance.

A practical tip for modern enthusiasts recreating this technique is to monitor the temperature of the pitch closely. Overheating can cause it to become brittle, while insufficient heat prevents proper adhesion. Aim for a temperature range of 120°C to 150°C (248°F to 302°F) when melting pitch. Additionally, applying the mixture with a wide, flat brush or spatula ensures even coverage, particularly in the crevices between planks. For added durability, consider embedding a layer of fine cloth or fiber between coats, a technique historically used to reinforce weak spots.

Comparatively, modern synthetic coatings offer convenience but lack the historical charm and environmental benefits of pitch and resin. Natural coatings are biodegradable, non-toxic, and renewable, making them an eco-friendly choice for restoration projects. While they require more effort to apply, the result is a vessel that not only functions effectively but also honors centuries-old craftsmanship. This approach is particularly appealing for those restoring antique boats or seeking an authentic, traditional finish.

In conclusion, pitch and resin coatings remain a testament to the ingenuity of early mariners. Their ability to create a waterproof barrier on wooden hulls ensured the success of countless voyages, from fishing trips to grand explorations. By understanding and replicating these techniques, modern builders and restorers can preserve the legacy of wooden boats while appreciating the simplicity and effectiveness of natural materials. Whether for historical accuracy or practical durability, this method continues to prove its worth in the world of maritime craftsmanship.

Clematis Rouge Cardinal: Old Wood Growth Explained for Gardeners

You may want to see also

Explore related products

Careful craftsmanship ensures tight fits and minimal gaps in construction

The secret to a watertight wooden vessel lies in the meticulous attention to detail during construction. Every joint, seam, and connection must be crafted with precision to ensure a tight fit, leaving no room for water intrusion. This level of craftsmanship was a hallmark of traditional boatbuilding, where the skill of the artisan directly correlated to the vessel's seaworthiness.

The Art of Joinery:

Imagine a puzzle where each piece is uniquely shaped to fit seamlessly with its neighbors. This is the essence of traditional wooden boat construction. Artisans employed various joinery techniques, such as dovetail, scarf, and lap joints, to interconnect wooden planks and frames. These joints were not merely glued or nailed together; they were crafted to interlock, creating a mechanical bond that resisted separation. For instance, a dovetail joint, with its distinctive fan-like shape, provides an extensive surface area for gluing and an inherent mechanical lock, making it incredibly strong and watertight.

Sealing the Deal:

While precise joinery is crucial, it's not solely responsible for a boat's watertight integrity. Artisans used natural sealants and caulking materials to fill any microscopic gaps. Traditional caulking involved hammering cotton or hemp fibers into the seams, followed by a coating of hot pitch or tar. This process, known as "paying the seams," created a flexible, waterproof barrier. Modern builders might use silicone or polyurethane sealants, but the principle remains the same: filling gaps to prevent water penetration.

A Masterful Process:

Achieving a leak-free wooden boat is a testament to the builder's skill and patience. Each step requires careful planning and execution. For instance, when joining planks, artisans would ensure the wood's grain direction promoted strength and flexibility. They'd also account for wood movement due to moisture changes, allowing for expansion and contraction without compromising the structure. This level of craftsmanship ensures that the boat not only floats but remains dry, even in the harshest of seas.

Preserving the Craft:

In an era of modern materials and mass production, the art of traditional wooden boatbuilding endures as a testament to human ingenuity. Preserving this craft is essential, not just for historical accuracy but for the inherent beauty and functionality of these vessels. By understanding and appreciating the meticulous craftsmanship involved, we can ensure that the knowledge of building leak-free wooden boats continues to sail through generations. This includes documenting techniques, training apprentices, and promoting the use of traditional methods in modern boatbuilding, where applicable.

Do Perennial Lantana Thrive on Old Wood? Gardening Insights

You may want to see also

Frequently asked questions

Old wooden boats used a combination of techniques, including caulking (sealing seams with fibrous materials like oakum and pitch) and overlapping wooden planks (clinker or carvel construction) to create a watertight hull.

Fibrous materials like oakum (hemp or jute fibers) were stuffed into the gaps between planks, and then sealed with hot pitch or tar to create a waterproof barrier.

Regular maintenance, including re-caulking and reapplying pitch, was essential. Additionally, the natural swelling of wood fibers when wet helped to tighten seams and reduce leakage.

![[Black] 5200 Marine Sealant - Fast Cure, High Bond Strength, UV Resistant Underwater 5200 Fast Cure, Marine Adhesive Sealant for Boats, Hulls, Decks, & RVs Caulk Black with Gloves, Nozzle 10oz](https://m.media-amazon.com/images/I/71xilLZNebL._AC_UY218_.jpg)

![Pitch Perfect Trilogy [DVD]](https://m.media-amazon.com/images/I/81-h4UOy9FL._AC_UY218_.jpg)

![Pitch Black [4K Ultra HD / UHD] [Blu-ray]](https://m.media-amazon.com/images/I/81sde2wO1RL._AC_UY218_.jpg)

![Pitch Perfect [Blu-ray]](https://m.media-amazon.com/images/I/81efdq5+TvL._AC_UY218_.jpg)

![Pitch Perfect 2 [Blu-ray]](https://m.media-amazon.com/images/I/71BS5Kvpp0L._AC_UY218_.jpg)

![Pitch Perfect 3 [Blu-ray]](https://m.media-amazon.com/images/I/81bsDMJvdmL._AC_UY218_.jpg)